3D Printing: A Manufacturing Revolution

By Fang Minghe

3D Printing

Cars, food, clothing, houses… Can you imagine these things being printed? More and more facts indicate that 3D printers are no longer exclusive machines for designers and scientists; they are gradually emerging from laboratories and factories, having an increasingly significant impact on the lives of ordinary people.

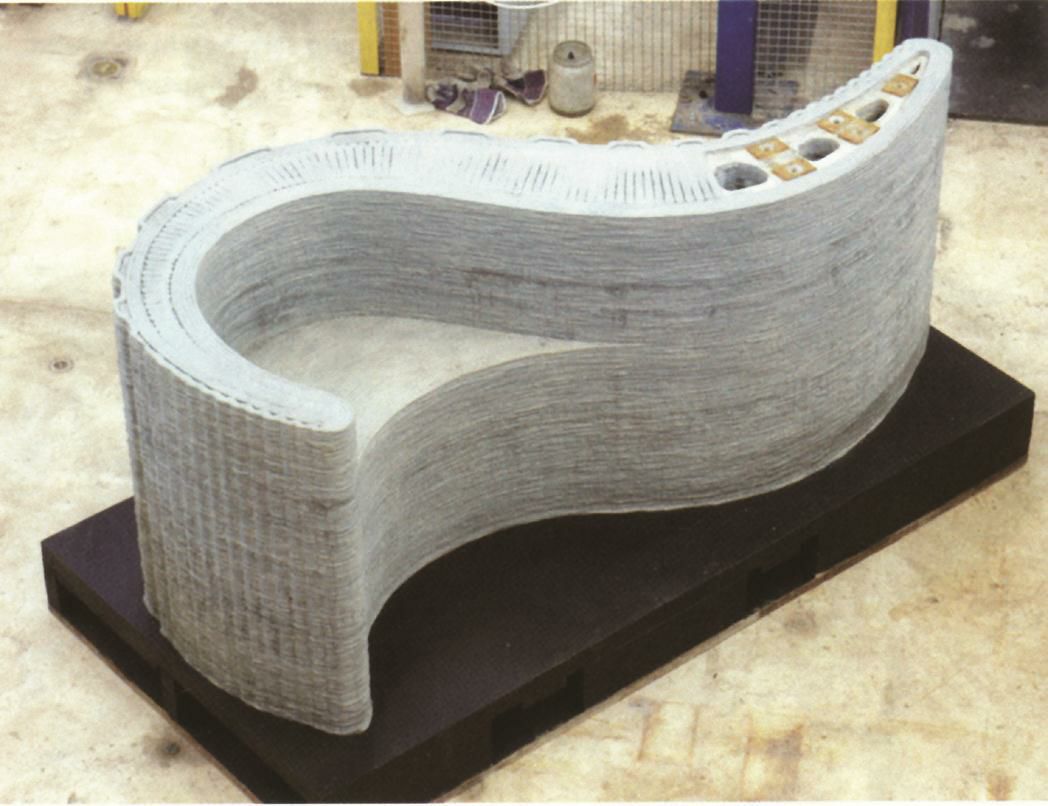

▲Various objects created by 3D printing

3D printing, also known as “additive manufacturing,” is a forming technology based on data design files that uses powder-like metals or plastics and other adhesive materials to deposit or bond materials layer by layer to create three-dimensional objects.

The main difference between 3D printing and traditional manufacturing lies in the product forming process. The entire manufacturing process in traditional manufacturing typically involves steps like mold creation, casting, cutting, and assembly, while 3D printing can achieve one-time forming, eliminating complex processing. Additionally, 3D printing can create complex objects without increasing costs. In traditional manufacturing, the more complex the shape of the object, the higher the manufacturing cost; however, for 3D printing, the cost of manufacturing complex items does not increase, and creating an elaborate, complex item does not consume more time or cost than printing a simple cube. Therefore, 3D printing can achieve designs that traditional manufacturing cannot, producing more complex structures. 3D printing technology can help improve the production capacity of personalized products while providing engineers and designers with a new avenue for design and manufacturing.

▲Cement products from 3D printing, creating internal hollow pipes that are impossible with traditional cement pouring techniques

Currently, 3D printing technology is integrating with information, materials, biology, and control technologies, which will have a significant impact on the future production modes of the manufacturing industry and human lifestyles.

The concept of 3D printing originated in the United States in the late 19th century. During this time, techniques for photorealistic sculpture and terrain modeling were developed, leading to the core manufacturing ideas of 3D printing technology.

The modern meaning of 3D printing technology was born in the 1980s. Although relevant patents were published early on, commercialization was not achieved. In 1986, Charles Hull patented the 3D printing technology known as stereolithography, subsequently founding 3D Systems and developing the first commercial 3D printer.

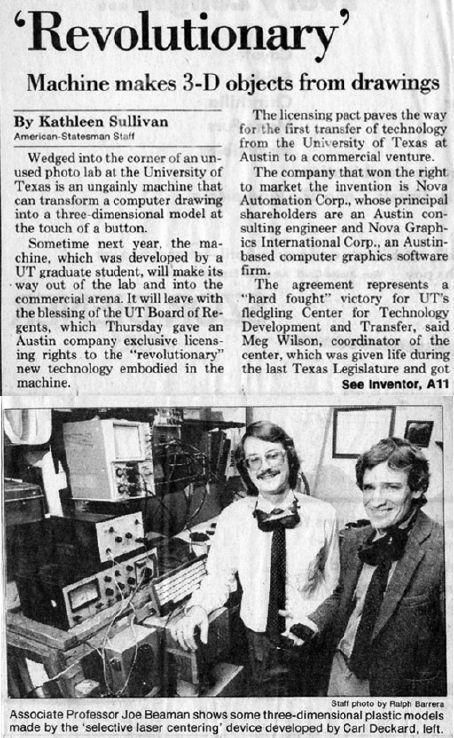

A number of American small and medium-sized tech companies, represented by 3D Systems and DTM, developed mainstream technology routes such as Stereolithography (SLA), Selective Laser Sintering (SLS), and Fused Deposition Modeling (FDM) from the late 1980s to the early 1990s.

▲Report on the invention of the first Selective Laser Sintering printer by Carl Deckard and Joe Beaman of the University of Texas

After more than 20 years of development and continuous improvement, various 3D printing technologies have matured, and the prices of 3D printers have gradually decreased, with their application range also expanding.

The working principles of 3D printers mainly fall into two categories: the first type creates objects by depositing raw materials layer by layer, and the second type creates objects by binding raw materials, referred to as Selective Deposition Printing and Selective Adhesive Printing, respectively.

The raw materials used by Selective Deposition Printers can include soft plastics that harden upon contact with the print bed, raw cookie dough, or live cells in special medical gels. The 3D printing process actually begins before the print head officially starts working. The first step of 3D printing is positioning the software design file. Users need to save the design file in a special format that can be read and used by the 3D printer’s built-in software, which informs the printer’s software what needs to be printed. While the printer firmware reads the design file, it calculates the mechanical path and actions of the print head. For instance, where the print head will deposit the outline of the shape and how much material to spray at different positions. Subsequently, the physical printing process begins. The print head typically moves along a series of horizontal and vertical tracks (engineers call it a “truss”). During the first layer deposition, the print head first outlines the object to be printed, and then the print head scans back and forth to fill in the outline. Once the first layer is completed, the print head slightly lifts and then lowers to begin the second layer. The 3D printer continues to repeat this process until it prints every cross-section of the object depicted in the design file, which may take several hours or even days.

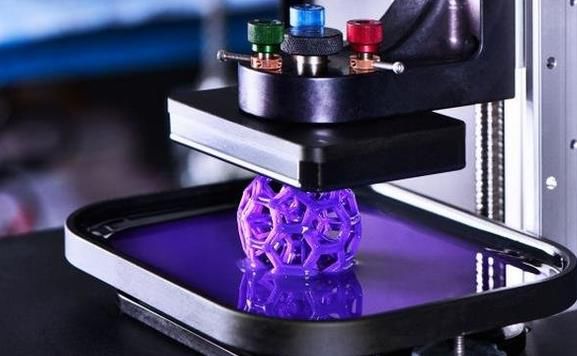

▲Fused deposition 3D printing, where the print head melts plastic into a semi-liquid state, extruding and then solidifying

Early commercial printers mostly used Selective Adhesive Printing processes, where stereolithography and laser sintering were widely applied.

Stereolithography is one of the earliest commercial 3D printing methods. A small barrel filled with liquid photosensitive polymer is placed inside the printer. This polymer hardens when exposed to UV laser. The printer scans the surface of the polymer with a laser, which follows the outline and cross-section of the printed shape layer by layer. After each laser scan, a movable platform sinks the already printed part a certain distance. The printed part sinks into the liquid, and new photosensitive polymer covers its top. Some printers work in the opposite way, aiming the laser upwards at the polymer and then lifting the printed object so that its bottom is submerged in fresh liquid. After the object is 3D printed using this method, post-processing is still required. Excess material must be washed away, some surfaces may need to be manually polished, and sometimes the object needs to be further cured as required.

▲UV laser scans along continuous cross-section shapes, raising the cured part from the liquid polymer

The advantage of stereolithography is that laser operations are fast and precise. Multiple laser beams can work in parallel, and its resolution is higher than that of extrusion-type 3D print heads. The downside is that photosensitive polymer dust is often toxic, and photosensitive polymers are not as strong and durable as industrial thermoplastics.

Selective Laser Sintering employs technology similar to stereolithography, but instead of liquid photosensitive polymer, it uses powder. This printer scans the surface of a powder bed with a high-power laser beam; the powder exposed to the laser melts, and the internal roller of the printer brushes a new layer of powder over the powder bed and lowers the print platform. Since most raw materials can be made into powder form, its application range is broader. The downside of this process is that the objects produced often have internal pores and rough surfaces. Since improper handling of certain powders can lead to explosions, Selective Laser Sintering printers must use nitrogen-filled sealed chambers.

The characteristics of 3D printing give it a significant advantage in manufacturing complex structures, but certain shortcomings compared to traditional manufacturing processes currently limit the large-scale application of 3D printing.

Material Limitations: The materials that can be used for 3D printing are limited, with thermoplastics currently being the most widely used. Although metals, ceramics, and other materials can also be 3D printed, they often fall short of strength and precision requirements in most cases. The range of selectable materials is a significant factor restricting the development of 3D printing technology. Another material-related limitation is that most current 3D printers can only print a single material. The ability to manufacture composite materials composed of multiple components is still significantly lacking in 3D printing. From a longer-term perspective, the core of 3D printing technology is the ability to print multiple materials simultaneously.

Production Efficiency: 3D printing adopts a layer-by-layer manufacturing approach, resulting in low efficiency in production. For products of the same size, traditional injection molding machines only take a few seconds, while 3D printing often requires several hours or even days. The advantage of 3D printing is that it does not require molds, thus significantly shortening manufacturing time in small batch production. However, for large-scale manufacturing, current 3D printing is still not competitive.

Manufacturing Costs: Most industrial products currently have established processing procedures and supply chains, with optimized costs for each component, while the supply chain for 3D printing is still incomplete. Although the material consumption for 3D printing is low, the raw materials used for 3D printing require high manufacturing processes, which increases material costs. Additionally, lower yields and post-processing of printed parts also raise production costs.

▲Post-processing of 3D printed parts, removing support structures and cleaning powder

In summary, while 3D printing technology is revolutionary, it is not disruptive. It is unlikely to replace existing production organizational structures in the short term, but it can greatly enhance the efficiency of the current industrial system.

1. Bioprinting

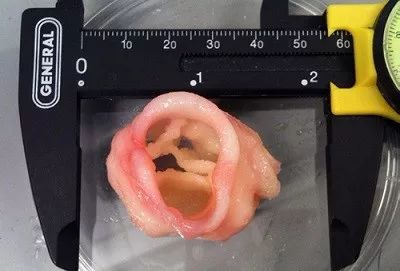

3D printing’s highly customizable nature gives it enormous potential for development in the medical field in the future. The ultimate goal of 3D bioprinting is to integrate technologies from medicine, engineering, and biology to “print” a replacement that is identical to human tissue or organs for tissue repair and organ transplantation.

▲3D printed heart valve by a research team at Cornell University

Currently, 3D printing technology using a limited number of specific types of living cells as raw materials has become feasible. However, not all types of cells can be isolated and cultured in vitro, nor can all cells maintain their biological activity after undergoing the 3D bioprinting environment. Moreover, the vast majority of organs are not made up of a single type of cell, making it challenging to precisely control the positions and interactions of biological materials, cells, and growth factors within the overall 3D structure to achieve physiological activity similar to the printed organs. These are problems that are difficult to solve in the short term.

2. Space Manufacturing

Due to the enormous transportation costs between Earth and space, if astronauts could manufacture the necessary products in orbit, it would greatly enhance the flexibility of space station experiments, reduce the types and quantities of spare parts needed for the space station, lower operational costs, and decrease the station’s dependence on ground supplies. 3D printing technology is a key technology for space production and may be crucial for the industrialization of space.

In 2014, the first space 3D printer was successfully installed on the International Space Station. In 2016, the Chongqing Green Intelligent Technology Research Institute of the Chinese Academy of Sciences, along with the Space Application Center of the Chinese Academy of Sciences, successfully developed the first domestic on-orbit 3D printer after more than two years of effort and completed parabolic weightlessness flight tests.

▲The 3D printer developed by Made In Space completed its first printing task in the International Space Station

If we can utilize materials from asteroids for base construction using 3D printing technology in future space development, it will greatly enhance humanity’s ability to explore the universe.