Introduction:

This article is published with permission from A Bao 1990, the author is A Bao 1990.

The automotive camera is known as the “eye of autonomous driving”. It mainly collects image information through lenses and image sensors. In recent years, cameras have become one of the most common intelligent tools in automotive vision solutions. In this article, let’s explore the past and present of automotive cameras.

1

Pinhole Imaging

2

Camera Obscura

3

Silver Plate Photography

4

Film Cameras & Digital Cameras

5

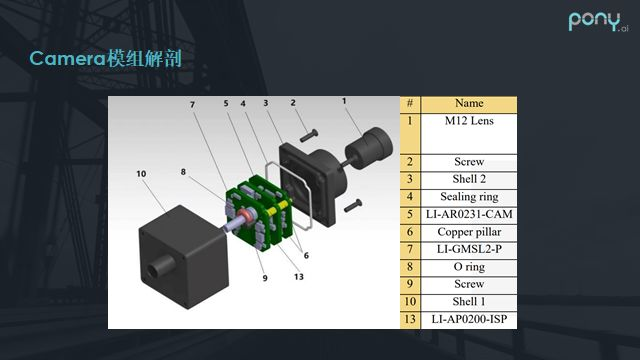

Explanation of Camera Module Internal Structure and Working Mechanism

6

Automotive Camera Architecture

7

Differences Between CCD and CMOS Image Sensors

8

Analysis of CMOS Sensor Composition and Key Parameters

9

Key Parameters of Image Sensors

45

Conclusion