Click the blue text above to follow us!

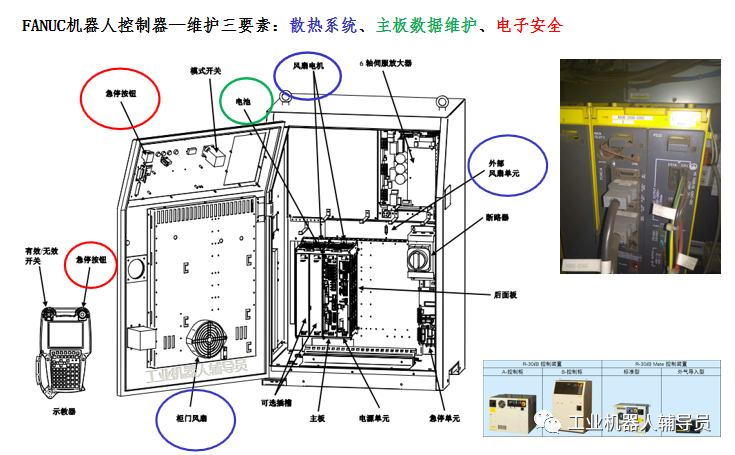

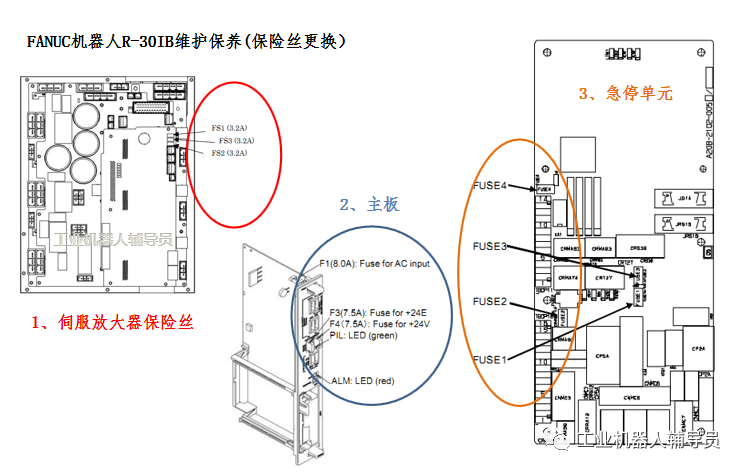

FANUC Robot Controller—Three Key Elements of Maintenance

This question has been raised by someone a long time ago, and I have not had time to organize it. Today, I have summarized it a bit for everyone’s reference!

Moreover, I sincerely thank everyone for their support, and I hope more robotics technology enthusiasts will contribute and share, focusing on actual cases of industrial robots, with no limits on the scope! Friends with questions can leave a message in the background.

For more information, please check the history records

About KUKA Robot KRC4 Power Distribution Process

FANUC Robot Fault Case SRVO—157 GHGAL alarm (G:1 A:2)

Mitsubishi Robot Belt Tension Testing Parameter Table

Mitsubishi Robot Maintenance Instructions (Pinned for backup)

KUKA KR16-2 Timing Belt Inspection and Adjustment

ABB Robot Serious Collision Incident Recurs!

ABB Robot Collision Incident Analysis (On-site Case)

FANUC Robot Motor Encoder Analysis (Illustrated)

FANUC Robot Load Manual Setting Method Reference

Yaskawa Robot Parallel IO Distribution (Inquiry)

Industrial Robot Electrical Design Component Selection Rules Reference

Yaskawa Motor and Servo Amplifier Circuit Wiring Diagram

ABB Robot Reducer Oil Leakage Detection Testing

ABB Robot Compact Control Cabinet Internal Structure (Diagram)

KUKA Robot CCU Board Signal Indicator Lights (Determine Status by Color)

Industrial Robot Servo Motor Fault Analysis

Thank you for your attention, please leave a message if you have any questions! Please indicate the source when reprinting!