The thinning of display panels mainly involves using chemical etching and physical grinding to reduce the thickness of the panel module and display glass, meeting the demand for lightweight display products. By thinning the TFT-LCD panel, the following application requirements can be achieved.

1. Use chemical or physical methods to reduce the thickness of the panel glass to achieve lightweight panels.

2. Reduce the weight of the display; provide clearer and brighter image quality.

3. Minimize occupied space, reduce the thickness of the TFT-LCD module, leaving more space for increasing battery capacity, etc.

4. Achieve a certain flexibility in the glass substrate to produce curved screens, enhancing visual effects.

TFT-LCD Glass Thinning Process Flow

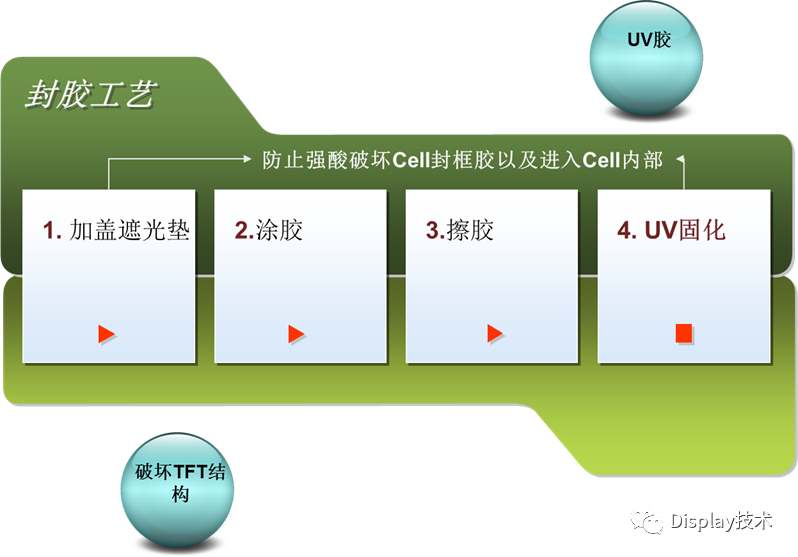

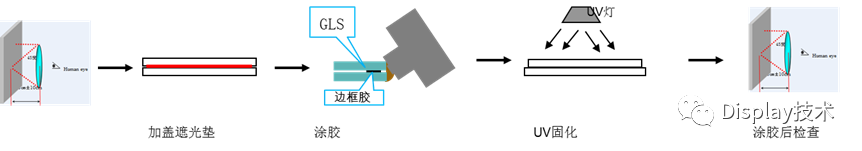

1. Sealing Process

Prevents acidic and alkaline solutions from entering the liquid crystal box from the edges, damaging the sealing glue, and affecting product performance.

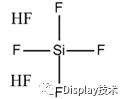

2. Etching Thinning Process

Thinning principle: 6HF+SiO2->H2SiF6+2H2O Liquid + Solid (Glass) -> Liquid

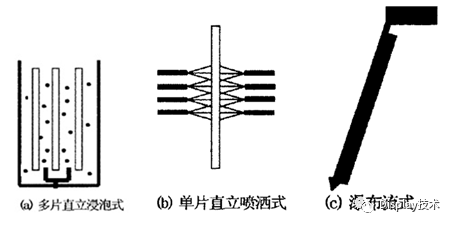

Thinning methods:

1. Multi-piece upright immersion

Advantages: Can process multiple pieces of glass at the same time.

Disadvantages: Large equipment. Surrounding precipitates, white powder, easily adhere to Glass.

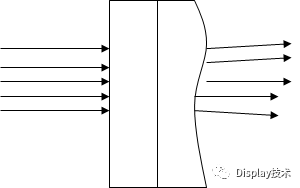

2. Single-piece upright spraying

Advantages: Can meet different etching requirements on both sides.

Disadvantages: Etched surface prone to pitting.

3. Waterfall flow

Advantages: The smoothest surface, may not require polishing.

Thinning process and main components of equipment:

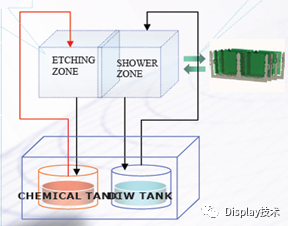

Process: Loader—Pre-cleaning—Etching—Cleaning—Drying—Unloader

Equipment components: Acid supply device, HF acid concentration meter, temperature controller, washing gas device

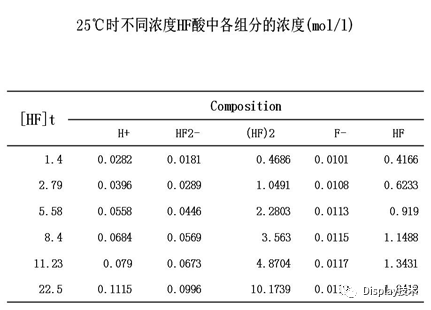

Thinning process parameters

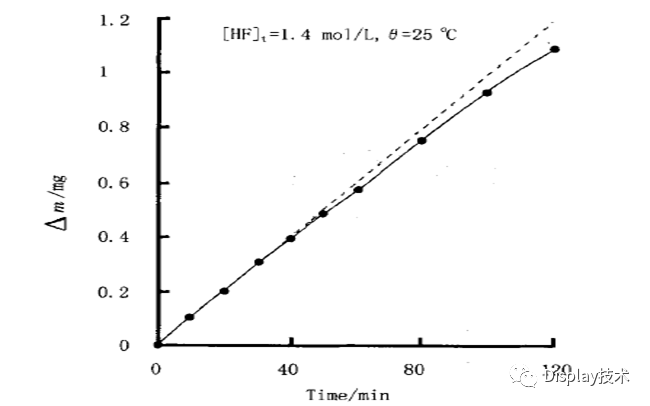

1. Relationship between reaction time and glass quality loss

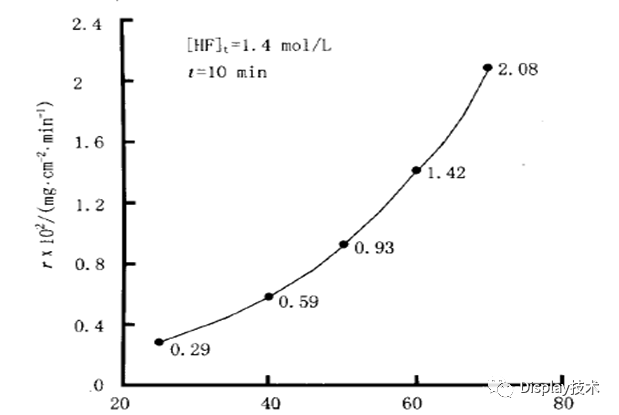

2. Relationship between reaction rate and reaction temperature

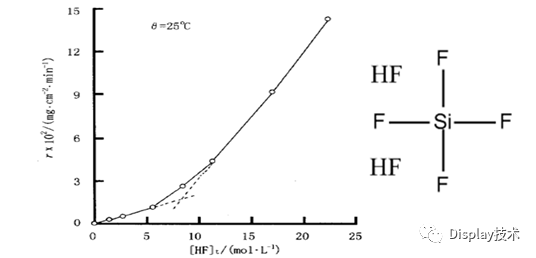

3. Relationship between reaction rate and HF acid concentration

Note: (HF)2 is the main active component in HF acid solution, as the H-F bond in hydrogen bond form is weaker than the H-F bond in HF molecules, making it easier to break when reacting with SiO2.

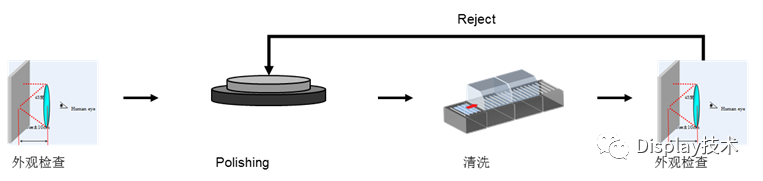

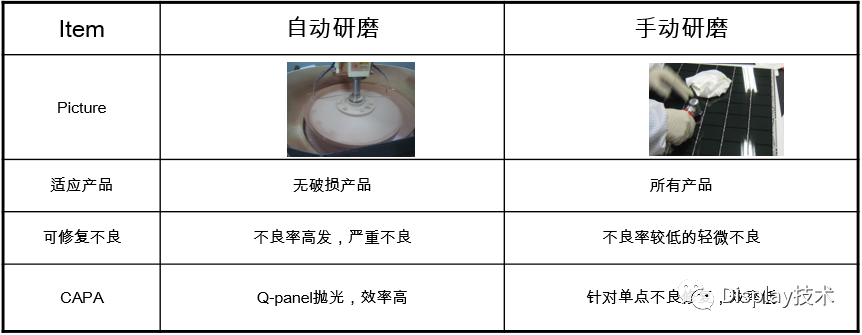

3. Grinding Process

Process flow:

Defects of the Thinning Process

1. Cannot wipe off dirt

2. Uneven thinning

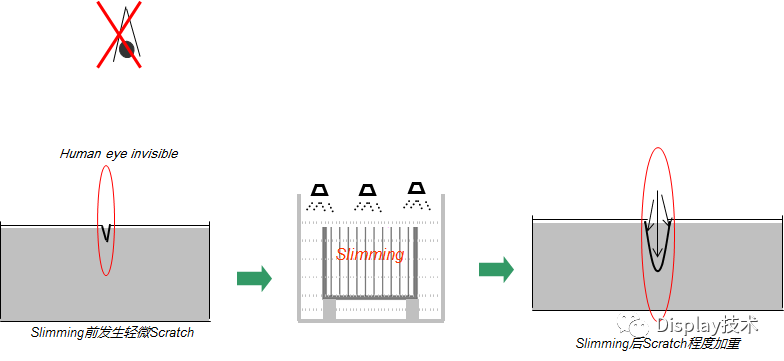

3. Scratches after slimming

4. B-ITO defects

Phenomenon: After completing B-ITO on ADS products, the ITO at the contact point with the BOX is severely corroded, similar to the marks left on the product surface after water dries.

Reason: The BOX has been circulated for a long time in the Slimming workshop, where acidic gas has long adhered to the surface of the BOX, making it acidic.

5. Resistance exceeds standard

Reason: Acid residue

Durability Related to Thinning

1. Impact and drop: Subjecting the LCM to impact and drop. Conducting display and appearance inspections on the LCM.

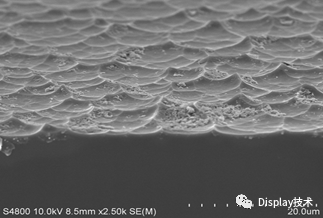

2. Confirmation of glass substrate surface etching condition: Placing it in alternating hot and cold tanks for display inspection and microscope examination of the Glass appearance of TFT.

3. Confirmation of corrosion condition at the TFT terminal: Continuous aging in a high-temperature and high-humidity aging tank. SEM observation and analysis of the surface and cross-section of the TFT terminal.

Source: Display Technology