The newly developed technologies include not only pure electric and fuel cell drive systems but also modern internal combustion engines using hydrogen and synthetic fuels.

As in the previous annual meeting, Professor Stefan Pischinger (Ph.D. in Engineering), director of the Institute for Internal Combustion Engines at RWTH Aachen University, and Professor Lutz Eckstein (Ph.D. in Engineering), director of the Institute for Automotive Engineering (ika), represented their respective institutes at the conference, which was jointly organized by both institutes.

In their opening speeches, Professors Pischinger and Eckstein emphasized the importance of climate neutrality and the concept of zero carbon for achieving the goals of the EU’s “Fit for 55” legislative proposal.

The two-day annual meeting included a total of 110 technical lectures and keynote speeches, presented through 32 sessions held in five halls at the Eurogress conference center. Due to the ongoing impact of the COVID-19 pandemic, 11 speakers were unable to attend in person and delivered their talks via video.

Electric Mobility and Digitalization – Opportunities and Driving Forces for the Automotive Industry

Speaker: Markus Duesmann, Master of Engineering, Audi AG

Mr. Duesmann emphasized the importance of electric mobility for climate change. In his view, the main problem of climate change lies in the use of fossil fuels. He believes that the automotive industry and politics must work together to significantly reduce CO2 emissions from fossil fuels and increase the use of green electric energy. Currently, fossil fuels account for 76% of the automotive market, while green electric energy only accounts for 17%. He stated, “Instead of discussing the issue of decarbonization, we should discuss the ban on the use of fossil fuels.”

Audi’s roadmap for electric mobility is as follows:

2025: Production of the last new fuel vehicle model

From 2026: All new Audi models will be electric

2033: Cease production of fuel vehicles

Audi aims to completely stop using fossil fuels by 2040.

Additionally, Mr. Duesmann presented the following fuel efficiency data, illustrating the significant fuel efficiency losses associated with hydrogen and synthetic fuels compared to directly using renewable electric energy:

|

Fuel Efficiency Comparison |

Pure Electric Vehicle |

Fuel Cell Vehicle |

Vehicle Using Internal Combustion Engine + eFuel |

|

Well-to-Tank Model Electricity → Energy |

85% |

61% |

48% |

|

Tank-to-Wheel Model Energy → Mobility |

78% |

46% |

25% |

|

Well-to-Wheel Model Electricity → Mobility |

66% |

28% |

12% |

At the end of his speech, Mr. Duesmann stated that as the prices of batteries and photovoltaic systems decrease and the supply of electric vehicles continues to increase, electric mobility will soon become a more economical mode of transportation.

The Future of Mobility

Dr. Stefan Hartung, Engineering Doctor, Robert Bosch GmbH

Like Mr. Duesmann, Dr. Hartung also called for a significant reduction in the use of fossil fuels, and he believes it is necessary to seek new fuels such as Blue Gasoline and Blue Diesel. Blue Gasoline and Blue Diesel contain 33% renewable energy components and are claimed to reduce CO2 emissions by 20% in the well-to-wheel model. If using CARE diesel (mainly synthesized from diesel by-products and waste), the reduction in the well-to-wheel model can reach 65%, while eFuel based on renewable energy can achieve a 100% reduction in CO2 emissions.

Dr. Hartung believes that the scale of existing vehicles in the market is the problem. Therefore, he expects that by 2030, the electrification ratio of existing vehicles in Europe will only reach about 25%.

At the end of his speech, Dr. Hartung called on young students, stating that much research is still needed to achieve climate goals and address ecological issues.

A1.2 Economic, Safe, and Highly Integrated Future Battery Systems (FEV Europe)

Speaker: Dr. Moritz Teuber, FEV Europe GmbH

Dr. Teuber introduced two possible methods to increase the range of pure electric vehicles:

1) Optimize the chemical composition of battery cells

2) Optimize the integration of battery cells and battery packs on the vehicle chassis

The chemical composition of battery cells is the most fundamental element determining vehicle performance such as range and charging time. Currently, automakers rely on lithium-ion batteries in electric vehicles. In order to improve the performance of batteries and even electric vehicles, new types of battery cells are continuously being developed. Indicators such as safety, sustainability, cost, cycle life, capacity, and power largely depend on the composition of the positive electrode materials of the battery cells.

Dr. Teuber then introduced the advantages and disadvantages of the current state-of-the-art positive electrode materials, which are made from metal oxides, including lithium cobalt oxide (LiCoO2) (LCO), lithium nickel oxide (LiNiO2) (LNO), and lithium manganese oxide (LiMnO2) (LMO).

LCO (lithium cobalt oxide) materials were very popular in the past due to their outstanding performance. However, due to their scarcity, LCO materials are relatively expensive, and poor mining conditions lead to a poor ecological footprint, prompting a shift to LNO (lithium nickel oxide) as the positive electrode material, but LNO materials have poor thermal stability and structural stability. To eliminate these shortcomings, cobalt, aluminum, and/or manganese oxide are often used to replace LNO. Cobalt doping improves the cycle life of the battery cell at high charge states, aluminum doping enhances chemical stability, while using manganese oxide instead of LNO increases the applicable operating voltage of the battery cell.

Recently, a new positive electrode material called NMC (nickel manganese cobalt) is under development, which is made from a mixture of LNO, cobalt, and manganese. The performance of NMC battery cells depends on the selected substrate materials and their mixing ratios. Nickel can enhance the discharge capacity of the battery cell, while cobalt helps to enhance the stability of the battery cell.

More new material combinations may appear on the market, and various well-known chemical component combinations (such as lithium iron phosphate (LFP)) may be further developed and put into use in the future.

Dr. Teuber believes that price reduction and increased energy density are the general development trends for battery cells before 2030 (see table below). Compared to high-energy NMC materials, LFP materials will still be a low-cost and safe alternative. Before 2025, the nickel content in NMC materials will remain high. After 2025, in order to reduce costs, the manganese content in NMC materials will increase. The prospects for solid-state battery (SSB) technology are very bright and may become a good alternative, but this depends on the development results of SSB under the best-case (BC) and worst-case (WC) scenarios.

|

Expected Energy Density (Wh/kg) and Development Cost (€/kWh) of Different Chemical Component Battery Cells |

2020 |

2025 |

2030 |

|

LFP |

175Wh/kg @ 70€/kWh |

185Wh/kg @ 65€/kWh |

200Wh/kg @ 50€/kWh |

|

NMC |

280Wh/kg @ 100€/kWh (NMC 811) |

290Wh/kg @ 60€/kWh (NMx 640) |

300Wh/kg @ 50€/kWh (NMx 7xx) |

|

280Wh/kg @ 100€/kWh (NMC 811) |

325Wh/kg @ 75€/kWh (NMC 9055) |

350Wh/kg @ 50€/kWh (NMCA 9xx) |

|

|

SSB (WC) |

200Wh/kg @ 1000€/kWh |

350Wh/kg @ 500€/kWh |

400Wh/kg @ 250€/kWh |

|

SSB (BC) |

200Wh/kg @ 1000€/kWh |

350Wh/kg @ 500€/kWh |

450Wh/kg @ 150€/kWh |

In addition to the chemical composition of the battery cells, the integration of battery cells and battery packs in the vehicle also affects the range of electric vehicles. Currently, the assembly of battery cells uses cell-to-module (C2M) technology, which assembles 12 or 16 battery cells into a battery module. These modules are then integrated into a closed shell to form a battery pack, which is ultimately integrated into the electric vehicle.

Cell-to-Pack (C2P) technology can optimize this integration method, reducing the weight of the battery pack while saving the required installation space.

Cell-to-Vehicle (C2V) integration technology can maximize packaging advantages. In vehicle architectures using C2V technology, the battery pack becomes part of the chassis component, and this technology will also affect more links in the battery value chain. In C2V technology, the battery and chassis are treated as one component, eliminating redundant structures currently existing in electric vehicles. The so-called “open chassis” and “closed chassis” refer to merging the battery top cover with the chassis floor below.

Dr. Teuber concluded his speech by stating that there is no optimal integration solution in the development process of any pure electric vehicle. For example, using C2M technology simplifies the service process, C2P technology saves costs and increases the energy density of battery cells, while C2V technology has the greatest packaging advantage, prompting a rethink of the battery value chain. The optimal design of the battery pack and vehicle integration scheme depends on the specific requirements of the automaker.

A4.1 Mercedes-Benz Fourth Generation Plug-in Hybrid Drive System (Mercedes-Benz)

Speaker: Matthias Klöpfer, Master of Engineering, Mercedes-Benz

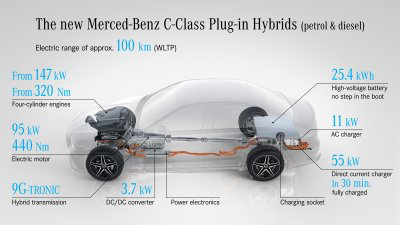

Modular design of the plug-in hybrid drive system of the Mercedes-Benz C-Class

After briefly introducing the previous three generations of plug-in hybrid drive systems from Mercedes-Benz, Mr. Klöpfer detailed the improvements and advantages of the newly developed fourth generation plug-in hybrid drive system using the all-new Mercedes C-Class (release date: September 2021 (sedan) / end of 2021 (station wagon)) as an example.

The modular concept developed by Mercedes-Benz includes the following three main components:

-

Optimized Mercedes-Benz “FAME (Modular Engine Family)” internal combustion engine: gasoline engine models M 254/M 256 (for C-Class/S-Class models), diesel engine model OM 654 M. -

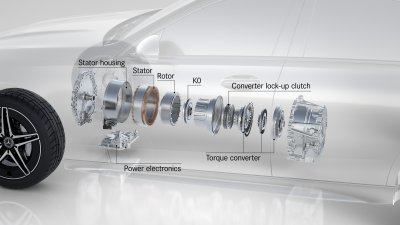

Hybrid drive unit integrated with motor, separate clutch, and torque converter, greatly improving the overall layout of the vehicle and supporting direct contact with AC power, achieving a shared cooling circuit with the transmission. The permanent magnet internal rotor synchronous mechanism enables higher power density. -

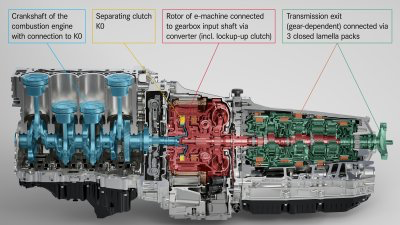

NAG3M 9G-TRONIC automatic transmission containing a four-wheel drive module, consisting of four sets of planetary gears and six shifting actuators. Integrating the power electronics into the transmission housing not only saves the required installation space but also simplifies the assembly process in the vehicle factory.

Powertrain with power electronics and NAG3M 9G-TRONIC automatic transmission

The improved motor (power 95kW) adopts a hairpin-type full-cut stator, optimizing drive noise. The motor can achieve a peak torque of 440Nm on the first rotation of the engine, ensuring high responsiveness and dynamic handling when the vehicle starts.

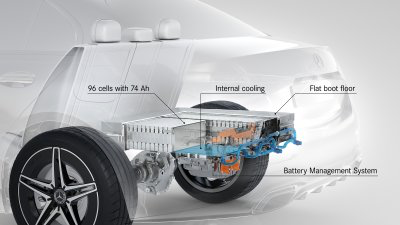

Fourth generation high-voltage battery installed at the rear of the new C-Class

The fourth generation high-voltage battery developed by Mercedes-Benz has higher power and a more compact size due to a significant reduction in the number of high-voltage connections. The C-Class is equipped with a soft-pack battery containing 96 battery cells (each with a capacity of 74Ah), with a total capacity of 25.4kWh. The internal cooling system allows the battery to have a high power density, while the thermal management system can independently control the working temperature of the battery without being affected by the vehicle’s air conditioning.

The new C-Class plug-in hybrid vehicle adopts a new engine starting procedure that no longer relies on a traditional 12V starter:

-

Camtronic (variable valve lift technology) pressure relief device for gasoline engines -

Before starting the engine, the camshaft switches to pressure relief mode via a pin that extends from the engine during the previous shutdown. After the engine starts, the pin immediately retracts, and the camshaft switches back to normal operating mode. This process is automatically executed at each engine start. -

Pulsed starting technology for diesel engines -

The sliding clutch only transmits friction torque; the input torque is not within the transmission range (at least while the clutch is in a sliding state). If the input torque exceeds the friction torque, the clutch speed will increase, but the propulsion torque will remain unchanged. Excess power is converted into rotational energy, allowing the torque required to start the engine to be transmitted to the drive system. In this way, the clutch (K0) can generate a starting torque of 150Nm, mainly derived from pulse attenuation.

Components enabling pulse start

Before concluding his speech, Mr. Klöpfer summarized the improvements and advantages of the fourth generation plug-in hybrid vehicle as follows:

-

Higher power -

Longer pure electric range, reaching about 100km -

Optimized driving program -

Flattened trunk floor, providing more storage space -

Fast charging technology with a maximum power of 55kW -

Engine achieves fast, vibration-free starting

However, Mr. Klöpfer also emphasized that the correct use of plug-in hybrid vehicles (i.e., always ensuring charging) is a prerequisite for making a significant contribution to reducing CO2 emissions from road vehicles.

B3.3 New Battery Cooling System Using Immersion Cooling Technology for Mainstream Pure Electric Vehicles (Ricardo)

Speaker: Dr. Cedric Rouaud, Ricardo

Dr. Rouaud introduced the I-CoBat (Immersion Cooling Battery) project, which is funded by the UK innovation agency Innovate UK and implemented by UK technology materials company M&I Materials Ltd., UK powertrain technology consulting company Ricardo UK Ltd., and the University of Warwick.

The goal of the I-CoBat project is to develop immersion cooling battery modules for pure electric and plug-in hybrid vehicles using synthetic esters as dielectric fluids, meeting industry needs and overcoming major development challenges of batteries (including battery life, energy density, safety risks, and fast charging technology).

Ricardo is responsible for the production and functional testing of battery modules in this project.

To compare the cooling performance of different battery modules, Ricardo has designed two battery modules with the same number of cells, one cooled by a cooling plate and the other by immersion cooling technology.

The parameters of both modules are the same:

|

Battery Module Structure |

3 series 26 parallel (3 cells in series form a group, 26 groups in parallel) |

|

Total Number of Cells |

78 |

|

Voltage |

Minimum Voltage: 7.5V Nominal Voltage: 10.8V Maximum Voltage: 12.6V |

|

Capacity |

1.1kWh (Samsung 40T cells) |

|

Thermal Test Results at 3.9C Charging Rate: Comparison of Cooling Technologies |

Immersion Module |

Cooling Plate Module |

|

Maximum Temperature of Cells |

35℃ |

50℃ |

|

Bus Temperature |

<40℃* |

70℃ |

* The immersion cooling solution can achieve direct cooling of the bus

Development results of I-CoBat immersion cooling battery modules

Dr. Rouaud concluded that the optimized synthetic ester immersion cooling technology has significant advantages over the state-of-the-art cooling plate technology in terms of maximum charging power (increased by 43%) and volume power density (increased by 48%). Furthermore, immersion cooling technology can reduce battery costs and extend their lifespan. Finally, overcharging and puncture tests demonstrate that immersing battery cells in dielectric fluids can suppress thermal runaway and prevent thermal propagation within the battery pack.

B5.1 Selection Between Pure Electric Vehicles and Fuel Cell Vehicles (Roland Berger)

Speaker: Dr. Wolfgang Bernhart, Roland Berger Management Consulting

The German management consulting firm Roland Berger investigated the challenges, risks, and opportunities in the supply chain for pure electric vehicles and hydrogen fuel cell vehicles. As two major zero-emission technologies, the automotive industry hopes to achieve global CO2 reduction targets through the application of pure electric vehicles and hydrogen fuel cell vehicles by 2035.

Roland Berger’s investigation led to the following conclusions:

-

The stability of supply and price risks in the mining/refining of active materials for positive electrodes (i.e., nickel, cobalt, and lithium) is the highest -

Due to China’s dominance, the supply of cobalt and negative electrode active materials (i.e., natural and synthetic graphite) poses political risks -

Global demand for lithium-ion batteries is expected to approach 3TWh by 2030 (based on automakers’ electricization targets), but there is currently a lack of sufficient raw materials and intermediate material supplies to meet this demand scale, and product delivery cycles are long, requiring significant investment across the supply chain (by 2030, investments in Europe will exceed €100 billion, and globally will exceed €250 billion) -

The costs of active materials for positive electrodes may rise and be passed on to lithium-ion battery customers -

Obtaining the necessary power capacity from renewable energy (such as green hydrogen) is challenging, which will hinder the popularization of hydrogen fuel cell vehicles

Based on the above conclusions, Roland Berger provides five recommendations for industry companies to consider in the near future:

-

Automakers should ensure the supply of battery raw materials and refined materials. For example, automakers can consider collaborating with upstream companies and potential integration opportunities (integrating down to mining companies) to save important costs for survival and development. -

Battery cell manufacturers need funding channels and should collaborate with upstream companies (down to mining companies) and downstream companies (battery pack manufacturers) to provide complete solutions to small and medium-sized automakers at stable prices. -

Active material suppliers for positive electrodes must establish relevant business capabilities upstream and downstream to reduce dependence on input materials (thereby lowering costs), and they need to optimize the chemical system of positive materials overall while reducing processing costs. Additionally, they need to collaborate to promote regional supply chains that comply with legislative goals in the EU, the US, and Asia. -

Small and medium mining companies should consider long-term cooperation opportunities with value positioning based on sustainable operations and stable prices to gain new capital from the automotive industry. -

Legislators in Europe, the US, and Asia must support the smooth supply channels for raw materials in their respective markets, specifically by establishing cooperative relationships with countries that have the mineral reserves needed to achieve zero-emission mobility goals.

After achieving zero-emission goals in the future, companies wishing to maintain competitiveness can use Roland Berger’s “Transportation Decarbonizer” framework, which provides references for companies in terms of timing and investment decisions and helps them achieve goals through five steps: establish baseline, analyze, confirm, develop roadmap, and implement.

B5.3 Cost Analysis of Road Vehicles Before 2050 (Forschungszentrum Jülich)

Speaker: Mr. Stefan Kraus, Forschungszentrum Jülich GmbH

Mr. Kraus first explained the motivation for conducting a Total Cost of Ownership (TCO) analysis at Jülich Research Center, which aims to determine the most suitable powertrain from a technical and economic perspective for the future.

Jülich Research Center developed a TCO model for vehicle analysis using Python, which can be used to evaluate costs over the entire lifecycle of a vehicle, covering production, maintenance, fuel costs related to fuel production, and infrastructure costs.

First, the analysis targets different vehicle types:

-

Different categories of road vehicles: passenger cars, buses, commercial vehicles -

Vehicles equipped with different types of powertrain systems: fuel vehicles, hybrid vehicles, trolleybuses (vehicles that rely on contact networks: including buses and semi-trailers), pure electric vehicles, and fuel cell vehicles.

The analysis results indicate that by 2050, regardless of vehicle category or application, fuel cell vehicles or pure electric vehicles may be the most cost-effective choice.

In the subsequent key factor analysis, researchers evaluated the impact of range, annual mileage, and fuel costs to determine the suitable application types for each vehicle category.

Based on the comprehensive TCO analysis results, researchers reached the following conclusions:

-

All analyzed cases indicate that by 2035 at the latest, the prices of pure electric vehicles and fuel cell vehicles will be lower than those of fuel vehicles, due to lower maintenance and fuel costs for the former. -

By 2050 at the latest, the production costs of pure electric vehicles and fuel cell vehicles will be at least comparable to those of fuel vehicles. -

The specific year when production costs converge largely depends on the application scenarios of pure electric vehicles, fuel cell vehicles, and fuel vehicles. -

From 2040 onwards, the TCO analysis results for pure electric vehicles and fuel cell vehicles will, in some cases, become very similar. -

Due to the introduction of fuel efficiency measures and the rising costs of non-fossil liquid fuels, the costs of traditional powertrain systems will increase. -

Although there is currently a cost difference between pure electric passenger vehicles and fuel cell passenger vehicles, the expansion of fuel cell capacity can equalize the production costs of the two within a decade.

Finally, Mr. Kraus stated that from both technical and economic perspectives, the best powertrain system depends on the application scenario rather than the vehicle type. Additionally, he noted that vehicles requiring longer ranges will be equipped with larger capacity batteries, which will disadvantage pure electric vehicles. However, such large-capacity batteries are rarely utilized over the vehicle’s lifecycle. As the sensitivity analysis results indicate, the ratio of range/battery capacity to annual mileage is a key factor. Lastly, he emphasized that the higher the market penetration rate, the lower the production and infrastructure costs, which will also help increase the sales of fuel cell vehicles.

B6.1 Concept of Mild Hybrid Solutions and CO2 Emission Reduction Effects (Dayco)

Speaker: Mr. Gianluca Cariccia, Master of Science, Dayco

Dayco is a global leader in powertrain system design and manufacturing, with products used in automotive, heavy industry, and industrial sectors. At this annual meeting, Dayco, in partnership with the Polytechnic University of Turin, introduced its innovative technology: mild hybrid solutions. Experts from Dayco and the Polytechnic University of Turin presented a Dayco innovative BSG (Belt Starter Generator) mild hybrid system solution called P0 ECO plus. Dayco verified a more environmentally friendly drive system through theoretical and experimental means, which can reduce vehicle CO2 emissions by 2.5g/km under WLTP conditions.

The expert team from Dayco includes Mr. Gianluca Cariccia, Vice President of R&D and Design at Dayco, Mr. Stefan Brandin, Global Key Account Director at Dayco, and Professor Andrea Tonoli from the Polytechnic University of Turin, who demonstrated the application of mild hybrid electric vehicles, which is an important factor in meeting Euro 7 emission standards.

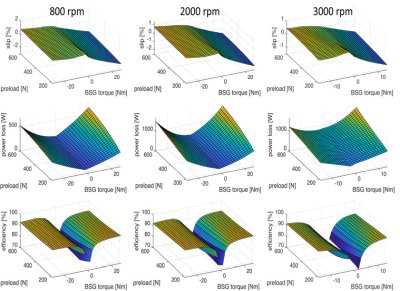

The efficiency distribution map (ƞ_Boost=P_CS/P_BSG) is based on data of speed, torque, and belt static state.

During the presentation, the expert team stated that Dayco’s mild hybrid system solution improves system energy efficiency not only through optimized drive components but also through optimized control logic, giving the system additional advantages. In this new solution, Dayco created an efficiency distribution map for the P0 (i.e., BSG motor) based on internal combustion engine speed, motor torque, and belt pre-tension data. Subsequently, the control logic optimized the energy efficiency of the P0 system using information from the efficiency distribution map.

Mr. Gianluca Cariccia, Vice President of R&D and Design at Dayco, stated: “Dayco’s P0 ECOplus system is a decisive and universally applicable solution for energy flow management in the PX hybrid architecture (i.e., different architecture types classified by motor position), developed based on a new model. This system has been exclusively designed for components and system integration, improving drive efficiency through real-time control functions without using static calibration maps, further enhancing system efficiency.”

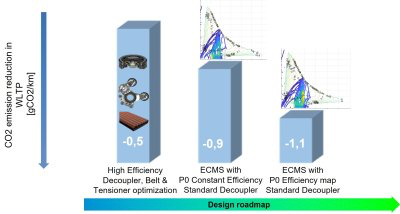

System design conclusions related to CO2 emission reduction

Dayco’s technical experts also introduced that the key to further optimizing CO2 emissions is integrating vehicle modeling and control strategies, thereby minimizing vehicle fuel consumption under WLTP conditions. If Dayco’s innovative BSG mild hybrid system is used and the driving method is fully optimized, the CO2 emissions per kilometer can be reduced by 2.5g, a result that has also been validated in real vehicle tests.

Dayco achieved the above results through collaboration with the Polytechnic University of Turin, with whom they established a partnership in early 2019, and this achievement is part of that collaboration.

Dayco has over 10 years of successful experience in developing innovative technologies. As a next-generation evolutionary technology, the mild hybrid system (P0 ECOplus) will continue to bring revolutionary changes to the automotive industry and support the establishment of a sustainable ecosystem in the industry.

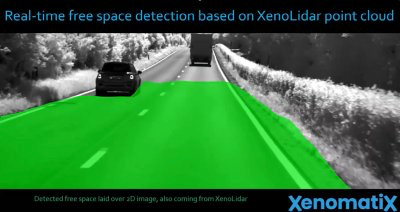

D2.1 Enhanced Safety and Comfort LiDAR (XenomatiX)

Speaker: Mr. Karsten Bronowski, XenomatiX

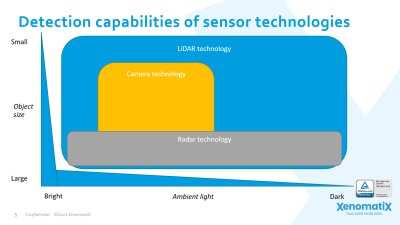

Comparison of detection capabilities of LiDAR, radar, and cameras

At the beginning of the presentation, Mr. Bronowski briefly introduced XenomatiX. The company, founded in 2013 and headquartered in Leuven, Belgium, is the world’s first company to develop true solid-state LiDAR sensors based on multi-beam laser concepts and risk-free, scalable semiconductor technology.

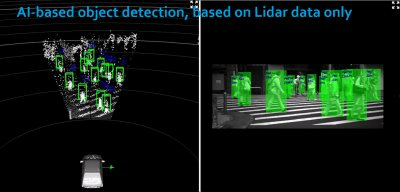

Mr. Bronowski stated that LiDAR is expected to fill the gap left by cameras and radar sensors in vehicle applications. Cameras can detect and classify objects, but their sensors perform poorly in darkness, fog, low-contrast environments, and when identifying small objects from a distance. Radar sensors can detect objects at long distances but lack accuracy, making object classification nearly impossible. In contrast, LiDAR data can be used for localization, detection, classification, tracking, and prediction.

XenomatiX has developed the following two major product families:

-

XenoLidarX is a long-range solid-state LiDAR sensor with multi-beam projection technology that can analyze the environment around the vehicle through high-resolution images. This product can be customized for mass production according to OEM requirements. The standard product is divided into the following two versions:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-

XenoTrack is a solid-state high-precision LiDAR used to detect the longitudinal profile of roads at close range, which can be installed on any vehicle. This product supports millimeter-level detection accuracy and can be used to detect road conditions, road geometries, and even objects that are almost invisible, and it is available in two versions:

|

|

|

|

|

|

|

|

Both LiDAR sensors come pre-installed with XenoWare 3D point cloud software, supporting ADAS (Advanced Driver Assistance Systems) and autonomous driving applications.

Mr. Bronowski stated that vehicle-mounted LiDAR should not only play a role in safety but also provide comfort.

Safety Functions of LiDAR

The SAE-defined Level 3 autonomous driving achieves partial automation of steering, acceleration, and deceleration operations that require environmental measurement, thus creating a demand for LiDAR. LiDAR supports many ADAS and autonomous driving functions:

-

Collision warning and avoidance (Automatic Emergency Braking (AEB) and Adaptive Cruise Control (ACC)) -

Detection of available space, safe path planning -

Keeping the vehicle in the current lane and guiding the vehicle during lane changes (Lane Keeping Assistance (LKA) and Lane Change Assistance (LCA)) -

Congestion automatic driving assistance and highway automatic driving -

Automatic parking and autonomous valet parking -

Mapping and SLAM (Simultaneous Localization and Mapping) -

Intersection safety monitoring -

Traffic flow monitoring and toll booth reminders -

Fully autonomous driving in all traffic scenarios and driving environments

|

|

|

|

Available space and pedestrian detection technology based on LiDAR point cloud data |

(30th Aachen Colloquium – Sustainable Mobility, organized by Aachener Kolloquium Fahrzeug- und Motorentechnik GbR / Image source: XenomatiX)

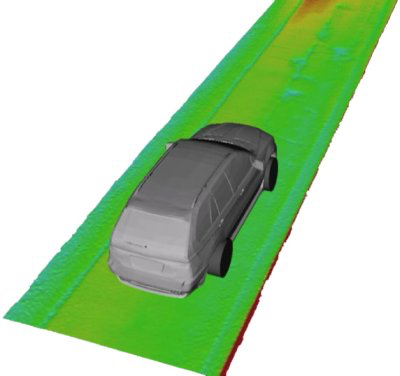

Comfort Functions of LiDAR

XenomatiX’s close-range LiDAR features an active suspension system with preview capabilities, significantly enhancing comfort experience. This LiDAR can emit thousands of laser beams simultaneously to measure road conditions in front of the vehicle with millimeter-level precision. The measurement data obtained from the simultaneously emitted laser beams will be used to create real-time digital maps, extracting the height profile for each wheel, which will provide predictive data to the suspension controller.

Finally, Mr. Bronowski introduced the use of LiDAR in road management. To accurately assess road quality, XenomatiX uses multiple high-precision laser systems, high-precision GNSS (Global Navigation Satellite System), INS (Inertial Navigation System), and high-resolution cameras and LiDAR sensors.

Before concluding his speech, Mr. Bronowski emphasized the importance of collaboration among automotive and road stakeholders, as it is beneficial for sharing LiDAR data and enhancing the safety and comfort functions of LiDAR. Additionally, he suggested that LiDAR development companies should focus on both the detection objects and traffic conditions while also paying attention to the roads themselves, as driving comfort is becoming increasingly important, affecting whether vehicle owners can enjoy a pleasant autonomous driving experience.

|

|

|

|

ACCOCAR demonstration vehicle equipped with preview function LiDAR on the roof |

LiDAR digitizes the road for preview and road diagnostics |

(30th Aachen Colloquium – Sustainable Mobility, organized by Aachener Kolloquium Fahrzeug- und Motorentechnik GbR / Image source: XenomatiX)

Closing Plenary Session (NVIDIA, Hyundai Mobis)

Ways to Make Vehicles Smarter

Speaker: Dr. Ralf G. Herrtwich, NVIDIA

NVIDIA provides AI-based autonomous vehicle development solutions to help automakers and OEMs shape the future of mobility.

Professor Herrtwich first stated that people are experiencing a paradigm shift not only in engine technology but also in software development. Currently, software is still in the manual development stage, but in the future, software writing will be done by machines. Achieving this progress requires the involvement of new software developers.

NVIDIA’s software experts are already developing various deep neural networks to support the safe and reliable operation of autonomous driving systems.

The autonomous driving simulation software “DRIVE Sim” helps developers improve efficiency and expand testing scope, shortening the time to market while minimizing the need for real-world autonomous driving testing.

|

|

|

|

NVIDIA’s AI-based autonomous vehicle development solutions |

NVIDIA’s autonomous driving simulation software “DRIVE Sim” |

(30th Aachen Colloquium – Sustainable Mobility, organized by Aachener Kolloquium Fahrzeug- und Motorentechnik GbR / Image source: NVIDIA)

Mobis: A Reliable Partner in Building the Future Vision of Electric Vehicles

Speaker: Dr. Byung-Ki Ahn, Hyundai Mobis

After briefly introducing the company, Dr. Ahn explained Hyundai Mobis’s roadmap for 2025. The company plans to collaborate with the Hyundai-Kia Automotive Group to launch 44 environmentally friendly vehicles and has set a goal for parts standardization.

Hyundai Mobis will work with the Hyundai-Kia Automotive Group to develop the following electric mobility solutions: electric powertrain architecture for 48V mild hybrid vehicles, three-in-one drive module, drive motor, inverter, DC-DC converter, power module, battery system, battery management system, battery system assembly, on-board charger, and integrated control unit.

Hyundai Mobis regards fuel cell technology as one of the alternatives to traditional fossil fuels and announced plans to build two hydrogen fuel cell system factories in South Korea. The hydrogen fuel cell systems produced by the new factories will be installed in Hyundai’s new fuel cell vehicles, which will be launched in 2023.