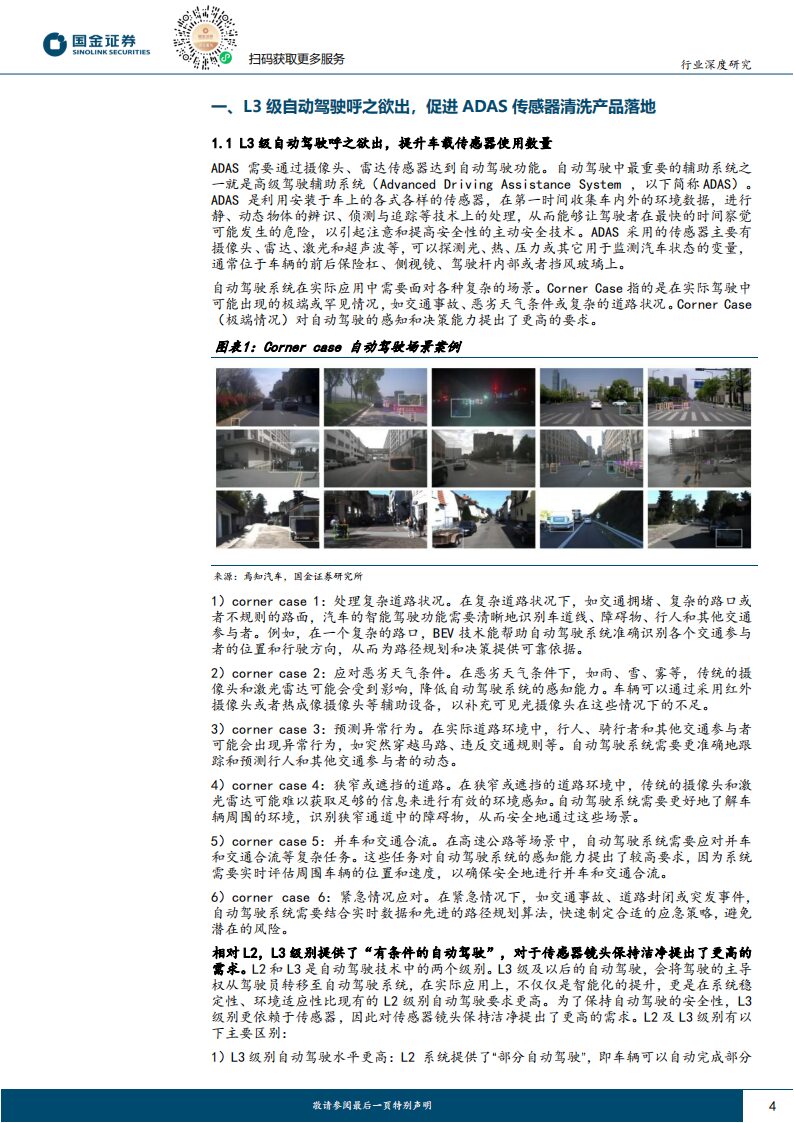

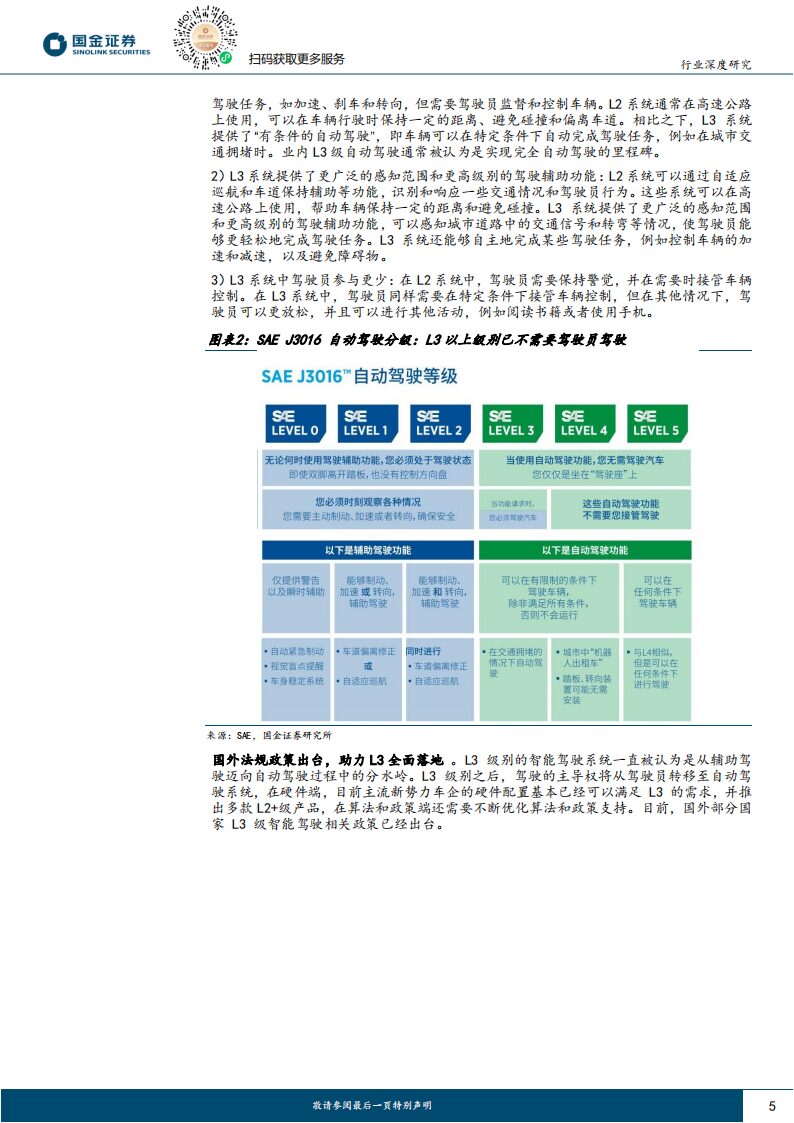

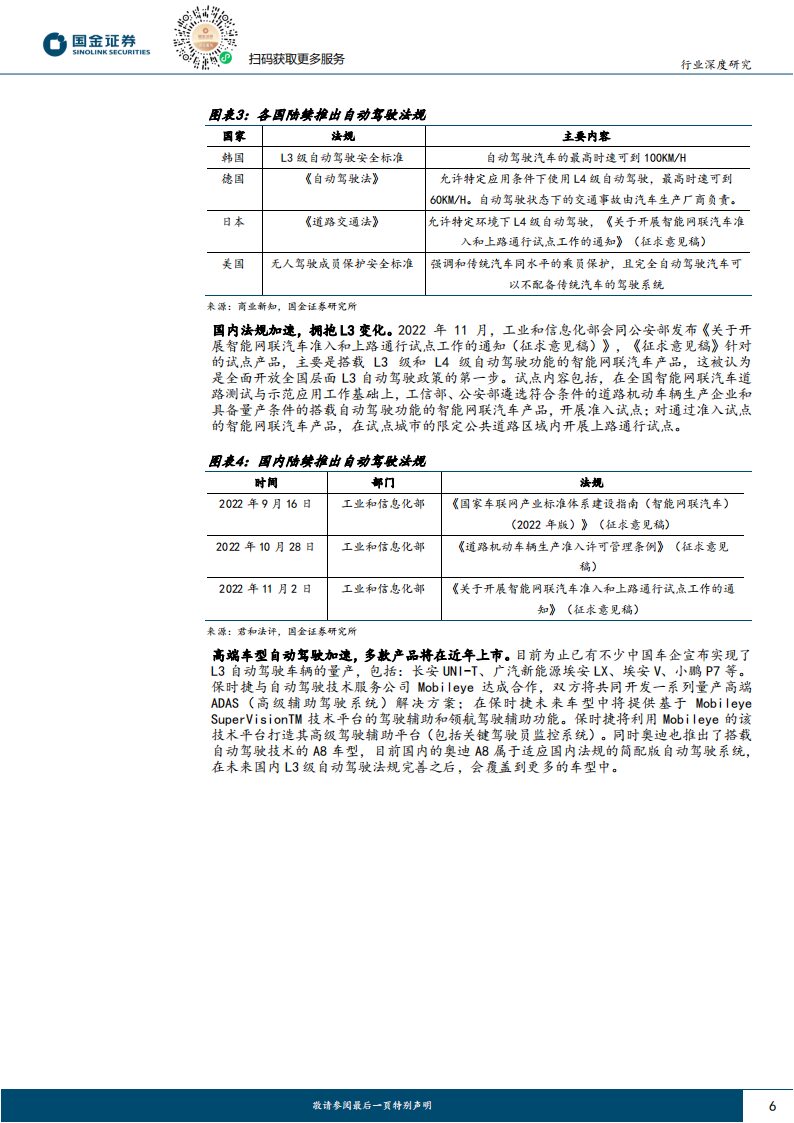

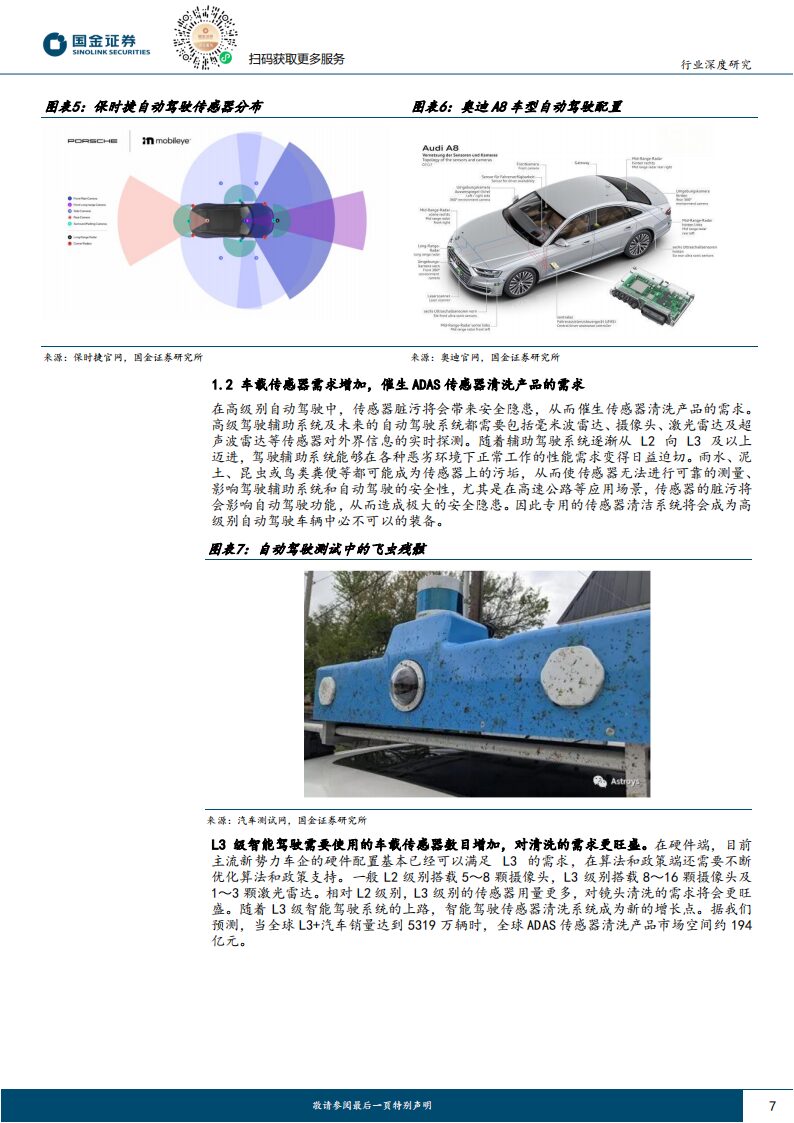

L3+ autonomous driving is about to be realized, creating a trillion market space for sensor cleaning products. L2 and L3 are two levels of autonomous driving technology: 1) L3 level has a higher autonomous driving capability; 2) L3 systems provide a broader perception range and higher-level driving assistance features; 3) Driver involvement is less in L3 systems. Generally, L2 level vehicles are equipped with 5 to 8 cameras, while L3 level vehicles are equipped with 8 to 16 cameras and 1 to 3 LiDARs. Compared to L2, L3 level vehicles require more sensors, leading to a greater demand for lens cleaning. With the advent of L3 intelligent driving systems, intelligent sensor cleaning systems become a new growth point. According to our predictions, when global L3+ vehicle sales reach 53.19 million units, the global ADAS sensor cleaning product market space will be approximately 19.4 billion yuan.

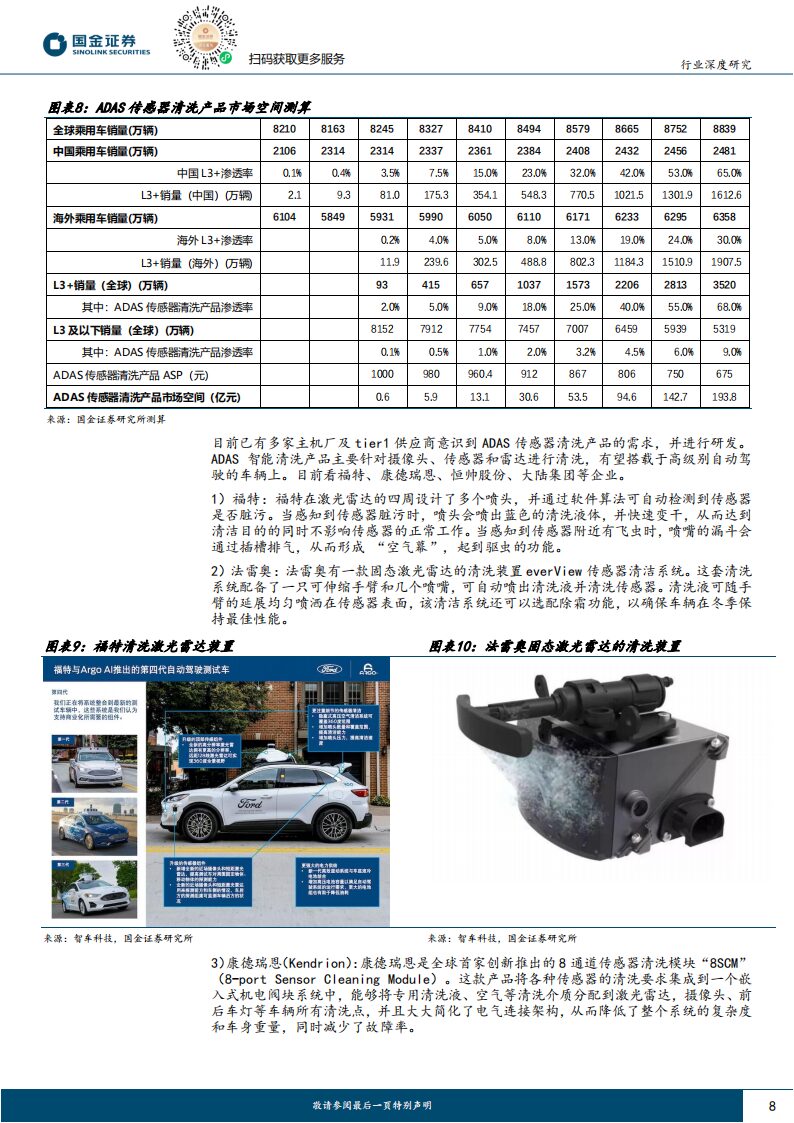

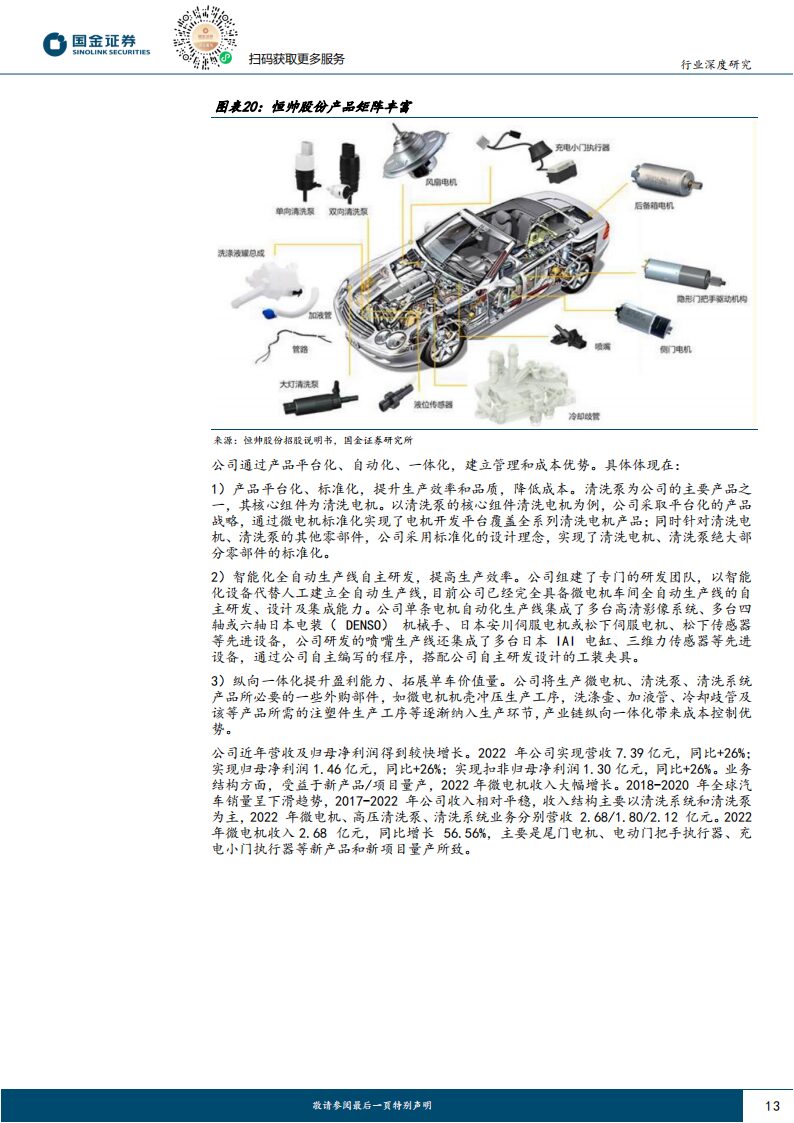

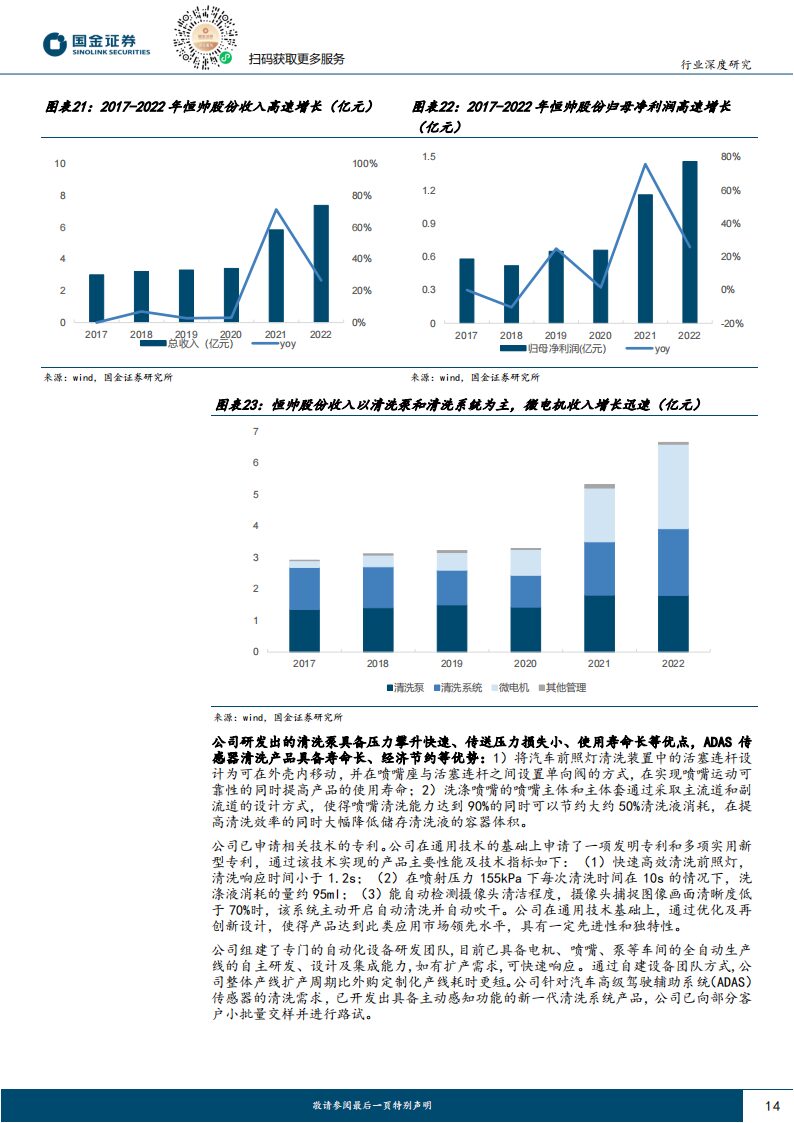

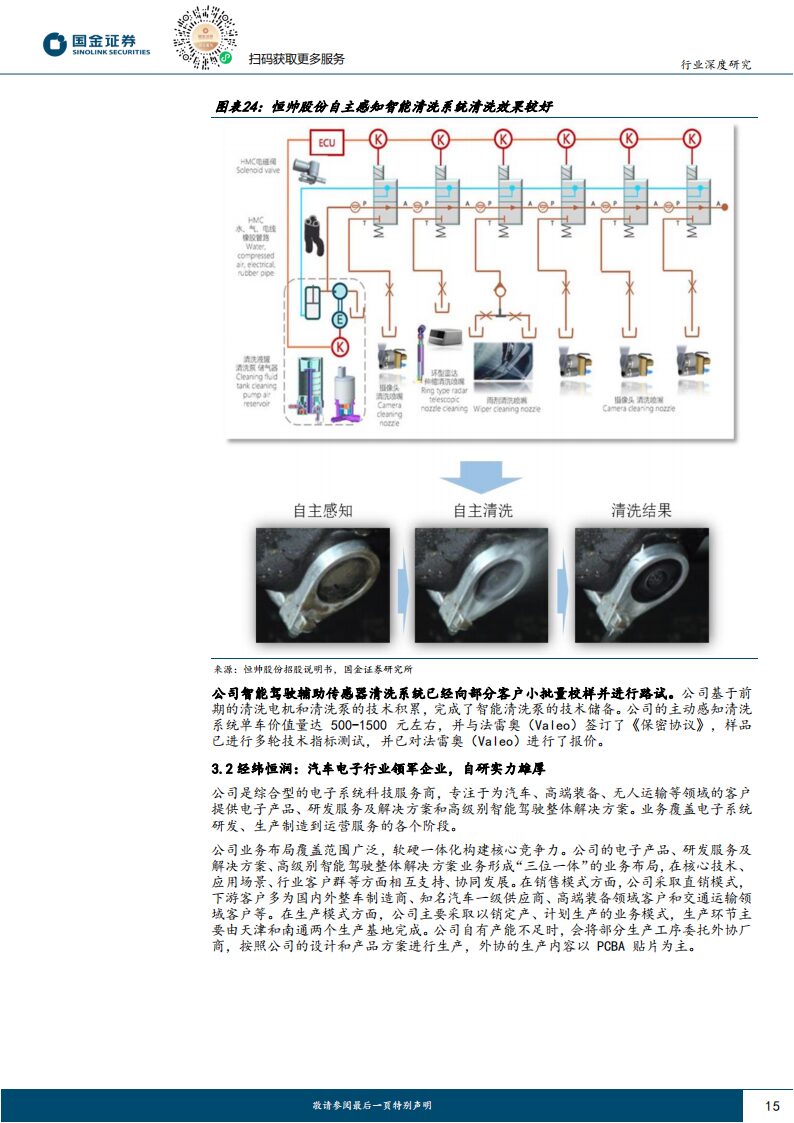

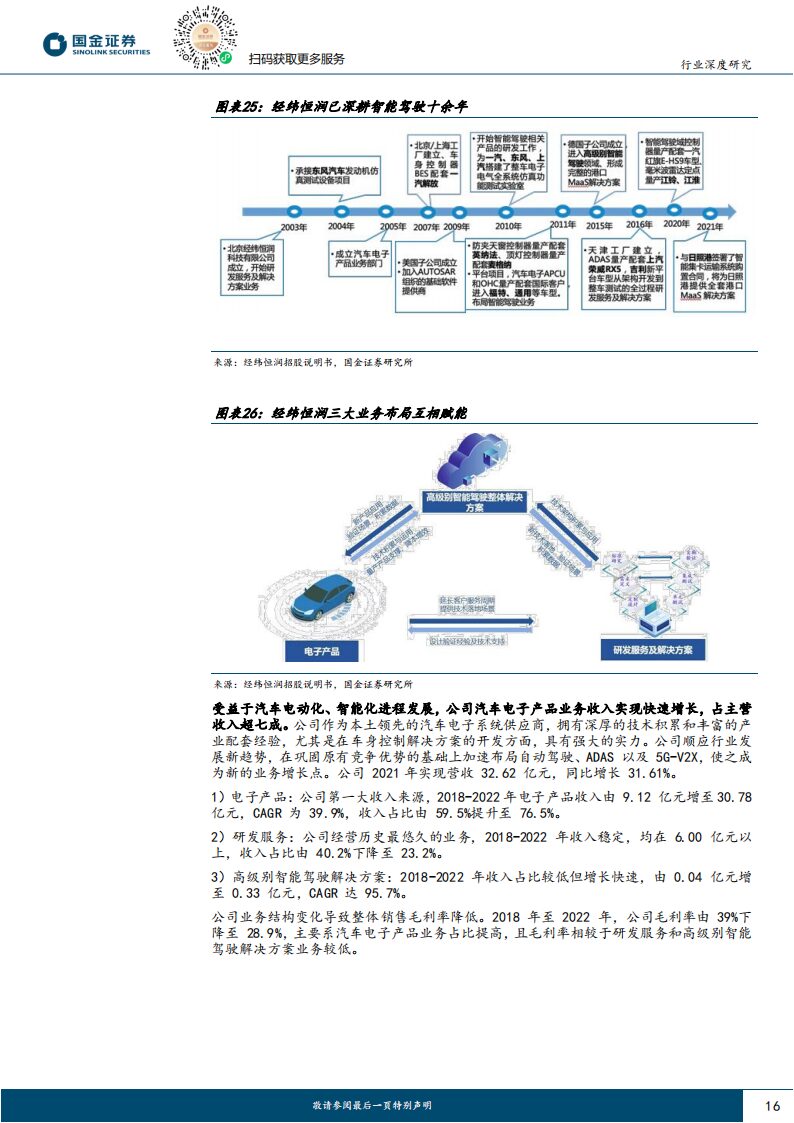

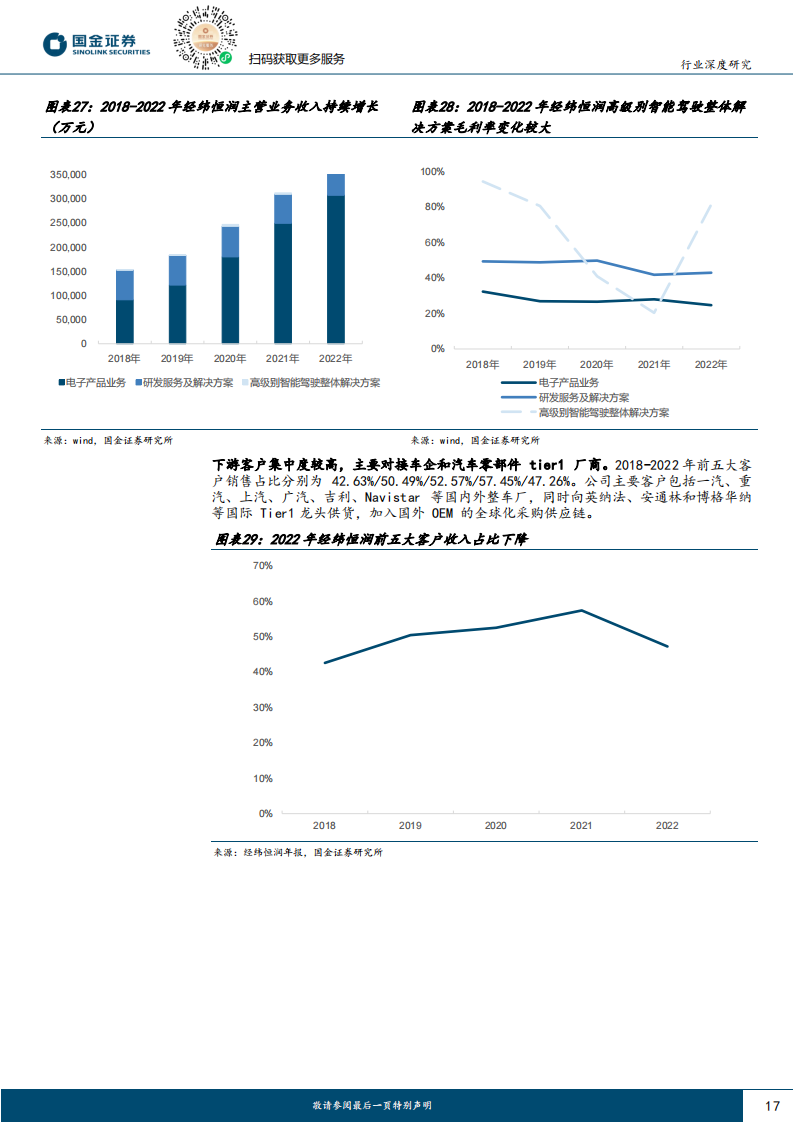

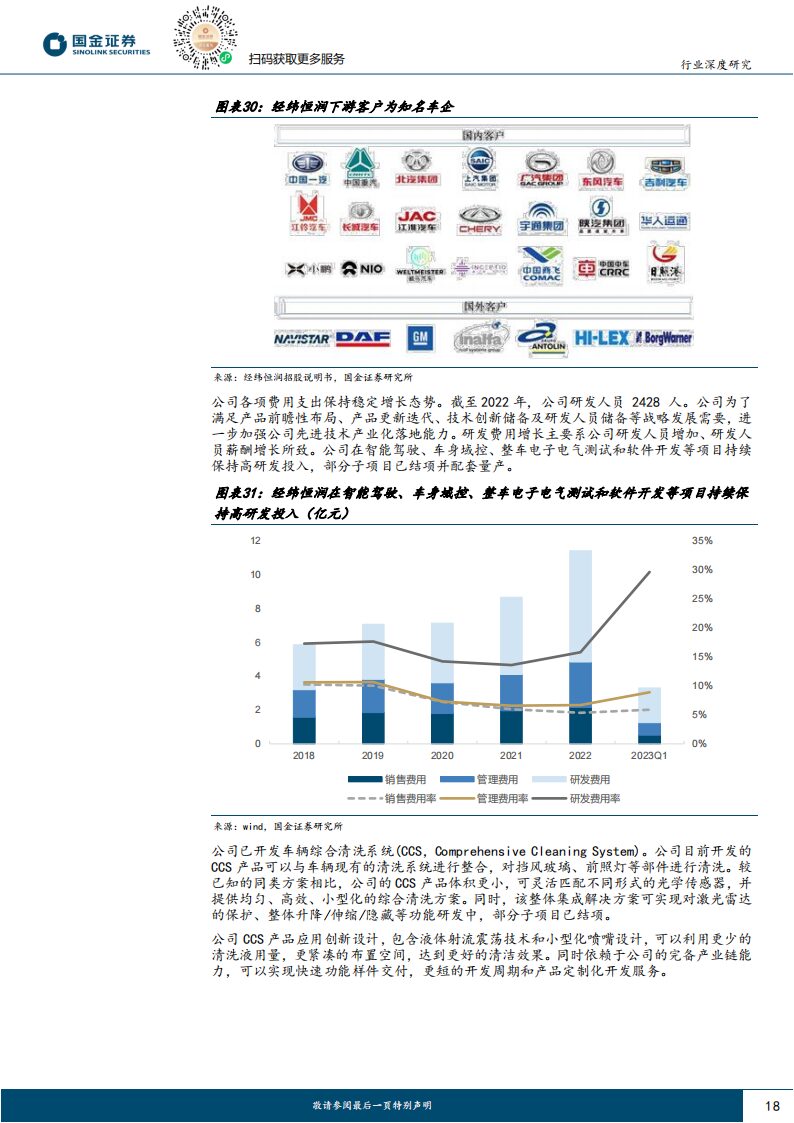

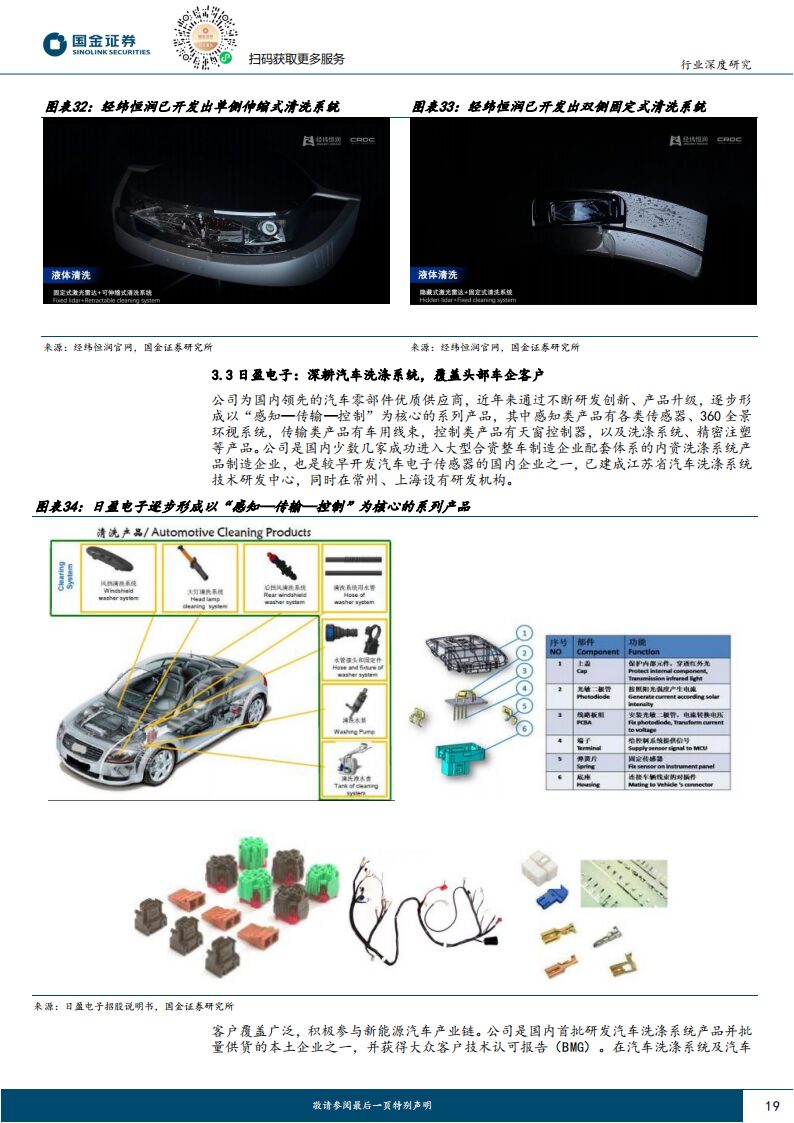

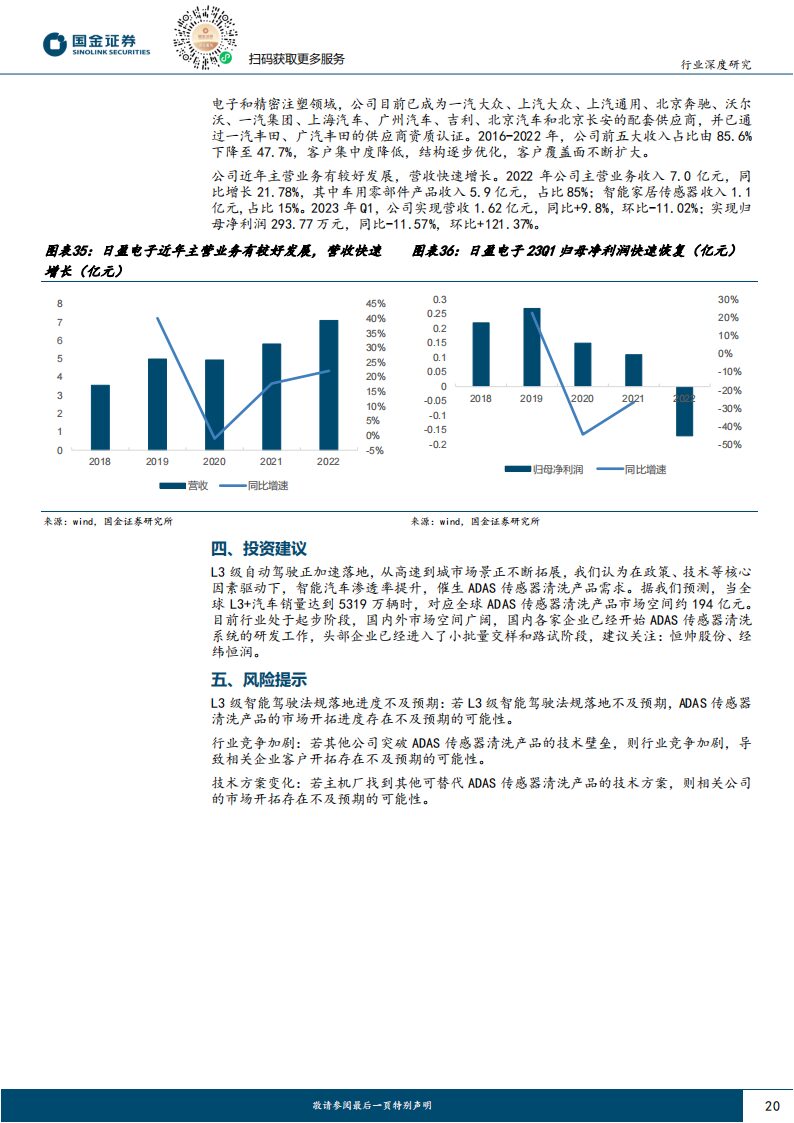

Many domestic and foreign companies are involved in the layout, with Hengshuai Co., Ltd. products having advantages such as long lifespan and high economy. Currently, many OEMs and Tier 1 suppliers have recognized the demand for ADAS sensor cleaning products and are conducting research and development. Currently, Valeo, Ford, Kande Rein, Hengshuai Co., Ltd., Jingwei Hengrun, and Riying Electronics have developed or are preparing to equip corresponding products. Among them, Hengshuai Co., Ltd. has ready-made products that have entered batch production or small-scale testing, and some projects of Jingwei Hengrun’s ADAS cleaning products have been completed, expected to enter small-scale testing and delivery. The cleaning pump developed by Hengshuai Co., Ltd. has advantages such as rapid pressure rise, small pressure loss during transmission, and long service life; ADAS sensor cleaning products have advantages such as long lifespan and economic savings: 1) Designing the piston connecting rod in the automotive headlight cleaning device to move within the shell, and setting a one-way valve between the nozzle seat and the piston connecting rod to ensure reliable nozzle movement while improving the product’s service life; 2) The nozzle body and main sleeve of the washing nozzle are designed using a main flow path and a secondary flow path, achieving a cleaning capability of 90% while saving about 50% of cleaning liquid consumption, significantly reducing the volume of the container for storing the cleaning liquid while improving cleaning efficiency.

Welcome to all angel round enterprises in the entire automotive industry chain (including the power battery industry chain)Around enterprises to join the group (Will recommend to 800 automotive investment institutions including top-tier institutions)There are communication groups for leaders of science and technology innovation companies, automotive industry complete vehicles, automotive semiconductors, key components, new energy vehicles, intelligent connected vehicles, aftermarket, automotive investment, autonomous driving, vehicle networking, and dozens of other groups. To join the group, please scan the administrator’s WeChat (Please indicate your company name)