Click the blue text to follow us

Simulation design of intelligent trash can based on 51 microcontroller (Proteus simulation + program + design report + schematic diagram + explanation video)

Simulation software: Proteus 8.9 and above

Compiler: Keil 4/Keil 5

Programming language: C

Design number: S0089

Main Functions:

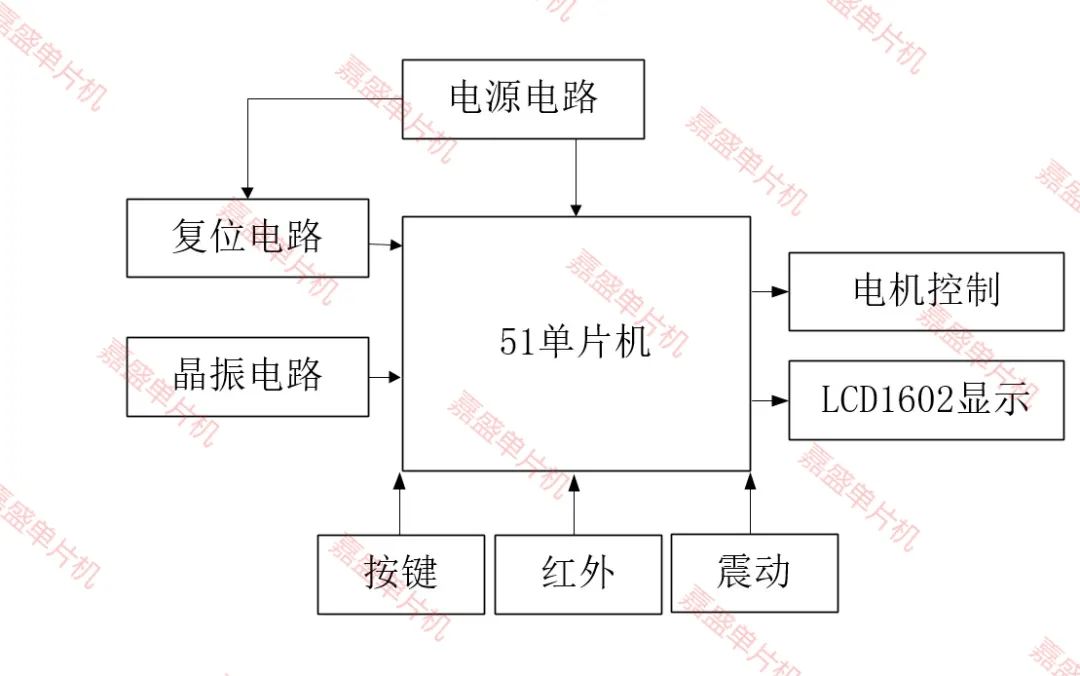

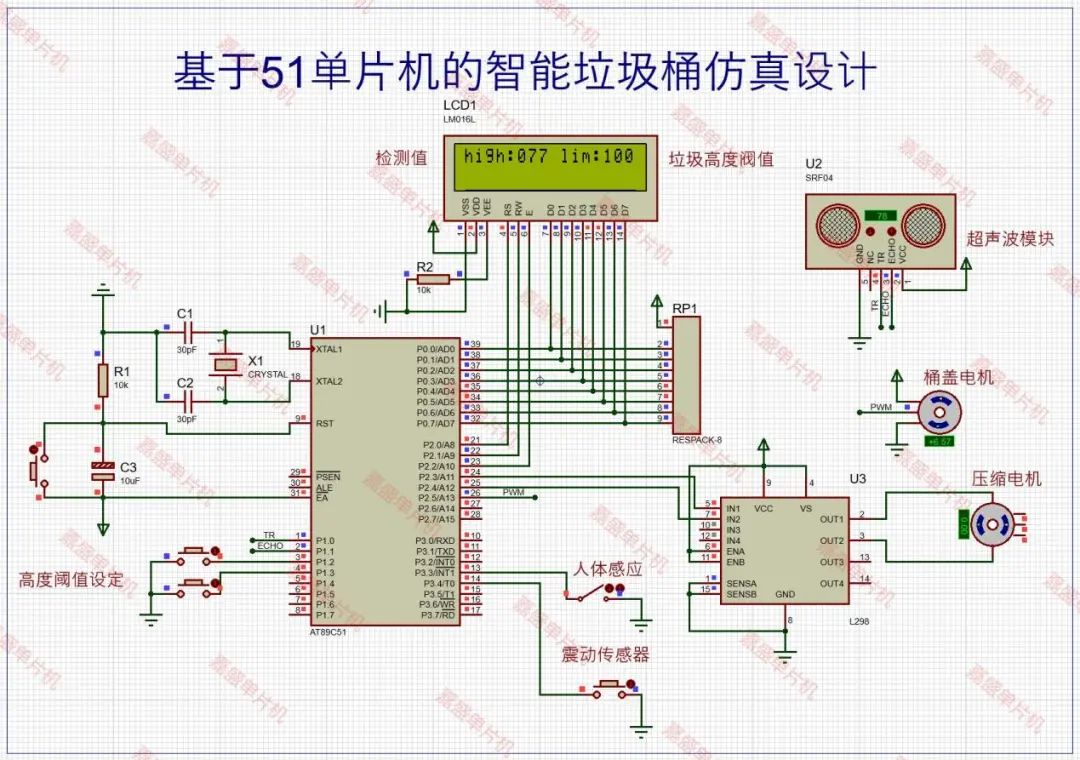

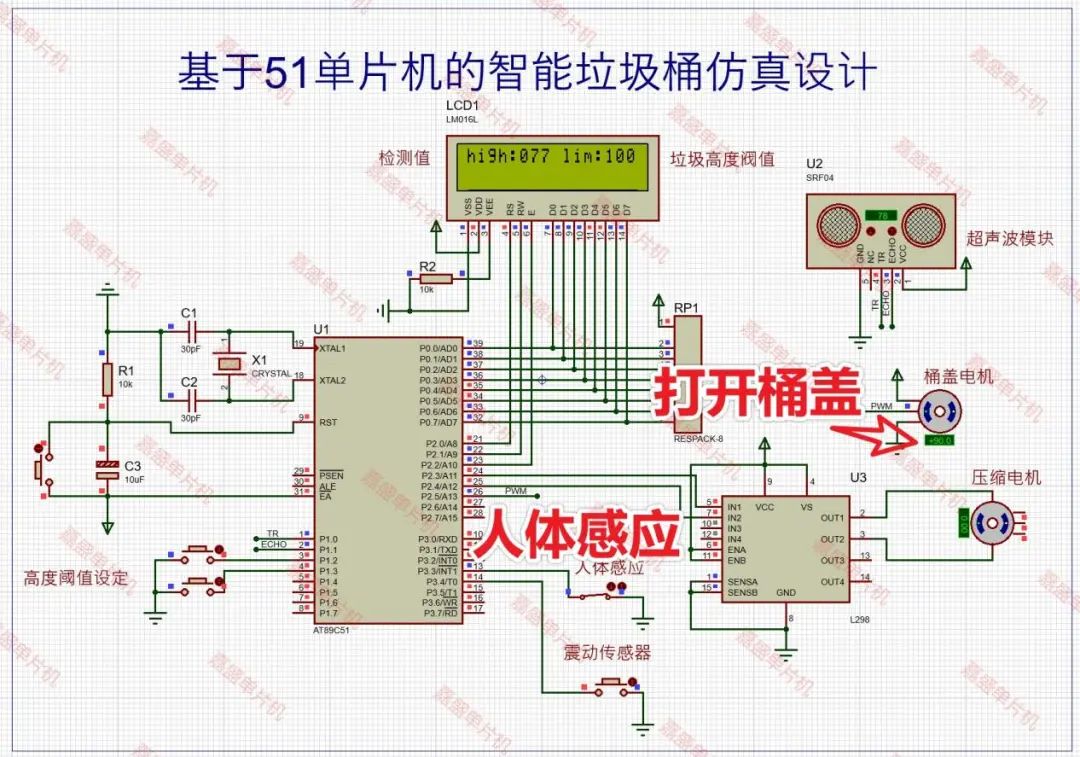

Simulation design of intelligent trash can based on 51 microcontroller

1. Human body induction and body vibration sensing control the servo to rotate 90 degrees to open the lid;

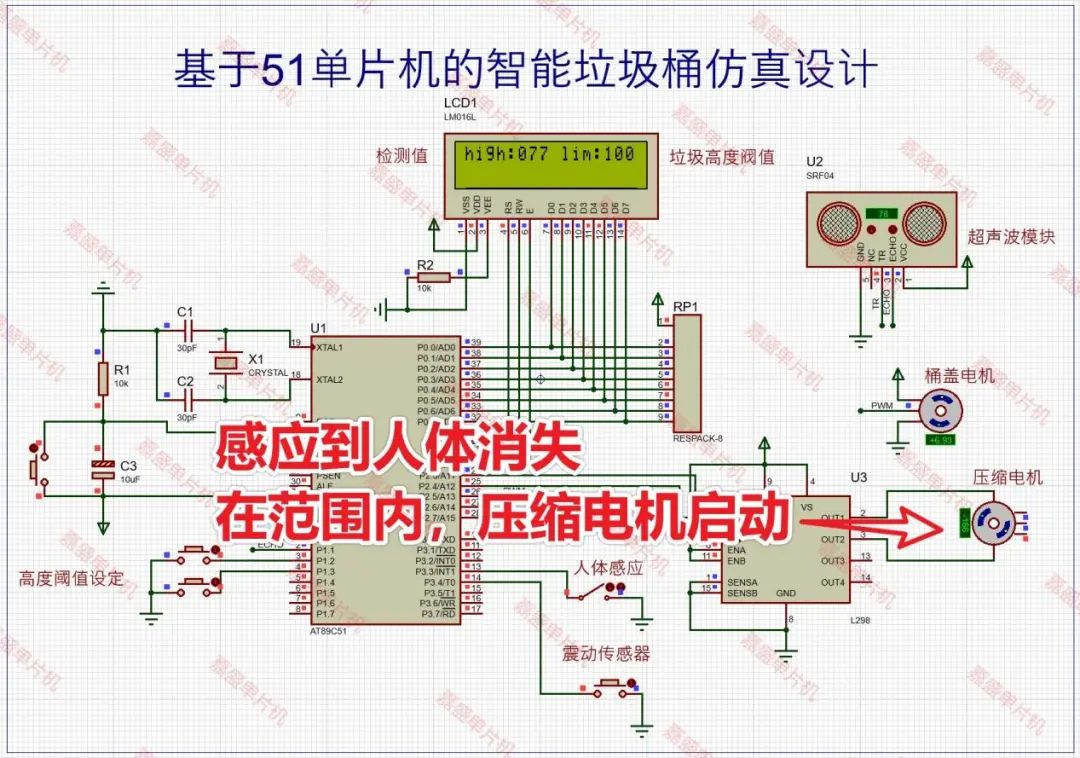

2. After opening, if no human is detected within the sensing range, the motor reverses 90 degrees to close the lid;

3. Ultrasonic module SRF04 performs height sensing to detect the garbage height inside the trash can;

4. The height limit can be set via buttons, and the LCD1602 displays the measured height and limit value;

5. The garbage compression motor operates within the height limit, compressing the garbage when rotating forward, and returning when rotating backward;

Note that the 51 microcontroller chip used in the simulation is compatible; AT89C51 and AT89C52 are specific models of the 51 microcontroller, with the same core. In the same schematic diagram, whether STC or AT, the pin functions are the same, and the program is compatible. The chip can be replaced with STC89C52/STC89C51/AT89C52/AT89C51 and other 51 microcontroller chips.

Download link for materials:

[Tencent Document] S0089 Cloud Disk Link

https://docs.qq.com/doc/DS0tmcmlhSXBtVnVF

The following is the display of the design materials:

Explanation video:

The explanation video includes simulation operation explanation and code explanation

Simulation Design:

Open the simulation project, double-click the microcontroller in Proteus, select the hex file path, and then start the simulation. After starting the simulation, the digital tube displays the current garbage height and the garbage height threshold. If the garbage height is below the threshold, the compression motor will start after throwing garbage; otherwise, it will not start.

Simulate human induction by toggling the switch, the lid motor rotates 90 degrees, simulating the opening of the trash can. Wait for the human induction to disappear, and the motor reverses 90 degrees to close the lid.

After the lid closes, the garbage compression motor operates within the height limit, rotating forward to compress the garbage and reversing to return.

The height limit can be set via buttons, and the LCD1602 displays the measured height and limit value;

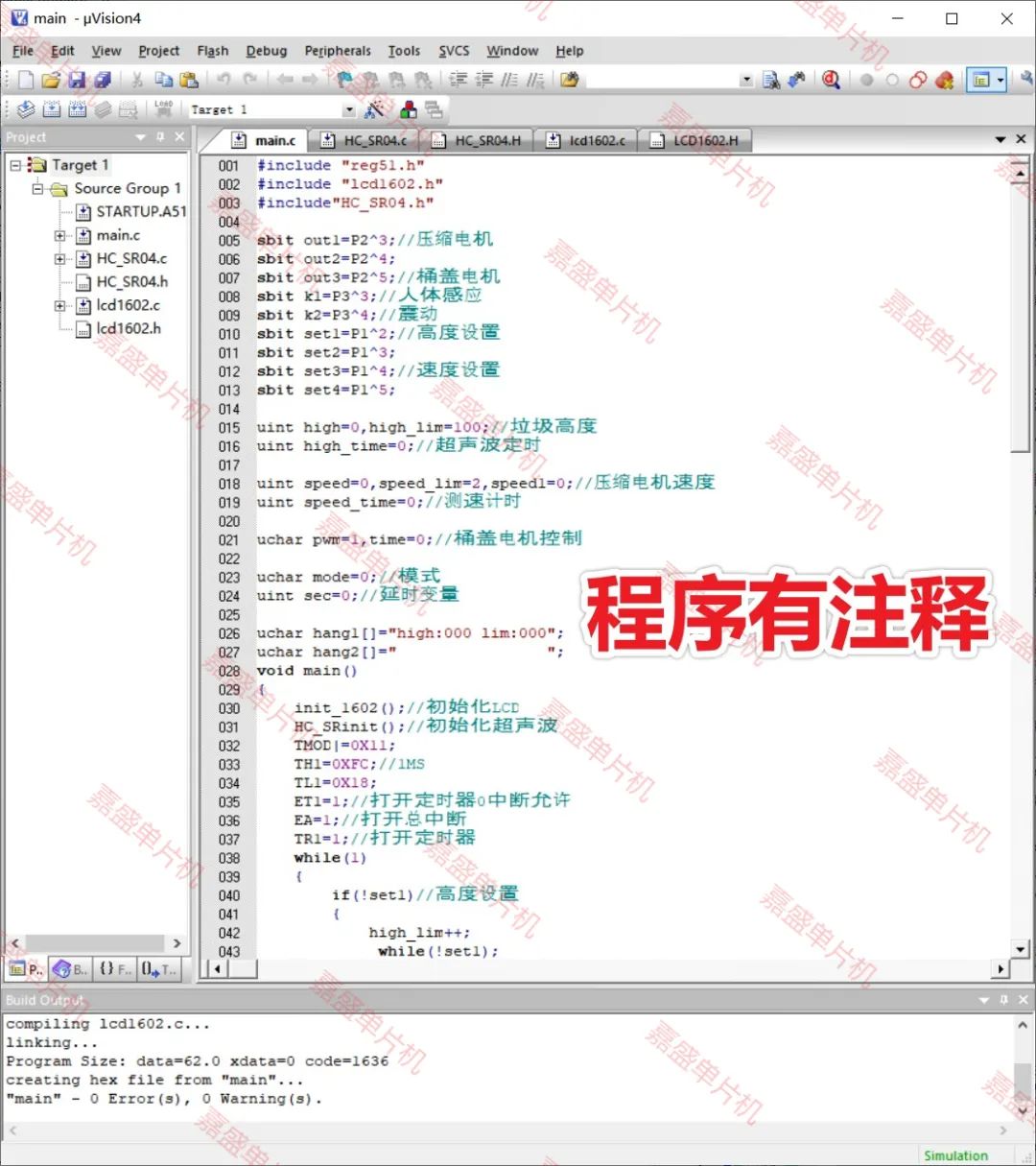

Program Code

Use Keil 4 or Keil 5 to compile, the code is commented, and can be understood in conjunction with the video to grasp the meaning of the code.

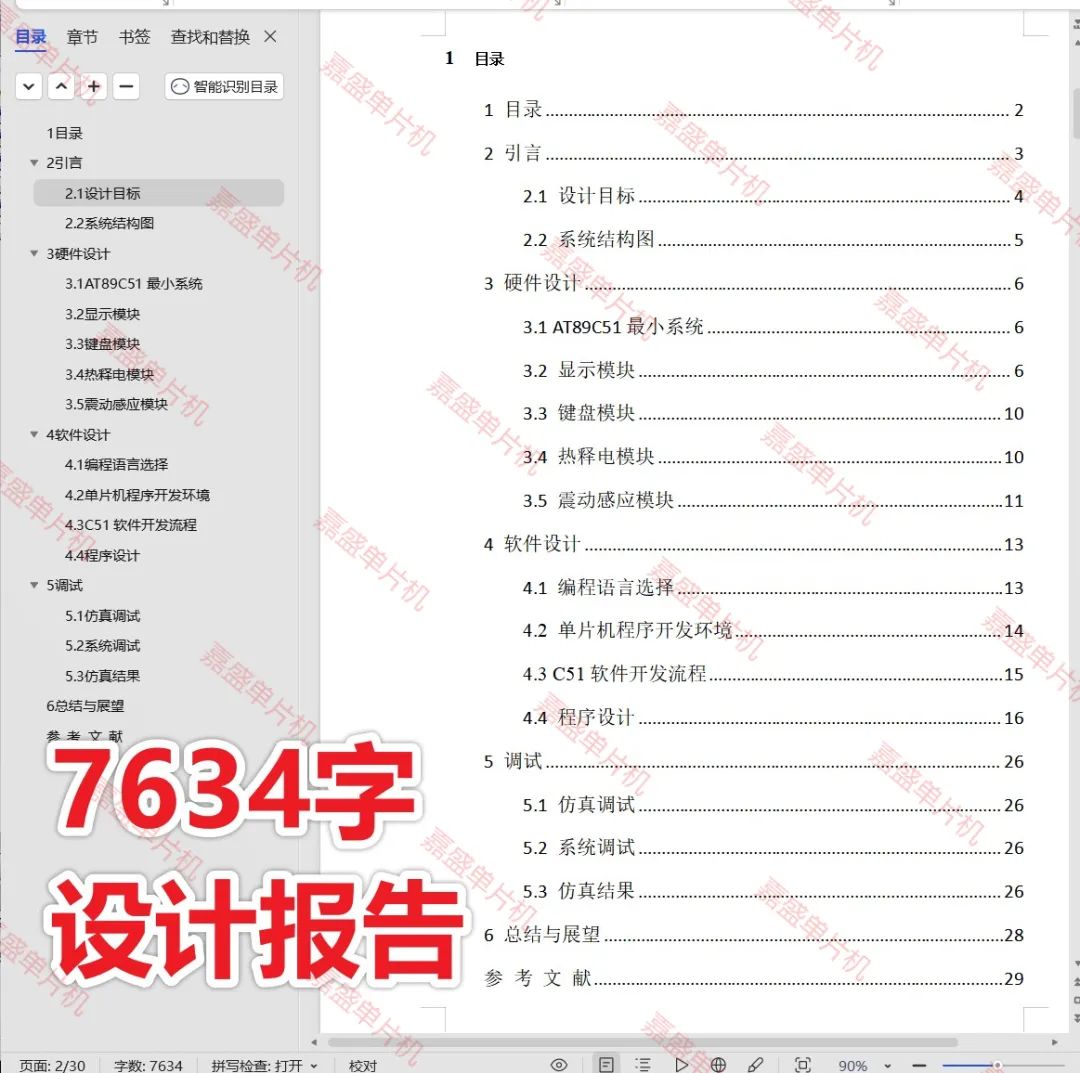

Design Report

7634-word design report, including hardware design, software design, soft and hardware block diagrams, debugging, conclusions, etc.

With the rapid development of technology and the deepening of global environmental protection concepts, intelligent home devices play an increasingly important role in modern society. The intelligent trash can, as a component of the intelligent home ecosystem, has been favored by a wide range of users due to its efficient and convenient functional design and user-friendly experience. By integrating advanced automation technology, it not only realizes contactless operation during the garbage disposal process but also has functions such as garbage compression to optimize space utilization and full-load automatic reminders. These innovative features greatly enhance residents’ convenience and the quality of their living environment, and strongly promote the implementation of garbage classification and resource recycling.

This course design project follows this trend, selecting the classic 51 series microcontroller as the core control element, combined with the powerful electronic design simulation software Proteus platform, aiming to simulate and construct an intelligent trash can system integrated with human body induction control, height detection, and automatic compression functions. The goal of this design is to allow students to gain hands-on experience, deeply understand and master the hardware structure principles of microcontroller systems, microcontroller programming logic, the application methods of various sensors (such as infrared or ultrasonic sensors), and key technical knowledge in areas such as motor driving. In addition, students will also learn how to effectively integrate these technologies to solve problems in real-life scenarios, enhancing product practicality and user experience.

Through the implementation of this project, students can not only gain valuable practical experience and enhance their ability to connect theory with practice but also deeply appreciate the importance of technological progress in improving daily life and promoting social sustainable development. At the same time, this is also a beneficial attempt and exploration for cultivating innovative capabilities in future intelligent home talent.

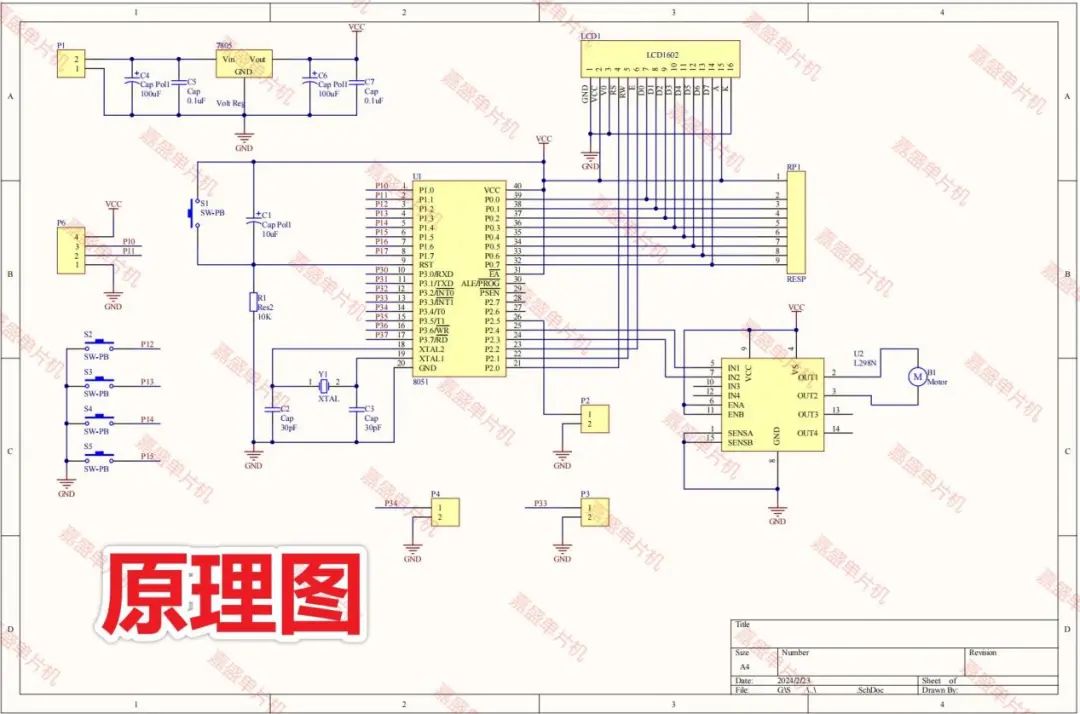

Schematic Diagram

The schematic diagram is drawn using AD, and can be referenced for the actual object. Simulation is different from the actual object; do not easily engage in the actual object without sufficient experience.

Differences between Proteus simulation and physical work:

1. Operating environment: Proteus simulation runs on a computer, while the physical work runs on a hardware circuit board.

2. Debugging method: In Proteus simulation, step-by-step debugging and observing variable value changes can be easily done, while in the physical work, debugging needs to be done through a debugger or serial output.

3. Circuit connection method: In Proteus simulation, circuit connection modifications can be made through software settings, while in physical work, modifications need to be done through hardware circuit boards and connecting wires.

4. Operating speed: Proteus simulation is generally faster than physical work because simulation runs on a computer, while physical work needs to consider physical limitations and response times of components on the circuit board.

5. Function implementation: In Proteus simulation, different functions can be achieved through software settings, while in physical work, implementation needs to be based on circuit design and component performance.

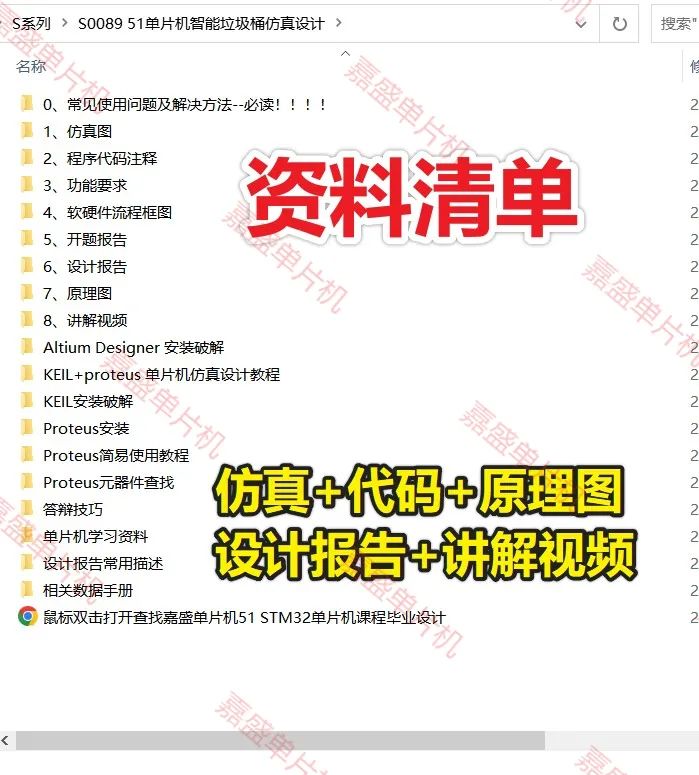

Design Material Content List & Download Link

The design material includes simulation, program code, explanation video, functional requirements, design report, soft and hardware design block diagrams, etc.

0. Common usage issues and solutions – Must Read!!!!

1. Program

2. Proteus simulation

3. Functional requirements

4. Soft and hardware flow chart

5. Proposal report

6. Design report

7. Schematic diagram

8. Component list

9. Explanation video

Altium Designer installation and crack

KEIL + Proteus microcontroller simulation design tutorial

KEIL installation and crack

Proteus component search

Proteus installation

Proteus simple usage tutorial

Microcontroller learning materials

Relevant data sheets

Defense skills

Common descriptions in design reports

Double-click to open and find the Jiasen microcontroller 51 STM32 microcontroller course graduation design.url

Method 1: Copy and open in the browser

Material download link:

https://docs.qq.com/doc/DS0tmcmlhSXBtVnVF

More resources click the link below:

https://docs.qq.com/sheet/DS0xIa0llTmtNakRW

Method 2: Long press to scan the code

WeChat Official Account

Jiasen Microcontroller

Website | www.eemcu.cn