Introduction

The first five issues of the “Research on Industrial Transformation” special edition received strong reactions and unanimous praise from the industry after publication. Recently, the sixth issue of the “Research on Industrial Transformation” special edition has been officially published. This public account will continue to report on the articles included in the sixth issue of the “Research on Industrial Transformation” special edition. Readers are welcome to follow.

This article is co-authored by Zhang Hanqing, Business Manager of the Collaborative Expansion Department of CITIC Cloud Network Co., Ltd., Xiao Gang, Chief Business Officer of CITIC Cloud Network Co., Ltd., and Ge Lue, Director of the Collaborative Expansion Department of CITIC Cloud Network Co., Ltd., published in the “Research on Industrial Transformation” special edition, August 2022, Issue No. 336, and is shared here for readers.

△ Sixth Issue of the “Research on Industrial Transformation” Special Edition

Research on IoT Technology Applications in Manufacturing

By/Zhang Hanqing Xiao Gang Ge Lue

Business Manager of the Collaborative Expansion Department, CITIC Cloud Network Co., Ltd.

Chief Business Officer, CITIC Cloud Network Co., Ltd.

Ge Lue

Director of the Collaborative Expansion Department, CITIC Cloud Network Co., Ltd.

Industrial Internet of Things (IIoT) technology integrates sensors and controllers with perception and monitoring capabilities, as well as ubiquitous technologies, network technologies, artificial intelligence, edge computing, and other technologies into every aspect of the production process. It can improve industrial manufacturing levels, enhance product quality, reduce costs and resource consumption, and realize the transformation from industrial automation to intelligence, which is the direction for future development in manufacturing. This article focuses on the application of IoT in industry, discussing the overall architecture, key technologies, and case deployment situations, and finally presents challenges and prospects for this technology in the future.

From Germany’s “Industry 4.0”, America’s “Manufacturing Revival Plan”, Japan’s “Rebirth Strategy”, to China’s “Made in China 2025”, all emphasize that the future aims at advanced manufacturing technology and the upgrading of industrial structures. The structural integration of IoT is one of the fundamental characteristics of intelligent manufacturing, and the emergence and development of IoT’s “thing-to-thing connection” is an extension and development of the first three industrial revolutions and the foundation of the fourth industrial revolution.

In the era of Industry 3.0, many enterprises improved production efficiency and product quality by achieving automated production. However, when industrial production technologies and management models cannot meet the development requirements of the industrial field, industrial production technologies must break free from the traditional M2M (Machine to Machine) production model. In today’s Industry 4.0 environment, the production model emphasizes the transition from automation to intelligence, with IoT serving as a key technology for intelligent production.

Industrial Internet of Things (IIoT) technology integrates sensors and controllers with perception and monitoring capabilities, as well as ubiquitous technologies, network technologies, artificial intelligence, edge computing, and other technologies into every aspect of the production process. It can improve industrial manufacturing levels, enhance product quality, reduce costs and resource consumption, and realize the transformation from industrial automation to intelligence, which is the direction for future development in manufacturing. This article focuses on the application of IoT in industry, discussing the overall architecture, key technologies, and case deployment situations, and finally presents challenges and prospects for this technology in the future.

From Germany’s “Industry 4.0”, America’s “Manufacturing Revival Plan”, Japan’s “Rebirth Strategy”, to China’s “Made in China 2025”, all emphasize that the future aims at advanced manufacturing technology and the upgrading of industrial structures. The structural integration of IoT is one of the fundamental characteristics of intelligent manufacturing, and the emergence and development of IoT’s “thing-to-thing connection” is an extension and development of the first three industrial revolutions and the foundation of the fourth industrial revolution.

In the era of Industry 3.0, many enterprises improved production efficiency and product quality by achieving automated production. However, when industrial production technologies and management models cannot meet the development requirements of the industrial field, industrial production technologies must break free from the traditional M2M (Machine to Machine) production model. In today’s Industry 4.0 environment, the production model emphasizes the transition from automation to intelligence, with IoT serving as a key technology for intelligent production.

As the world’s largest industrial manufacturing country, China has successively introduced policies such as “Made in China 2025”, “Guidance on Deepening the Integration of Manufacturing and the Internet” and “Guidance on Developing Industrial Internet with Internet + Advanced Manufacturing”. These policies clarify that China’s main direction by 2025 is intelligent manufacturing. Given the opportunities and challenges faced by future factories, the use of industrial IoT technology will accelerate the development of intelligent industries.

01

Architecture and Key Technologies of Industrial IoT

Industrial Internet of Things (IIoT) technology is the IoT technology applied in the industrial field. It integrates sensors and controllers with perception and monitoring capabilities, as well as key technologies such as 5G, digital twin technology, industrial intelligence technology, blockchain, and edge computing, applied to every aspect of the production process, achieving improvements in industrial manufacturing levels, product quality, cost reduction, and resource consumption, ultimately realizing the transformation from industrial automation to intelligence and achieving qualitative breakthroughs. From the current application status, IIoT presents many advantages such as reliability, real-time performance, automation, environmental adaptability, embedded systems, interoperability, and connectivity.

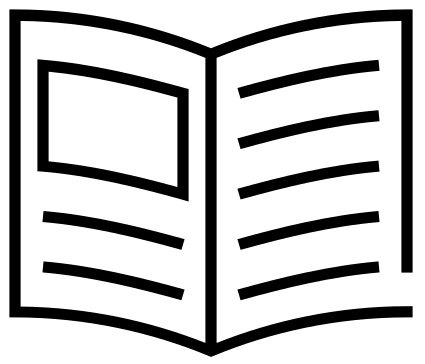

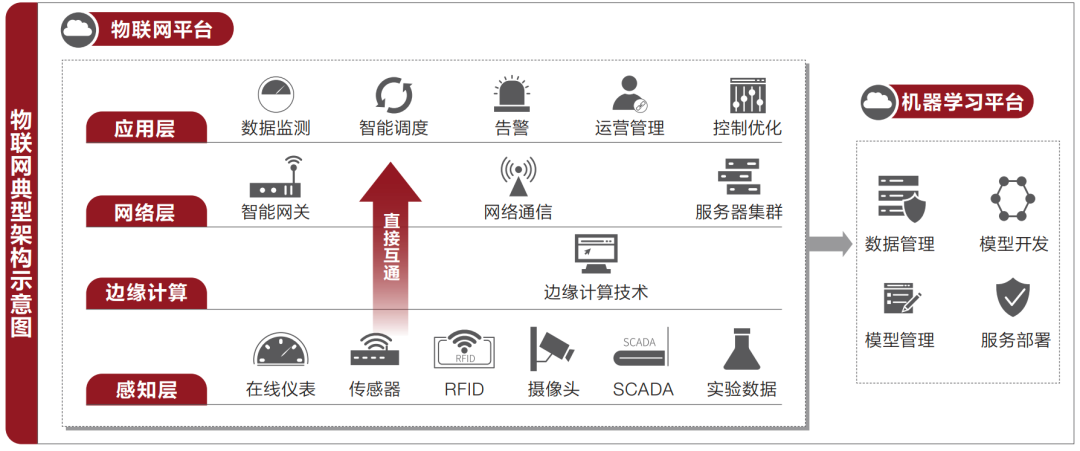

The typical architecture of IoT consists of three layers: the perception layer, the network layer, and the application layer. It can work with key technologies like edge computing and artificial intelligence to form an integrated intelligent manufacturing solution that effectively plays its role.

The perception layer is responsible for connecting industrial machines with IoT devices, achieving real-time data collection through end devices such as sensors, cameras, RFID, and transmitters. The network layer mainly transmits the information collected by sensors to the application layer using telecommunication networks or Ethernet, serving as a bridge between local data construction and remote data analysis centers in factories, enabling data transmission anytime and anywhere. The edge computing layer assists the application layer, serving as an open platform based on edge nodes to compute, process, optimize, and store data close to the IoT edge, reducing dependence on cloud centers and significantly improving computing efficiency. The application layer is the ultimate value embodiment of IoT, analyzing data from the perception layer on production processes, machine operating conditions, etc., using technologies like big data, artificial intelligence, and machine learning to provide guiding decisions for enterprises and industry development in forms like dashboards, electronic screens, and mobile apps, such as optimizing production processes, guiding production management, improving operational efficiency, and predicting industry development, achieving widespread intelligence.

In the transition from automation to intelligence, artificial intelligence technology is a very important component, with intelligent control being its key core system function. Technicians can use artificial intelligence technology to solve intelligent control problems in IoT, maximizing the functional use of IoT. Technicians may still have oversights in data analysis; they can leverage artificial intelligence to connect with IoT platforms, analyzing and mining massive amounts of data to build related models, intelligently processing expert knowledge and experience, discovering trends, models, attributes, and structures contained in the data, ultimately achieving automated processing of object recognition information, realizing the development goal of unattended operations, reducing the workload of staff while maximizing overall operational and work efficiency.

Based on the above characteristics and architecture of IoT, in the field of industrial manufacturing, IoT is the basic pillar of digitalization and intelligent manufacturing. It can connect all industrial assets, including machines and control systems, with information systems and business. After collecting a large amount of data, it can be analyzed, cleaned, and provide solutions to improve manufacturing efficiency, enhance product quality, reduce product costs, and resource consumption, thus optimizing industrial operations.

02

Case Study on Smart Water Management

The industrial application of artificial intelligence covers everything from low-level applications (such as intelligence) to high-end artificial intelligence with decision-making capabilities, which can classify information and predict and make decisions more accurately than humans. Therefore, artificial intelligence is a powerful analytical and decision-making tool. Industrial IoT can integrate the powerful analytical processing capabilities of artificial intelligence, providing functions such as smart monitoring, smart control, intelligent diagnosis, intelligent decision-making, and intelligent maintenance, ultimately achieving the goals of improving productivity, reducing energy consumption, and optimizing decision-making.

Taking the smart water management scenario as an example, a set of industrial IoT smart water management platform is developed and customized based on customer needs, integrating information resources with cloud computing, machine learning, big data, IoT, and mobile internet technologies. This platform perceives comprehensive changes in the water management environment, production, and status through sensing devices, transmits and stores data, and uses modeling and machine learning to achieve intelligent analysis of massive data, ultimately enabling smart dosing, smart aeration, MBR membrane pollution treatment, and other intelligent management.

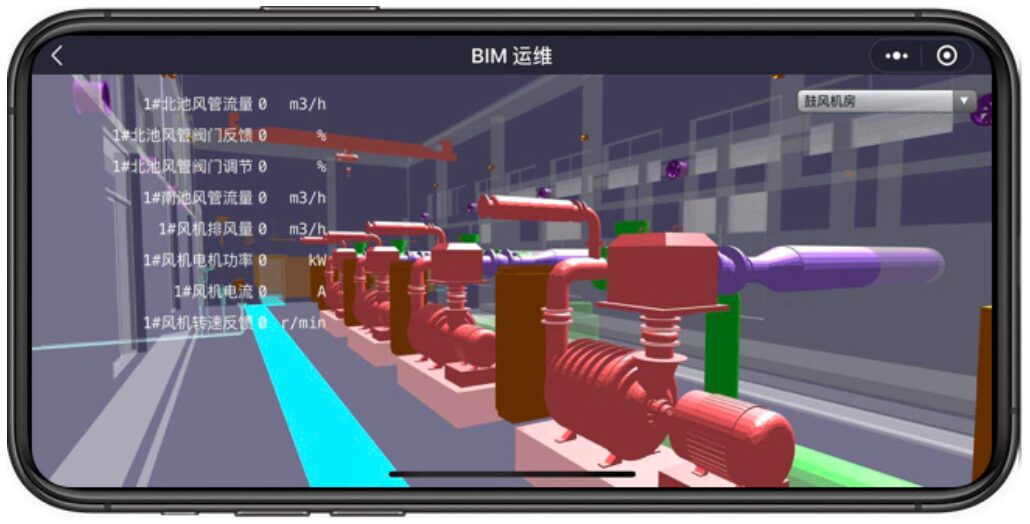

The multi-source heterogeneous information fusion platform uses BIM components as carriers to integrate all data information related to the equipment, facilitating communication within different teams or externally during the water plant’s production process. BIM serves as a bridge between data and reality, reducing communication costs and improving efficiency.

BIM Visualization Diagram

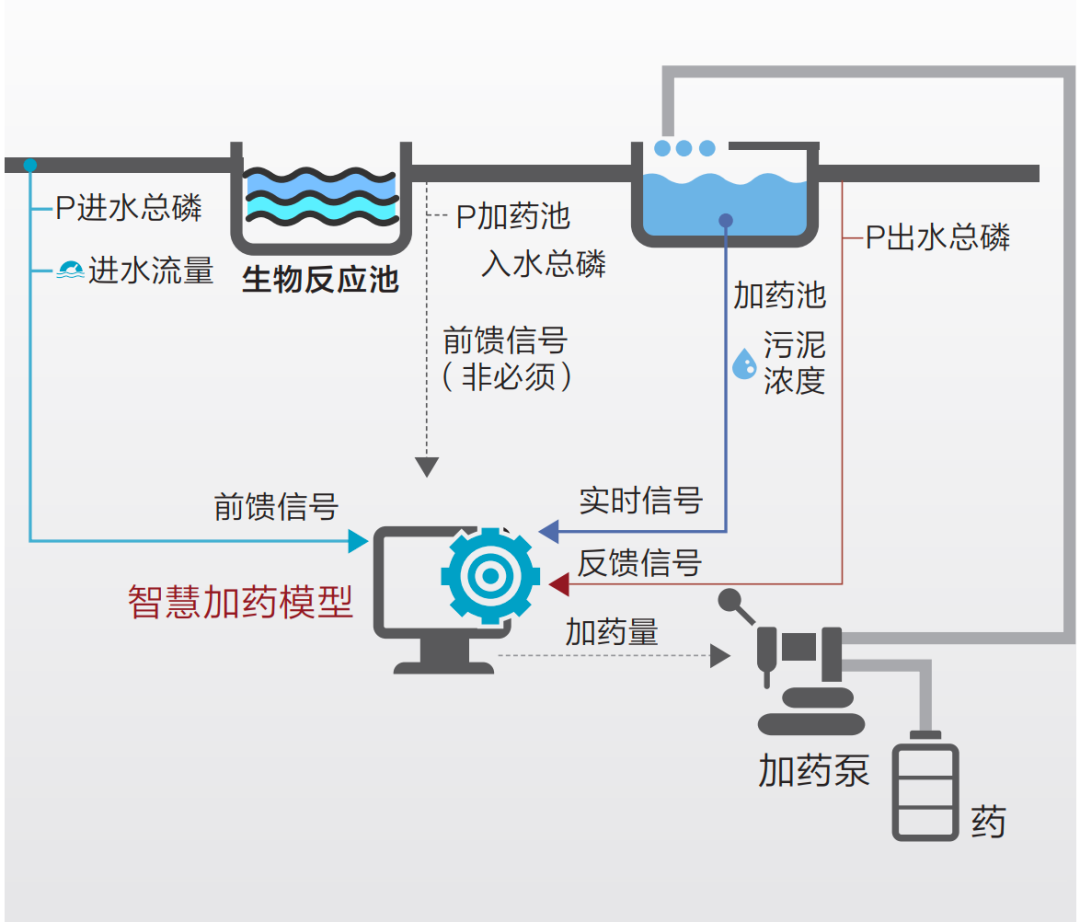

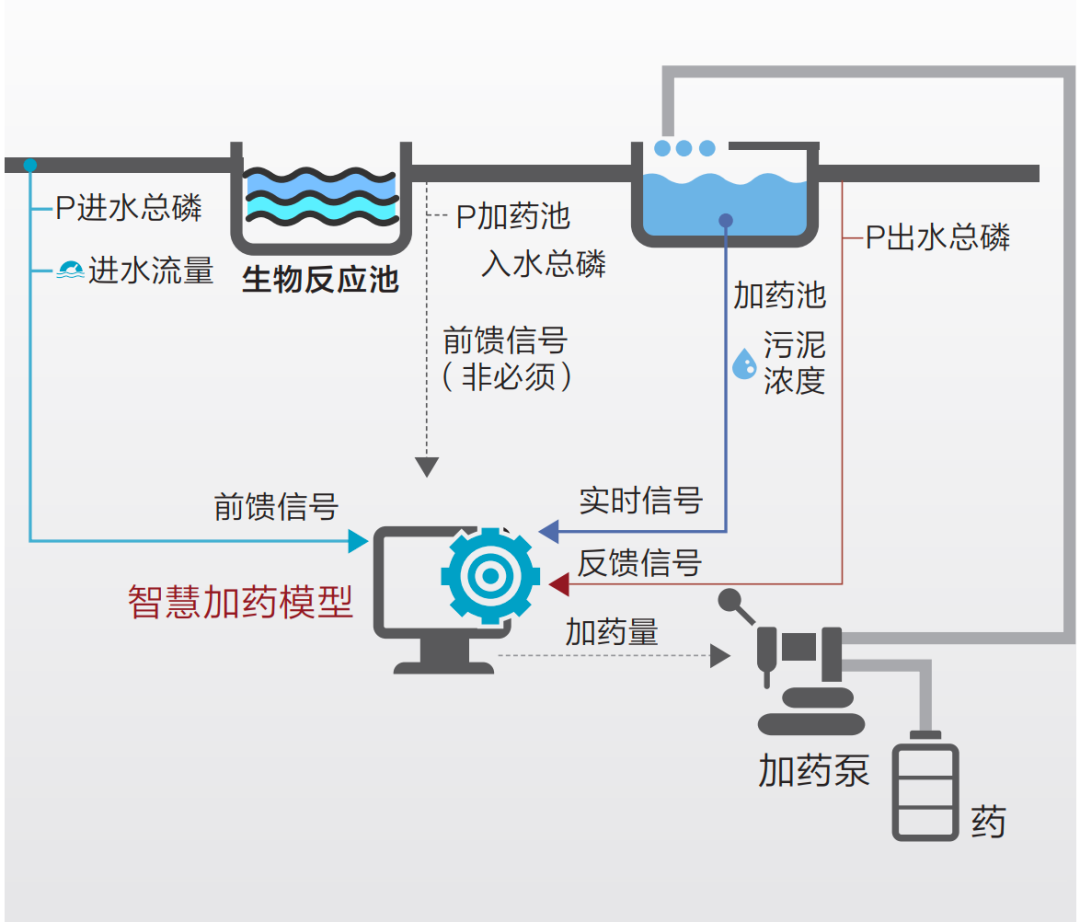

Fit the total phosphorus of incoming and outgoing water quality with the dosing amount; calculate the required dosing amount based on the feed water quality’s feedforward signal; and adjust the dosing amount in real-time according to the trend of the feed water quality’s feedback signal. Ensure that the outgoing water quality does not exceed standards while dosing as needed, reducing waste of chemical agents and linking with the dosing pump for automated dosing.

Smart Dosing Diagram

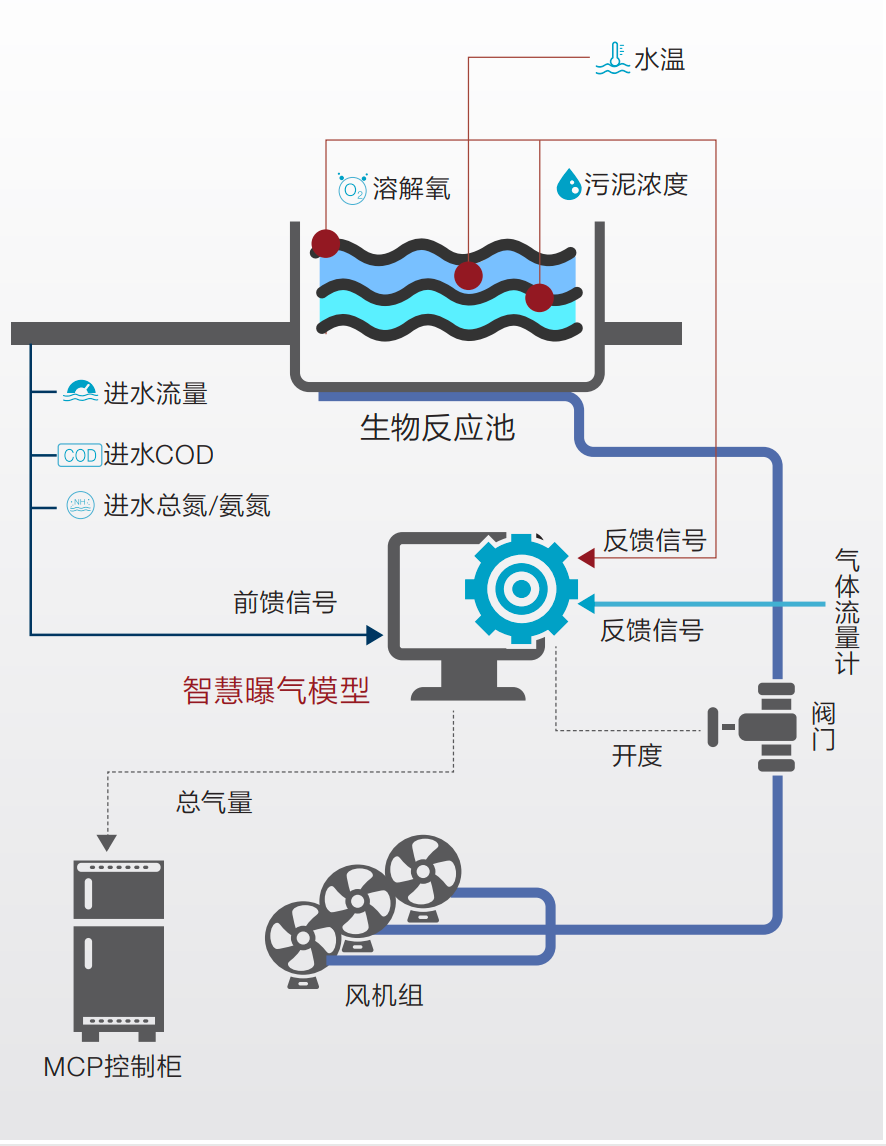

In the sewage treatment process, which features multi-variable, non-linearity, time-variance, and hysteresis, the smart aeration model uses methods such as neural networks and multiple regression to establish a dynamic relationship model between biochemical pool operating indicators, aeration volume, and other variables, adjusting model parameters in real-time based on aeration feedback effects, iteratively optimizing, distributing air volume as needed, and precisely controlling the dissolved oxygen in the biological reaction pool, reducing energy consumption and saving costs. Variables from sensors such as water quality/environment include 20-30, with minute-level data; model training requires over three months of data, while model operation needs only 24 hours of data. New water plants needing to verify algorithm feasibility require over a week of data. Ultimately, the dissolved oxygen stabilizes within ±0.5mg/L of the set value, greatly enhancing the stability and reliability of the sewage treatment industry, improving the plant’s ability to withstand incoming shock loads, and ensuring outgoing water meets standards, with stable dissolved oxygen in the biological pool.

In the sewage treatment process, which features multi-variable, non-linearity, time-variance, and hysteresis, the smart aeration model uses methods such as neural networks and multiple regression to establish a dynamic relationship model between biochemical pool operating indicators, aeration volume, and other variables, adjusting model parameters in real-time based on aeration feedback effects, iteratively optimizing, distributing air volume as needed, and precisely controlling the dissolved oxygen in the biological reaction pool, reducing energy consumption and saving costs. Variables from sensors such as water quality/environment include 20-30, with minute-level data; model training requires over three months of data, while model operation needs only 24 hours of data. New water plants needing to verify algorithm feasibility require over a week of data. Ultimately, the dissolved oxygen stabilizes within ±0.5mg/L of the set value, greatly enhancing the stability and reliability of the sewage treatment industry, improving the plant’s ability to withstand incoming shock loads, and ensuring outgoing water meets standards, with stable dissolved oxygen in the biological pool.

Smart Aeration Diagram

Based on the model’s suggested values, accurately supply aeration as needed, achieving a blower power-saving rate of 10%-15%, effectively reducing unit processing energy consumption and saving costs. The operational parameters of the biological pool form a closed-loop control with the aeration valve, automatically completing detection, alarms, and adjustments, reducing the difficulty of manual operations. The mobile end can view the operational status of the biological reaction pool and blower in real-time, facilitating control and management.

MBR Membrane Pollution Treatment

In the long-term process of membrane treatment of wastewater, membrane pollution problems are inevitable. Membrane pollution can reduce membrane flux and permeability, increase transmembrane pressure difference and membrane surface resistance, leading to decreased effluent quality and shortened service life. Permeability can directly reflect the degree of membrane pollution; by predicting permeability, one can forecast the degree of membrane pollution, allowing timely cleaning and maintenance of the membrane, thus improving its service life. However, permeability cannot be directly measured. Traditional water plants generally estimate permeability through calculation methods, resulting in significant lag in records and failing to achieve precise online prediction of membrane pollution status. Using intelligent permeability detection methods, i.e., extracting characteristic variables through feature analysis and establishing a permeability soft measurement model based on recursive RBF neural networks, allows for high prediction accuracy and simple operation, reducing the complexity of permeability calculations, achieving precise online measurement and real-time correction, providing an effective method for membrane pollution status, improving efficiency and economic benefits in the MBR membrane wastewater treatment process.

03

Main Issues Faced in Industrial IoT Applications

Lack of a Unified Relevant Standard System

In the application of IoT technology in China’s manufacturing industry, there are many manufacturers and a lack of unified communication standards, which easily leads to difficulties in information reception between different controllers and sensors, making timely transmission and exchange very challenging, and also complicating effective analysis, resulting in wasted information resources. Equipment compatibility issues must rely on unified standards; therefore, China’s manufacturing industry needs to quickly standardize communication standards and data structures to ensure overall application.

Currently, only a few IoT companies in China have achieved R&D cooperation with universities and research institutions. Although China has made achievements in supporting technologies such as sensor systems, computer systems, and communication technology in the IoT field, there remains a significant gap in product and technology innovation compared to developed countries in Europe and America, which cannot provide strong support for the transformation of China’s manufacturing industry.

Network Security Assurance Needs Improvement

As devices connected to the internet are integrated into the production process, the risk of cyber attacks also increases. The three-layer structure of IoT will face different security risks. The first layer, the perception layer, faces massive data, which may be subject to risks such as malicious code attacks, radio frequency interference, and eavesdropping that lead to data leakage. The second layer, the network layer, may face security risks such as man-in-the-middle attacks, deception attacks, and RFID attacks. The third layer, the application layer, may face security risks such as buffer overflow, web attacks, malware, code injection, and phishing. Currently, many core devices for cloud computing and big data in China rely on imports, and without strict information security guarantees, there is a high risk of data leakage, thus blocking the promotion and construction of IoT and the intelligent transformation of the manufacturing industry.

Small and Medium Enterprises Facing Financial Difficulties

In China’s IoT applications, large enterprises have sufficient funds to break through cost constraints and truly integrate IoT into all aspects of production. However, for most small and medium enterprises, the cost of traditional system integration and custom development is too high, and their capacity to bear investment risks is limited, making it difficult for IoT and manufacturing to achieve deep integration in budget-constrained small and medium enterprises.

04

Suggestions for Accelerating the Integration of IoT and Manufacturing

China’s intelligent manufacturing is still in its infancy. The following development suggestions are proposed to address the difficulties in integrating IoT with manufacturing. First, enhance the independent innovation capability of key technologies. Establish an industrial IoT technology alliance among enterprises, universities, and research institutes to cultivate and introduce relevant talents, improve the independent development capabilities of basic software, and focus on solving technical challenges in integrating IoT with manufacturing. Second, formulate a general standard system for industrial IoT, breaking the barriers of different protocols among manufacturers, accelerating the formulation of standards for data structures, sensors, network interfaces, etc. At the same time, actively participate in the formulation of international rules, paying attention to the connection between national standards and international standards, so that more IoT technologies in China gain international recognition. Third, strengthen the supervision of network security, improve the relevant laws and regulations for information security management to avoid risks such as hacker attacks or data leakage, ensuring safety during the use of industrial IoT platforms. Fourth, increase financial support for the integration of IoT and manufacturing, improving the financing environment for IoT companies. Establish special funds for IoT technology to provide relevant financial support for manufacturing enterprises, alleviating the financing difficulties of small and medium enterprises in upgrading to intelligent systems.

Industrial intelligence is the mainstream direction for future development, and industrial IoT is an indispensable pillar. The continuous increase in application penetration is its most significant feature. In 2022, the global industrial IoT market size reached 216.13 billion USD, and this market is expected to continue to grow in the coming years, reaching 1.11 trillion USD by 2028. The continuous development of key technologies such as artificial intelligence and big data will drive the development and application of industrial IoT technology, further promoting the transition from automation to intelligence; advanced intelligent technologies based on deep learning, machine vision, and other computational analyses will also be the development trend of industrial IoT technology in the future. Based on industrial IoT technology, precise improvements in robotics and automation technology in industrial production will ultimately lead manufacturing plants towards the direction of unmanned factories. In the face of the development of industrial IoT, the manufacturing industry must pay sufficient attention and apply IoT technology to enhance industrial production processes to complete the transition from automation to intelligence as soon as possible.

Ordering Information

The “Research on Industrial Transformation” special edition is now on sale for issues one to six. Readers wishing to purchase can click on the “Read the original text” link at the end of the article or contact the following teacher to order:

Teacher Zhu Xuting:

Contact number: 010-83021220

Email address: [email protected]

Issues One to Three of the “Research on Industrial Transformation” Special Edition

(From left to right, click on the image to read the special edition collection)

Issues Four to Six of the “Research on Industrial Transformation” Special Edition

(From left to right, click on the image to read the special edition collection)

Editor, Images|Duan Wenxiu

Reviewed, Edited|Yang Fan