Click the blue text to follow “Textile Report”

Column Introduction

The smart textile market is gradually becoming a new engine for global economic growth. Market research firm ReportLinker predicts that the global smart textile market is expected to grow from $2.52 billion in 2021 to $9.3 billion by 2026, with a compound annual growth rate of 28.7%. In the next decade, during the Internet of Things era, smart textiles are likely to change human life alongside artificial intelligence, human-computer interfaces, and cloud technology. This publication has established a special column on recent advances in smart textiles, aiming to provide readers with a deeper understanding of smart textiles through comprehensive introductions.

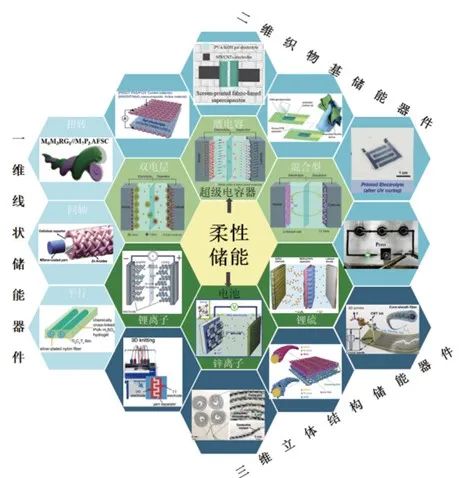

Continuous and stable operation is a fundamental requirement for smart textile systems, and the power supply issue poses a significant challenge.To address the power supply problem of electronic textile devices, current solutions mainly focus on developing energy storage and energy harvesting textile devices.The main types of textile-based flexible energy storage devices are shown in Figure 1. Figure 1 Textile-based Flexible Energy Storage Devices

Figure 1 Textile-based Flexible Energy Storage Devices

Energy Storage Textile Devices

Flexible batteries and supercapacitors are currently the two most widely researched types of flexible energy storage devices, among which lithium-ion batteries have a high energy density and operating voltage, but they are prone to safety issues such as electrode material shedding, electrolyte leakage, and short circuits under external forces; supercapacitors achieve high power density and excellent safety through a combination of Faradaic reactions and rapid reversible Faradaic reactions. Among these, flexible electrodes are crucial components of both types of flexible energy storage devices. Currently, the substrates for flexible electrodes mainly include metal materials, fabrics, polymer films, nano-carbon, and carbon nanotube films. Among them, textile materials possess natural flexibility, excellent mechanical properties, and a large specific surface area, allowing them to withstand multi-directional bending and folding, and can be cut into any size and shape, making them an ideal substrate for flexible energy storage devices.Currently, textile-based supercapacitors exhibit characteristics such as lightweight, high power density, long cycle life, good thermal stability, and environmental stability, but they still face issues such as low volumetric capacitance, low energy density, significant self-voltage drop, and difficulties in packaging. To achieve commercialization and large-scale application of textile-based flexible energy storage devices, future research and development goals should focus on:

Flexible batteries and supercapacitors are currently the two most widely researched types of flexible energy storage devices, among which lithium-ion batteries have a high energy density and operating voltage, but they are prone to safety issues such as electrode material shedding, electrolyte leakage, and short circuits under external forces; supercapacitors achieve high power density and excellent safety through a combination of Faradaic reactions and rapid reversible Faradaic reactions. Among these, flexible electrodes are crucial components of both types of flexible energy storage devices. Currently, the substrates for flexible electrodes mainly include metal materials, fabrics, polymer films, nano-carbon, and carbon nanotube films. Among them, textile materials possess natural flexibility, excellent mechanical properties, and a large specific surface area, allowing them to withstand multi-directional bending and folding, and can be cut into any size and shape, making them an ideal substrate for flexible energy storage devices.Currently, textile-based supercapacitors exhibit characteristics such as lightweight, high power density, long cycle life, good thermal stability, and environmental stability, but they still face issues such as low volumetric capacitance, low energy density, significant self-voltage drop, and difficulties in packaging. To achieve commercialization and large-scale application of textile-based flexible energy storage devices, future research and development goals should focus on:

(1) Selecting appropriate packaging materials and processes to maximize the retention of the flexibility and electrochemical performance of electrode materials, ensuring the durability of flexible energy storage devices;

(2) Researching the interface issues between electrode materials and textile substrates, as well as the flow of liquid electrolytes, to further improve electrochemical stability and eliminate safety hazards during the use of flexible energy storage devices;

(3) Evaluating and comparing the flexibility and wearable-related performance of flexible energy storage devices to lay the foundation for commercialization and standardization.

Energy Harvesting Textile Devices

Energy harvesting technology is a green and sustainable technology that converts environmental energy (solar, wind, thermal, mechanical, electromagnetic, etc.) into electrical energy, providing ubiquitous, environmentally friendly, and sustainable energy solutions for wearable electronic products in the Internet of Things era. Various forms of energy that can be converted into electrical energy exist in the human body and its surrounding environment, including biomechanical motion energy, body heat, biochemical energy from bodily fluids, and solar energy (Figure 2), enabling power generation through the integration of textiles with power generation.

Energy harvesting technology is a green and sustainable technology that converts environmental energy (solar, wind, thermal, mechanical, electromagnetic, etc.) into electrical energy, providing ubiquitous, environmentally friendly, and sustainable energy solutions for wearable electronic products in the Internet of Things era. Various forms of energy that can be converted into electrical energy exist in the human body and its surrounding environment, including biomechanical motion energy, body heat, biochemical energy from bodily fluids, and solar energy (Figure 2), enabling power generation through the integration of textiles with power generation. Figure 2 Schematic Diagram of Energy Harvesting Textile DevicesNano-generators, as a new type of self-powered device, combine flexible textile materials with nano-generators to create textile-based nano-generators, retaining the basic characteristics of textiles while adding the self-powered functionality of nano-generators, making it one of the current research hotspots. Currently, four types of generators based on piezoelectric, triboelectric, pyroelectric, and photoelectric principles have been developed.

Figure 2 Schematic Diagram of Energy Harvesting Textile DevicesNano-generators, as a new type of self-powered device, combine flexible textile materials with nano-generators to create textile-based nano-generators, retaining the basic characteristics of textiles while adding the self-powered functionality of nano-generators, making it one of the current research hotspots. Currently, four types of generators based on piezoelectric, triboelectric, pyroelectric, and photoelectric principles have been developed.

Textile-based Triboelectric Nano-generator

The essence of textile-based triboelectric generation lies in the physical contact between two different materials with different electron affinities, generating opposite static charges on the contact surface. Gaps or disturbances caused by external mechanical forces can establish a potential difference between the two charged surfaces, thus generating voltage and polarization-induced current. This converts environmental mechanical motion into electrical energy, serving as both a sustainable energy source and a self-powered active sensor. Currently, the manufacturing techniques for textile triboelectric nano-generators (TENGs) mainly include layer stacking, yarn crossing, and 3D printing. The triboelectric materials used include polydimethylsiloxane (PDMS), polyester (PET), nylon 6 (PA6), and polytetrafluoroethylene (PTFE), while the electrode materials include metals such as copper, silver, nickel, or carbon-based textile materials, achieving a power density of up to 2 W/cm2. However, several challenges limit the development of TENGs: (1) Packaging; moisture or water in everyday environments significantly hinders the output power of textile TENGs. Systematic research on related hydrophobic materials and existing waterproof yarns or fabrics, as well as a deeper understanding of the manufacturing technologies involved, is crucial for achieving long-term reliability; (2) Mechanical durability; the adhesion between the fiber/fabric electrodes and the active triboelectric materials is another bottleneck for achieving long-term mechanical durability. In-depth research on the rational selection of conductive materials and corresponding interface design is necessary to ensure that the device can withstand the accompanying deformation during daily use; (3) Mass production; considering that textile TENGs consist of multiple components and require layered assembly, existing manual, laboratory-scale, centimeter-length weaving methods have limited potential for scalable manufacturing. Therefore, it is necessary to redesign functional fibers to adapt to industrial weaving/knitting machines or develop corresponding special weaving/knitting equipment, but currently, there is little research focusing on the latter.

The essence of textile-based triboelectric generation lies in the physical contact between two different materials with different electron affinities, generating opposite static charges on the contact surface. Gaps or disturbances caused by external mechanical forces can establish a potential difference between the two charged surfaces, thus generating voltage and polarization-induced current. This converts environmental mechanical motion into electrical energy, serving as both a sustainable energy source and a self-powered active sensor. Currently, the manufacturing techniques for textile triboelectric nano-generators (TENGs) mainly include layer stacking, yarn crossing, and 3D printing. The triboelectric materials used include polydimethylsiloxane (PDMS), polyester (PET), nylon 6 (PA6), and polytetrafluoroethylene (PTFE), while the electrode materials include metals such as copper, silver, nickel, or carbon-based textile materials, achieving a power density of up to 2 W/cm2. However, several challenges limit the development of TENGs: (1) Packaging; moisture or water in everyday environments significantly hinders the output power of textile TENGs. Systematic research on related hydrophobic materials and existing waterproof yarns or fabrics, as well as a deeper understanding of the manufacturing technologies involved, is crucial for achieving long-term reliability; (2) Mechanical durability; the adhesion between the fiber/fabric electrodes and the active triboelectric materials is another bottleneck for achieving long-term mechanical durability. In-depth research on the rational selection of conductive materials and corresponding interface design is necessary to ensure that the device can withstand the accompanying deformation during daily use; (3) Mass production; considering that textile TENGs consist of multiple components and require layered assembly, existing manual, laboratory-scale, centimeter-length weaving methods have limited potential for scalable manufacturing. Therefore, it is necessary to redesign functional fibers to adapt to industrial weaving/knitting machines or develop corresponding special weaving/knitting equipment, but currently, there is little research focusing on the latter.

Textile-based Piezoelectric Nano-generator

The essence of textile-based piezoelectric generation is the movement of internal positive and negative charge centers in certain types of materials in response to applied mechanical stress, generating an internal electric field. Integrating piezoelectric materials with textiles can be used for harvesting mechanical energy from human motion. Since the discovery of the direct piezoelectric effect in 1880, a large number of piezoelectric materials have been reported, including organic materials such as polyvinylidene fluoride (PVDF), polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE), and inorganic materials such as zinc oxide (ZnO), lead zirconate titanate (PZT), and barium titanate (BaTiO3). Depending on the device structure and preparation process, textile piezoelectric devices can be realized using multilayer stacking and yarn crossing methods. In addition to the commonly used electrospinning process, some studies have also focused on using thermal stretching spinning processes to prepare filaments with piezoelectric effects. However, the energy efficiency and material preparation of such piezoelectric textile devices still need improvement. Recently developed triboelectric-piezoelectric hybrid energy harvesting smart textile devices may be an effective solution to this challenge.

The essence of textile-based piezoelectric generation is the movement of internal positive and negative charge centers in certain types of materials in response to applied mechanical stress, generating an internal electric field. Integrating piezoelectric materials with textiles can be used for harvesting mechanical energy from human motion. Since the discovery of the direct piezoelectric effect in 1880, a large number of piezoelectric materials have been reported, including organic materials such as polyvinylidene fluoride (PVDF), polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE), and inorganic materials such as zinc oxide (ZnO), lead zirconate titanate (PZT), and barium titanate (BaTiO3). Depending on the device structure and preparation process, textile piezoelectric devices can be realized using multilayer stacking and yarn crossing methods. In addition to the commonly used electrospinning process, some studies have also focused on using thermal stretching spinning processes to prepare filaments with piezoelectric effects. However, the energy efficiency and material preparation of such piezoelectric textile devices still need improvement. Recently developed triboelectric-piezoelectric hybrid energy harvesting smart textile devices may be an effective solution to this challenge.

Textile-based Pyroelectric Nano-generator

Thermal energy is the most common form of energy in daily life. In the wearable field, smart textiles can harvest energy from body heat. Unlike intermittent biomechanical energy that requires body movement, body heat is continuously present in the human body even at rest. An adult can release about 100 to 525 W of body heat daily. Two working mechanisms can be used to collect human thermal energy, including the pyroelectric effect utilizing time and spatial temperature differences. Although the surface temperature of the human body does not vary much over time (maintaining around 33.5 °C), the spatial temperature difference between adults and the environment can generate thermal flows of up to 10 mW/cm2, at which point the thermoelectric effect plays a significant role. Textile thermoelectric devices typically rely on two structures: the textile substrate and the yarn as building units. Constructing thermoelectric devices on textile substrates is an effective way to harvest human thermal energy. Textile materials not only exhibit good compliance, effectively contacting curved skin to absorb heat, but also have low thermal conductivity. Textile-based thermoelectric units show many attractive features due to their insulation and relative conformity to human skin. However, this configuration requires coating/printing/sewing TE arms onto the textile substrate, which largely compromises the breathability of smart textiles. Using TE yarns as building units to construct thermoelectric textiles through weaving or knitting is a better strategy to address the above issues, where the design of yarn-type TE units is a crucial determinant of the thermoelectric effect of textile devices.

Thermal energy is the most common form of energy in daily life. In the wearable field, smart textiles can harvest energy from body heat. Unlike intermittent biomechanical energy that requires body movement, body heat is continuously present in the human body even at rest. An adult can release about 100 to 525 W of body heat daily. Two working mechanisms can be used to collect human thermal energy, including the pyroelectric effect utilizing time and spatial temperature differences. Although the surface temperature of the human body does not vary much over time (maintaining around 33.5 °C), the spatial temperature difference between adults and the environment can generate thermal flows of up to 10 mW/cm2, at which point the thermoelectric effect plays a significant role. Textile thermoelectric devices typically rely on two structures: the textile substrate and the yarn as building units. Constructing thermoelectric devices on textile substrates is an effective way to harvest human thermal energy. Textile materials not only exhibit good compliance, effectively contacting curved skin to absorb heat, but also have low thermal conductivity. Textile-based thermoelectric units show many attractive features due to their insulation and relative conformity to human skin. However, this configuration requires coating/printing/sewing TE arms onto the textile substrate, which largely compromises the breathability of smart textiles. Using TE yarns as building units to construct thermoelectric textiles through weaving or knitting is a better strategy to address the above issues, where the design of yarn-type TE units is a crucial determinant of the thermoelectric effect of textile devices.

Textile-based Photoelectric Nano-generator

Solar cells can directly convert solar energy into electrical energy and are currently the most mature energy harvesting devices. Flexible textile-based solar cells can be directly integrated with textile clothing through textile technology, achieving a truly integrated form that provides optimal comfort and functionality. The conversion efficiency of flexible textile-based solar cells ranges from 0.1% to 5%. In contrast, silicon-based solar cells have much higher efficiencies (10% to 20%). The methods for manufacturing flexible textile-based solar cells are generally divided into two types: one is to directly prepare fibrous solar cells and then use textile technology for weaving to create textile-structured solar cells; the other is to use textile materials as substrates to directly produce fabric solar cells. The preparation process for fabric-based planar solar cells is relatively mature, and many processes can integrate solar cells into textile coatings. Currently, researchers also face challenges in applying micro-scale wafer thin layers that make up solar cells (bottom electrodes, photovoltaic layers, and top electrodes) onto rough fabrics. Compared to planar solar cells, flexible fibrous solar cells break through the limitations of substrates, featuring lightweight and bendable characteristics that better meet the requirements of wearable electronic devices. However, flexible fibrous solar cells still need technological breakthroughs to be woven using traditional weaving or knitting techniques.In recent years, an increasing number of scholars have begun to focus on wireless radio frequency energy harvesting technology. The antennas of energy harvesting devices receive electromagnetic energy through electromagnetic coupling technology, generating alternating current in the antenna; rectifiers convert alternating current into direct current, which can be used directly by sensing nodes or stored in supercapacitors. Energy harvesting antennas require wide bandwidth and high gain characteristics. Although the output power of fabric-based radio frequency energy harvesting systems can reach milliwatt levels, exceeding the power consumption of LED lights, their output power still cannot meet the demands of energy-intensive smart textiles (such as electric heating fabrics and heated underwear). Furthermore, existing research has rarely evaluated the environmental adaptability of systems, and there is a contradiction between the flexibility and performance stability of fabric-based radio frequency energy harvesting systems, making the balance between the two a significant challenge. Through antenna structure design and the development of new textile materials, fabric-based radio frequency energy harvesting systems that are small in size, low in cost, resistant to interference, low in loss, and high in output power will be a key focus of future research and development.

Solar cells can directly convert solar energy into electrical energy and are currently the most mature energy harvesting devices. Flexible textile-based solar cells can be directly integrated with textile clothing through textile technology, achieving a truly integrated form that provides optimal comfort and functionality. The conversion efficiency of flexible textile-based solar cells ranges from 0.1% to 5%. In contrast, silicon-based solar cells have much higher efficiencies (10% to 20%). The methods for manufacturing flexible textile-based solar cells are generally divided into two types: one is to directly prepare fibrous solar cells and then use textile technology for weaving to create textile-structured solar cells; the other is to use textile materials as substrates to directly produce fabric solar cells. The preparation process for fabric-based planar solar cells is relatively mature, and many processes can integrate solar cells into textile coatings. Currently, researchers also face challenges in applying micro-scale wafer thin layers that make up solar cells (bottom electrodes, photovoltaic layers, and top electrodes) onto rough fabrics. Compared to planar solar cells, flexible fibrous solar cells break through the limitations of substrates, featuring lightweight and bendable characteristics that better meet the requirements of wearable electronic devices. However, flexible fibrous solar cells still need technological breakthroughs to be woven using traditional weaving or knitting techniques.In recent years, an increasing number of scholars have begun to focus on wireless radio frequency energy harvesting technology. The antennas of energy harvesting devices receive electromagnetic energy through electromagnetic coupling technology, generating alternating current in the antenna; rectifiers convert alternating current into direct current, which can be used directly by sensing nodes or stored in supercapacitors. Energy harvesting antennas require wide bandwidth and high gain characteristics. Although the output power of fabric-based radio frequency energy harvesting systems can reach milliwatt levels, exceeding the power consumption of LED lights, their output power still cannot meet the demands of energy-intensive smart textiles (such as electric heating fabrics and heated underwear). Furthermore, existing research has rarely evaluated the environmental adaptability of systems, and there is a contradiction between the flexibility and performance stability of fabric-based radio frequency energy harvesting systems, making the balance between the two a significant challenge. Through antenna structure design and the development of new textile materials, fabric-based radio frequency energy harvesting systems that are small in size, low in cost, resistant to interference, low in loss, and high in output power will be a key focus of future research and development. Figure 3 Radio Frequency Energy Harvesting System and Circularly Polarized AntennaIn summary, although research on textile-based energy storage and harvesting devices is increasing and performance is continuously optimized, they still face a series of challenges, such as low energy density and energy conversion efficiency, high costs, inability to mass-produce, and poor durability, indicating that practical applications are still a long way off.

Figure 3 Radio Frequency Energy Harvesting System and Circularly Polarized AntennaIn summary, although research on textile-based energy storage and harvesting devices is increasing and performance is continuously optimized, they still face a series of challenges, such as low energy density and energy conversion efficiency, high costs, inability to mass-produce, and poor durability, indicating that practical applications are still a long way off.

(The content of this article is excerpted from “2024 World Textile Industry Trend Outlook” in the article “Recent Advances in Smart Textiles,” authored by Meng Fenye, Hu Jiyong, and Zhang Yong, with images sourced from the article)

Special Collection

Recent Advances in Smart Textiles | Development History and Classification of Smart Textiles

This publication has established a special column on recent advances in smart textiles, aiming to provide readers with a deeper understanding of smart textiles through comprehensive introductions.

2

Recent Advances in Smart Textiles | Composition and Characteristics of Smart Textile Systems – Flexible Textile Sensors

3

Recent Advances in Smart Textiles | Composition and Characteristics of Smart Textile Systems – Textile Actuator Devices

4

Recent Advances in Smart Textiles | Composition and Characteristics of Smart Textile Systems – Information Transmission and Interaction Textile Devices

Welcome to reprint, please indicate the source, thank you!

“Textile Report” magazine is a guiding scientific and technological journal sponsored by the China Textile Information Center, aiming to provide in-depth reporting and analysis of textile technology development trends, authoritative interpretation of scientific and technological policies and industry rules, serving as a barometer for government agencies and industry organizations’ scientific and technological policies and trends, and an important window for helping industry and enterprise decision-makers grasp the current state of textile technology and the technological market context.

Textile Report Official Website:www.texleader.com.cn

Distribution Hotline:010-84463638-8850

Advertising Inquiries:010-84463638-8830