“Chemical production surrounding the Yangtze River” is a major issue faced by the Yangtze River Basin, especially in the middle and lower reaches. Poor production safety and heavy pollution emissions have become two major bottlenecks in contemporary chemical industry. Yangtze River Center Micro-Flow Green Chemical Technology Research Institute has developed related technologies that utilize miniaturized equipment and technology to achieve clean and safe production in the chemical industry, establishing a “desktop factory” for traditional chemical industry, which is hailed as “Chemical 4.0” technology.

Guo Kai, Professor at Nanjing University of Technology, PhD supervisor. National “Ten Thousand Talents Program” scientific innovation leading talent, recipient of the National Natural Science Foundation Excellent Youth Fund, leading talent in the “Innovation Talent Promotion Program” of the Ministry of Science and Technology, recipient of Jiangsu Province Outstanding Youth Fund, and recognized as Jiangsu Province “Six Major Peak Talents” and “Youth Double Innovation Talent”.Mainly engaged in micro-flow technology research and bio-based materials research, successfully breaking through the bottleneck of large-scale engineering application of micro-flow technology.

Micro-flow technology refers to reaction technologies with characteristic scales at the micron level, which is an efficient process intensification technology. It has the following technical advantages:

-

Micro-scale effects lead to a significantly large reaction specific surface area. Heat transfer efficiency improves by 1-3 orders of magnitude, reaction speed increases by 1-2 orders of magnitude, shortening reactions that take more than ten hours to just minutes.

-

Miniaturized equipment, small online quantities. Easy process control, suitable for hazardous processes; the online liquid holding capacity of a ten-thousand-ton/year flux reactor is only a dozen liters.

-

Continuous flow enhances reaction selectivity. Low back-mixing, controls side reactions, achieving an average reduction of over 50% in emissions and over 40% in energy consumption.

The Micro-Flow Green Chemical Technology Research Institute uses micro-flow reaction technology as a platform technology, committed to green manufacturing of fine chemicals while strengthening the development of bio-based materials. After years of hard work, it has achieved the development of new bio-based materials such as bio-based polyester (degradable plastics, medical material raw materials, etc.), polyurethane (hard foam, soft foam, adhesives, coatings), polyamide (nylon, aramid), and polyimide, as well as bio-based non-toxic plasticizers, adhesives, surfactants, and other material additives, among which products like bio-based polyurethane and bio-based non-toxic plasticizers have achieved industrial transformation on a scale of over ten thousand tons.

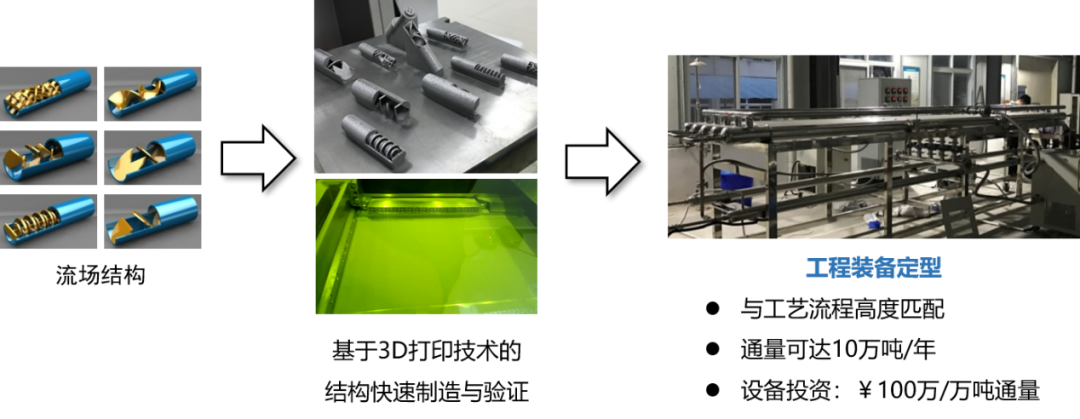

The research institute has developed high-throughput, low-cost, multi-material, and highly compatible micro-flow engineering equipment for different reaction types and specific reaction needs, demonstrating good process compatibility and applicability, with manufacturing costs less than 5% of similar imported equipment, and the equipment flux is more than ten times that of imported equipment, showing strong competitiveness.

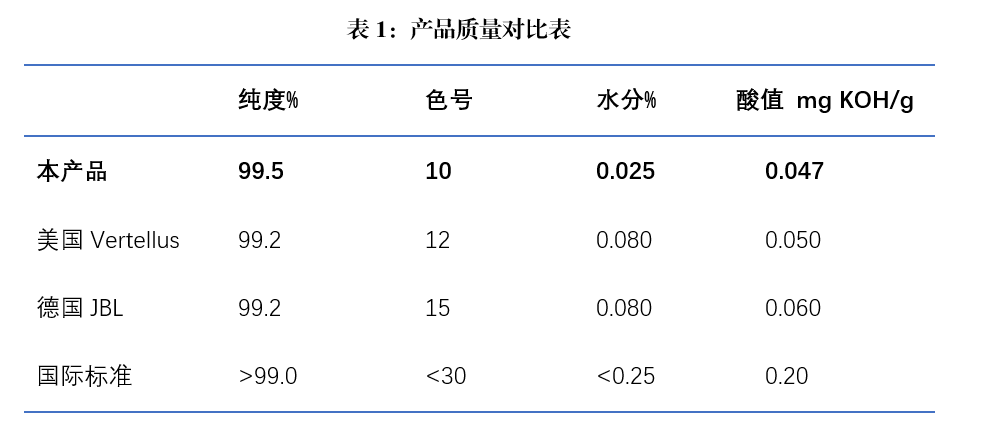

Traditional production of bio-based non-toxic plasticizer products like citric acid esters has low purity and poor color, leading to a reliance on imports for high-end products. The research institute couples micro-flow reaction technology with multi-vessel series reaction technology, increasing product purity from less than 98% to99.5%, with color stability controlled around No. 10, and all quality indicators exceeding international standards and similar foreign products. A 50,000-ton/year production line has been established at Jiangsu Raymond Chemical Technology Co., Ltd., creating the only domestic green manufacturing process for citric acid esters with stable production quality meeting international standards, breaking the market monopoly of foreign manufacturers and forcing them to exit the Chinese market. Currently, green plasticizer citric acid ester products occupy over 95% of the domestic high-end product market share and are exported to international markets.

Yangtze River Ecological Civilization Innovation CenterMicro-Flow Green Chemical Technology Research Institute (Nanjing Advanced Bio-materials and Process Equipment Research Institute) is one of the first member institutes of the center’s ecological and environmental protection industry technology research institute. The research institute relies on the disciplinary advantages of the National Bio-Chemical Engineering Technology Research Center at Nanjing University of Technology, focusing on promoting the industrial application of micro-flow reaction technology and equipment, advancing the development of new bio-based materials and additives, and enhancing the greening and safety of bio-chemical and fine chemical processes, effectively extending the bio-chemical industrial chain, providing technical support for the transformation and upgrading of industries such as bio-chemicals, fine chemicals, and material chemicals, and for high-quality development.

Contact: Manager Ji, 18913388248

Long press the QR code to follow us ▶▶▶

-

【Yangtze River Protection, Yangtze River Center in Action】Enzyme Group Technology Reduces Load for Sludge Treatment

-

【Yangtze River Protection, Yangtze River Center in Action】”Sword” VOCs Governance Battle to Win the Blue Sky Defense War

-

【Yangtze River Protection, Yangtze River Center in Action】Smart Water Management System Prevents “Urban Flooding”

-

【Yangtze River Protection, Yangtze River Center in Action】Micro-Interface Reaction Intensification Technology Aids in Breaking “Heavy Chemical Surrounding the River”

-

【Media Focus】Yangtze River Protection, Yangtze River Ecological Civilization Innovation Center in Action!