In today’s world, everything is interconnected.

The level of intelligence is increasing.

The core components supporting the operation of the Internet of Things (IoT)

have always faced the tricky issue of power supply.

Recently, a team at Harbin Engineering University

that specializes in magnetic sensors and detection research

has made new progress in this area.

They have designed and developed a new type of weak magnetic energy harvester structure

that allows sensors to operate without batteries,

achieving ‘self-power generation’

and increasing output power by approximately 120% compared to traditional magnetic energy harvesting structures.

Let’s applaud Harbin Engineering University’s intelligent manufacturing!

Recently, Associate Professor Chu Zhaoqiang from the Marine Magnetic Sensor and Detection team at the School of Underwater Acoustics published an academic paper titled “Significantly Enhanced Power Generation from Extremely Low‐Intensity Magnetic Field via a Clamped‐Clamped Magneto‐Mechano‐Electric Generator” in the internationally renowned journal Advanced Energy Materials (IF: 29.368).

Associate Professor Chu is the first author and corresponding author. The corresponding authors also include Professor Gao Junqi from Harbin Engineering University and Professor Dong Shuxiang from Peking University. Harbin Engineering University is the primary institution for this paper. Advanced Energy Materials is a top academic journal under Wiley Publishing, holding significant influence in the field of energy materials.

The intelligent development across various fields of modern society relies on the Internet of Things, and sensors, which play a decisive role in IoT technology, are currently facing energy supply challenges. Previously, battery-powered sensors required timely battery replacements to ensure continuous normal operation, which brought many inconveniences to sensor networks.

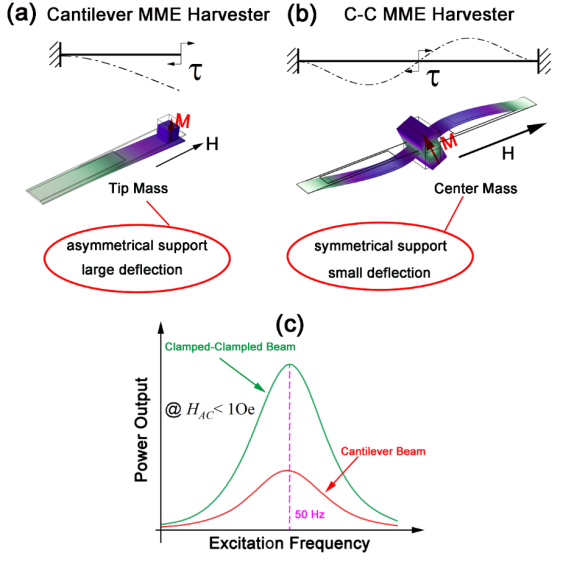

In recent years, researchers have attempted to use magnetic field energy harvesting technology to replace batteries for powering wireless sensors, leading to the emergence of cantilever beam-type magneto-mechano-electric (MME) harvesting devices. However, these devices generally only perform well in magnetic fields greater than 5 Oe. The safe magnetic field that humans can be exposed to is no higher than 1 Oe, making it necessary to design new device structures to enhance the weak magnetic response of magnetic energy harvesting devices.

Associate Professor Chu Zhaoqiang’s paper proposes a clamped-type resonant structure, providing a new approach for magnetic energy harvesting technology. Its second-order working mode reduces the kinetic energy of the magnetic mass block, significantly enhancing the system’s output performance under weak field conditions while increasing the volume of the magnet. Experiments show that under the same excitation conditions, the output power of this energy harvester is approximately 120% higher than that of traditional cantilever beam structures, making it fully capable of allowing battery-free sensors to operate normally and communicate with mobile terminals.

The Marine Magnetic Sensor and Detection team was established in 2017 and has been continuously growing. The team focuses on the fundamental theories, key technologies, and engineering applications of multi-sensor detection of underwater targets, conducting comprehensive research on basic magnetic materials, magnetic sensor development, underwater information perception, and processing technologies, contributing to the construction of a strong marine nation, manufacturing power, and network power.

Little Cheng is here to guide you~

Scroll to the bottom of this article and click ‘Read the original text’

to view the original paper online!

“π-type” national-level teaching master,

opening a window for students to gaze at the universe!

Role model!

This team from Harbin Engineering University has been selected as the second batch of ‘National University Huang Danian-style Teacher Teams’!

Harbin Engineering University’s ‘Intelligent’ manufacturing empowers the ‘Dream of Cooling Under the Grain’!

Collaboration between schools and enterprises forms a community of destiny for technological revitalization in Longjiang!

Harbin Engineering University teachers engage in ‘immersive’ practice in enterprises to hone their skills.

Harbin Engineering University

— heu19530901 —

Written by | Huo Ping

Layout by | Dong Xinyao

Edited by | Huo Ping

Reviewed by | Lü Dongshi, Jin Sheng