ToB investment, welcome to communicate via WeChatPalantir’s latest insights on the Agentic AI market:

- Traditional software continues to expose its shortcomings

- The market is flooded with lightweight tools that merely wrap existing processes, providing insights that cannot be translated into enterprise actions

- Enterprises are forced to adapt their business to the limitations of software

- AI products seem to be abundant, but the market lacks applications that can span the entire business loop

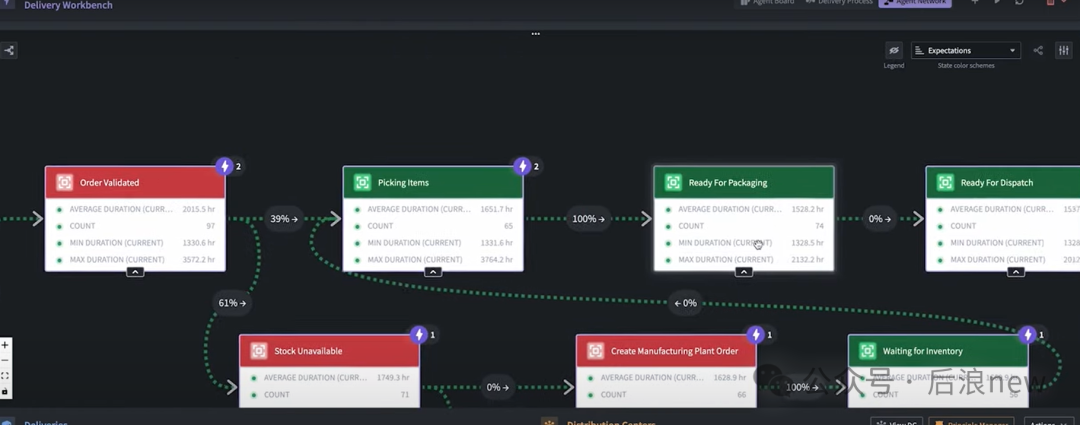

This year, overseas major companies have focused on the development of Multi-Agents orchestration platforms. I have also introduced several failure modes of overseas Agent implementations.Counter-consensus | Looking at the future from the overseas Agent implementation, is enterprise-level Manus a true proposition?While other vendors are still in the idea and demo stages,Palantir has taken the lead in successfully deliveringMulti-Agents, a case that spans the entire process from production manufacturing to inventory management to order fulfillment, and has detailed the“Agent Chains”chain optimization methodology → From the current usage effect, the Multi-Agents network can automatically handle most of the work frominventory management to order fulfillment, whileemployees and Agents can collaborate in an orderly manner within the same AI OS.From the employee’s perspective, there is a customized business dashboard:

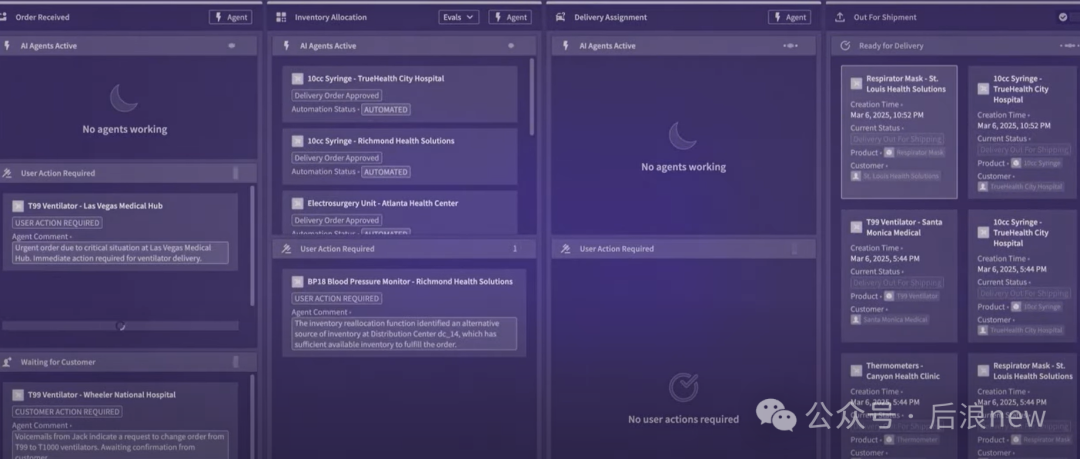

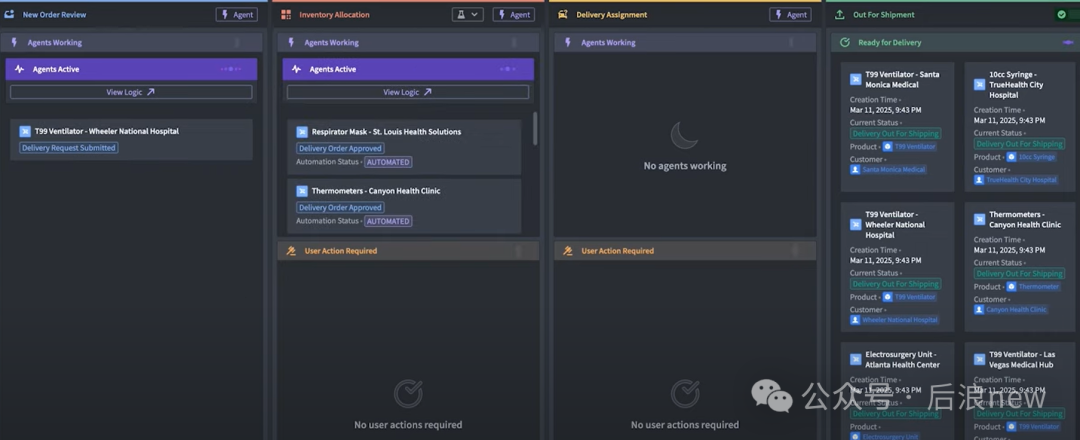

From the current usage effect, the Multi-Agents network can automatically handle most of the work frominventory management to order fulfillment, whileemployees and Agents can collaborate in an orderly manner within the same AI OS.From the employee’s perspective, there is a customized business dashboard: After the Agent processes most orders, it will automatically mark some orders that require employee intervention and provide execution suggestions.Employees do not need to manually sort and simulate various scenarios; they only need to review suggestions, edit approvals, and annotate feedback. After employees issue instructions, the orders willreturn to the process coordinated by the agent:

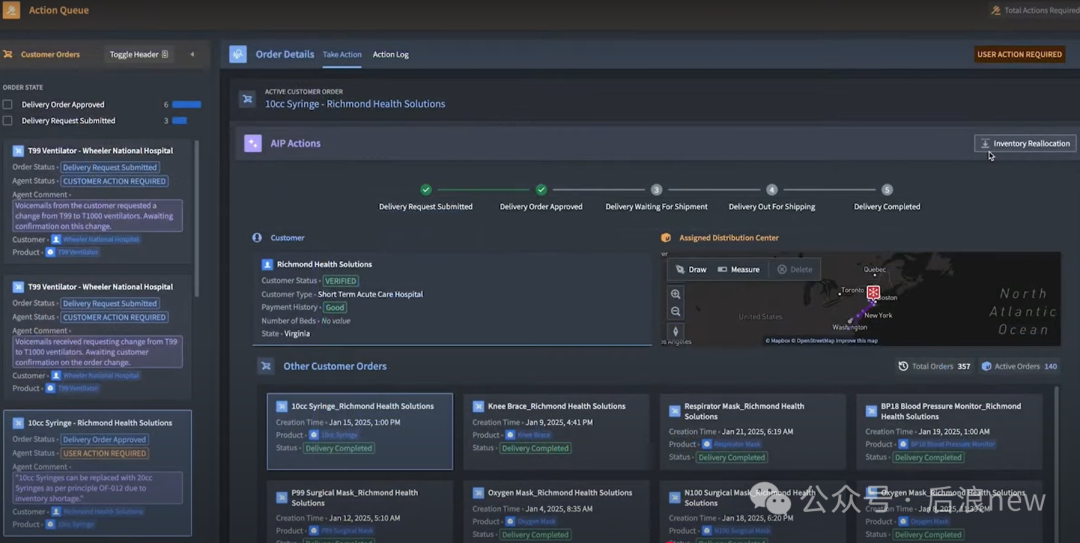

After the Agent processes most orders, it will automatically mark some orders that require employee intervention and provide execution suggestions.Employees do not need to manually sort and simulate various scenarios; they only need to review suggestions, edit approvals, and annotate feedback. After employees issue instructions, the orders willreturn to the process coordinated by the agent: The operations performed by employees will also be fed back to the source systems, such as ERP, MRP, APS, and project management systems, keeping all information synchronized as quickly as possible. Employees can view the agent’s work log at any time—data access, tool usage, and how these factors contribute to the final automated decision:

The operations performed by employees will also be fed back to the source systems, such as ERP, MRP, APS, and project management systems, keeping all information synchronized as quickly as possible. Employees can view the agent’s work log at any time—data access, tool usage, and how these factors contribute to the final automated decision: The experience knowledge, background information, and business logic in employees’ minds form a feedback loop, applied to the business flow,redefining “human-machine collaboration” in the Agentic AI era. While it may not be the ultimate form, Palantir already represents the highest level at present.

The experience knowledge, background information, and business logic in employees’ minds form a feedback loop, applied to the business flow,redefining “human-machine collaboration” in the Agentic AI era. While it may not be the ultimate form, Palantir already represents the highest level at present. Let’s take a look at how Agent Chains are implemented,in the order fulfillmentscenario→Agents automate the completion of each key node:Initial order review (including checking customer communication information) —Matching inventory for each order — arranging shipment — optimizing on-time delivery rates while minimizing fulfillment costs as much as possible.

Let’s take a look at how Agent Chains are implemented,in the order fulfillmentscenario→Agents automate the completion of each key node:Initial order review (including checking customer communication information) —Matching inventory for each order — arranging shipment — optimizing on-time delivery rates while minimizing fulfillment costs as much as possible. key points→

key points→

- Parallel processing of new orders, automating the processing of hundreds of orders per minute

- The AIP platformconnects all enterprise systems, storing data and logic, while the multi-model data layer reads or virtualizes this content, and also feeds information back to the action systems

- This reflects a majorcore advantage of the AIP platform: no need to consider the underlying architecture while maintaining fine control over permission changes and data quality

- The entire Multi-Agents ecosystemlinks business scenarios, business flow logic, decisions, and actions,each element serves as acommon interface for agents and employees, available for both humans and agents

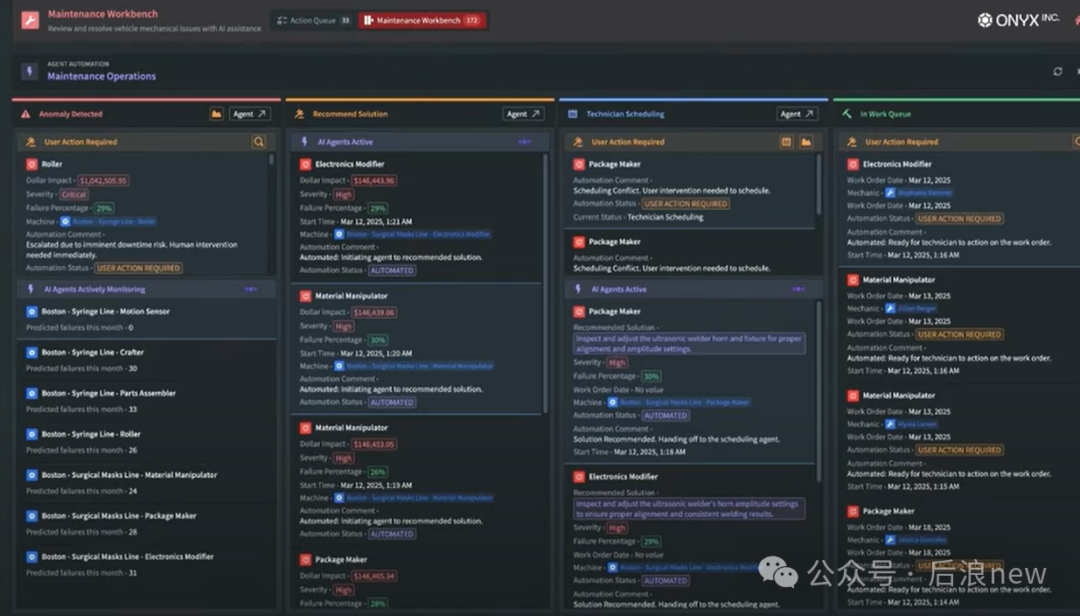

There are also Agent Chains cases in the upstream production manufacturing stage,in the equipment failurescenario→

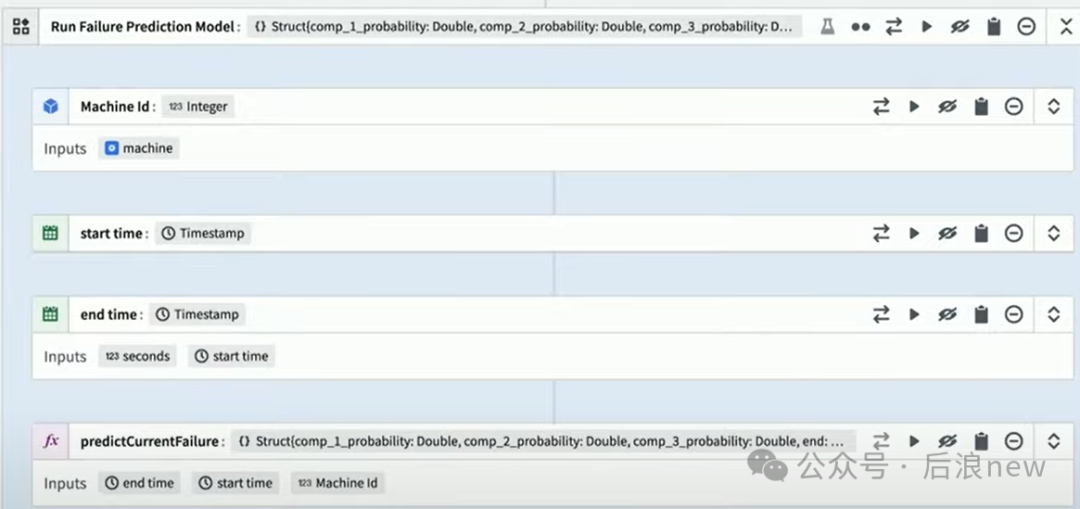

Palantir has developed a machine learning model that calculates the risk of production equipment failure based onreal-time telemetry data. In this Agent Chain,the first Agentregularly runs this model on all machines in the customer’s global factories for anomaly detection and risk identification:

Then,this agent will link multiple downstream modelsfor contextual analysis, such ascalculating maintenance costs, predicting revenue losses due to downtime, and dynamically determining priorities based on economic risks

Based on the risks identified by the agent,another Agent Chain solution will be automatically orchestrated and triggered:

-

Recommending the best solution for each alert based on relevant documents, maintenance records, and enterprise feedback loops

-

Arranging the most suitable technicians based on skill level and scheduling

Further breaking down how Palantir’s AIP platform drives Multi-Agents automation→

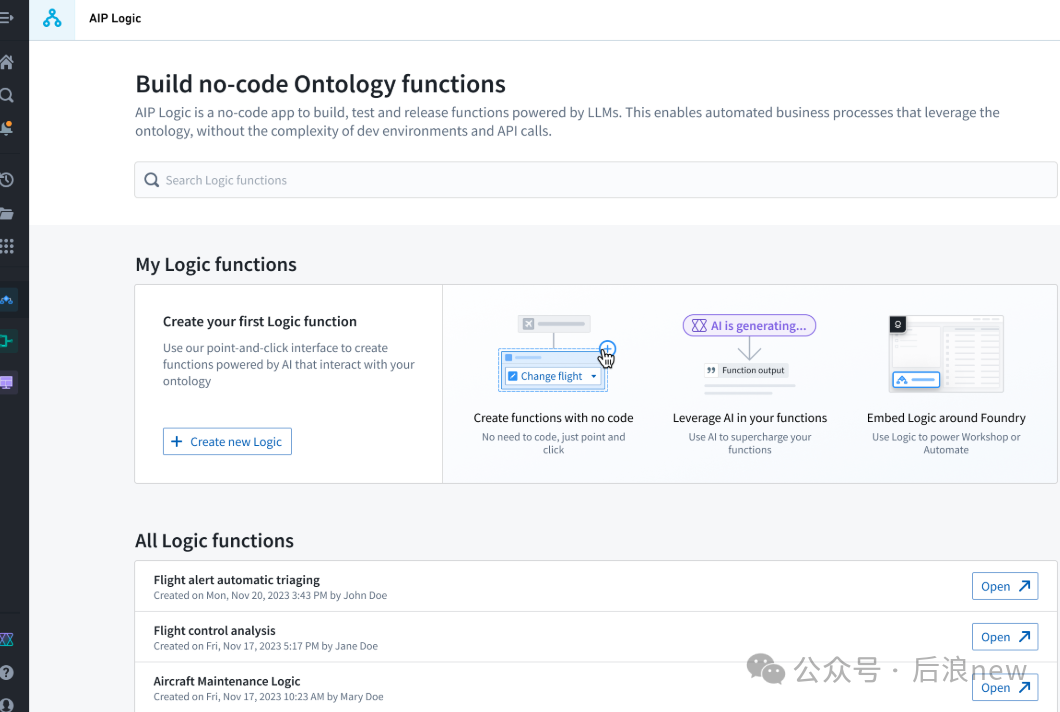

This is inseparable from AIP Logic, a no-code agent development platform:

AIP Logic provides the basic elements involved in the business flow to the LLM, and Logic automatically selects or fills in toolsets, prompts, etc.,without any additional configuration

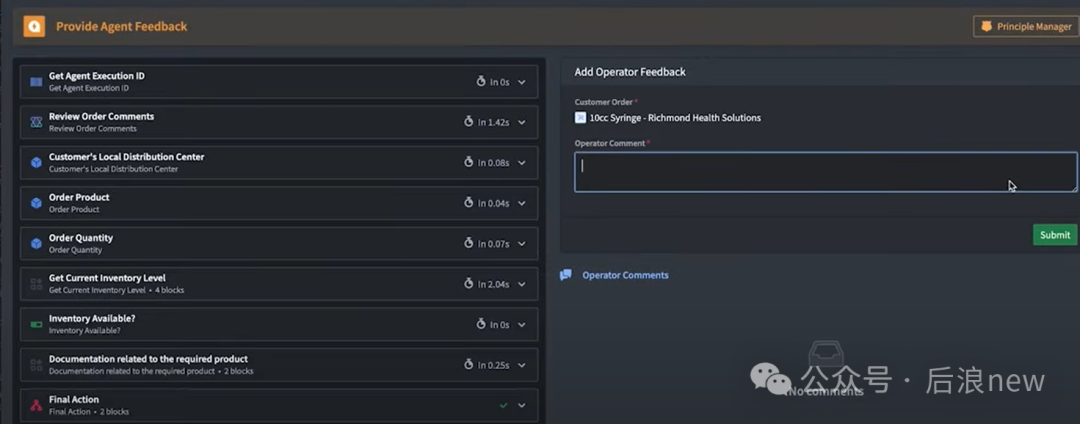

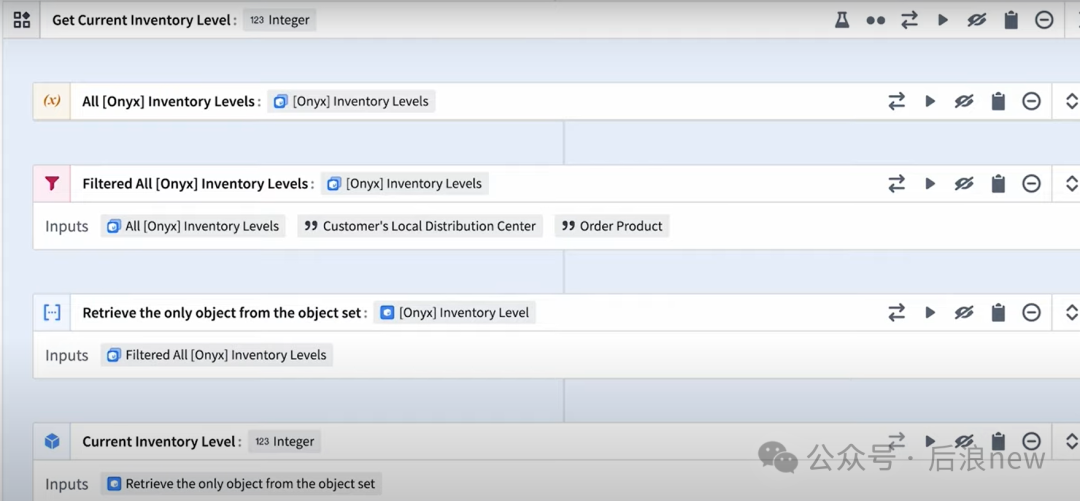

For example, the inventory allocation Agent is shown below, demonstrating how the Agent executes SOP by querying real-time inventory

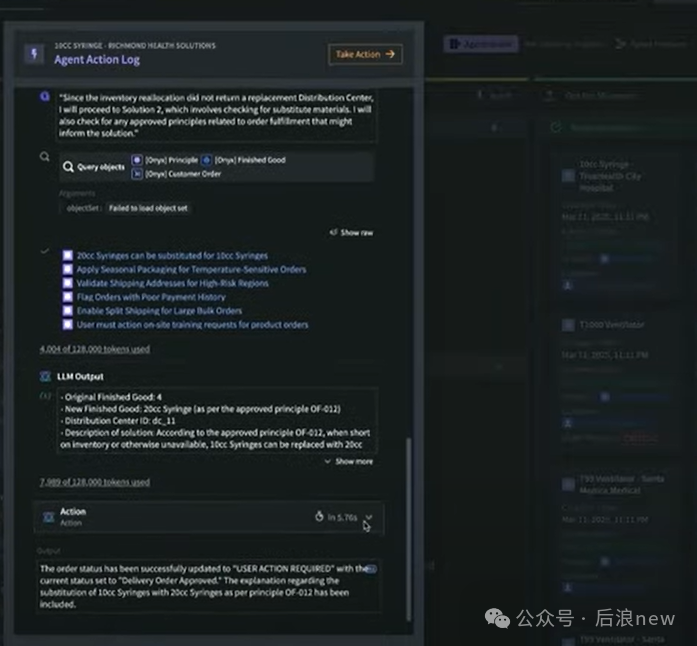

At the same time,the Agent will reason about inventory risksand find countermeasures, such ashandling inventory shortages:

At the same time,the Agent will reason about inventory risksand find countermeasures, such ashandling inventory shortages:

- Agent runsthe inventory reallocation model— the model simulates inventory transfer situations — combining backlogged orders and sales forecasts to assess downstream risks

- Agent reads product documentation to determine if replacing SKUs can alleviate inventory shortages

AIP Logic platform achievesfine control over the degree of Agent automation, like a tuning knob, allowing enterprises to adjust the level of automation based onthe determinacy and impact of the workflow:

-

Which operations can be automated and which cannot be automated

-

Control agent triggering standards

-

Control dynamic retries and other safety measures to ensure the highest reliability of Agents

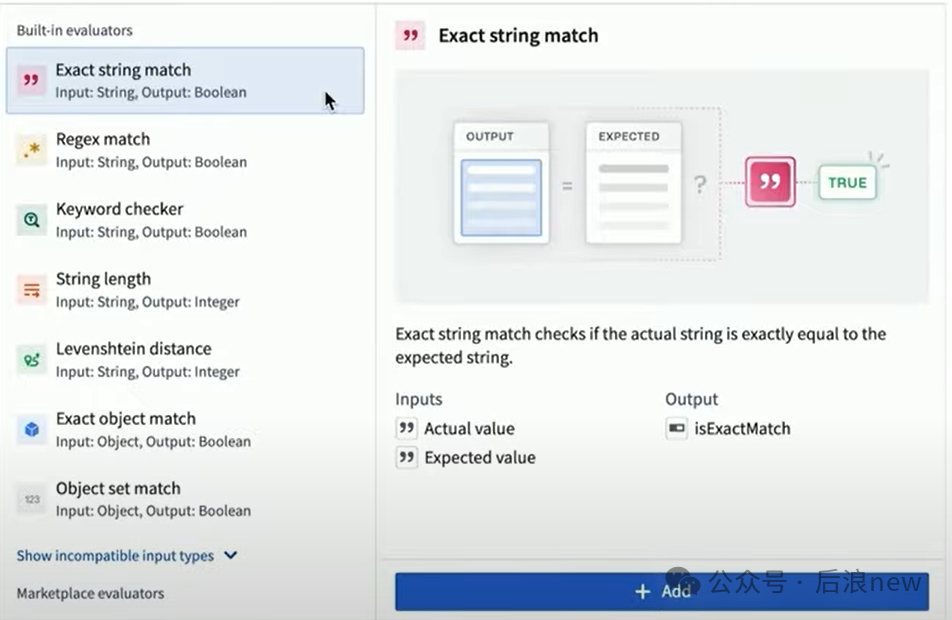

As Agents penetrate deeper, the breadth and depth of enterprise automation will continue to improve. Palantir has developedAIPE valves — tools for continuously assessing Agent operational status:

- Can set any number of test cases

- Can check specific output results

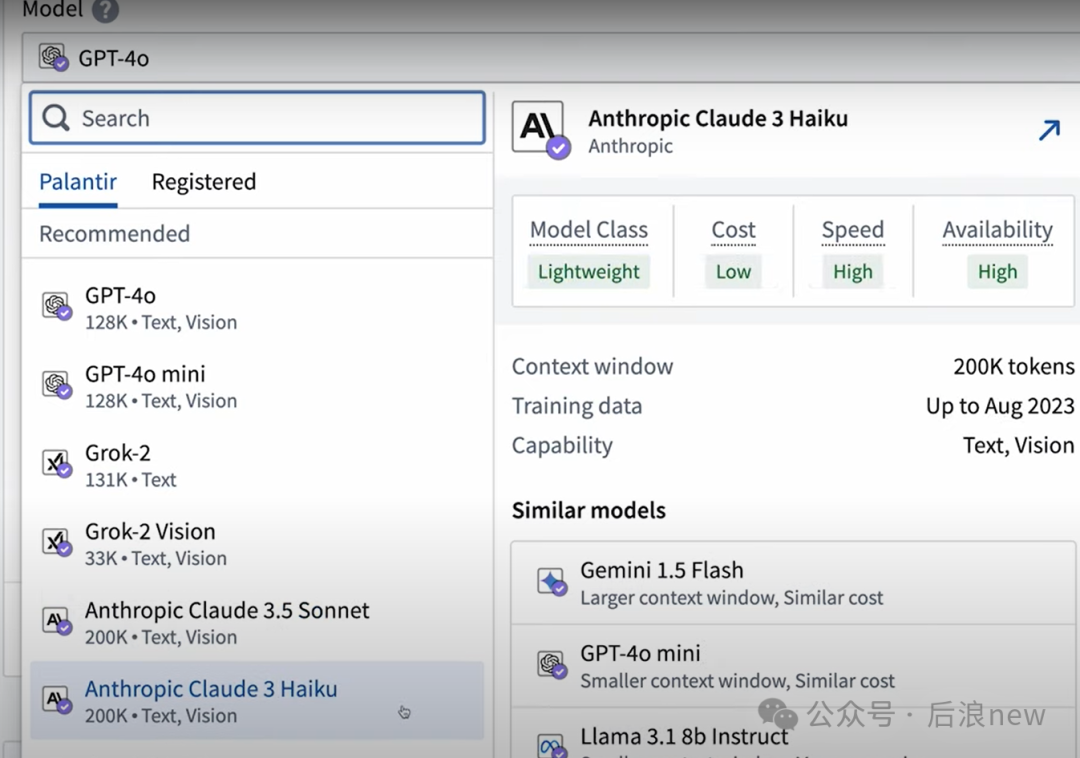

- Can switch LLMs freely, scoring based on criteria to quickly assess the most suitable LLM for the task

Thus, this Multi-Agents case has been successfully validated, not only at the delivery level,but the customer’s definition of success is: the Agent operates successfully with sustainability and high reliability.

- Counter-consensus | Looking at the future from the overseas Agent implementation, is enterprise-level Manus a true proposition?

- Palantir + smart cars, scarce business territory AI applications

- Palantir’s new batch of AI use cases, new heights for Agent implementation