Click the above “Material Person” to subscribe to us

In recent years, portable wearable electronic devices have begun to be widely used in professional fields and in daily life, evolving towards miniaturization, intelligence, multifunctionality, and flexibility. However, the main problem faced by wearable electronic products is that existing batteries are insufficient to provide continuous power supply. To solve the power supply issue, in addition to improving the energy density of batteries, another effective method that has recently attracted widespread attention is the integration of energy generation devices and energy storage devices into a self-charging power system (SCPS), allowing the collected energy to be stored for sustainable power supply. Researchers have successfully developed various energy harvesting devices, including triboelectric nanogenerators (TENG), piezoelectric nanogenerators (PENG), photovoltaic devices, and thermoelectric devices, which can be combined with storage devices (batteries, supercapacitors) and further integrated into flexible, wearable electronic devices.

Recently, Researcher Pu Xiong, Researcher Hu Weiguo, and Academician Wang Zhonglin (co-corresponding authors) from the Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences, comprehensively summarized the development status of self-charging power systems (integrating energy generation devices such as triboelectric nanogenerators and piezoelectric nanogenerators with energy storage devices such as batteries and capacitors), focusing on how independent device units are integrated with wearable and flexible electronic devices. This review, titled “Toward Wearable Self-Charging Power Systems: The Integration of Energy-Harvesting and Storage Devices”, was published in Small on November 30, 2017.

1.SCPSs for Collecting Mechanical Energy

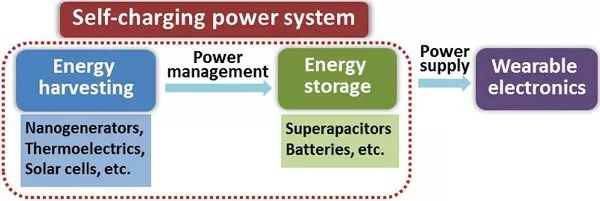

As shown in Figure 1, energy storage and harvesting technologies can be simultaneously integrated into the self-charging power system of wearable electronic devices.

Figure1. Schematic Diagram of Self-Charging Power System

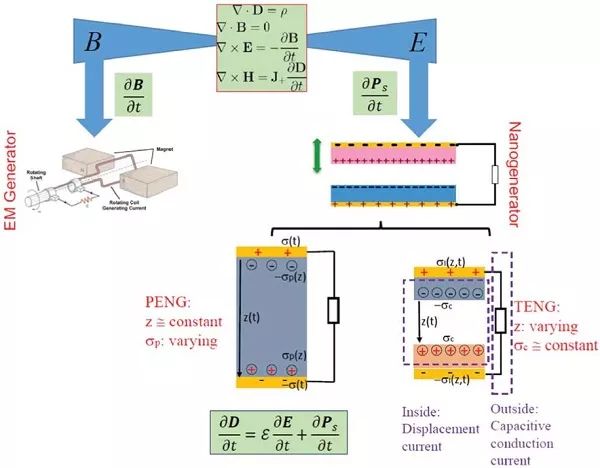

As shown in Figure 2, the theoretical basis of EMG (Electromagnetic Generator), TENG, and PENG can be traced back to Maxwell’s equations. The output current of EMG originates from the change of the magnetic field over time, while the current of TENG and PENG comes from the polarization field caused by surface polarization charges leading to part of Maxwell’s displacement current. The first term of Maxwell’s displacement current prompted the discovery of electromagnetic wave theory and the development of related technologies such as radio, wireless communication, and radar. The second term of Maxwell’s displacement current, which is the time-varying polarization field of surface polarization charges, led Academician Wang Zhonglin to invent PENG and TENG, proposing new energy technologies for the Internet of Things era, blue energy, self-powered sensors, and self-charging systems.

Figure2. Electromagnetic Generator, Piezoelectric Generator, and Triboelectric Nanogenerator

Basic Principles of Motors

Combining the piezoelectric and semiconductor properties of ZnO nanowire arrays, Academician Wang Zhonglin proposed the concept of PENG in 2006. In 2011, J. Bae and others began to integrate the energy harvester PENG with energy storage supercapacitors. Subsequently, the concept of self-charging power systems was proposed, and various prototypes of SCPS were presented.

1.1SCPSs Based on PENG

1.1.1SCPSs with Independent Units

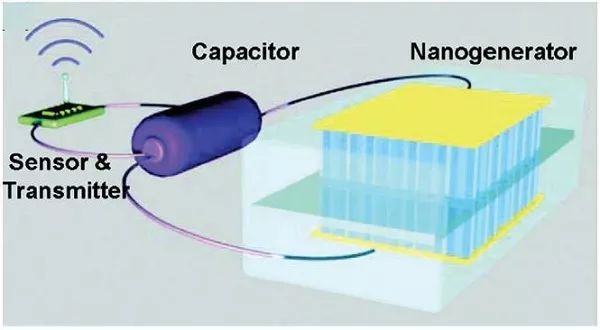

Figure 3 shows a self-powered system for wireless data transmission driven by SCPS, which integrates a ZnO nanowire PENG, a bridge rectifier, and a capacitor. The output voltage of PENG is 10 V, and the current is 0.6 μA (power density is 10 mW/cm-3). After charging, the capacitor can power the sensor and RF transmitter.

Figure3. PENG-Based SCPSs

1.1.2SCPSs Integrated in One Unit

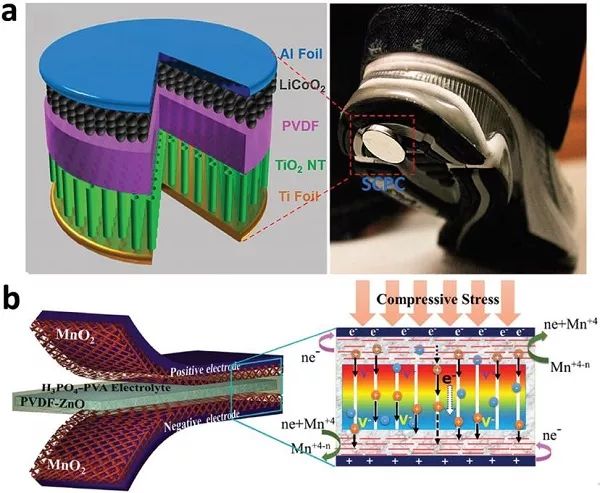

As shown in Figure 4a, this SCPS integrates PENG and LIB (Lithium-Ion Battery) into a coin-shaped unit. In this system, the separator of LIB is replaced with piezoelectric polyvinylidene fluoride (PVDF), and the electric energy generated by PENG is converted into chemical energy stored in LIB without any external circuit. As shown in Figure 4b, A. Ramadoss confirmed that supercapacitors can also be charged through external mechanical energy.

Figure4 PENG-Based SCPSs with Shared Electrodes

(a) Schematic Diagram and Photo of SCPS, where Piezoelectric PVDF Film is used as the Separator of LIB;

(b) Structural and Mechanism Diagram of SCPS, where Piezoelectric PVDF-ZnO Film is used as the Separator of Supercapacitor.

1.2SCPSs Based on TENG

Based on the coupling effect of triboelectricity and electrostatic induction, Academician Wang Zhonglin proposed TENG for electromechanical energy conversion in 2012. Due to the pulsed AC output and unstable mechanical energy input of TENG, it is necessary to store the electric energy generated by TENG in batteries or supercapacitors to provide continuous and stable power for wearable electronic devices.

1.2.1SCPSs with Discrete Units

Since TENG outputs AC, it needs an AC rectifier to convert the AC current to DC before charging the battery or capacitor. In this process, energy collection and storage are independent, connected through the rectifier circuit.

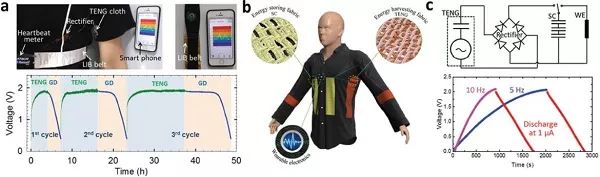

Textiles are ideal substrates for preparing wearable electronic products. As shown in Figure 5a, X. Pu developed a wearable textile SCPS by combining textile TENG with flexible LIB. The textile TENG can convert various mechanical energies from human motion into electrical energy, charging the flexible LIB, thereby providing a stable power source for heart rate monitors. Subsequently, the team further developed a solid-state yarn symmetric supercapacitor (shown in Figures 5b and 5c). This one-dimensional textile supercapacitor has advantages such as low cost, high performance, light weight, and flexibility.

Figure5. Textile TENG-Based SCPSs

(a) Photo of SCPS and Charge/Discharge Curves;

(b, c) Schematic Diagram, Equivalent Circuit, and Charge/Discharge Curves of Fully Textile SCPS.

1.2.2Integrated SCPSs

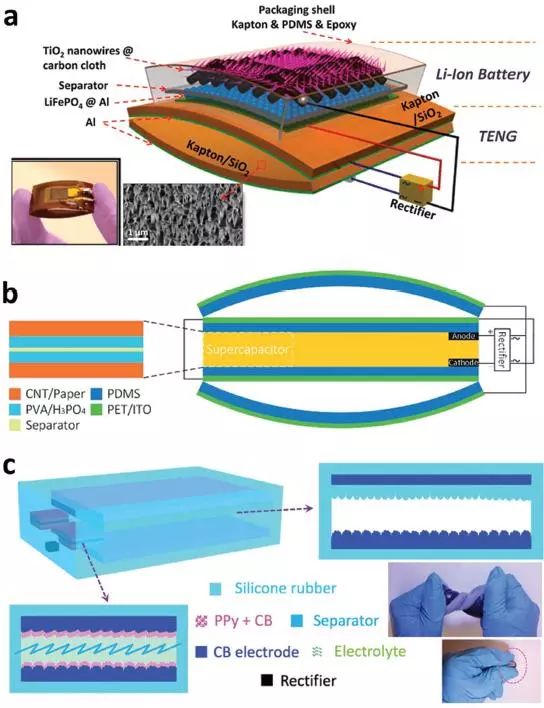

Although TENG and batteries or capacitors in SCPS cannot share electrodes, they can share substrates or be encapsulated together. As shown in Figure 6a, the flexible LIB is placed on top of the TENG and can serve as an integrated SCPS. As shown in Figure 6b, the SCPS developed by Y. Song and others has a stacked structure (TENG-SC-TENG), where the applied compressive stress on the SCPS is directly converted into electrical energy stored in the supercapacitor. In the aforementioned SCPSs, the rectifier circuit is separate from the supercapacitor and TENG, while the stretchable waterproof SCPS made by F. Yi successfully encapsulates TENG, supercapacitor, and rectifier circuit in a silicone matrix to form an integrated SCPS (Figure 6c).

Figure6. Integrated TENG-Based SCPSs

(a) Schematic Diagram and Photo of SCPS, where LIB is placed on top of TENG;

(b) Schematic Diagram of SCPS, where the middle capacitor also serves as an electrode for TENG;

(c) Schematic Diagram and Photo of Stretchable, Waterproof SCPS, where the supercapacitor, rectifier, and TENG are sealed in silicone.

1.2.3Power Management Circuit

In SCPS integrated with TENG and battery/supercapacitor, although TENG and electrochemical batteries can achieve high-efficiency energy conversion, the overall conversion efficiency of the SCPS still needs improvement. Therefore, it is necessary to design an appropriate power management circuit to maximize the energy efficiency of the SCPS.

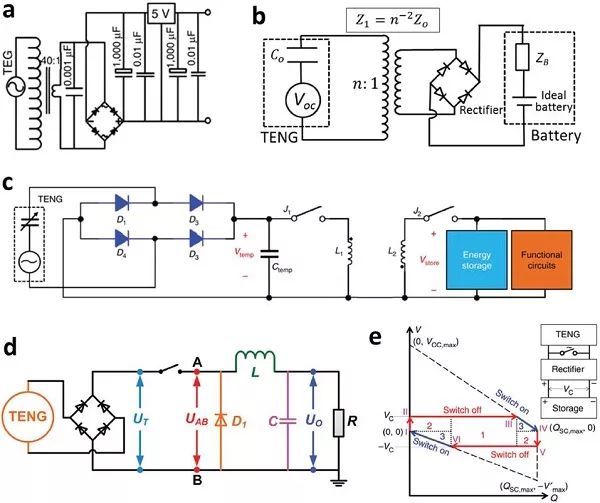

As shown in Figure 7a, the power management circuit composed of transformer, rectifier, voltage regulator, and capacitor can provide a constant voltage of 5 V within 0.5 s. The power management circuit can not only increase current and reduce impedance but also continuously power various electronic devices such as LEDs, digital clocks, and mobile phones. X. Pu and others also introduced inductive transformers to reduce the impedance of the rotary TENG. As shown in the equivalent circuit in Figure 7b, charging the battery can achieve an energy utilization rate of approximately 72.4%. Subsequently, S. M. Niu and others developed an SCPS with a power management circuit (Figure 7c), which is universally applicable to all TENGs with pulsed output, with an AC-DC conversion efficiency of up to 60%. The power management circuit designed by F. Xi can maximize energy transfer, achieve DC bulk conversion, and self-management, and is also applicable to all TENGs with pulsed output. As shown in Figure 7d, a classic DC-DC buck converter is coupled with an energy transfer maximization strategy to form an AC-DC buck conversion circuit. The switch alternates between opening and closing based on the motion of TENG, thus improving the energy transfer efficiency of TENG. Y. Zi designed a no-inductor power management circuit, as shown in Figure 7e, utilizing TENG’s V-Q curve, proposing a reasonable charging cycle to maximize the energy efficiency of SCPS. In addition, they also designed a motion-triggered switch to improve the charging speed of the battery, increasing efficiency by about 50%.

Figure7. TENG Based SCPS Power Management Circuit

(a) TENG Power Management Circuit, composed of transformer, rectifier, voltage regulator, and capacitor;

(b) Power Management Circuit of SCPS Based on Rotary TENG;

(c) Universal Power Management Circuit for Pulsed Output TENG;

(d) Universal Power Management Circuit for DC Bulk Conversion;

(e) No-Inductor Scheme: Effective Energy Transfer from TENG to Energy Storage Devices.

1.3SCPSs Based on Solar Cells

Solar energy is a widely used renewable energy source, and various types of solar cells have been developed to convert solar energy into electrical energy. Although solar cells can emit continuous DC electricity, the intensity of sunlight, its availability over time, and changes in weather and location can lead to unstable output power from solar cells. Therefore, integrating solar cells with storage devices (batteries or supercapacitors) helps provide continuous and stable power for wearable electronic devices.

1.3.1SCPSs with Discrete Units

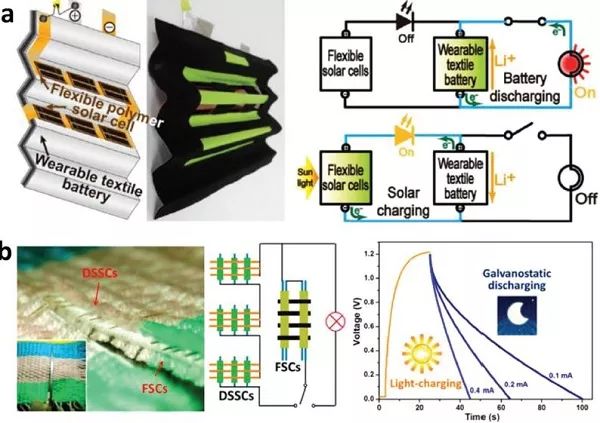

When batteries and supercapacitors are charged directly by solar cells through external wires, the solar cell and battery/supercapacitor in the integrated SCPS do not need to share electrodes. Recently, many flexible SCPSs integrated with organic solar cells have been reported. As shown in Figure 8a, polymer solar cells combined with textile LIB form flexible SCPSs. As shown in Figure 8b, Z. Chai and others reported a cuttable SCPS integrated with woven DSSC and fiber-like supercapacitor. The supercapacitor can be charged to 1.2 V in 17 s and discharge at 0.1 mA for 78 s.

Figure8. Discrete SCPSs Based on Solar Cells

(a) Photo, Schematic Diagram, and Equivalent Circuit of SCPS, where the Flexible Polymer Solar Cell is Attached to Wearable Textile LIB;

(b) Photo, Equivalent Circuit, and Charge/Discharge Curves of Cuttable SCPS, where the Fiber-Like Supercapacitor and Woven DSSC are Integrated into the Same Fabric.

1.3.2SCPSs with Shared Electrodes

In solar cell-based SCPSs, solar cells and batteries/supercapacitors can also share electrodes. This structure not only reduces the external connection lines between energy storage and harvesting units but also minimizes the size and weight of the entire system.

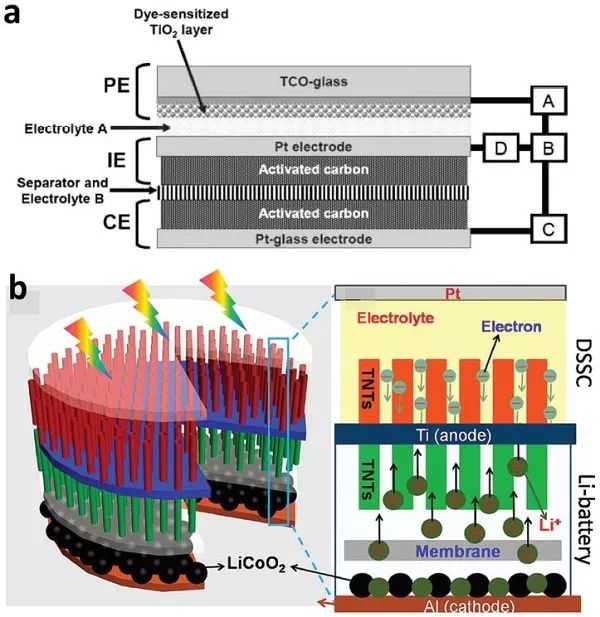

In-situ solar energy storage can be achieved through an integrated three-electrode structure, where the counter electrode (IE) or photoelectrode (PE) of the DSSC can simultaneously serve as the electrode for the battery or supercapacitor. As shown in Figure 9a, in the three-electrode structure of the dye-sensitized photo capacitor, the IE acts as a shared electrode for both the supercapacitor and DSSC. Additionally, the supercapacitor and DSSC can also share the PE electrode. As shown in Figure 9b, in the photo-generated carrier system, the TiO2 nanotubes grown on the Ti foil can serve as both the photoelectrode of DSSC and the anode of LIB. After the light charging process, the cathode and anode of LIB can discharge through an external load.

Figure9. Three-Electrode SCPSs Based on Solar Cells

(a) Schematic Diagram of SCPS, where DSSC is Integrated with Supercapacitor, where the Counter Electrode of DSSC also Serves as the Electrode of Capacitor;

(b) Schematic Diagram of SCPS, where DSSC is Integrated with LIB, where the Photoelectrode of DSSC also Serves as the Negative Electrode of the Battery.

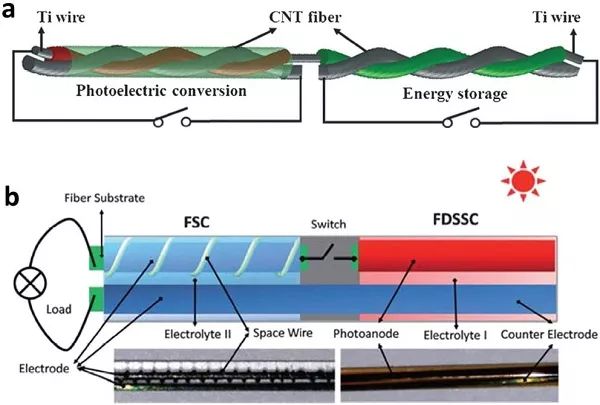

Researchers have developed fiber-like, three-electrode SCPS integrated with solar cells and supercapacitors, which can be used for flexible wearable devices. As shown in Figure 10a, T. Chen and others constructed an energy line, where the titanium wire coated with TiO2 nanotubes serves as the photoelectrode for photoelectric conversion and as the capacitive electrode for energy storage. Figure 10b shows a similar structure, where stainless steel fibers coated with PANI serve as the counter electrode of DSSC, achieving an overall energy conversion efficiency of 2.1%.

Figure10. Flexible Fiber-Type SCPSs with Three-Electrode Structure and Solar Cells

(a) Schematic Diagram of SCPS, where Different Parts of a Single Ti Wire are Used as the Photoelectrode of Solar Cell and Capacitive Electrode of Supercapacitor;

(b) Schematic Diagram of SCPS, where the Counter Electrode and Capacitive Electrode of DSSC are Fabricated on the Same Stainless Steel Wire.

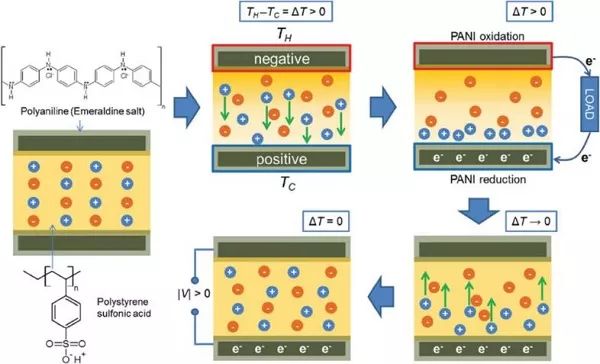

1.4SCPSs for Collecting Thermal Energy

A large amount of low-grade waste heat generated in various industrial sites and geothermal and solar heating can be collected using thermoelectric generators. Currently, the most researched thermoelectric generators are solid-state devices based on p-type and n-type semiconductors, and another alternative is thermoelectric chemical batteries. Recently, researchers proposed a new scheme integrating thermoelectric conversion and electrochemical energy storage based on the Seebeck effect. As shown in Figure 11, the thermally charged solid-state supercapacitor uses PANI-deposited graphene and CNT composite films as two symmetrical electrodes, where the temperature difference between the two electrodes leads to the migration of H+ from the thermoelectric electrode to the cold electrode, and electrons flow through the external circuit. After removing the temperature difference, protons return to a random distribution state, and the supercapacitor remains charged, meaning that thermal energy is directly converted and stored in the supercapacitor.

Figure11. Working Mechanism of SCPS Based on Thermoelectric Generator

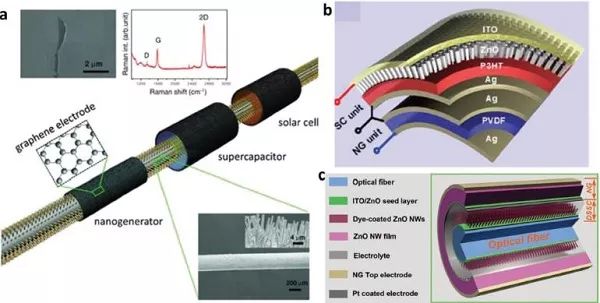

1.5Hybrid SCPSs for Collecting Multiple Energy Types

Renewable energy is not always available in certain environments or periods. Therefore, integrating two or more energy harvesting technologies into one device can effectively collect different types of energy. The demand for hybrid energy harvesting devices has driven the development of hybrid SCPS, such as the one-dimensional fiber-shaped hybrid SCPS shown in Figure 12a, where solar cells, PENG, and supercapacitors are integrated at different positions on a single fiber. Radially grown ZnO nanowires can serve simultaneously as the photoelectrode of solar cells, the piezoelectric layer of PENG, and the capacitive electrode of supercapacitors. As shown in Figure 12b, the stacked structure flexible hybrid battery integrates solar heterojunction OSC and thermoelectric/piezoelectric nanogenerators, which can be used for collecting thermal and mechanical energy. As shown in Figure 12c, DSSC and PENG are integrated on a traditional fiber, where the high voltage of PENG and the large current of DSSC are cleverly combined to better charge the capacitor.

Figure12. SCPSs with Multiple Energy Harvesting Devices

(a) Hybrid SCPS, integrating TENG, supercapacitor, and solar cell into a single fiber;

(b) Schematic Diagram of SCPS, integrating solar cell for collecting solar energy, thermoelectric generator for collecting thermal energy, and piezoelectric generator for collecting mechanical energy into one system.

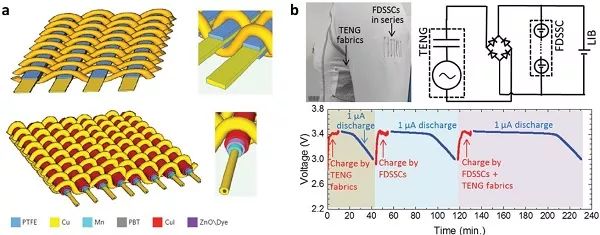

The aforementioned fiber-based solar cells, TENG, and fiber energy storage devices have high flexibility, which can better serve wearable electronics and smart textiles. As shown in Figure 13a, the micro-power textile SCPS can be used to simultaneously collect sunlight and mechanical motion energy. As shown in Figure 13b, X. Pu and others proposed a new scheme for constructing a fiber DSSCs and TENG fabric hybrid system, utilizing a mask plating method to fabricate comb-shaped conductive electrodes on ordinary textiles. The average power efficiency of the fiber DSSC is 6%, with an open circuit voltage of 0.68V. When the TENG fabric and seven FDSSCs are connected in series, a LiFePO4-Li button battery charged for 10 minutes can discharge at a current of 1 μA for 98 minutes.

Figure13. Wearable Textiles with Multiple Energy Harvesting Devices

(a) Schematic Diagram of Energy System, integrating Textile TENG and Textile DSSC;

(b) Photo, Equivalent Circuit, and Charge/Discharge Curves of SCPS, integrating TENG fabric, fiber DSSC, and LIB.

The latest research progress of SCPSs is as follows: ① Prototypes of various energy integration systems have been proposed; ② SCPSs for collecting different energies each have their advantages; ③ SCPSs have numerous potential applications, such as flexible/wearable electronic devices, personal healthcare, motion monitoring, and self-powered sensors.

The main issues faced by SCPSs are as follows: ① Most SCPSs are still in the proof-of-concept stage; ② The efficiency of each integrated unit in SCPS is relatively low; ③ The overall system efficiency of SCPS is currently the biggest issue; ④ It is crucial to select suitable batteries and supercapacitor systems for SCPS; ⑤ The mechanisms of several SCPSs, especially thermal SCPS, are not yet fully understood.

Literature Link: Toward Wearable Self-Charging Power Systems: The Integration of Energy-Harvesting and Storage Devices (small, 2017, DOI: 10.1002/smll.201702817)

This article is contributed by Researcher Pu Xiong, Researcher Hu Weiguo, and Academician Wang Zhonglin’s research group, edited and compiled by the New Energy Group of the Material Person Editorial Department.

The Material Cow Network focuses on tracking technological and industrial developments in the materials field, gathering graduate students, first-line researchers, and industry professionals. If you are interested in tracking technological advancements in the materials field, interpreting high-level articles, or reviewing the industry, click here to join the editorial family..

Everyone is welcome to promote scientific achievements and conduct in-depth interpretations of literature in the Material Person. Submission email: [email protected].

For submissions and content collaboration, please add the editor WeChat: RDD-2011-CHERISH, Ren Dandan, and we will invite you to join the expert group.

Technical Services

The Material Person provides material performance analysis, composition analysis, microscopic analysis, and other material performance analysis testing.

The Material Person offers four major specialized services, including solving material calculation problems, hardware rental, and providing various types of paper cover images, illustrations, flowcharts, etc.

If necessary, please contact QQ: 3234370334 (Testing Customer Service) / 3419043216 (Service Customer Service), or WeChat: iceshigu, or enter Testing Valley Network to search for related products.