1. Overview

(1) Introduction to 3D Printing Technology

3D printing, also known as additive manufacturing, is a technology that creates physical objects by gradually adding material. Compared to traditional subtractive manufacturing processes, which involve material removal, 3D printing is a “bottom-up” manufacturing method. Computer-controlled additive manufacturing technology first appeared in the 1980s.3D printing technology has a wide range of applications, including aerospace, medicine, defense, custom production, prototyping, art, craft design, and education.

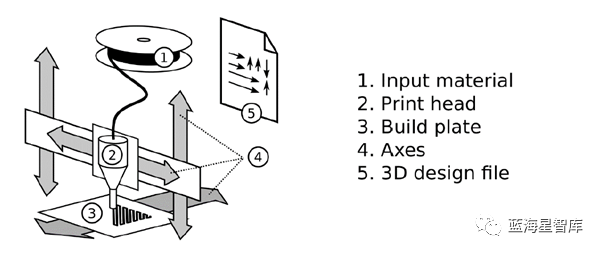

Overall, a 3D printer consists of five parts: input material, print head, build plate, axes, and 3D model design files (see Figure 1).

Figure 1 Components of a 3D Printer

(1) Input Material: The input material for 3D printing can be in the form of solid filaments, granules, liquids, or powders.

(2) Print Head: The input material is deposited at the tip of the print head, which can be achieved through various methods, including pushing filaments or granules into a metal extruder, using lasers to melt powders, or utilizing light to solidify liquids.

(3) Build Plate: This is the base on which the printed parts are constructed. At the beginning of the printing process, the print head is almost touching the build plate; as layers are added, the distance between the print head and the build plate increases.

(4) Axes: These control the relative movement between the print head and the build plate, allowing each layer to stack in a specific shape, ultimately forming the final product from the accumulation of layers.

(5) 3D Model Design Files: The 3D printing process is controlled by digital 3D model design files, which dictate the movement of the printer’s axes and alter the relative position of the print head and build plate, determining the shape of each printed layer and the final product.

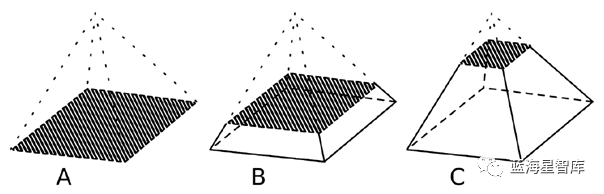

Figure 2 Simple Illustration of the 3D Printing Process

Figure 2 Simple Illustration of the 3D Printing Process

(2) Brief Review of the Development of 3D Printing Technology

The first major patents for 3D printing methods emerged in the 1980s, and the industrial application market for 3D printing began to take shape.

By the 1990s, 3D printers using materials such as plastics, metals, paper pulp, ceramics, and wax were introduced, with prices ranging from thousands to hundreds of thousands of dollars.

In the early 21st century, the 3D printing market expanded into specialized industries such as medicine, dentistry, and jewelry manufacturing. At the same time, new plastic printing materials were developed.

During the first decade of the 21st century, with easier internet access for ordinary consumers, user-friendly computer-aided design software became more widely adopted, leading to a wave of consumer-grade 3D printing, with open-source 3D printing communities, 3D printing file-sharing websites, and “on-demand printing” companies emerging.

After 2010, as technology matured, the 3D printing market rapidly grew, prices decreased, and sales of both consumer-grade and industrial-grade 3D printers continued to rise.

2. Current Status of 3D Printing Materials and Performance

There is a wide range of prices and performance among different 3D printers, with costs ranging from hundreds to millions of dollars.

Consumer-grade 3D printers are typically designed to print plastic parts. Various plastic materials are available, including rigid nylon, flexible rubber-like plastics, carbon fiber reinforced plastics, soluble plastics, transparent plastics, and decorative plastics with wood or metal appearances, each varying in price and performance. Some consumer-grade 3D printers can also print using materials like ceramics or chocolate. Structural plastics infused with metal can also be used in consumer-grade 3D printers, but require additional high-temperature post-processing to remove the plastic, leaving only the full metal product. The high temperatures required for post-processing can be achieved using pottery kilns, sintering machines, or other specialized equipment.

Industrial-grade printers can use a more diverse range of materials and have broader application fields. Compared to consumer-grade 3D printers, these printers can manufacture larger, more detailed, and more reliable structures, or use materials that the former cannot print, such as bioprinting with live cells. Metal 3D printers can utilize titanium, steel, or other metals to print parts, potentially at a lower cost than traditional subtractive manufacturing processes. Large-format plastic 3D printers can print parts nearly 2 meters tall. Some concrete 3D printers can be used to construct entire walls of buildings.

3. Impact of 3D Printing Technology on Manufacturing

In some cases, 3D printing has advantages over traditional manufacturing methods (such as injection molding, drilling, welding, etc.). The advantages of 3D printing technology stem from its unique design, which has a broad impact on defense, manufacturing, and economic sectors.

(1) Advantages of 3D Printing Technology

Reduced Waste. Generally, the additive manufacturing process uses only materials close to the volume of the product itself; whereas subtractive manufacturing processes require removing excess material to create products, inevitably generating waste. Therefore, additive manufacturing generates very little material waste, and even if some material is not utilized, it can be recycled.

Ability to Manufacture Parts with Highly Complex Internal Structures. Parts produced through 3D printing are built layer by layer, allowing for the easy construction of complex internal geometries (such as internal cavities or small channels).

High Cost-Effectiveness for Small Batch Production. When new parts need to be manufactured or modifications are required on existing components, 3D printing does not require significant reassembly of the production line; in contrast, traditional manufacturing methods like injection molding or die casting require substantial costs to reconfigure the production line when component designs need to be changed.

Easier Design Modifications. Digital 3D design files can be easily modified or forwarded.

(2) Impact of 3D Printing Technology on Manufacturing

(1) 3D printing can create parts with highly complex internal structures, consolidating multiple manufacturing steps (such as machining and welding) into a single printing operation. As a result, 3D printing can be used to manufacture parts that were previously impossible to produce or too costly. This integrated forming manufacturing method also effectively reduces the number of weak points in the parts.

(2) 3D printing provides a new option for commercial companies considering machine tool investments. In some cases, 3D printing may have a higher cost-effectiveness than traditional solutions, especially for manufacturing small batches, customized, or complex structured parts. For components that can be completed with fewer traditional processing steps, 3D printing’s cost-effectiveness is even lower. The smaller size of 3D printers compared to traditional manufacturing equipment also saves factory space and associated costs.

(3) 3D printing allows for easy modification of design files, and the high cost-effectiveness of manufacturing small batches makes it highly suitable for rapid prototyping, facilitating design optimization and timely adjustments.

(4) The ability of 3D printing technology to produce complex internal structures helps reduce the quantity of parts used, lighten component weight, or enhance strength, particularly in aerospace and automation industries.

(5) 3D printing helps reduce inventory. Mass-produced parts are typically manufactured using traditional methods to lower unit costs, necessitating the storage of many products as inventory. The “on-demand manufacturing” capability of 3D printing enables manufacturers to reduce inventory. With low production preparation costs and suitability for small batch production, 3D printing effectively reduces the capital tied up in inventory and related storage and insurance costs.

(6) 3D printing is suitable for large-scale personalized custom production. It allows modifications to basic designs to manufacture products that meet individual user needs.

(7) 3D printing reduces waste and does not require reconfiguration of production lines, making the manufacturing process more environmentally friendly. It can also refurbish damaged areas of old parts, contributing to energy conservation.

(8) 3D printing can manufacture products in a “decentralized” manner, reducing the time it takes for products to reach customers, as well as lowering costs, energy consumption, and environmental impacts from transportation.

(9) The relatively low cost of 3D printing equipment can lower the entry barriers to the manufacturing industry, which has both advantages and disadvantages. While 3D printing can expand legitimate manufacturing industries, it can also be used to produce prohibited items, including optical weapons or nuclear weapon components. The low entry barriers of 3D printing may present challenges for established companies facing new competitors.

Figure 3 Firearms Manufactured Using 3D Printing Technology

Figure 3 Firearms Manufactured Using 3D Printing Technology

(Blue Ocean Star)

Recommended Articles

1

Revolutionary Developments in 3D Printing of Lightweight Flexible Functional Materials

2

Swiss 3D Printing Develops “Flink” Bacterial Ink

3

US Navy Southwest Regional Maintenance Center Delivers 3D Printed Parts

4

French Aircraft Carrier “Charles de Gaulle” Equipped with 3D Printer

5

Newport News Shipbuilding Delivers First Naval 3D Printed Metal Parts

For more research on foreign defense strategies, military industry, equipment development, and cutting-edge technologies, please follow the WeChat public account of Blue Ocean Star Think Tank: SICC_LHX

Reproduction is welcome, please indicate the source.