|

Advertisement 1: API 5DP 2nd Edition Chinese Version, API 7-1 Chinese Version, API 7-2 Chinese Version, NS-1 Chinese Version, ASTM Standards Chinese Version, ASME BPVC I–IX Chinese Version… Various drilling tool-related standards can be freely combined and bound for daily use, with a complimentary electronic English version. Jaeger reading card for inspection personnel’s vision check, in stock, original imported, same-day shipping. |

1. About DS-1

1) The publisher of the DS-1 standard, TH HILL, is a subsidiary of Bureau Veritas (BV) in France;

2) The strict level of the DS-1 standard is adopted by most international oil service companies, such as Mobil, Chevron, Saudi Aramco, ADNOC, Total, etc.; for domestic drilling tool products to enter the world market, the DS-1 standard is an unavoidable reference guideline.

3) The DS-1 standard is generally suitable for experts in the 5DP and 7-1 industries, with a certain level of English proficiency and familiarity with the English abbreviations of products; it is not suitable for beginners;

4) The 5th edition of DS-1 Volume 3 was released in August 2020, consisting of six volumes, which are:

• Volume 1: Drilling Column Product Specifications

• Volume 2: Drilling Column Design and Operations

• Volume 3: Drilling Column Inspection

• Volume 4: Drilling Tools for Use

• Volume 5: Drill Bit Inspection Techniques

• Volume 6: Aluminum Alloy Drill Rods

5) The DS-1 standard does not require certification, is not utilitarian, and genuinely contributes to the improvement of the global drilling tool industry.

6) You may choose not to follow the DS-1 requirements, but you cannot be unaware of the industry’s benchmark requirements.

| Specialized in rectifying various tricky API non-compliance issues! Specialized in API consulting for Chinese overseas companies, with a full set of English materials. |

2. New Changes in DS-1 5th Edition Volume 3

1) The design of the shoulder suspension slot on the drilling collar is no longer supported, which has also been removed from Volume 1 of DS-1, retaining only the slip slot. However, the latest version of API 7-1 still retains the suspension slot, which is expected to be revised in the future.

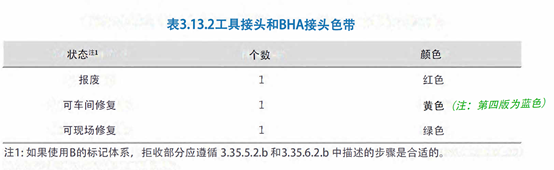

2) Changes in the color of tool joint tape: the color for workshop repair has changed from blue to yellow to distinguish it from the blue of premium drill pipe bodies.

3) Regarding personnel competency assessment: In the fourth edition (and earlier versions), there was a specific procedure for assessing personnel (Procedure 3.28, Personnel Assessment). This procedure was intended to strengthen the validity of each DS-1 inspection, but many were unclear about its applicability. To highlight the essence of these requirements, the 5th edition has moved them to Chapter 2 of the standard (Section 2.20). Moreover, the use of industry-standard competency language and patterns has somewhat expanded the requirements.

4) Regarding the calibration of measuring tools: In the fourth edition, the calibration requirements for inspection instruments were listed in the specific tools section to be used. To simplify the reading of inspection procedures and help inspection companies have a unified list of requirements for reference, the fifth edition has moved the calibration requirements for inspection instruments to Section 2.21 at the beginning of the standard. All relevant equipment sections in Chapter 3 point to this requirement set.

5) Regarding Table 2.3: Inspections of Category 1 and Category 2 historically used Level 2 acceptance criteria as the default. These inspections are very suitable for “maintenance” inspections in low-cost environments, but most contracts and expectations are written around high-quality standards. The default acceptance criteria for Levels 1 and 2 have been changed to high-quality levels.

6) Regarding full-length ultrasound (WT/TL/Obl): In the 4th edition and earlier versions, it was a combination of full-length ultrasound procedure 1 and full-length ultrasound procedure 2. The difference between full-length ultrasound 1 and 2 is that ultrasound 1 covers the full-length wall thickness reduction inspection of the drill pipe body, longitudinal and transverse flaw detection. Full-length ultrasound 2 also adds oblique flaw detection. This method combines these procedures to prevent redundant flaw detection and increases the possibility of only testing the full-length thickness. The differences in options are given in the brackets after the inspection names: “WT” for full-length wall thickness detection, “TL” for transverse and longitudinal flaw detection, “Obl” for oblique flaw detection. Therefore, the full-length ultrasound procedure 1 in the 4th edition is the full-length ultrasound (WT/TL) in the 5th edition, and the full-length ultrasound procedure 2 in the 4th edition is the full-length ultrasound (WT/TL/Obl) in the 5th edition.

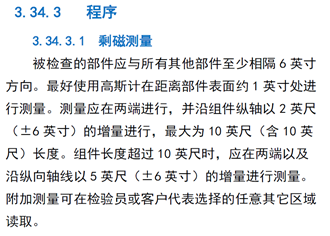

7) Regarding demagnetization: Previously, the method for demagnetization after component inspection only required the inspector to measure the magnetism of the component—no specific location instructions were provided. The 5th edition adds this measurement method, which also allows users to simply specify the measurement method as a field inspection method, as shown in the figure below.

8) For many requirements, the 5th edition has added “when applicable.”

9) Regarding the selection of thread grease: The 4th edition specified API thread grease, while the 5th edition changed it to acceptable thread grease.

10) Other changes

………

3. Considerations for Interpreting DS-1:

1) DS-1 Volume 3 specifies six inspection levels (CAT1-CAT5 and HDLS) and 36 inspection method procedures, with inspection procedures combined into applicable inspection schemes.

2) Reface: Refers only to the trimming of the shoulder surface;

3) Rethread=Recut: Refers to reworking of threads;

4) The DS-1 inspection after reworking threads includes the flatness of the shoulder surface, which is not specified in API 7-2;

5) The DS-1 specifies that after reworking the threads of BHA and weighted drill rods, cold rolling must be performed, whereas API 7-1 is optional.

API 7-1 regulations are as follows:

6) The DS-1 specifies a simple method for testing the adhesion of the phosphating film, recommending the use of an eraser.

7) The DS-1 clearly specifies the method for cold rolling of threads, which can serve as a supplementary reference to API standards.

……………..

|

Latest Chinese API Standards: API 5CT Casing and Tubing 10th Edition (Comparison Version) API 5B Thread Processing and Testing 16th Edition API 5DP Drill Rod Specifications 2nd Edition (Comparison Version) API 7-2 Rotating Step Thread Connections 2nd Edition, including Errata 1, Errata 2, Supplement 1 API 7-1 Rotating Drilling Tool Component Specifications 1st Edition, latest revision sequence, including Supplements 1-4, Errata 1 API 7G-2 Recommendations for Inspection and Classification of Drilling Column Components 1st Edition API 5A3 Thread Grease 3rd Edition API 6A Wellhead and Christmas Tree 21st Edition API 11D1 Packers and Bridge Plugs 3rd Edition All referenced documents in API standards (English)……… |

We also provide the following value-added services:

|

1 API Q1 On-site training, covering all clauses thoroughly, guaranteed to learn (can sign a performance agreement); 2 Quality, Safety, and Environmental Management System Certification, with complimentary Q1 training; 3 HSE, HSSE certification recognized by the three major oil companies; 4 AAA Credit Management Certification; 5 API Authentic English standards, as well as ASTM, ASME, etc.; 6 API Remote correction of non-compliance, average of 1000 yuan each, guaranteed to pass; 7 Free provision of resources in the oil casing and steel pipe industry; 8 Special joint drawings for oil casing; 9 Purchase Chinese standards, receive a version change MOC, a change content identification table, and an ASNT TC 1A-2020 edition non-destructive testing personnel training outline. 10 Heat treatment technology services for oil casing and drill rods (can sign a performance agreement, guaranteed delivery) |

Contact Number: 13805464188

WeChat: 13165256432