This article’s images are sourced from: AutomationDirect

Author | Damon Purvis

In the past, PLCs and HMIs were primarily used for real-time control; now, they can perform more tasks, easily enabling data analysis and other requirements through edge computing technology.

Today, consumers are more eager than ever to choose products that meet their needs from a wide variety of options, prompting manufacturers to install advanced automation and control equipment at the edge to satisfy consumer demands. The flexibility of manufacturing brings a challenge: typically, mass production and standardization are the best ways to improve efficiency and reduce costs, but this does not align well with consumer demand for customized products.

To meet consumer needs, many industries are turning to data-driven solutions to enhance product quality, service, and responsiveness in manufacturing. This, in turn, promotes deeper integration between operational technology (OT) production systems and information technology (IT) enterprise systems, with edge computing providing assistance in this area.

These integrations are necessary not only for mass customization but also for collecting and processing data for continuous improvement, quality control, and tracking. This data also forms the basis for predictive, prescriptive, and descriptive analytics.

Data is key to achieving agile production dynamics, optimizing operations, and energy consumption. For these reasons, industrial enterprises are seeking the most effective ways to connect the valuable data contained within their manufacturing systems and fully leverage this data. How can industrial automation designers, especially original equipment manufacturers (OEMs), adapt to the growing demand for data and the need for deep integration with enterprise systems?

01

Growing Manufacturing Data

It is evident that production systems generate products, but they are increasingly generating data as well. The amount of data generated today is greater than ever before in history. The creators of the “Data Never Sleeps” infographic, Domo, claim that as of 2022, the total amount of data created, captured, copied, and consumed globally over the past decade is 97 zettabytes (ZB). The manufacturing sector leads in this regard, storing more data than any other sector, including government.

To generate and process this data, the entire industry has implemented digital transformation, smart devices, and Industrial Internet of Things (IIoT) technologies on a large scale. Most manufacturers and OEMs recognize that the data generated by shop floor control and monitoring systems is digital gold, provided that this data can be easily accessed and acted upon swiftly.

There are more data sources than ever before, and similarly, there are many technological options for connecting to this data. However, connecting, contextualizing, transmitting, and processing large datasets can be complex and costly due to the required infrastructure and security.

02

Development of Data Collection and Analysis in Manufacturing

For users attempting to access industrial data sources and take action on them, the challenge lies in connecting various target devices located at the edge and then transmitting and storing the data in a place where computation and analysis can be performed.

Traditionally, industrial automation systems are designed with programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to provide basic control and monitoring functions. In a typical scenario, data can be collected via OPC data servers and contextualized in historical databases or supervisory control and data acquisition (SCADA) systems.

PLCs, HMIs/SCADA, and historical databases are often separate from IT infrastructure. With improvements in OT devices and the development of related networking and communication protocol technologies, data collection has become simpler, and to some extent, OT devices can even interact more directly with IT systems.

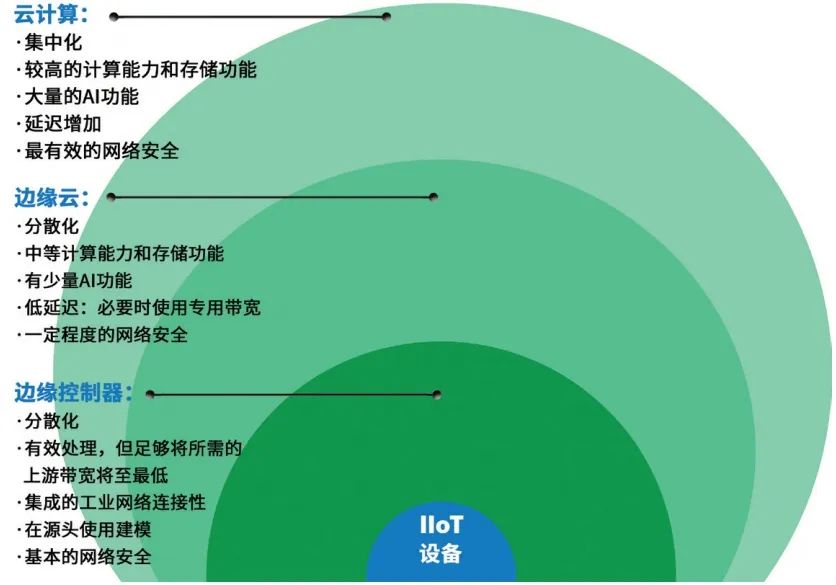

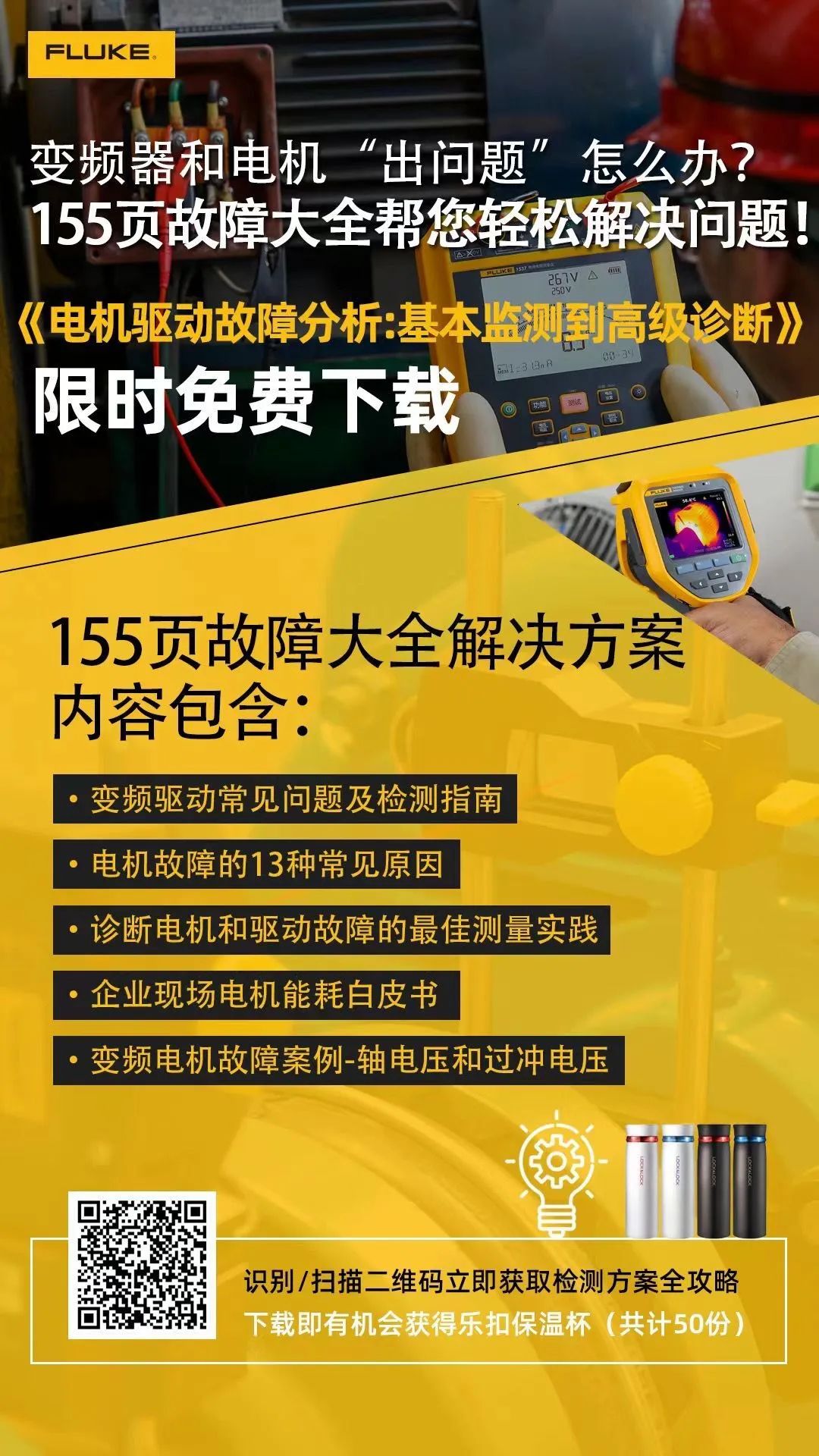

The convergence of OT and IT technologies has led to another key development: a new type of industrial control and computing device, commonly referred to as edge controllers. Edge controllers typically combine real-time PLC control with general PLC/SCADA computing and communication capabilities. Edge controllers communicate well with both OT and IT assets, and they also enable storage and computing resources to be shifted from central data centers or the cloud to the edge locations where data is generated (Figure 1).

▲Figure 1: PLCs and IIoT devices at the facility edge provide important and valuable data, and there are now many pathways to transmit this data to on-site or cloud-based resources for monitoring and analysis through edge controllers.

For certain applications, edge controllers may be appealing, but one consequence of such devices is that the technology stack becomes deeper, making it potentially impractical for many OEM machine manufacturers or smaller end-user applications due to overall costs and required development time.

03

Practical Approaches to Achieving Data Access at the Edge

Even as secure remote connections, data access, and agile production become increasingly important, machine manufacturers will always focus on robust real-time control and convenient visualization.

In certain special cases, such as machines with annual production volumes in the tens of thousands, developing custom control, computing, and connectivity solutions may make sense. In other cases, some projects may support edge controllers and the associated development costs.

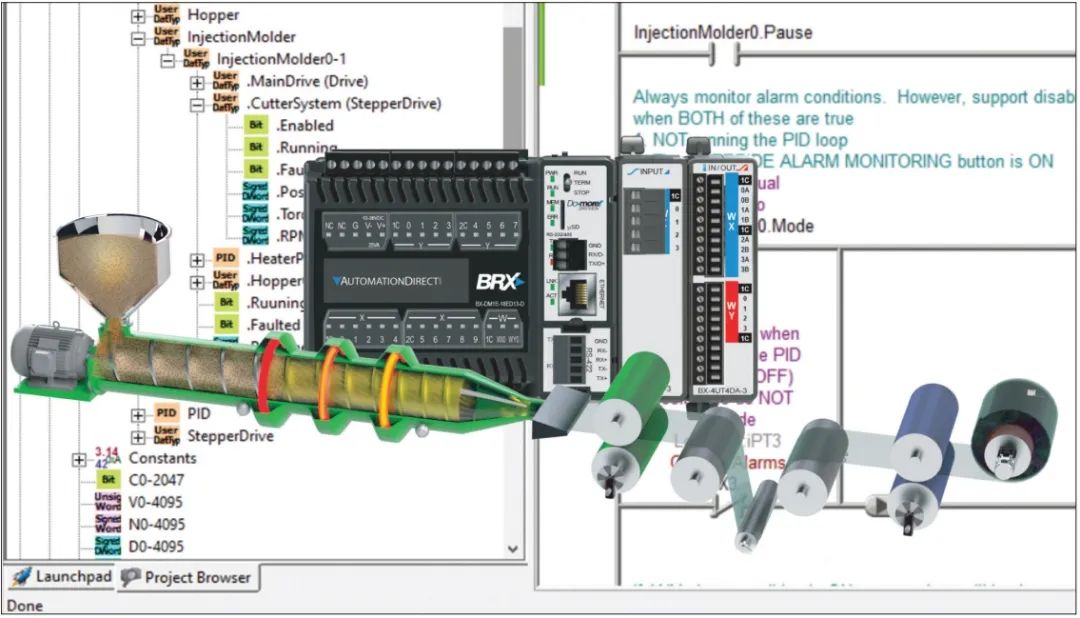

However, the reality is that modern PLCs and HMIs can easily serve most machines, even small to medium-sized general automation applications, even when data access is a priority (Figure 2).

▲Figure 2: OEMs and designers can use the latest PLCs to automate devices and provide simple connectivity, rather than developing custom platforms or specifying edge controllers.

This is because the latest devices include networking and data processing capabilities, allowing them to meet most IT accessibility requirements at a reasonable cost and with simple implementation. They support edge computing needs, such as remote connectivity and advanced monitoring and analytics integration. In modern PLCs, at least three features are evident:

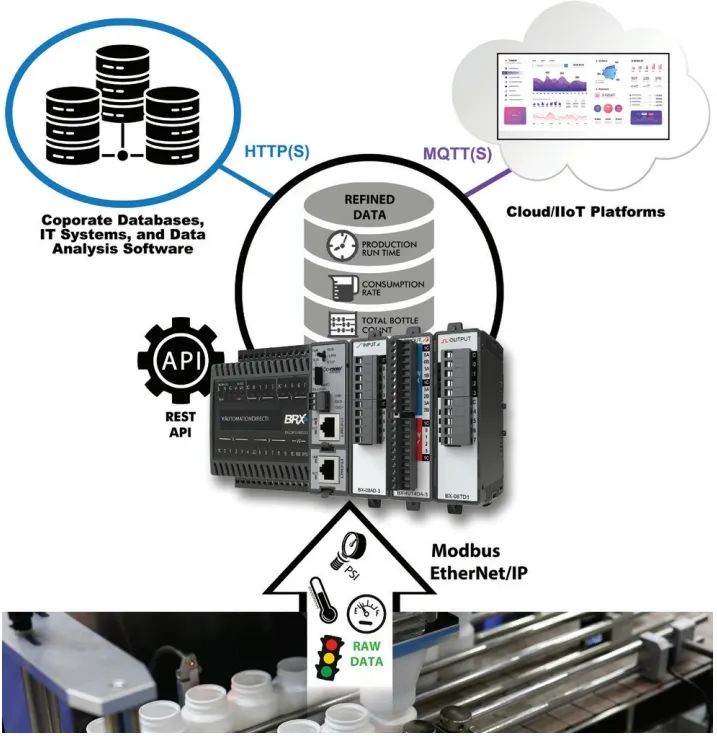

1. Networking and Communication: Modbus, EtherNet/IP, and Profinet are the most popular OT-based communication protocols or fieldbuses, and most modern, and even some traditional PLCs support these protocols. However, until recently, PLCs rarely included protocols that allowed seamless integration with enterprise systems. Additionally, issues such as encryption, data privacy, and other cybersecurity concerns were either not addressed or only considered after the fact. However, some modern PLCs have natively integrated IT capabilities into their communication stacks by supporting OPC UA, secure integration with local and enterprise email services, Microsoft-certified Azure integration, secure REST APIs, and using Sparkplug B for secure message queue telemetry transport (MQTT), along with a multitude of fieldbus protocols (Figure 3).

▲Figure 3: Edge computing capabilities require integration at multiple levels. Advanced PLCs can communicate with various OT devices using popular fieldbuses and can interact with higher-level IT systems in many different ways.

2. Data Contextualization: Traditional PLCs often contain unstructured data, which requires significant rework at the regulatory layer for enterprise systems to utilize. Modern PLC software allows automation designers to create data structures and definitions at the data source in one go, and PLC firmware can expose data models for use, providing a “single source of truth” for systems using the data.

3. Low-Latency Data Processing: Due to memory and other computational resource limitations, traditional PLCs often cannot aggregate data at the edge or prioritize it lower than executing control code. Modern PLCs balance memory and processing, allowing for on-site collection and aggregation of essential data while prioritizing the execution of real-time control code. Preprocessing low-latency data at the source is most effective and can reduce upstream network traffic and processing required for data acquisition and transformation.

With modern PLCs, designers now have scalable options to develop reliable future-ready automation systems that integrate with enterprise systems and provide edge computing capabilities.

04

Modern PLCs Beyond Basic Automation Functions

Industrial automation designers and developers pursue standardized solutions to make devices easier to develop, operate, and maintain. However, some developers may worry that investing in standardized solutions could limit innovation as product ranges and demands expand.

Since modern PLCs and HMIs can ensure reliable overall functionality while performing basic tasks, they also allow for more advanced computing in the future, thus addressing these concerns.

Today, users can implement such edge technologies using familiar platforms to provide appropriately sized and cost-effective automation systems while keeping the door open for creating higher-level applications (such as edge computing capabilities) as needed. Now, more advanced IIoT platforms, cloud computing, and even complex strategies like machine learning can interact directly and securely with OT digital assets without the need for complex intermediary steps.

This new realm opened up by modern PLCs and HMIs provides designers with the real-time control capabilities currently needed while enhancing data processing and access capabilities. The rich computational resources of these devices also provide a platform for addressing future demands, whether anticipated or unanticipated.

Key Concepts:

■ Edge controllers provide computing and advanced communication capabilities, but may be too complex or expensive for small applications.

■ Modern PLCs go beyond the real-time control of traditional PLCs, featuring edge computing capabilities that support data collection and analysis for more flexible production and higher efficiency.

Consider This:

How do modern controllers and edge devices help manufacturers collect data to improve production and efficiency?

– END –

▲This article is from the August 2023 issue of CONTROL ENGINEERING China magazine, “Cover Story”: Integrating Edge Computing Capabilities into Modern PLCs and HMIs

✦

Recommended Reading

✦