Modbus Debugging is Like Dating! These 3 Command Tips Work Every Time!

Have you ever been tormented by Modbus communication debugging to the point of exhaustion? You configure everything according to the manual, yet the communication fails, and you watch time slip away without any progress. To be honest, when I first entered the industry over a decade ago, facing Modbus debugging felt like deciphering a foreign language, completely at a loss.

One day, I was at an industrial site facing a stubborn flow meter and host computer, unable to establish communication. After three hours, I was sweating profusely, and my boss had called me seven or eight times. Just when I was about to give up, an experienced technician walked over, observed my debugging process, and smiled, saying, “Young man, Modbus debugging is like dating; you need to know how to sweet-talk and do it the right way.”

His words completely changed my perspective on Modbus debugging. Now, I want to share the experiences I’ve accumulated over the years, especially with those who are new to the field.

Modbus debugging is like dating because it requires both parties to establish effective communication while considering each other’s “temperament.” Just as you cannot use the same sweet talk to impress everyone, different devices have their specific “preferences” for Modbus communication. However, there are a few “sweet talk” commands that work every time, and I will share these key debugging steps below.

【First Sweet Talk】: First, confirm if both parties are on the same channel

In dating, both parties must be on the same channel to communicate smoothly. The same goes for Modbus communication; first, ensure that the communication parameters match perfectly.

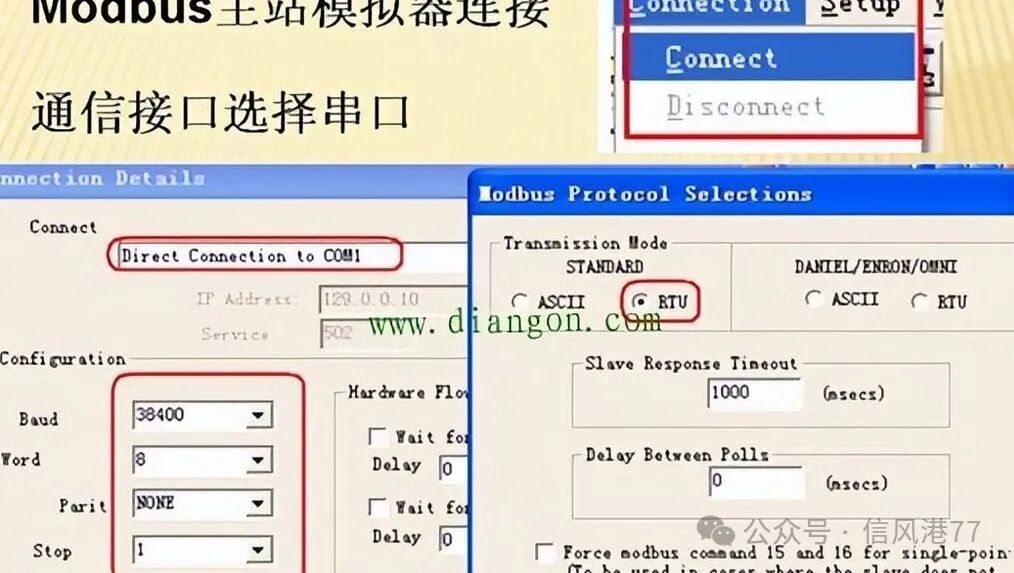

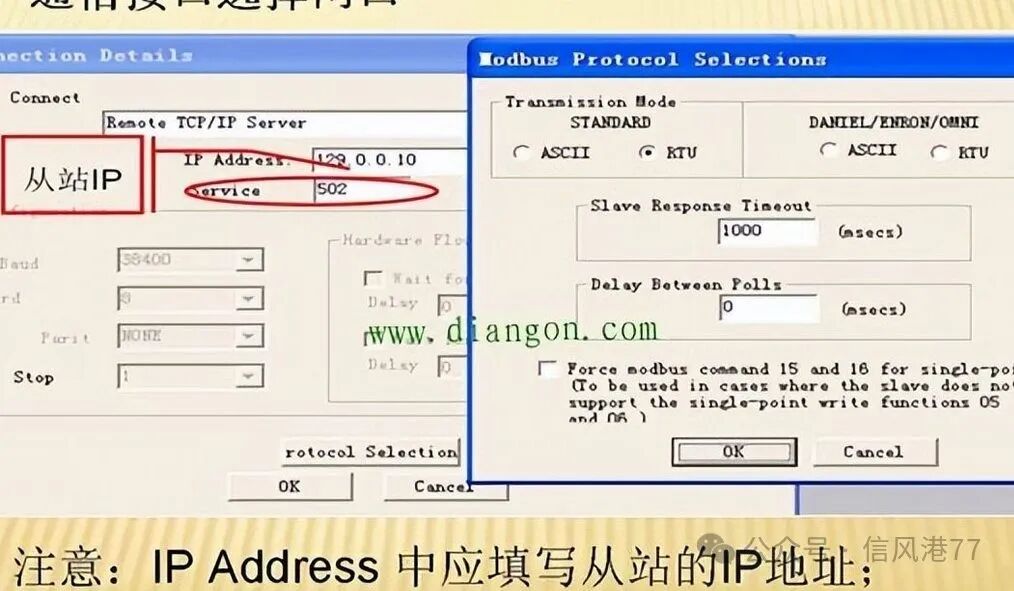

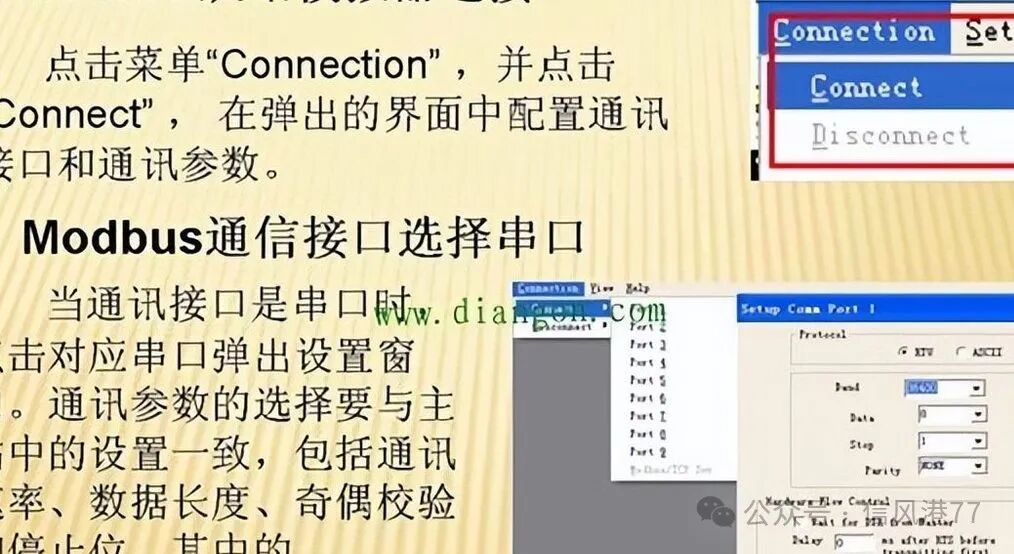

● 【Baud rate and parity must match】: Just like two people need to coordinate their speaking speed and tone, the baud rate, data bits, stop bits, and parity bits of both communication parties must be completely consistent.

● 【Communication interfaces must be correctly connected】: The wiring method in serial communication is particularly important; ensure that the receiving and transmitting lines are correctly connected and not reversed.

At this point, I must mention a painful lesson. Last year, during a project at a petrochemical plant, I spent two whole days debugging a simple temperature instrument, only to find out that it was just because two communication wires were reversed. Remember, using a multimeter to test the continuity of communication lines can help you avoid such embarrassing situations.

【Second Sweet Talk】: Understand the other party’s secret garden (data structure)

Understanding the inner world of the other party is key to maintaining a relationship. Similarly, understanding the data storage method of the device is central to Modbus debugging.

● 【Confirm starting address and data type】: Different manufacturers may define Modbus addresses differently; some start from zero, while others start from one. Floating-point numbers are even more complex, potentially having four different byte orders.

● 【Use a simulator for verification】: Before directly connecting to the actual device, first use a Modbus simulator to verify that the communication parameters and data format are correct.

I once encountered an interesting case. While debugging a Japanese-imported flow meter, I configured it according to the manual but could not establish communication. Later, I used Modscan32 software to test four different floating-point data formats and ultimately discovered that this device used a non-standard byte order. This made me realize that sometimes device manufacturers can be a bit “difficult.”

【Third Sweet Talk】: Patiently listen and express at the right time (timeout settings and retry mechanisms)

Communication in a relationship requires patience and cannot be rushed. Modbus communication also requires reasonable timeout settings and retry mechanisms.

● 【Set reasonable timeout periods】: It is generally recommended to set it to 【three to five seconds】 to give the other party enough time to respond.

● 【Implement a reliable retry mechanism】: Communication cannot be 100% successful, especially in complex industrial environments; an appropriate number of retries can improve the success rate of communication.

Next, I want to share a small tip. When using tools like Modscan32 or ModSim32, do not rush to guess the serial port parameters. There are up to ninety-six combinations of serial port parameters for common devices on the market, and your chances of guessing correctly are lower than winning the lottery. The best method is to consult the device manual or directly contact the manufacturer.

Honestly, over the years, I have seen too many engineers take detours in Modbus debugging. Some forcefully apply experience, some refuse to consult the manual, and others are unwilling to use debugging software. Remember, no one can successfully debug Modbus communication through guesswork, just as you cannot guess the thoughts of your partner in a relationship.

I personally believe that the essence of Modbus debugging lies in understanding rather than memorization. Once you understand the principles of communication and debugging ideas, you can quickly find the entry point even when facing unfamiliar devices. This is much more useful than rote memorization of a specific configuration.

Have you ever felt frustrated while debugging Modbus? Have you ever wasted a lot of time due to a small parameter setting error? I am curious, which Modbus issues are the most troublesome in your work? Is it wiring issues, parameter configuration, or data format?

I want to say that Modbus debugging is indeed like dating; it requires patience, understanding, and skills. Mastering these three “sweet talk” commands will make your debugging journey much smoother. Next time you encounter a Modbus communication issue, don’t forget to first check the communication parameters, then confirm the data format, and finally set reasonable timeout and retry mechanisms.

If this article has been helpful to you, feel free to share your debugging experiences and insights in the comments. What has been the most challenging Modbus issue you’ve encountered recently? How did you solve it? I look forward to communicating with you!