According to a report on the consumer goods 3D printing market published by VoxelMatters, the number of 3D printed consumer goods parts reached nearly 37 million in 2023, a 23% increase compared to 2022. 3D printing technology is fundamentally transforming the manufacturing methods in the consumer goods industry, opening up new growth paths.

Rayming Laser has developed the LiM-X400M device to meet the high-efficiency production needs of users in the consumer goods industry, primarily providing comprehensive solutions for metal 3D printing in mold manufacturing, 3C electronics, medical, education, and cultural creation fields. Based on the efficient and stable production of the device, we have also integrated user feedback and, after multiple optimization tests, upgraded the LiM-X400M series devices.

On one hand, the LiM-X400M device’s laser configuration has been updated, allowing users to optionally equip two 3000W ultra-high-power lasers to achieve 0.4mm layer thickness printing, further improving production efficiency. On the other hand, we have launched the LiM-X400M+ device, with a forming size upgraded to 400mm×300mm×450mm, providing a larger forming space to meet more users’ needs for the production of complex structural components and mass production.

Multiple Layer Thicknesses, One Print, More Efficient Production

The LiM-X400M series devices are equipped with self-developed software that can achieve the completion of parts with multiple layer thicknesses in one print, such as flexibly adjusting from a 0.04mm layer thickness to a 0.02mm layer thickness, saving downtime during operations and effectively improving part forming efficiency.

Base Temperature, Set Separately, Superior Forming

The slicing end provides a temperature control function, allowing for different base temperatures to be set for different printing heights and stages (the base preheating temperature range is 20°C~350°C), ensuring smooth printing while effectively improving stress and deformation caused by structural features of the product, thus ensuring forming quality.

Efficient Prediction, Avoiding Problems, Smarter Management

For the most common powder overflow bucket full alarm during printing, predictive maintenance is provided, allowing users to predict the cleaning time of the overflow bucket through the powder amount curve, avoiding unexpected downtime. Sensor data and log files during the printing process are recorded on a per-print job basis to support production quality management.

Process Detection, Real-Time Monitoring, More Consistent Quality

A configurable melt pool monitoring system allows for real-time monitoring, analysis, and evaluation of the melt pool information from the laser selection melting device, achieving defect detection and process quality traceability in additive manufacturing. On one hand, it can detect whether the melt pool is unstable in real-time, and on the other hand, it serves as a quantitative indicator for optimizing process strategies, ensuring the quality and consistency of parts.

Since the release of the LiM-X400M series devices, their stability, forming quality, and production efficiency have been highly recognized by users. In the mold manufacturing field, they have significantly improved mold performance and production efficiency; in the 3C electronics field, they efficiently meet the needs for new product trials and small batch production, injecting vitality into the industry’s continuous development.

Shaped Cooling Waterway Molds

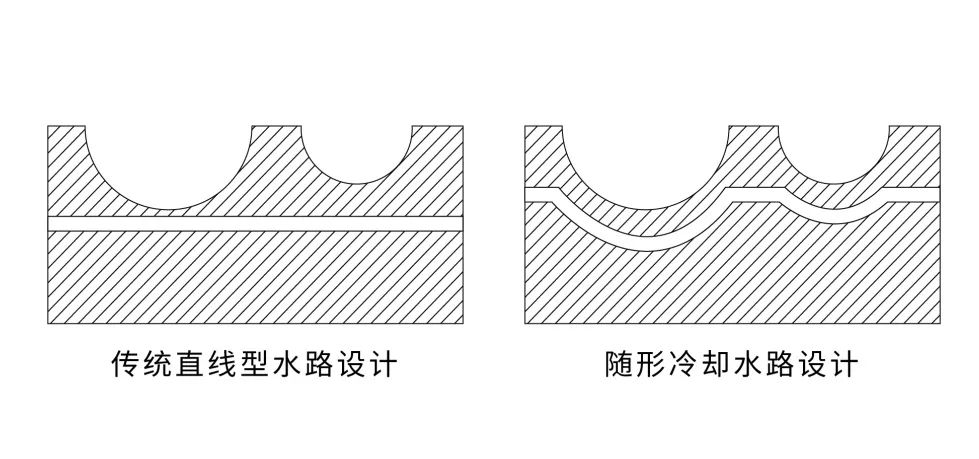

The injection molding process involves injecting high-temperature molten plastic into a cooler mold under high pressure, where it cools and solidifies to form the desired product. Temperature control of the mold is a crucial part of injection molding, typically achieved through cooling waterway systems for rapid and uniform cooling. The design of the cooling waterway layout directly affects the quality of injection molded products and production cycles.

In traditional processing methods, mold cooling waterways can only form cylindrical straight holes, failing to closely adhere to the surface of the injection part to achieve the best mold temperature state, resulting in uneven cooling, low efficiency, and affecting the quality of the finished product and production efficiency.

Comparison of Traditional Waterways and Shaped Cooling Waterways

Metal 3D printing technology can break through the limitations of traditional processing, producing molds with complex shaped cooling waterway systems: within a reasonable range, the shape and cross-section of the cooling waterways can be freely designed, closely following the contour changes of the mold cavity surface, achieving faster and more uniform cooling effects, thereby improving the quality of injection molded parts, shortening cooling time, and increasing production efficiency.

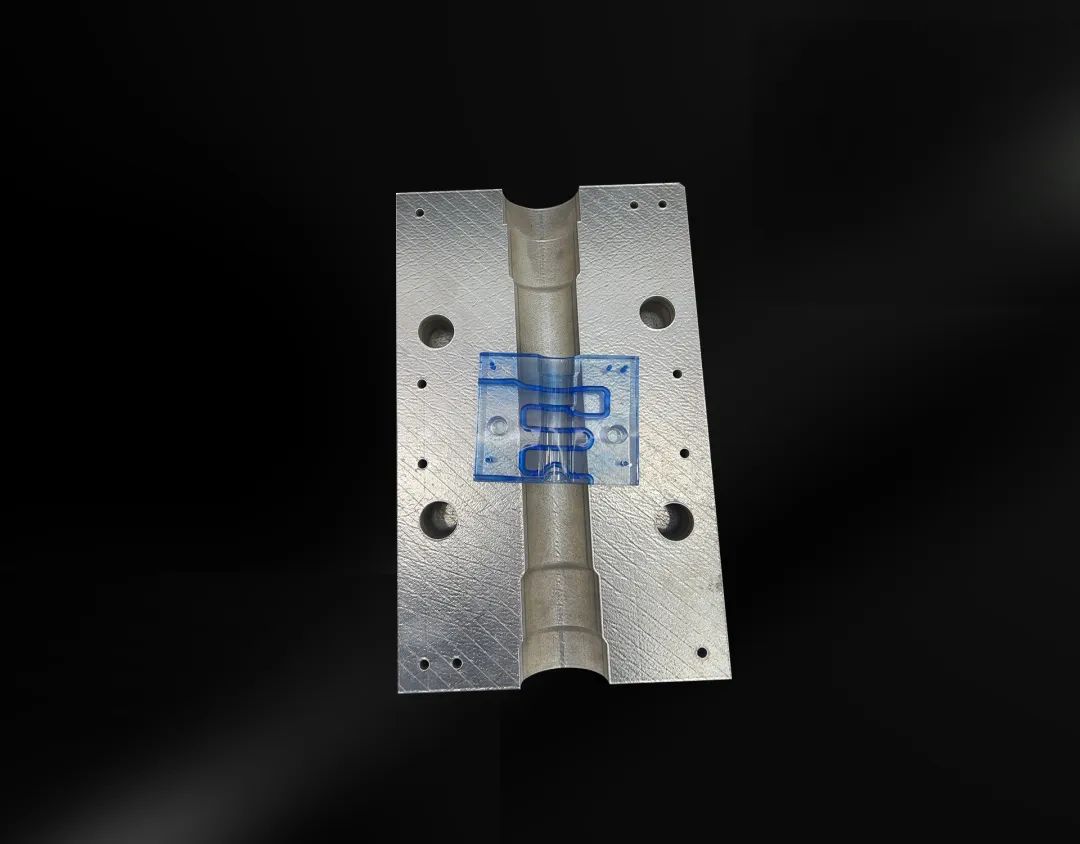

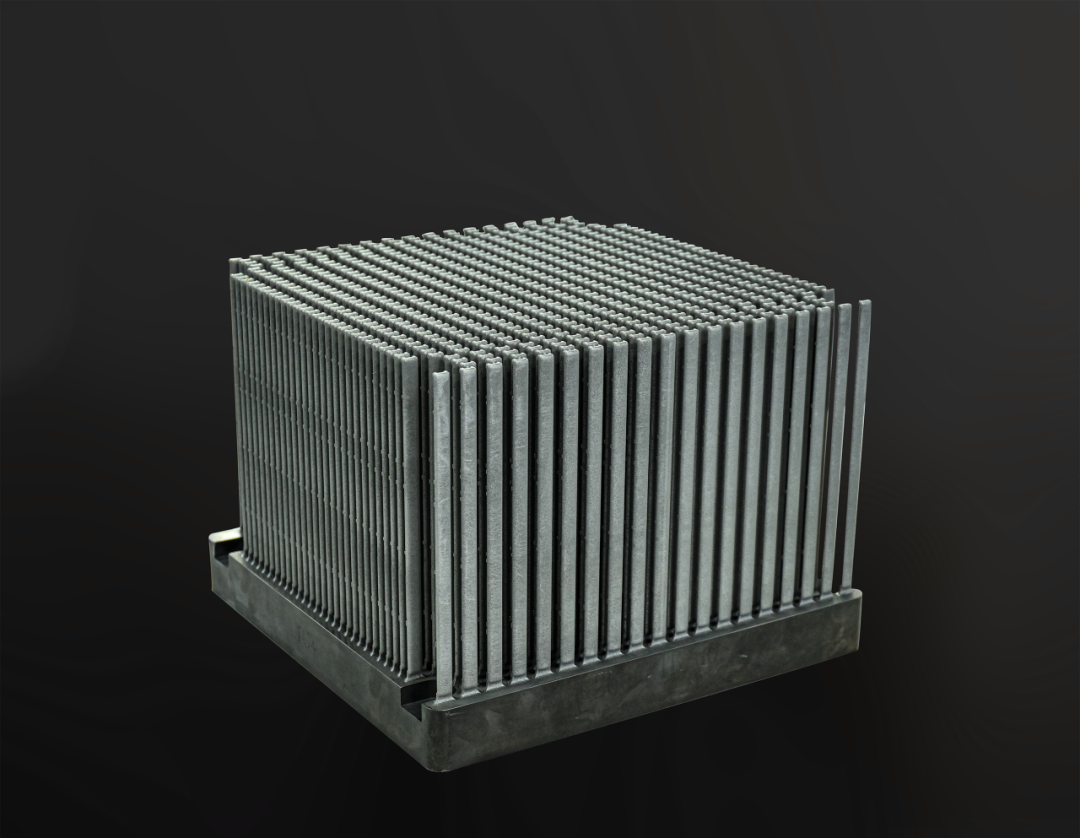

Mold Blank and Internal Waterway Showcase

Mold Size: 344mm×204mm×85mm

Forming Material: Stainless Steel

This mold blank is produced using large-format printing of the LiM-X400M series devices, featuring rich internal channels and complex structures, effectively reducing production difficulty and significantly enhancing production efficiency.

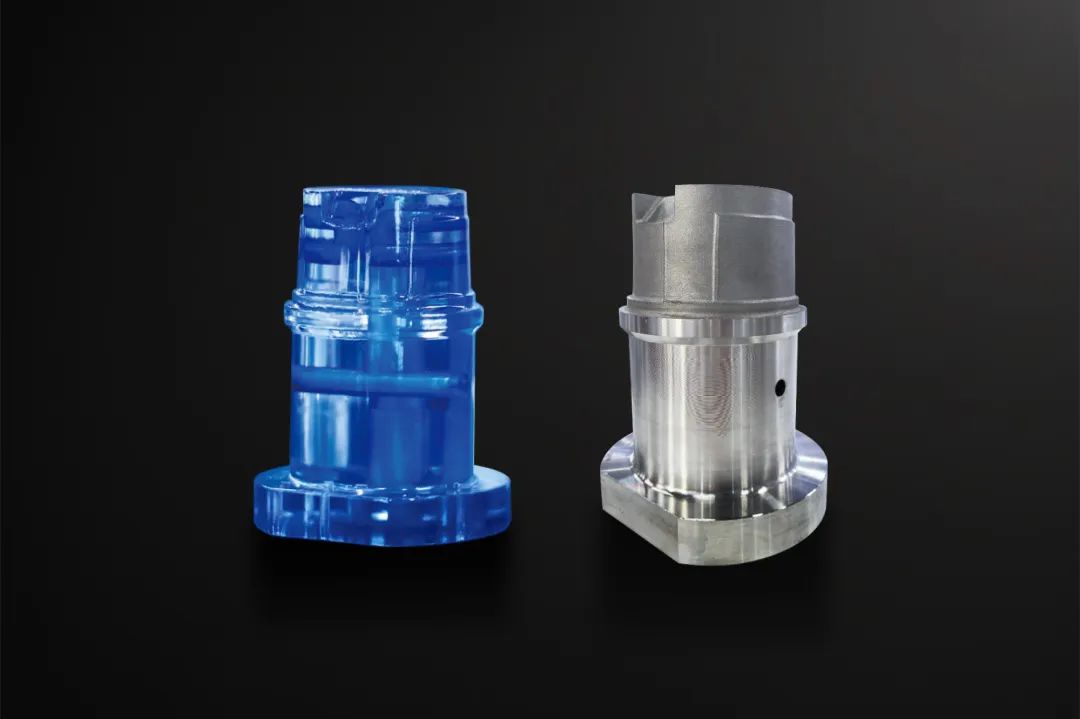

Grafted Waterway Molds

In the practical application of mold manufacturing, various factors such as technology, cost, and efficiency are often considered, adopting a method of combining additive manufacturing with traditional subtractive processing to produce special structural components, known as grafted printing. This method is mainly used to separately form the shaped cooling parts of mold inserts on the machining surfaces of traditionally machined parts, which helps reduce internal stress, avoid deformation and cracking risks, and complete the production of complex waterway molds at lower costs and faster efficiency.

Showcase of Grafted Waterway Molds and Internal Channels

However, during the forming process, it is essential to achieve effective fusion between different components and different metal materials while efficiently and accurately completing the position deviation calculations for the shaped cooling parts and grafted bases, which requires high technical demands. Rayming Laser’s automatic grafting technology, based on “machine vision,” achieves high-precision calibration of grafting forming, with positioning accuracy reaching ±0.1mm, ensuring stable and efficient grafted printing.

Small Batch Production Applications

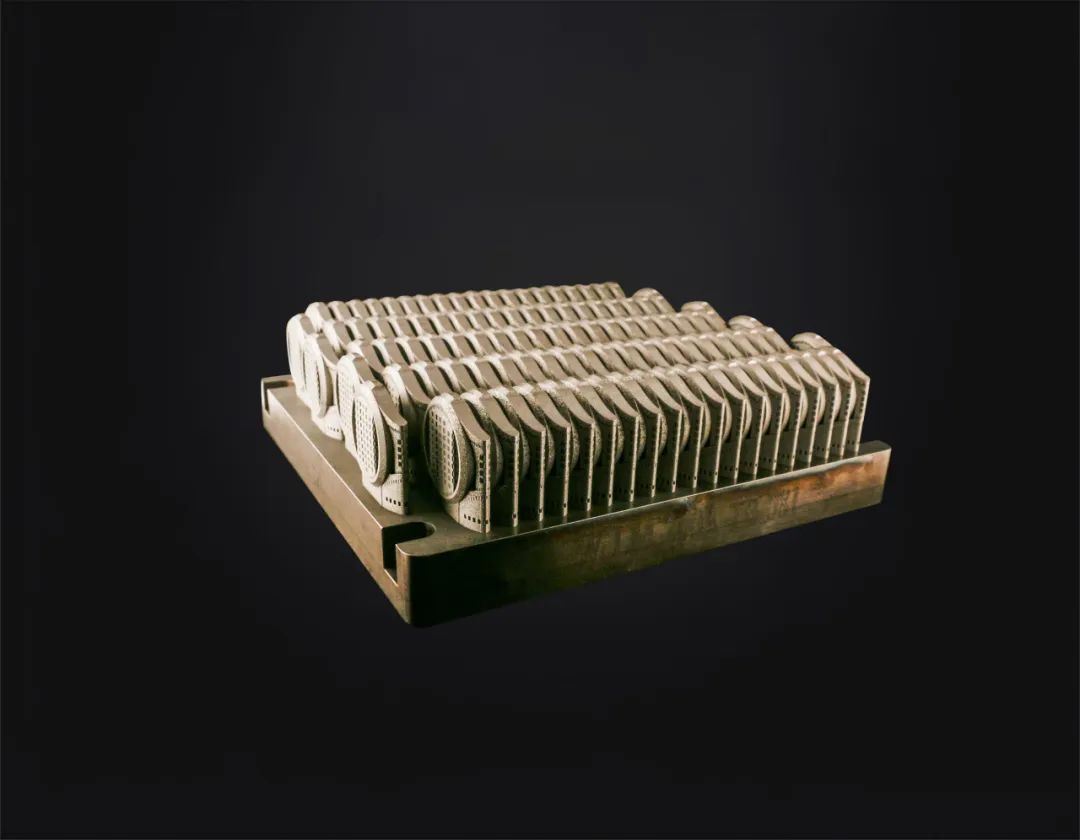

In the 3C electronics field, Rayming Laser’s LiM-X400M series devices, with their high quality, high efficiency, and high precision forming capabilities, achieve batch production of precision components such as watch frames, hinges, and phone frames.

Full-plate printing of titanium alloy watch frames

Full-plate printing of phone hinges

Development never stops, and innovation continues. Rayming Laser always adheres to application-driven and market-oriented approaches, exploring rich application scenarios around the needs of various fields, and proactively laying out future industries, providing more users with high-quality and efficient comprehensive solutions for metal 3D printing, assisting users in transformation and upgrading.