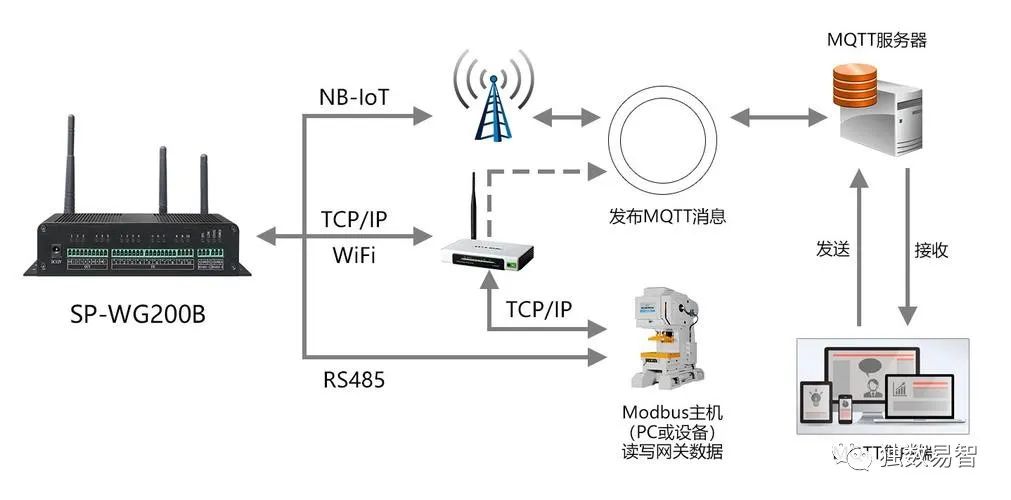

The IoT gateway, also known as the Internet of Things gateway, is a network device responsible for connecting and controlling various devices within an IoT system, linking them to the cloud, local servers, or other devices. It can facilitate both wide-area and local interconnections, enabling interoperability and data exchange between different types of sensing networks through protocol conversion.The IoT gateway features a variety of interface types, making it easy to connect various devices, such as network ports, USB interfaces, terminal forms like RS485 and RS232, digital input (DI), relay outputs, etc. It also incorporates multiple common protocols to meet the data interconnection and transmission needs of various devices.Additionally, the IoT gateway has device management capabilities, allowing operators to manage the underlying sensing nodes through the IoT gateway device, understand relevant information about each node, and achieve remote control. The IoT gateway enables interoperability and data exchange among various devices in the IoT system, enhancing the intelligence and efficiency of devices, making it a crucial component of IoT systems.

Current types and performance of IoT gateways used in manufacturing:

-

Access Capability: IoT gateways used in manufacturing typically need to support simultaneous access to multiple platforms, such as local HMI displays, SCADA configuration software, and upper management software like OPC UA’s MES systems. They should also be capable of connecting to multiple MQTT protocol industrial IoT cloud platforms, such as Alibaba Cloud, Huawei Cloud, Thingsboard, Thingworx, Sparkplug B, AWS, etc.

-

Multi-Protocol Integration and Conversion: IoT gateways used in manufacturing usually require multi-protocol integration and conversion capabilities, allowing a single device to convert multiple industrial protocols simultaneously, achieving true system integration and simplification. For example, collecting data from different brands of PLCs and converting data from Modbus RTU and Modbus TCP protocols into MQTT, OPC UA, and other protocols.

-

Data Security Protection: IoT gateways used in manufacturing typically need to ensure data transmission security, supporting encryption measures such as OPENVPN, SSL, and TLS to ensure data is secure and reliable.

-

Data Storage and Recovery: IoT gateways used in manufacturing often need to have data storage and recovery capabilities, including breakpoint resume functionality.

Moreover, there are specific types of IoT gateways applied in manufacturing for different types of industrial equipment, such as dedicated gateways for machine tools and robots. These gateways can collect data on the operational status and fault information of the equipment and transmit this data to cloud platforms or local servers for data analysis and processing.

At the same time, some high-end IoT gateways possess more powerful data processing and management capabilities, such as supporting large-scale device access and management, handling more data and more complex business logic, providing better support for the digital transformation of manufacturing. There are many types of IoT gateways used in manufacturing, each with varying performance, requiring selection based on specific application scenarios and needs.

Comparison of Software Gateways and Hardware Gateways: The main differences lie in functionality, performance, and reliability.

-

Functionality: A software gateway is a software program running on a computer that processes and forwards network data packets to enable communication between different networks. In contrast, a hardware gateway is a physical device typically used to connect different types of networks, such as linking a local area network to the internet.

-

Performance: Hardware gateways are generally faster than software gateways because they use dedicated hardware accelerators to perform network operations. However, with the continuous development of software technology, modern software gateways can also provide performance comparable to that of hardware gateways.

-

Reliability: Hardware gateways are usually more reliable than software gateways because they lack operating systems and other software components that may cause failures and crashes. However, software gateways can enhance reliability through backup and redundancy mechanisms.

-

Cost: Software gateways do not require dedicated hardware devices and can run on existing hardware, significantly reducing costs. In contrast, hardware gateways require the purchase of specialized hardware devices, which can be relatively expensive.

-

Scalability and Flexibility: Software gateways offer higher scalability and flexibility because they can run on general-purpose computers and can be updated to expand their functionality at any time. In contrast, the functionality of hardware gateways is typically fixed within the device, making scalability relatively poor.