PLC communication is a very important part of the automation control field, enabling information transmission and interaction between different devices to work together, improving the efficiency and intelligence of automated production systems. Below we will discuss common PLC communication protocols and methods:

01

PLC communication protocols are standards used to specify and describe the communication protocols and data formats between PLC devices. Different PLC communication protocols support various communication methods and data exchange methods. The following are some common PLC communication protocols.

1. MODBUS

MODBUS is an application layer protocol used for serial communication. It can run on serial communication methods such as RS-232 and RS-485, as well as on Ethernet. The MODBUS protocol has a simple structure, is easy to implement, and supports point-to-point and multipoint communication.MODBUS is widely used in the industrial control field, enabling communication between PLCs and communication between PLCs and host computers.

2. Profibus

Profibus is a communication protocol based on fieldbus technology, widely used in automation control systems. The Profibus protocol can run on media such as RS-485 and fiber optics, supporting high-speed communication with a maximum speed of 12Mbps.Profibus supports various data formats and communication methods, enabling communication between PLCs, PLCs and I/O devices, and PLCs and host computers.

3. Ethernet/IP

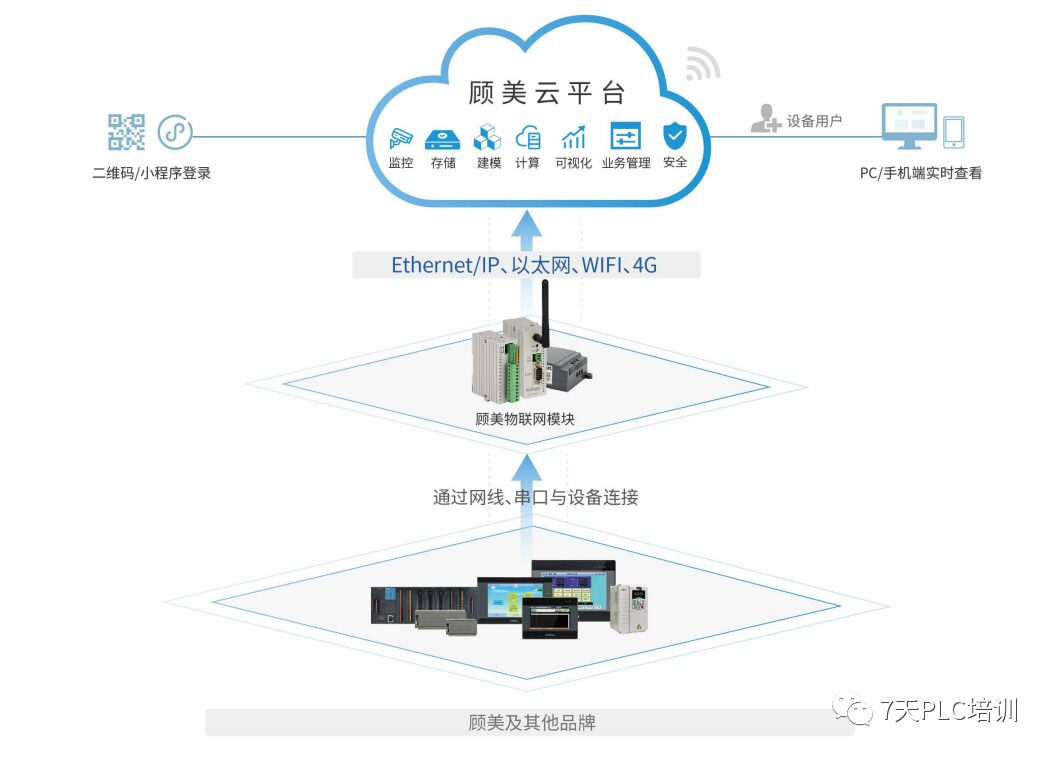

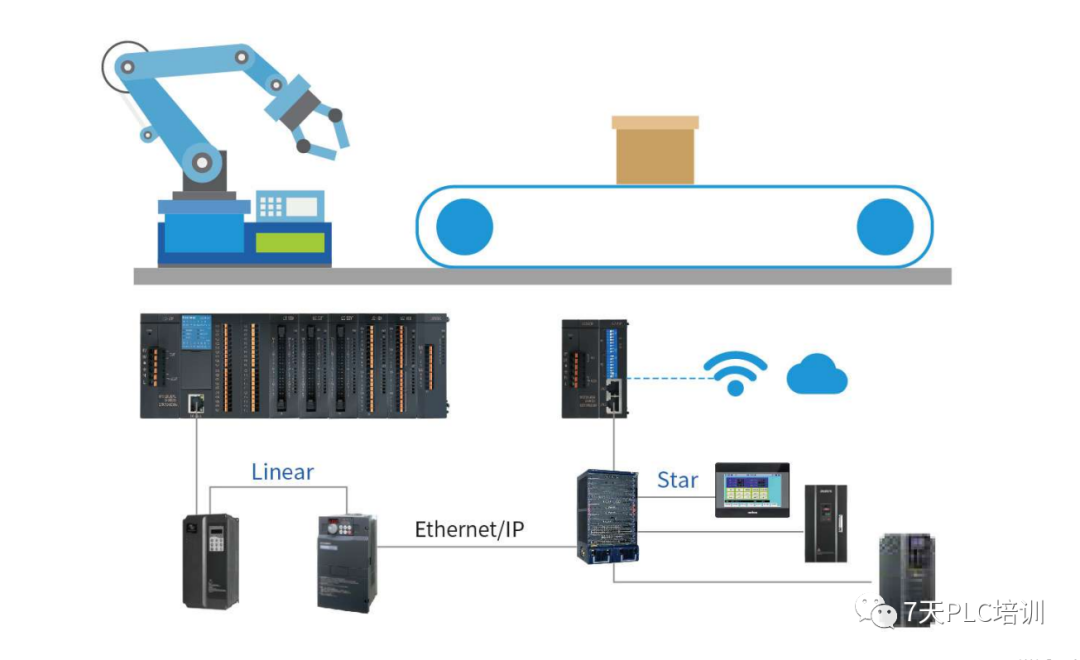

Ethernet/IP is an Ethernet communication protocol used in industrial control and automation fields. The Ethernet/IP protocol is based on TCP/IP, supporting high-speed and real-time communication.Ethernet/IP allows communication between PLCs, between PLCs and host computers, and between PLCs and other Ethernet devices.

4. CAN Protocol

CAN is a common controller area network protocol used for data exchange in control systems. The CAN protocol specifies the data format and communication protocol for communication between PLC devices, including data frame format, data types, register addresses, etc.CAN supports various communication methods, such as CAN bus and CANopen.

PLC communication methods refer to the physical connection methods used for communication between PLC devices. The different communication methods can affect communication speed, distance, stability, etc.:

1. Serial Communication

Serial communication is a PLC communication method based on serial communication, commonly used serial ports include RS232 and RS485.Serial communication is relatively slow, but the communication distance is short, suitable for applications that require point-to-point communication.

2. Ethernet Communication

Ethernet communication is a PLC communication method based on Ethernet, which has fast communication speed and long distance, suitable for applications requiring multipoint communication. Ethernet communication also supports TCP/IP protocol, enabling remote access and control.

3. CAN Bus Communication

CAN bus communication is a PLC communication method based on the CAN protocol, with a relatively fast communication speed and long distance, suitable for applications requiring multipoint communication and real-time control. CAN bus communication also supports hot-swappable nodes, making system maintenance and upgrades convenient.

4. Fiber Optic Communication

Fiber optic communication is a PLC communication method based on fiber optic transmission, with fast communication speed, long distance, and high stability, suitable for applications requiring long-distance communication and strong anti-interference capabilities. Fiber optic communication can also be extended through fiber optic switches.

5. Hardware Communication

Hardware communication is a PLC communication method based on PLC hardware interfaces, with fast communication speed and short distance, suitable for applications requiring high-speed real-time control. Hardware communication also supports hot-swappable nodes, making system maintenance and upgrades convenient.

Data communication in PLC learning is considered a relatively advanced application and can be somewhat challenging for beginners. Many friends feel overwhelmed when they first encounter communication and want to learn but don’t know where to start.

In fact, PLC data communication is not as difficult to learn as many think, as long as you understand the basic principles of communication, you can easily learn it! Scan the QR code below to join the 7-day PLC study group, and discover more PLC knowledge waiting for you!