Industrial computers (Industrial PCs) and tablets have continuously evolved, providing users with significant benefits in production capacity, usability, and diagnostic accuracy. The shift from wired controls, which rely on operator knobs and buttons, to wireless Ethernet touchscreen equipment is underway. These devices have developed in parallel with wireless devices in the personal consumer space, from smartphones to tablets, ensuring similar appearances and user experiences in areas such as intuitive feel and gesture-based graphical user interface browsing performance, making them usable on every device.

These innovations naturally expand the performance, operating range, and versatility of Industrial PCs. They also enhance robustness and user-friendliness for operators of varying experience levels. In certain designs, consistency must be maintained throughout the system’s lifecycle—attributes such as smaller form factors and low power consumption are always important.

Other demands are relatively new, stemming from the increasing requirements for device reliability, evolving communication standards and protocols, as well as emerging security considerations and the “app store” ecosystem and economic factors, all of which are changing how systems are customized.

Graphics Processing, Form Factor, and Power Consumption

One of the most valuable technological advancements in recent years has been high-performance graphics processing capabilities, including high-definition image resolution, video playback, and 3D graphics (which can use 360-degree visualization in high-precision applications).

In recent years, at the craft platform level, these graphics capabilities have generally been driven by various combinations of CPU and Graphics Processing Unit (GPU) chipsets, graphics cards, and input/output (I/O) controllers, but this can lead to oversized systems. As System-on-Chip (SoC) embedded processors have developed in design, the complexity of these processing platforms has gradually decreased, and system sizes have significantly reduced. The SoC processor architecture integrates low-power CPU, GPU, and I/O controller hubs, providing an integrated processing platform that not only saves system space but also reduces the number of motherboard layers and power consumption requirements.

The single-chip SoC structure is advantageous for applications requiring 3D graphics and video rendering. With SoC, the onboard CPU and GPU can share system memory resources, making it easier to switch workloads between the CPU and GPU, allocating the most suitable computing elements for high-speed multimedia processing. Thus, a more streamlined system can achieve more powerful processing capabilities, and due to its smaller size, it is easier to layout and use, saving precious space, further facilitated by popular handheld tablets, providing more convenience for mobility on-site.

Energy efficiency is a very important characteristic for any computing device. The energy efficiency of battery-powered portable devices is often much more precise than that of directly powered, fixed installations. This is particularly true for industrial tablets configured with high-performance graphics processing.

Low-power, high-performance SoC processors operate at 15W or less, helping to reduce the power consumption of industrial tablets and enhance the performance/power ratio, allowing for smaller batteries (which further reduces system size) while extending the operational time of on-site devices.

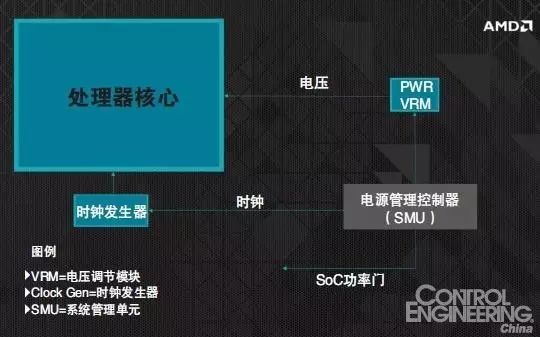

The reduction in power consumption also brings benefits in energy efficiency, allowing processor-level power consumption to vary in real-time with processing speed. Based on processor load, automatic triggering of limiting functions can reduce power consumption in standby gaps, with power consumption increasing only when higher performance and responsiveness are needed. This can improve energy efficiency, making “on-demand performance” possible.

Considering the evolving network systems in harsh environments like production workshops, it is very valuable for Industrial PCs and tablets to have the ability to adjust power consumption based on performance, especially when operating in higher ambient temperatures (a common scenario). Industrial PCs and tablets based on SoC processing platforms can utilize configurable thermal design features. A design with a thermal capacity of 15W can be adjusted to 10W, allowing it to maintain appropriate power loads and thermal thresholds even in high-temperature operating environments.

■ High-performance graphics processing, advanced embedded processors, and evolving performance demands are improving the appearance, user experience, and functionality of Industrial PCs. Image source: Advantech

■ High-performance graphics processing, advanced embedded processors, and evolving performance demands are improving the appearance, user experience, and functionality of Industrial PCs. Image source: Advantech

Cooling and Reinforcement

Low power consumption and low heat dissipation are critical factors in system cooling. If designed properly, industrial PCs and tablets can operate without fans. The absence of mechanical fans in the system offers numerous benefits, including significantly reducing the overall system size, ensuring high reliability, making operations quieter, and decreasing the likelihood of impact and vibration damage.

Fanless industrial PCs and tablets can also be encapsulated, with housings without ventilation holes, allowing for higher reliability in harsh environments. System memory crash failures caused by shock, vibration, and extreme high temperatures can be eliminated through processor-level error correction codes that can locate and correct bit faults.

Considerations regarding processor-driven power, cooling, and reliability should be clearly defined at the outset of procurement for industrial PCs and tablets, including performance requirements from low-end to high-end, and whether the product line’s scalability supports a wide range of environmental temperatures, etc.

Looking Ahead: The Operating System Revolution

The connectivity of interfaces, security, and the continuous development of wireless systems provide new opportunities for industrial PC systems. Customers expect industrial PC systems to accept new technologies and emerging communication protocols; no single industrial PC or tablet can encompass everything.

For such systems, adapting to multiple interconnection standards, peripheral device interconnections (PCIe), USB, Bluetooth, 3G, 4G, etc., is generally an advantage. Supporting flexible PCIe configurations is especially important, as it allows for the use of other industrial communication protocols and plugins. Applications of embedded processors that support 1×4 and 4×1 PCIe bus configurations are very popular in industrial PC systems.

Implementing wireless interconnectivity within industrial networks may introduce significant risks, such as intellectual property theft, tampering, viruses, and other unauthorized data breaches. Industrial PCs and tablets that utilize Trusted Platform Modules (TPM) can effectively guard against these attacks, ensuring secure authorized access and encryption of data in other protective measures. Security processors embedded in SoCs can support security measures, providing native TPM support and hardware-accelerated encryption capabilities, ensuring secure boot functionality to reduce software and hardware risks.

Perhaps the most important trend is the growing interest in the Android operating system. This transformation is still in the conceptual stage, but its potential benefits are worth exploring and discussing in the future.

Despite Microsoft Windows still dominating the existing industrial PC operating systems, Android represents an opportunity to reduce design and development costs, facilitate the application of app store methods to industrial PC software customization, and achieve functional specialization. By leveraging mainstream mobile operating systems, of course, through debugged and hardened commercial industrial computer applications, system integrators can recommend or choose the most suitable apps for industrial applications, allowing the final customer to implement customized solutions.

Customer customization at the hardware level is often required to be realized under this new model, especially for industrial PCs and tablets using special instruments. However, due to the software flexibility brought by the Android system, perhaps one day, upgrading new software tools and functionalities for industrial PCs and tablets could be as easy as installing applications on a mobile phone.