In this article, we will introduce how CERN (European Organization for Nuclear Research) investigates and monitors CANopen data on critical systems with minimal software configuration and intervention, thereby assisting technicians in fault analysis and diagnosis.

CERN Case Study ✦

Case Study

CERN (European Organization for Nuclear Research) operates the world’s largest particle physics laboratory. ATLAS is the largest general-purpose particle detector experiment in the Large Hadron Collider (LHC).

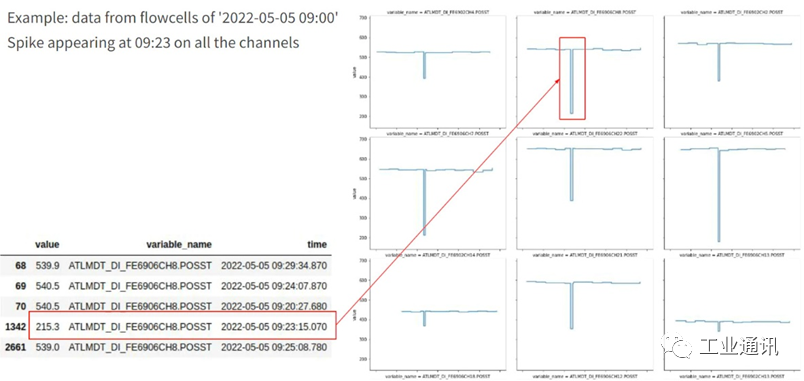

In the CERN LHC experiment, there are multiple gas detectors, each equipped with a “gas control system” (about 30 in total) responsible for providing the correct gas mixture to the detectors. During the experiment, technicians observed spikes in the flow of gas delivered to the detector through a single channel.

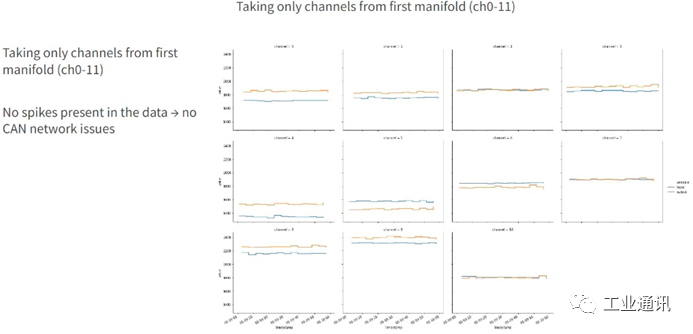

After excluding physical factors, CERN needed to find the root cause. The readings of the flowmeter (referred to as “flow pool” in this case) were obtained by allowing gas to flow through a channel equipped with PT100. By utilizing the thermal conductivity that varies with gas flow, we were able to calculate the actual flow through each channel. CERN used an Embedded Local Monitoring Board (ELMB) to read data, which is a multifunctional board providing digital/analog inputs and outputs, equipped with a CAN bus interface. Technicians wanted to confirm whether these spikes originated from the ELMB, such as due to a circuit board fault or firmware issue.

To do this, CERN needed a CAN recorder to sniff all messages passing through the CAN bus so that this data could be compared with archived data in our database.

HongKe CAN Recorder Solution ✦

HongKe Solution

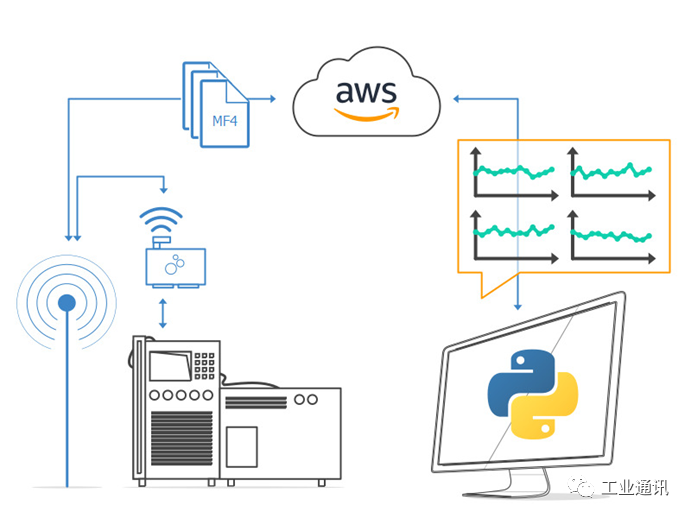

First, we set up an object storage service on CERN’s OpenStack infrastructure and specifically created an S3 bucket. Then, we configured a HongKe CANedge2 and connected it to CERN’s WiFi network so that it could directly upload data to the S3 bucket. Finally, we used the CANedge Python API to check the uploaded CANopen data and analyze the issues.