Get the latest tweets!

How to Integrate Embedded Systems?

A standard industrial camera is obviously too large, too expensive, and has too high power consumption. A board-level camera is a good choice, as this module retains the necessary parts for applications. For example, this module removes the packaging box because it can be directly integrated into the system you designed, saving space, cost, and power.

If your system requires a small size

We can use embedded processing platforms, such as SoC, which is the core electronic component of a computer, integrating GPU to perform vision tasks, while also integrating CPU, internal bus, interfaces, etc., all on one chip. Although the performance of SoC is not as good as that of PC processors, it can already meet many application scenarios.

If your system requires low cost

To ensure a low-cost design, SoC is directly soldered onto the PCB.

How does the camera module connect to the main processing board?

A major feature of embedded vision is its versatility. There are various optical devices, image sensors, and interfaces to accommodate many applications. Today, we will address one of the most critical choices you must make when building an embedded vision system: choosing the right interface.

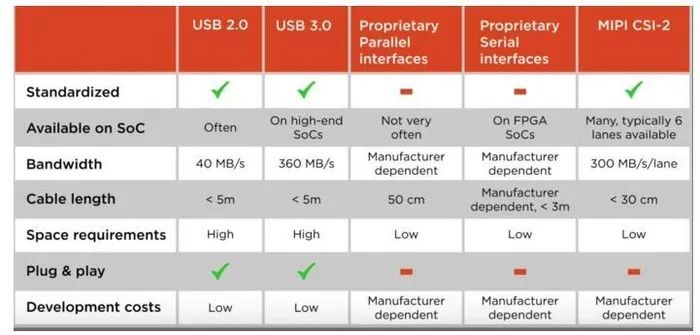

Camera modules have different interfaces, commonly using USB 2.0, USB 3.0, serial or parallel interfaces, MIPI CSI-2, each with its own advantages and disadvantages, detailed below. Each standard has its own price and performance trade-offs. Here, we discuss several commonly used interfaces.

Choosing Interfaces for Embedded Vision

MIPI CSI-2

MIPI CSI-2 (Mobile Industry Processor Interface) is the most widely used embedded vision interface. It was originally designed for mobile devices, and the MIPI camera working group updates it every two years. Other applications using it include head-mounted VR devices, IoT devices, and 3D facial recognition security systems. This is a proven technology that will continue to exist.

MIPI has four image data channels, each capable of reaching 1.5 Gb/s, totaling up to 6 Gb/s of high bandwidth, making it faster than USB 3.0. It is an efficient and reliable protocol that can handle 1080p video and can be used for 8K and above. Its low overhead provides higher net image bandwidth.

The third-generation technology, CSI-3, has already been developed.

CSI-2 can achieve low-power high-performance applications, making it the best choice for our automated lawn mower.

USB 2.0 is generally supported in SoC, meaning only a small amount of hardware requires a USB adapter. The downside is low bandwidth, only 40MB/s, which does not support high-speed, high-resolution scenarios.

USB 3.0

USB is currently the runner-up. USB 3.0 boosts the very common USB interface to 5 Gb/s. Since USB is plug-and-play, embedded vision devices with this interface can often be replaced instantly, making it easy to replace damaged devices.

Choosing USB 3.0 can save you the expensive and lengthy development time (and cost) of embedded vision interfaces. However, deploying USB 3.0 in tight spaces can be challenging. USB connectors are relatively large, and the standard rigid wiring is not ideal for some more compact embedded vision components.

Both USB 2.0 and USB 3.0 share a common point: they both require a large connector and inflexible cables, which may limit application scenarios. Moreover, only a few SoCs support USB 3.0.

Parallel interfaces connect camera modules to the mainboard via baseband lines. This module requires SoC with parallel video input (rare), with a maximum line length support of 50cm.

Serial interfaces are used to connect with FPGA. If the core of the embedded system is already FPGA, then a serial interface should be chosen. This camera module also communicates with FPGA through baseband lines, with some modules supporting 1m. Both parallel and serial interfaces require that the camera driver is already installed in the SoC.

The comparison of interfaces is as follows:

Recommended Articles:Clickto directly access related articles::

001: Research Resources and Journal/Conference Introductions in Computer Vision

002:German KUKA Robot vs. World Champion Table Tennis

003:120 Images Outline the Complete AI Industry Map!

004: Facebook Open Source Computer Vision System, Understanding Images at the Pixel Level (with Paper and Code)

005: Want to Become a Machine Learning Engineer? This Self-Study Guide is Worth Keeping

006: Eleven General Filtering Algorithms

007: Basics of Image Processing and Computer Vision, Classics and Recent Developments

008: In-Depth Report on the Robotics Industry (Full Version)

009: From Laundry Maid to Google Chief Scientist, She Changed the AI Field with Loneliness!

010:Industrial Grade Machine Vision Industry Research Report

011:Brief Introduction to the Principles of Dual-Centric Industrial Lenses

012: How to Equip an Academic iPad?

013: Overview of Machine Vision Systems

014: German Craftsmen: We Don’t Have “Value for Money” Products

015: Why is the Best Robotic Arm 7 Degrees of Freedom, Not 6?

016: The Most Powerful Technical Video Ever!

017: Comparison of the Top 10 Programming Languages in Robotics, Which One Do You Master?

018: Novel and Complex Mechanical Diagrams!

019: A Collection of Knowledge Related to Robot Control Systems 020: The Working Principles of Robots, the Most Detailed Analysis Ever!

021: Knowledge Points on Light Source Selection 022: This is a Mechanical Hand, This is Automation, What is Yours?023: Basic Knowledge of Cameras and Lenses024: Overview of the IoT Industry Chain (with 13 Major Electronic Industry Maps, Must Keep) 025: How Powerful is Japan? Breathless! Couldn’t Sleep After Watching 026: Germany’s Machinery Amazes the World: How Lonely is Invincibility