Automotive Hybrid Power

Fundamentals of Technology and Typical Products

Hybrid vehicles combine the advantages of internal combustion engines and electric motors, fully utilizing the strengths of both drive technologies. Compared to passenger cars based on a single drive technology, they exhibit greater flexibility and variability. The diverse hybrid power system architectures developed from different combinations of motors and engines each have their strengths, meeting the differentiated vehicle needs of various consumers and enriching the automotive powertrain technology routes.

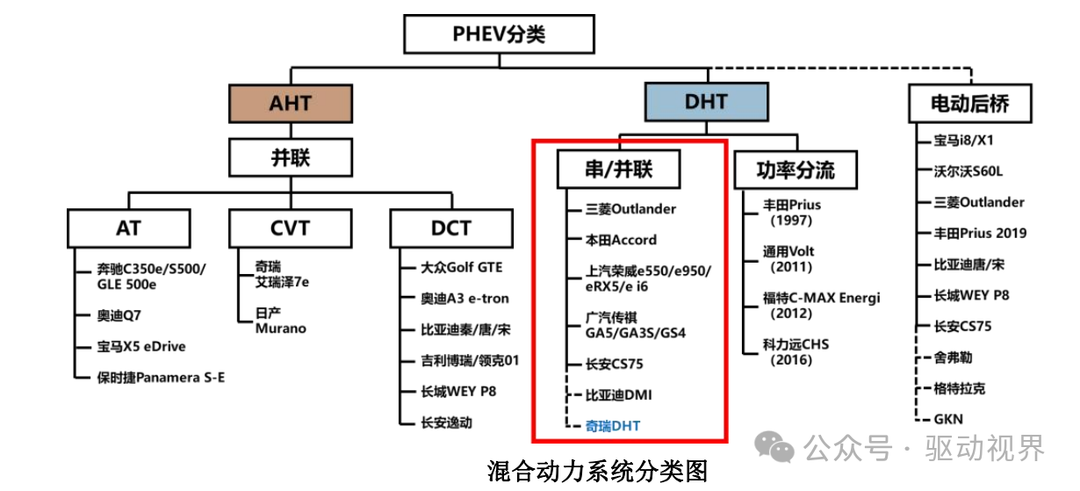

The hybrid power system architecture can be classified according to the oil-electric hybrid ratio and system architecture.

Classification of Hybridization

Based on the oil-electric hybrid ratio (degree of hybridization), hybrid vehicles can be divided into micro-hybrid, mild-hybrid, medium-hybrid, and strong-hybrid categories.

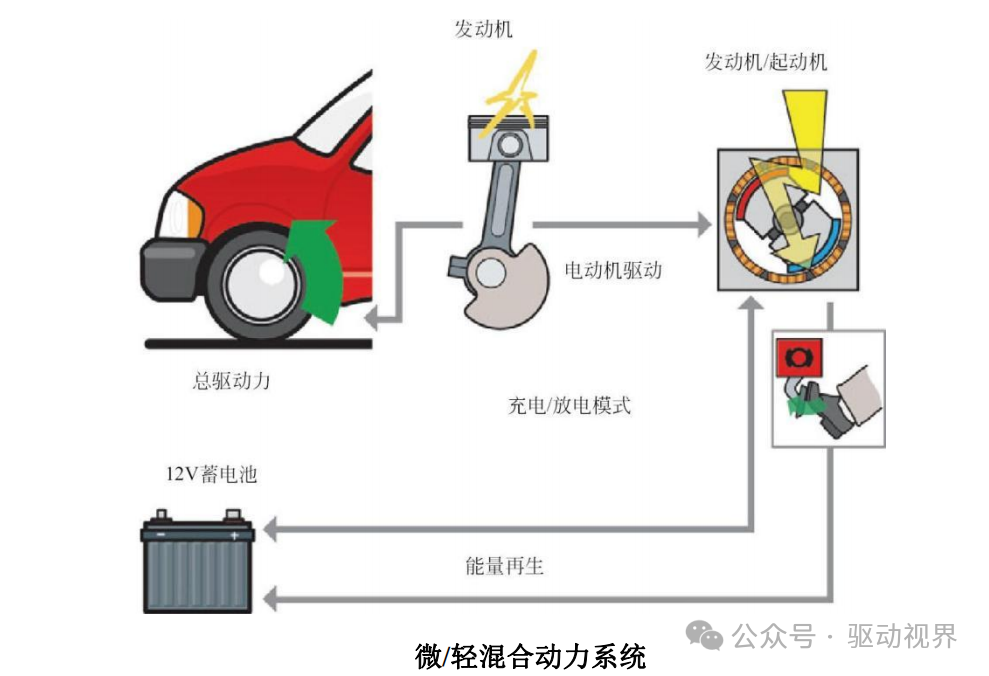

Micro-Hybrid

In traditional internal combustion engines, a belt-driven starter motor (Belt-alternator Starter Generator, BSG system) is added. This motor is an integrated generator/starter (Stop-Start) used to control the engine’s start and stop, thereby eliminating engine idling and reducing fuel consumption and emissions.

In micro-hybrid systems, the motor voltage is typically 12V or 42V (or 48V), with 42V motors mainly used in diesel hybrid systems.

Mild-Hybrid

Utilizes an Integrated Starter Generator (ISG system), with a hybridization degree below 20%, unable to drive the vehicle solely with the electric motor. Compared to micro-hybrid systems, mild-hybrid systems can not only control the engine’s start and stop with the generator but also recover some energy during deceleration and braking conditions. Additionally, the engine in mild-hybrid vehicles operates at a constant speed during driving, allowing the energy produced by the engine to be adjusted between the wheel drive demand and the generator’s charging demand.

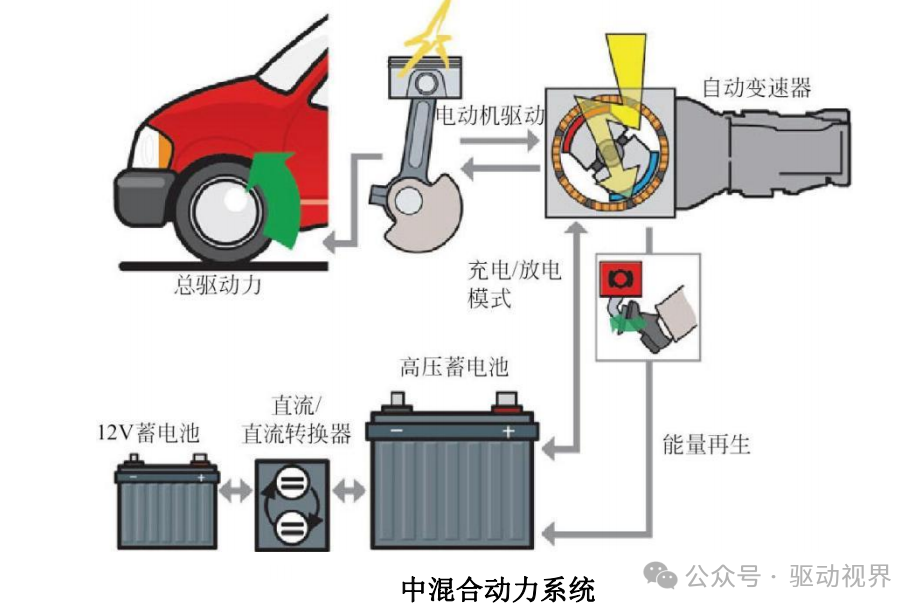

Medium-Hybrid

Also uses the ISG system, powered by a fuel engine, with the electric motor serving only as an auxiliary. However, with a hybridization degree reaching 30%, under specific conditions such as low-speed cruising, the medium-hybrid system can drive the vehicle solely with the electric motor.

In medium-hybrid systems, the electric motor can assist in driving the wheels, allowing the engine to start within its optimal efficiency range, supplementing the engine’s power output during acceleration or heavy load conditions, thereby improving overall vehicle performance.

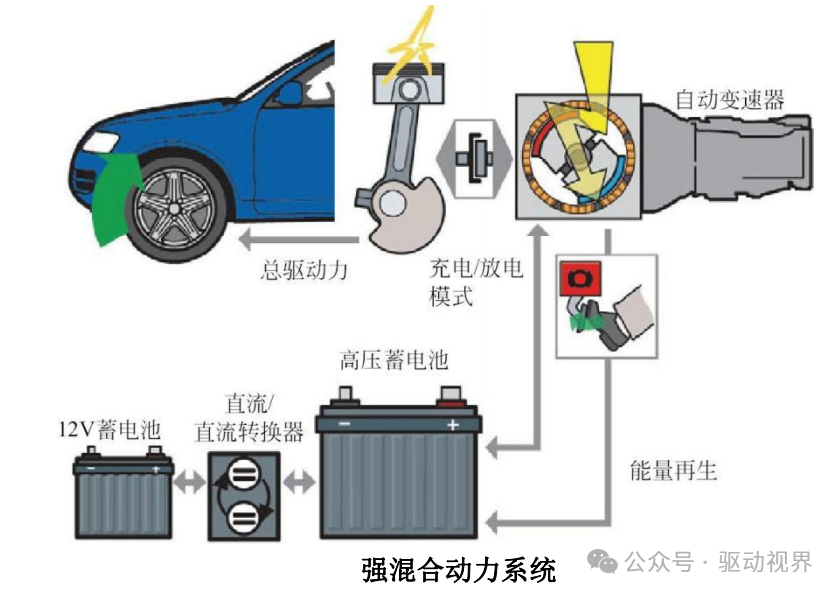

Strong-Hybrid

Utilizes a high-voltage starter motor ranging from 272 to 650V combined with the engine, with a hybridization degree exceeding 50%.

In strong-hybrid systems, both the engine and electric motor can independently drive the vehicle, enabling pure electric driving. The engine features an automatic start-stop function, and the clutch between the engine and motor can disconnect the connection between the two drive systems, allowing the engine to engage only when needed.

Plug-in hybrid electric vehicles (PHEVs) are an important branch of new energy vehicles, characterized by low fuel consumption similar to HEVs, achieving energy savings and emissions reductions compared to traditional fuel vehicles or non-plug-in HEVs. As shown in Figure 4-68, the carbon emissions of PHEVs are reduced by 80.9% compared to traditional gasoline vehicles and by 73.9% compared to HEVs. In the price range of 100,000 to 300,000 yuan, PHEVs have no mileage anxiety, can run on both electricity and fuel, can use electricity for short distances and fuel for long distances, are priced similarly to fuel vehicles, have low fuel consumption, and provide a pure electric driving experience, which aligns well with domestic consumer usage scenarios.

Hybrid System Architecture

Currently, strong hybrid systems are the mainstream direction for automakers developing hybrid models. Based on the hybrid system architecture model, strong hybrid systems can be further divided into series, parallel, and series-parallel types.

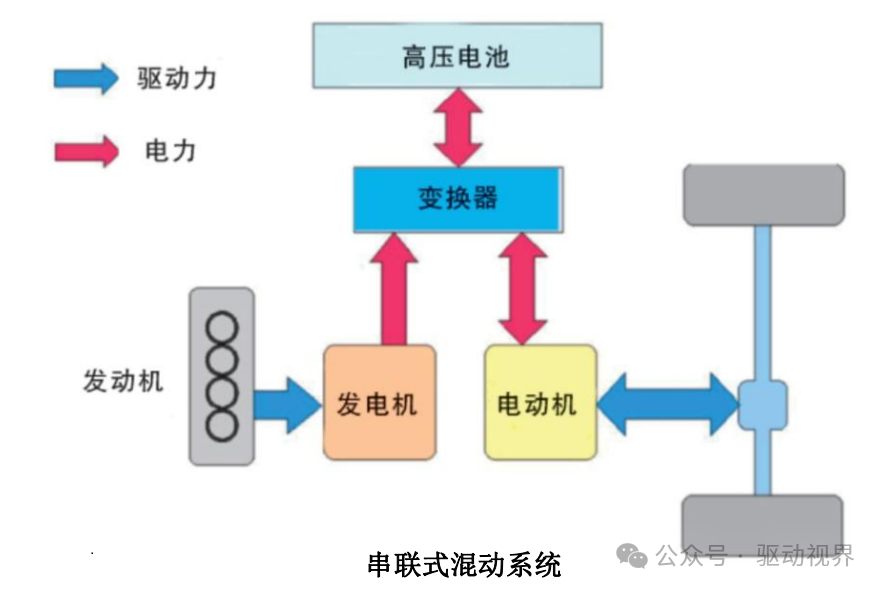

Series Hybrid

Series hybrid vehicles are driven by electric motors, with the fuel engine only driving the generator to charge the power battery, which supplies power to the electric motor.

Range-Extended Electric Vehicles (REEVs) are a type of series hybrid vehicle that adds a range extender to pure electric vehicles, coupling the engine and generator while decoupling from the wheels. When the power battery is sufficiently charged, it can operate as a pure electric vehicle, and the engine only engages when the power battery is low.

In series hybrid systems, the vehicle is driven by the electric motor, and the engine is only used for generating power without driving the vehicle. The advantage is that the vehicle’s power delivery is smoother, and NVH performance is better, with lower power requirements for the engine. The engine can always operate within its optimal working range, and low-speed energy consumption is better than that of comparable fuel vehicles.

However, since the engine does not directly drive the vehicle, the energy consumption during the processes of generating power, charging, and driving the motor consumes about 15% more energy, resulting in slightly higher fuel consumption at high speeds compared to similar fuel vehicles. Additionally, in low battery states, due to the lower power of the engine, the performance of series hybrid vehicles is relatively poor, and NVH at high speeds is also difficult to control.

Parallel Hybrid

In parallel hybrids, both the engine and electric motor can drive the vehicle together or separately, with three main operating modes:

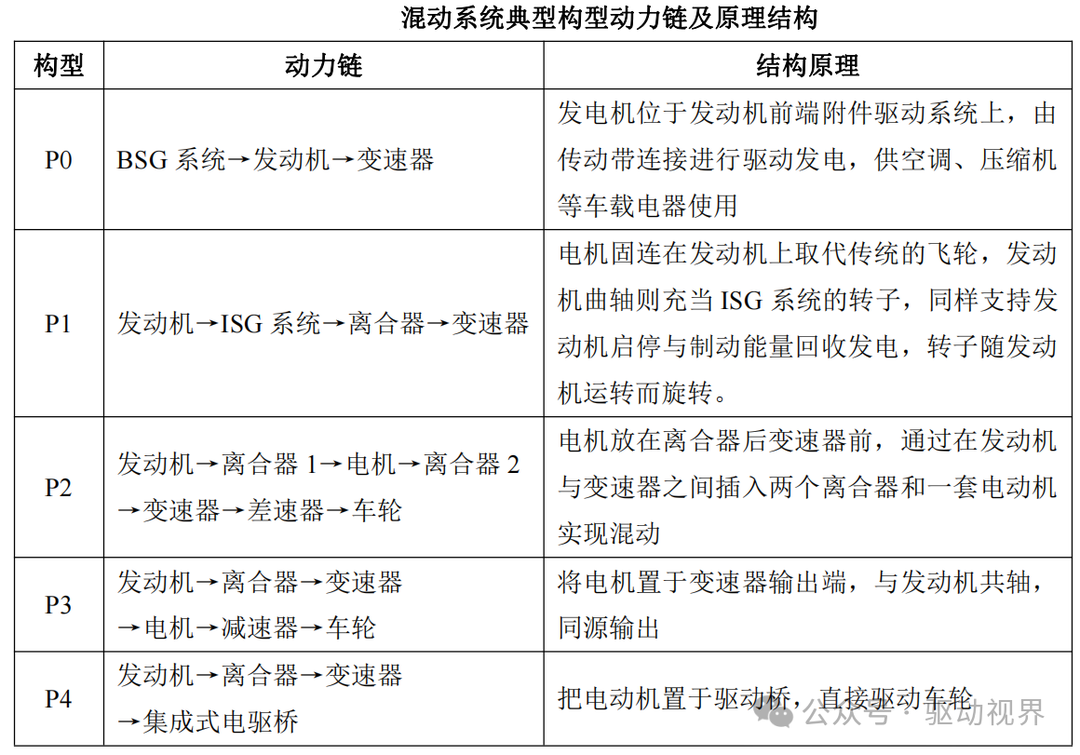

For single-motor parallel hybrid systems, they can be further subdivided into five configurations: P0, P1, P2, P3, and P4, based on the position of the motor relative to the traditional power system.

The advantage of parallel mode is that both the engine and motor can directly drive the vehicle, and multiple gear ratios can be used, resulting in good performance. In low-speed conditions, pure electric drive is used, while in mid-high speed conditions, the engine drives directly, ensuring that both the motor and engine operate within their optimal working ranges.

The disadvantage is that the transmission structure is complex and has many gears. Generally, parallel hybrid systems usually have 6-9 gears, thus requiring high demands on the transmission structure, making control more difficult.

Additionally, since there is only one motor in parallel hybrid systems, the engine can only coordinate with the transmission and cannot be used for generating power. In low battery states, it can only function as a fuel vehicle, and the weight of the battery and motor makes the energy consumption performance of parallel hybrid vehicles poor when the battery is depleted.

Series-Parallel Hybrid

Series-parallel hybrid vehicles combine the characteristics of both series and parallel hybrids, consisting of an engine, motor, and drive motor. Typically, based on the position of the engine and generator, they can be divided into series-parallel and power-split structures.

Series-parallel hybrid systems achieve torque coupling, combining the torque of the internal combustion engine and motor to transmit to the drive wheels. The torque of the internal combustion engine and motor is independent, and the vehicle control unit calculates the distribution, with the speeds of both proportional to the vehicle speed.

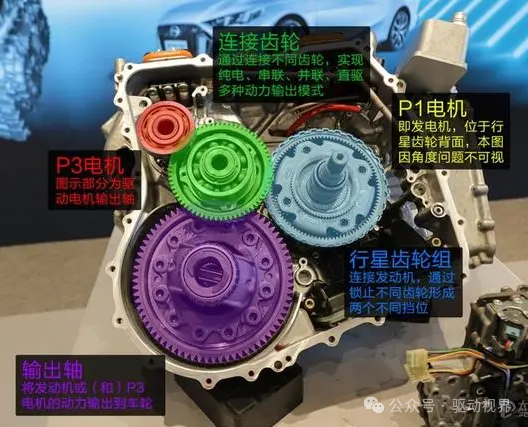

Series-parallel hybrids include architectures such as P1+P3, P0+P3, and P1+P3+P4, with the P1+P3 architecture being the most mainstream. In the P1+P3 hybrid system, P1 is the generator, and P3 is the drive motor. Figure 2-34 illustrates the series-parallel configuration.

The advantages of the P1+P3 architecture include a simple deceleration structure and high transmission efficiency. Additionally, the engine can be used for generating power without direct drive, allowing it to operate in a high-efficiency range. In low-speed conditions, pure electric drive can be achieved, providing a good driving experience.

However, the disadvantage of series-parallel hybrid systems is that the engine needs to reach a certain speed to engage in driving, limiting the vehicle’s performance. Furthermore, at high speeds, the engine must reach a certain power to engage in parallel, while in series mode, the long energy flow path and the characteristics of the motor can lead to higher fuel consumption. Additionally, multi-gear series-parallel structures increase system complexity, making smoothness and NVH control relatively difficult.

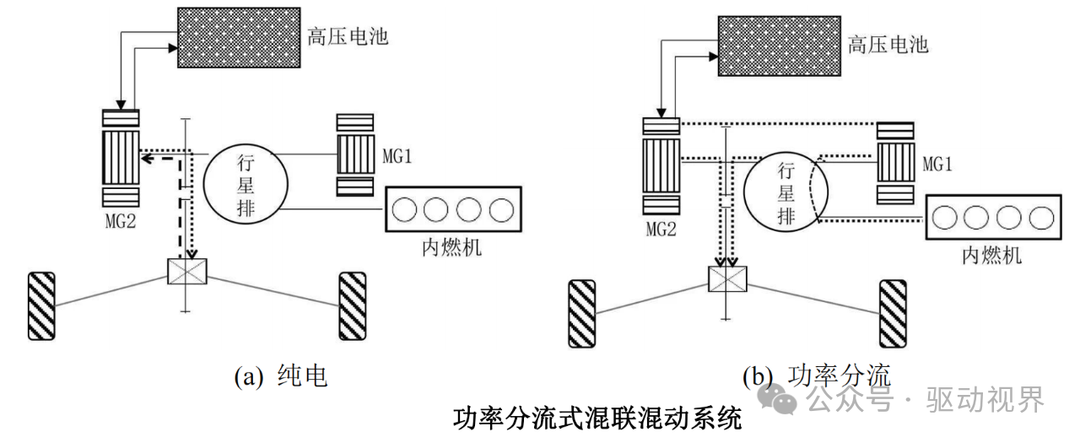

Power-Split

Power-split hybrid systems achieve power coupling, where the output torque and speed are linear algebraic sums of the internal combustion engine and motor’s torque and speed, allowing for free control of the engine’s torque and speed.

Power-split transmissions generally use planetary gear sets connected to the internal combustion engine and two motors. In power-split hybrid systems, MG1 is the generator, and MG2 is the drive motor. When the vehicle speed is low or at startup, the overall power demand is low, allowing for pure electric drive, where the MG2 motor directly drives the vehicle using the high-voltage battery, which is the pure electric mode. As the speed increases or during full throttle acceleration, if the power of the battery is insufficient to drive the vehicle, the internal combustion engine starts, utilizing the planetary gear set to achieve power splitting.

The PS architecture achieves smooth vehicle operation under various conditions by reasonably distributing the power output of the internal combustion engine and motor, thereby achieving fuel savings. Figure 2-35 illustrates the working modes of the power-split hybrid system.

Due to the need for precise matching of the coupling conditions between the motor and engine in power-split hybrid systems, along with Toyota’s patent protection, currently, only Toyota’s THS hybrid system employs this configuration. The advantages of this system are that the engine can operate solely for generating power without being affected by vehicle speed, maintaining operation in a high-efficiency range. Additionally, due to its use of continuously variable transmission, overall smoothness and comfort are good. However, the system’s deceleration mechanism is complex, making control difficult. Moreover, due to the high speeds of the engine and motor, NVH is poor. Additionally, vehicles using power-split mode tend to have relatively weak performance, making them unsuitable for B-class and above models.

BYD

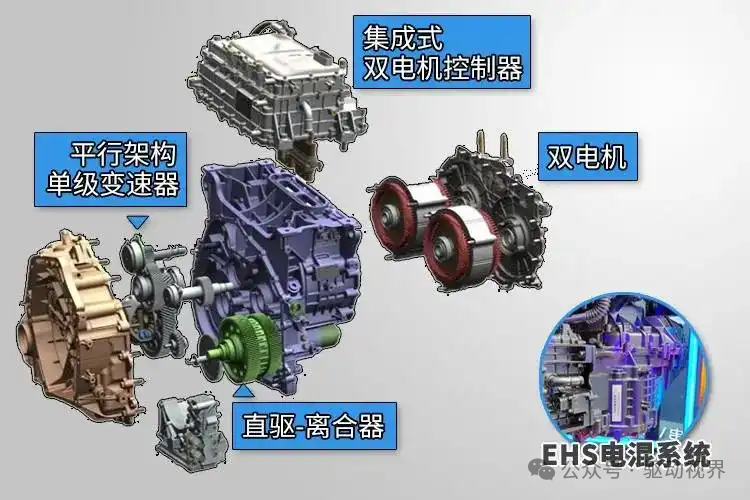

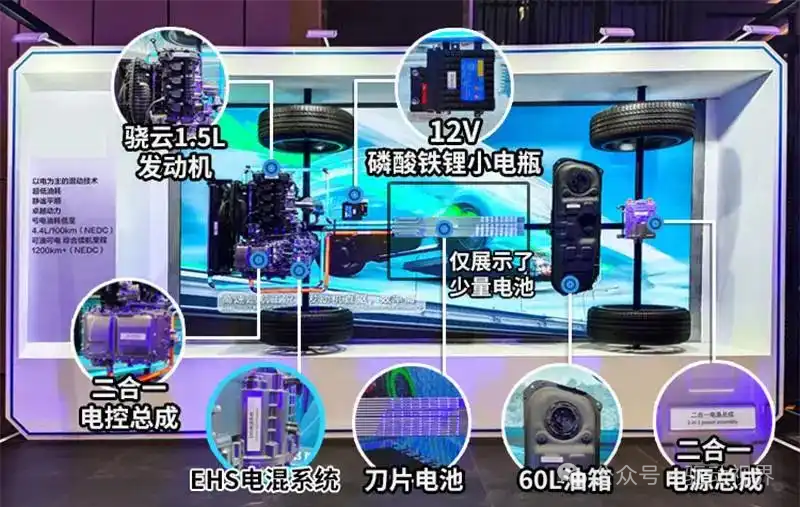

BYD’s DM-i power system and control system architecture include: dedicated high-efficiency engine, efficient EHS electric hybrid system, dedicated power-type blade battery, AC/DC charger, and other core components. The DM-i super hybrid system adopts a “strong electric hybrid” powertrain architecture, primarily driven by a large motor and powered by a large battery, with the engine mainly generating power and assisting in driving, achieving mechanical decoupling between the engine and wheels, allowing the engine to focus on high efficiency.

The power motor features a flat wire design, with a maximum speed of up to 16,000 RPM, peak power reaching 160 kW, and peak torque reaching 325 Nm;

The motor’s maximum efficiency reaches 97.5%, with an efficiency area exceeding 90% accounting for 90.3%; the reducer adopts a minimalist design, enhancing transmission efficiency; and the motor employs advanced oil cooling technology, significantly improving heat dissipation efficiency, thus increasing the motor’s power density to 44.3 kW/L. Meanwhile, the electronic control system is also equipped with BYD’s independently developed fourth-generation IGBT technology, achieving an overall electronic control efficiency of 98.9%. Through intelligent power distribution among the engine, generator, and drive motor, the DM-i super hybrid system can operate more frequently within the high-efficiency range.

In low-speed conditions, EV and series modes switch intelligently, resulting in low fuel consumption; in mid-high speed cruising conditions, the engine drives directly in parallel, with the drive motor intelligently compensating, resulting in a short energy transfer path and high efficiency. This achieves precise energy flow management, ensuring a balance between performance and economy under various conditions.

Models equipped with the DM-i super hybrid system can operate as pure electric vehicles when the battery is sufficiently charged, featuring the quietness, smoothness, and zero fuel consumption typical of pure electric vehicles. When the charging power is depleted, they function as ultra-low fuel consumption hybrid vehicles. Under NEDC conditions, when the battery is depleted, in urban conditions, the electric motor’s series drive accounts for 18%, while the power generated by the engine can still support 70% of the EV ratio; under WLTC conditions, when the battery is depleted, the series drive accounts for 28%, and the power generated by the engine can achieve a 54% EV ratio. In high-speed steady-state conditions with depleted battery, the engine operates primarily in parallel drive within the high-efficiency range; during acceleration and deceleration, the system switches to series drive, ensuring the engine operates more frequently within the high-efficiency range.

Geely

In terms of hybrid power applications, Geely launched the P1+P2 dual-motor multi-gear hybrid system in 2021, including a hybrid-specific transmission DHT-Pro and a series of hybrid-specific engines, known as the Thor hybrid system. The original intention of developing the Thor hybrid system is to leverage the advantages of electric vehicles and compensate for their shortcomings from the perspective of end customers.

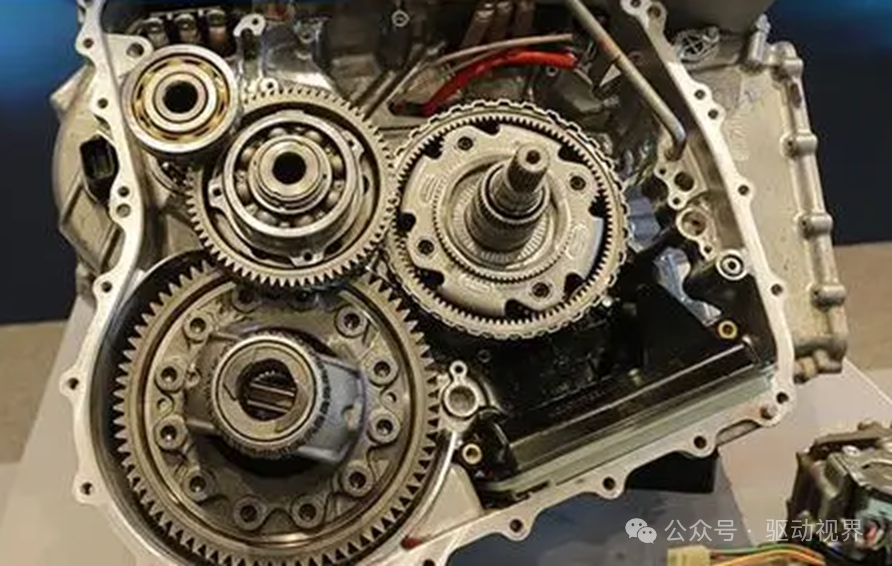

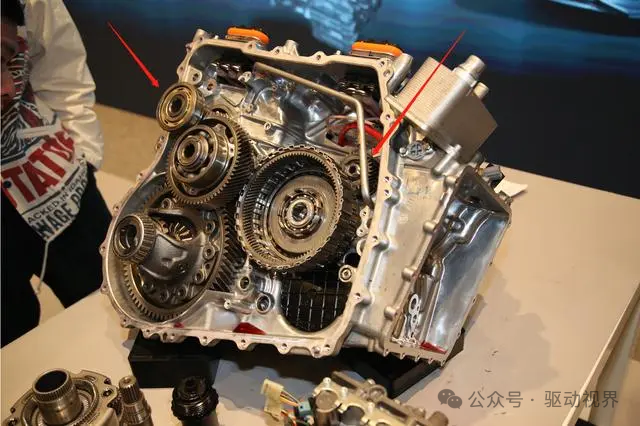

The transmission is the core of the hybrid system and the most critical part. Geely’s Thor hybrid transmission DHT-Pro adopts a dual planetary gear + dual-clutch + dual-brake + P1 + P2 dual-motor configuration, based on the characteristics of planetary gear sets with multiple transmission paths, compact structure, and good smoothness, employing a multi-gear layered coaxial nested design:

1) P1 and P2 motors are coaxially embedded within the transmission housing;

2) The rotors of P1 and P2 motors integrate C0/C3 dual-clutch and dual planetary gear sets, with brakes B1/B2 located between the two motors;

3) The clutch, brake, and gear shaft gear sets are three-axis concentric coupled, with lubrication and control oil channels within the shaft for executing clutching, shifting, and torque transmission;

4) Dual inverters, dual MCUs, and TCU are integrated with the transmission body.

DHT-Pro can achieve 3 electric drive gears + 3 engine gears, with a maximum wheel-side torque output of 4920 Nm, weighing only 120 kg, and an axial length of 354 mm, making it the smallest and highest torque output hybrid-specific transmission in its class.

Dongfeng

In 2021, Dongfeng Company launched its own passenger car power brand—Mach Power, covering the fields of fuel, hybrid, and electric power, including the energy-saving power platform Mach G, hybrid power platform Mach MHD, and pure electric drive platform Mach E.

The Mach Power MHD hybrid system also has two major systems for hybrid electric drive, one being a high-power HD system and the other a high-performance 4HD system. The high-power HD system is characterized by a large motor power, suitable for long-range PHEVs, where most of the time is spent using electricity. Therefore, to meet customer needs and provide a good pure electric driving experience, it is designed to satisfy customer driving preferences.

The high-performance 4HD system takes a different route, catering to HEV and PHEV models on the same platform. To meet future regulatory fuel consumption requirements for HEVs, it is necessary to introduce multi-gear configurations to satisfy HEV fuel consumption needs. Based on the overall vehicle requirements, product definitions, and engine power maps, extensive quantitative calculations were performed, resulting in the adoption of four gears. After introducing the four-gear system, the size of the motor can be appropriately reduced. For HEVs, since the engine’s engagement will far exceed that of plug-in hybrids, effectively utilizing HEVs reduces the motor’s power, size, and cost. Currently, the entire motor system, including the inverter, achieves an efficiency area of nearly 89%, with a maximum efficiency of nearly 95.6%.

Control technology has a significant impact on the overall vehicle performance. The more refined and better the control, the more fuel-saving effects can be achieved, resulting in a DHE+DHT, where 1+1>2. The Mach MHD hybrid system has all software/calibration under independent control, achieving integrated control of VECU and MTCU, based on the AUTOSAR architecture, marking the first integration of mass-produced ECU and VCU in the country, enabling faster and more precise control.

Chery

The hybrid DHT technology is one of Chery’s key development directions. Chery’s DHT combines all functional modes of both series and parallel, suitable for various actual driving scenarios of users. The multi-gear configuration of DHT can further enhance system efficiency, reducing motor power and size.

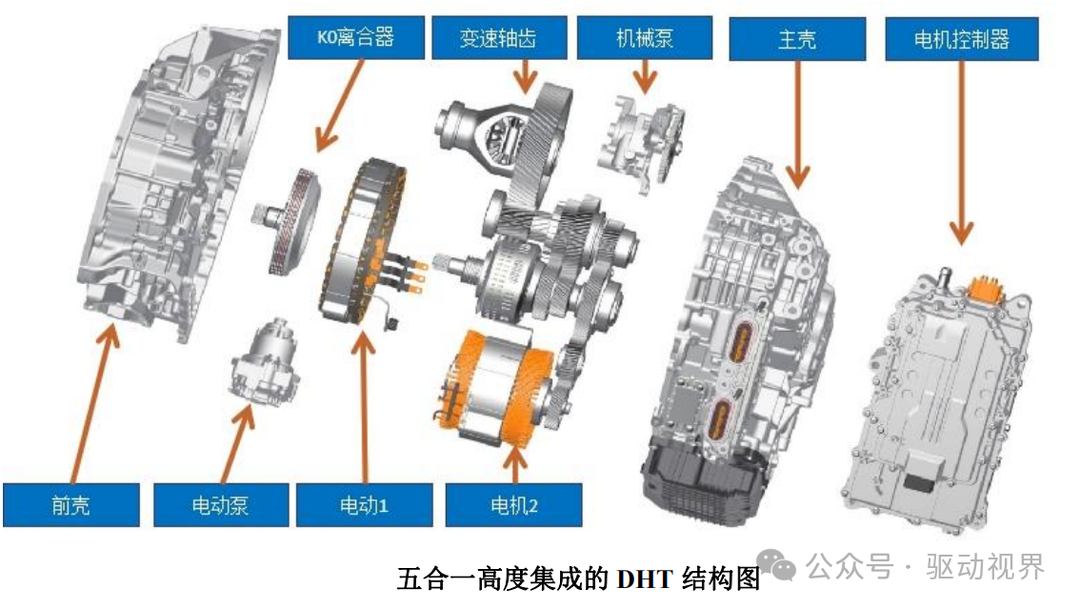

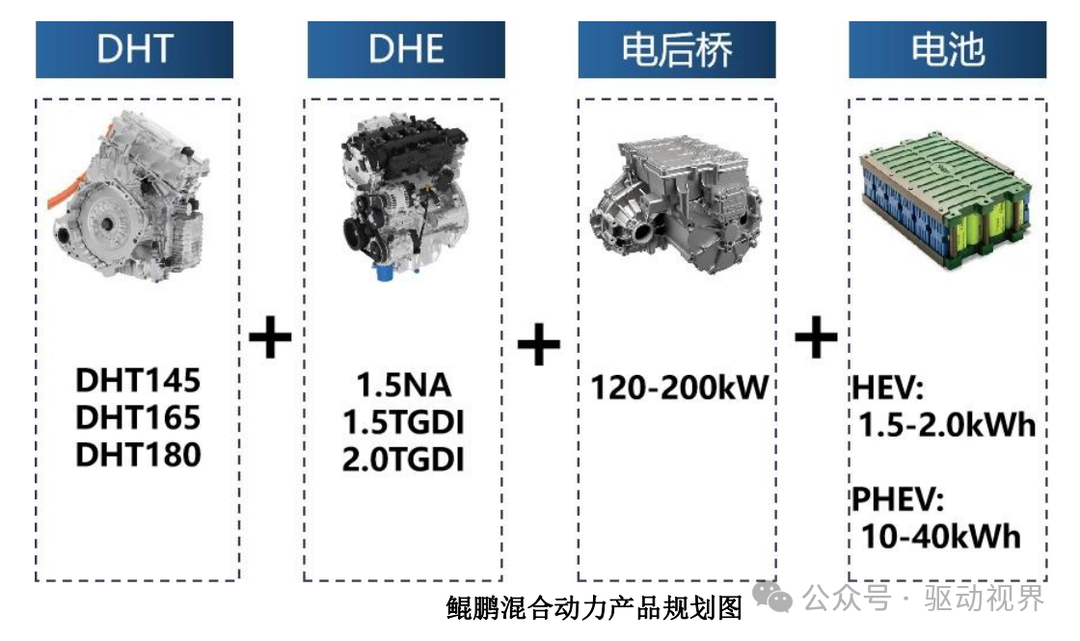

Chery’s Kunpeng plug-in hybrid system has now developed to its second generation, with a total of 9 working modes and 11 combination gears for the current DHT structure, covering all scenarios for daily vehicles, featuring all fuel-saving modes of hybrid power, allowing the engine and motor to operate efficiently. It is the first DHT in China’s independent brands that can be driven by dual motors and has the most gears.

The Kunpeng DHT integrates dual motors, dual motor controllers, and the transmission into a highly integrated 5-in-1 system, allowing the engine and motor to operate efficiently without interruption. The advantages of the Kunpeng DHT include high torque, high efficiency, small size, and light weight, making it suitable for application in SUVs and sedans.

Chery has future plans for the Kunpeng hybrid product, developing DHTs between 100-160 kW for different product combinations to meet the needs of various markets and models. For the engine, a 2.0 TGDI hybrid engine is under development, and an electric rear axle is being developed with a power range of 120-200 kW.

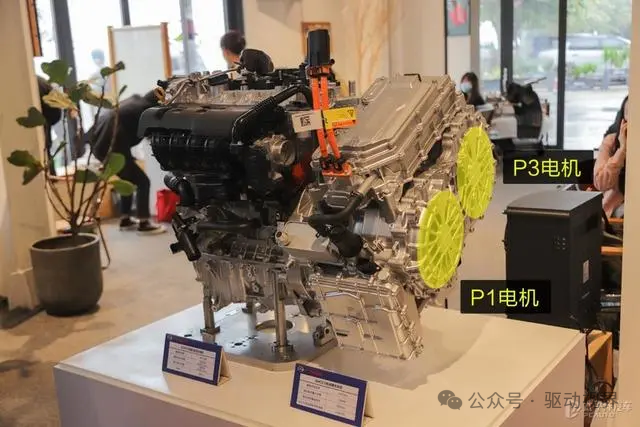

GAC

Currently, the second-generation GMC2.0 system adopts a P1+P3 dual-motor scheme, which is well compatible with HEV, PHEV, and REEV models. The dual-motor controller is integrated with the DHT body, achieving multi-in-one integration of dual motors, dual motor controllers, and transmission mechanisms.

The DHT features a 2-speed planetary gear, enabling multi-gear multi-mode driving and high torque output, effectively optimizing the engine’s working point, with smooth and impact-free shifting/mode switching.

In addition, the GMC2.0 system also features motor voltage boost technology, allowing the bus voltage of the power battery to vary between 266V and 650V, ensuring that the motor system always operates at the optimal voltage, resulting in higher efficiency and lower energy consumption, decoupling the motor voltage from the battery voltage, facilitating battery miniaturization and platformization.

The motor employs current harmonic optimization to reduce torque fluctuation control technology, effectively reducing the motor’s electromagnetic noise by 10dB. The motor controller uses segmented variable frequency control technology, enhancing motor efficiency while meeting noise requirements. The gear teeth are designed with high overlap and high rigidity, minimizing gear misalignment and controlling input gear transmission errors within 0.3um, effectively controlling gear whine, with the overall peak torque condition near-field (15cm) noise ≤85dB.

Using a dual-source integrated active cooling lubrication technology aimed at oil-cooled motors, it achieves on-demand supply of cooling lubrication flow and efficient distribution between the two sources, contributing to higher efficiency and energy savings of the entire machine. The high-low pressure decoupling control technology based on speed control reduces the high-pressure oil circuit flow during mode switching, achieving low energy consumption and high efficiency operation of the entire machine, dynamically controlling motor cooling based on demand, and pre-cooling control, enhancing cooling effects and motor working efficiency.

As shown in Figure 4-78, GAC will continue to strive in the following five areas:

(1) A seven-in-one super integration design covering A0/A class XEV platforms, filling the gap for full hybridization across the entire series, with a leading assembly torque-to-weight ratio in the industry.

(2) Third-generation flat wire winding, efficient winding, and rotor oil cooling motor technology, based on the best efficiency topology design for overall vehicle needs.

(3) A four-in-one controller that balances high and low voltage platforms, with domestic and customized integrated power devices, using multi-core integrated main control chips.

(4) Forward-looking high-voltage systems compatible with voltage boosting, allowing for flexible power upgrades, enhancing overall vehicle performance; compatible with high-capacity low-loss SiC, achieving extreme miniaturization while reducing overall fuel consumption.

(5) Hydrogen hybrid systems, with hydrogen consumption below 1kg per 100 kilometers, reducing vehicle lifecycle carbon emissions by over 70%, combining hydrogen internal combustion engines with GMC to significantly reduce carbon emissions while providing ample power.

The hardware platform in hybrid systems is the foundation of software-defined hybrid systems, determining the efficiency of energy conversion, while software determines the efficiency of energy management. Together, hardware and software define the future of automobiles. The core function of hybrid systems is intelligent energy conversion and control.

The public account platform has changed its push rules. If you do not want to miss the latest news from the Mechanical Branch, remember to “set as a star” + after reading, click “looking at”, so that every time a new article is pushed, it will appear first in your subscription list.

● The starlight does not ask the traveler

● The charm of the Greater Bay Area, the mechanical chapter | Classical Chinese blessing

● Watch the Spring Festival Gala online from previous years

● Remembering the flowing years at Hunan University

● Hello, Fuda Group, we are here!

● Thirty years later, fifty plus, returning to Lushan to pick up the flowers

● Former President | The list of members of the new selection policy committee of the Chinese Academy of Engineering and six other special committees has been announced

● Free visit process for Yuelu Academy for Hunan University alumni

● What touches you is not just these frames of photos, but your own most beautiful memories in your most beautiful times

● Two alumni news | The State Council appoints and removes national staff

● Huawei’s “2030 Intelligent Vehicle Solution” full report

● The design scheme for the emblem and flag of the Mechanical Branch of the Alumni Association of Hunan University in Shenzhen has been released

● The Mechanical Branch of the Alumni Association of Hunan University in Shenzhen: A home for students of the School of Mechanical and Transportation Engineering in Shenzhen

● A century of machinery series ⑤: Chapter Two – The Initial Development of the Mechanical Department of Hunan University (1926-1937)

● The Mechanical Branch, on its first expedition, won the runner-up

● The former president of Hunan University from the School of Mechanical Engineering—Mr. Zhong Zhihua

● Former presidents of Huazhong University of Science and Technology and South China University of Technology, Li Yuanyuan, recall the experience of being admitted to the Mechanical Department of Hunan University thirty-five years ago…

● After forty-six years of college entrance examination, which photo belongs to your memory?

● Hunan University ranked first in the total number of special prizes and first prizes in the 2021 China Machinery Industry Science and Technology Awards

● A letter of thanks from the Aerospace Electromechanical Equipment Research Institute to the School of Mechanical and Transportation Engineering of Hunan University

● Sun Fengchun: Academician of the Chinese Academy of Engineering, former Vice President of Beijing Institute of Technology for 14 years.

● Forever a dormitory

● Senior brother has something to say

● The 50th anniversary reunion video of the 63rd class of the Mechanical Department and the 40th anniversary reunion video of the 77th class

● My feelings for Hunan University: dozens of times dreaming back to Lushan, tears flowing with friends

● Remembering the years: A personal account of the college entrance examination in 1977

-END-

Mechanical Branch – Alumni Association of Hunan University in Shenzhen

WeChat contact: Scan the QR code on the right

Email contact: [email protected]