There are so many helmets on the market today that choosing a new one can be overwhelming. We know that helmets have passed the necessary impact safety tests, but is that enough? Many manufacturers aim to stay ahead of those testing standards to create safer helmets. Reducing rotational forces after an impact is currently a hot topic.

MIPS is a company dedicated to addressing this issue. Although they do not directly manufacture helmets, over 1.7 million helmets equipped with MIPS technology were sold in 2016 alone. So, let’s take a tour of this company located in Stockholm, Sweden, and explore their past and future plans.

MIPS is located in this semi-circular building in the suburbs of Stockholm. Many people ask if the building is a metaphor for the products they produce. Haha, it’s just a coincidence.

At the entrance, various helmets equipped with MIPS technology.

So, what exactly is MIPS?

The full name of MIPS is Multi-directional Impact Protection System. It sounds complex, but the principle is quite simple. A yellow low-friction layer is installed between the rider’s head and the foam part of the helmet, connected to the foam layer by elastic material. During an impact, this yellow plastic shell can slide against the helmet shell, thereby reducing the rotational forces on the brain. Why reduce rotational impact? The simplest term is “concussion.” When wearing a regular helmet, if you hit the ground at a certain speed, the skull stops moving, but your brain continues to move and rotate in the cerebrospinal fluid. This can lead to concussions, subdural hematomas, and diffuse axonal injuries.

“I’m not bald; my hair can also help with this, so why do I need MIPS?” This is indeed a common question. First of all, if you are bald, I recommend you buy a MIPS helmet… Actually, you will find that your scalp also has some sliding range. In fact, MIPS research shows that during an impact, hair and scalp can help reduce rotational forces, but that’s exactly why they invented this yellow plastic shell. This yellow plastic is useful against impacts.

Hons von Holst and Peter Halldin, the initiators of MIPS technology.

History

You might think MIPS is a new invention, but its history dates back to 1995 when Hans von Holst was a neurosurgeon at the Karolinska Institute in Stockholm. He began collaborating with the Royal Institute of Technology in the UK to study the biomechanics of head and neck injuries. Petter Halldin was a PhD student at the Royal Institute of Technology at the time, and together they proposed the initial idea for MIPS technology in the late 1990s.

The first molded helmets were used for equestrian athletes in 2007, and by 2010, bicycle, skiing, and motorcycle helmets began to incorporate MIPS technology, although it was still not common in mountain bike helmets. It wasn’t until 2014 that BRG (which owns Bell and Giro) invested in MIPS and produced the first MIPS mountain bike helmet. However, while BRG is an investor, other helmet manufacturers can still obtain MIPS licensing, so you can find MIPS in helmets from TLD, Scott, Smith, FOX, 100%, and others.

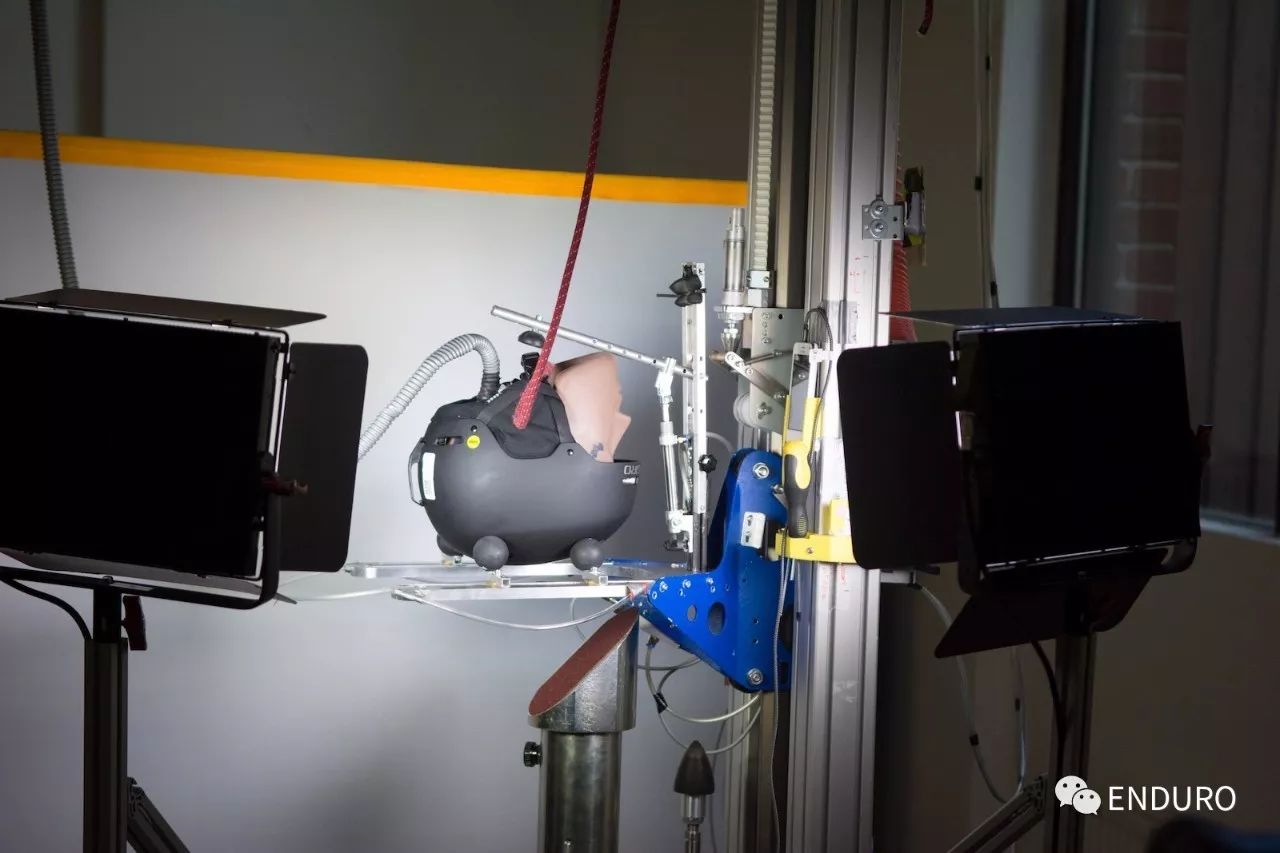

MIPS’s own laboratory, used to study and analyze what happens when a helmet impacts at an angle rather than directly.

From floor to ceiling, these boxes contain tested helmet samples.

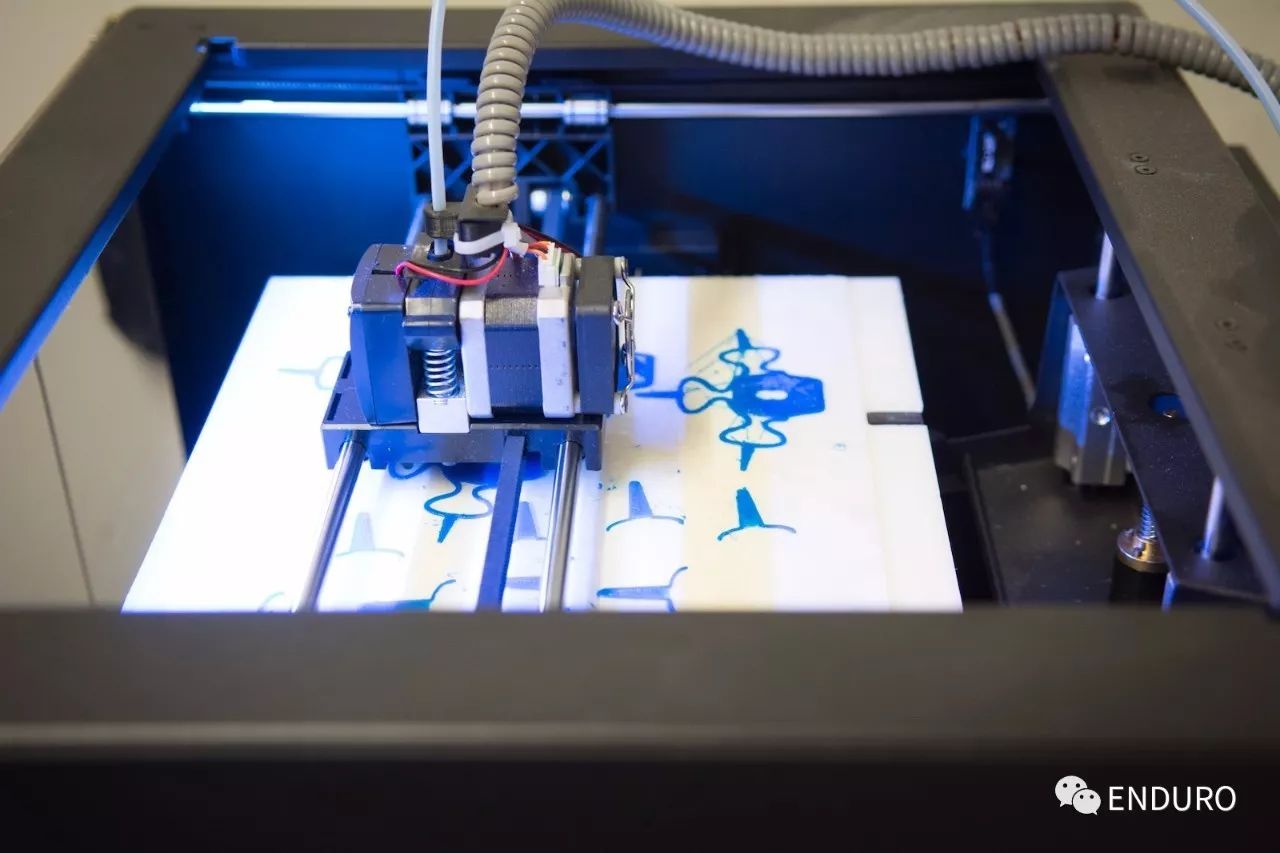

This 3D printer is used to create different elastic fixtures that connect the MIPS yellow plastic shell to the helmet shell.

Different head shape molds.

MIPS Testing Laboratory

If you look inside your helmet, there is usually a label that says CE, ASTM, CPSC, or SNELL, indicating the quality tests it has passed. However, there is currently no certification that discusses the effectiveness of helmets in reducing rotational impact forces. This will change in the coming years— a team of industry experts is discussing the details of this standard.

Although there is currently no official testing standard, MIPS has established its own laboratory and testing facilities for research. Over 13,000 tests have been conducted in the laboratory, providing MIPS with a wealth of data to continue improving their products. Additionally, MIPS uses computer modeling of the brain to simulate the effects of different impact forces and angles, simulating real accidents and comparing CT results with simulated results to assess the accuracy of the computer simulations.

In this test, the helmet is impacted at a speed of 6.5-7.5 meters per second at a 45-degree angle against a sandpaper surface.

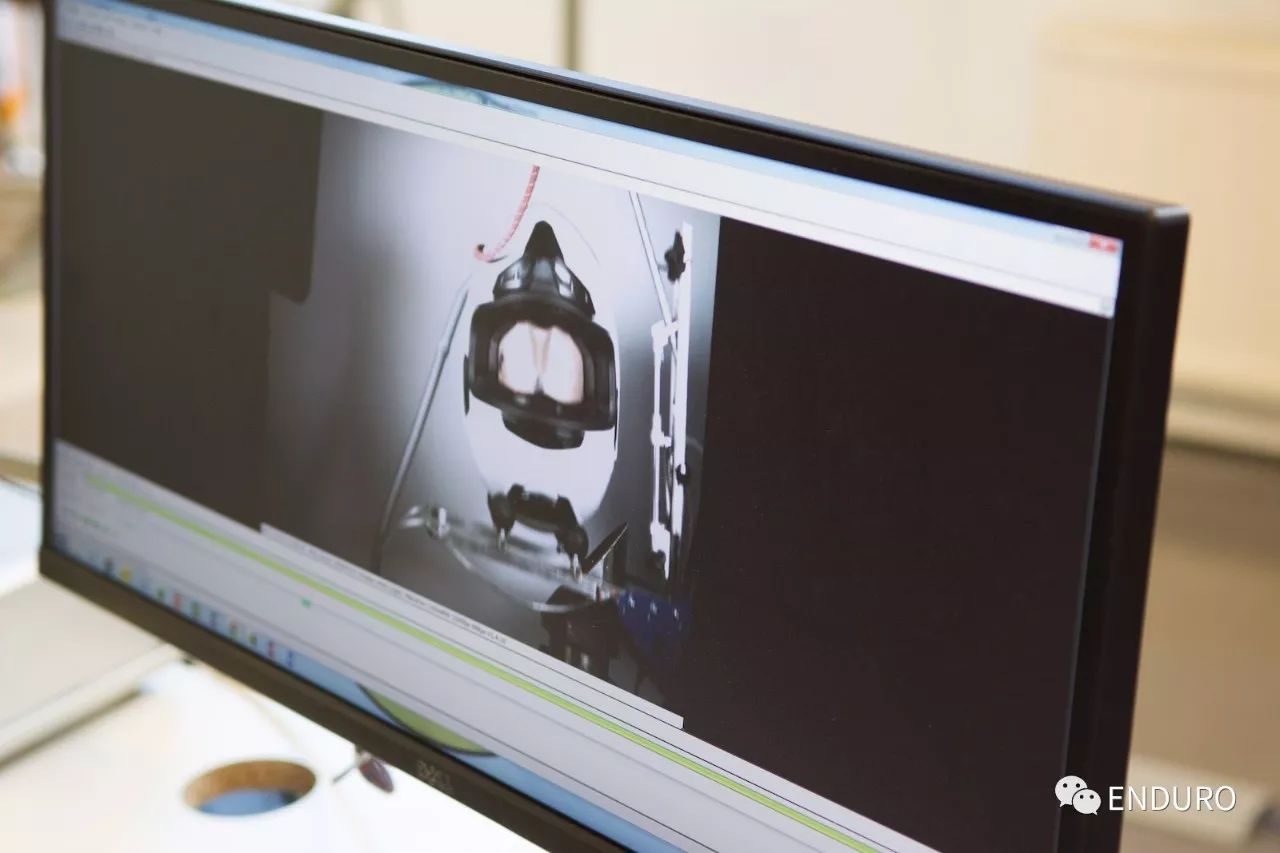

High-speed cameras record the impact process, and sensors record the forces at the moment of impact.

What does the future hold?

In fact, MIPS has several new products, such as the MIPS Spherical technology equipped in the new Bell Super DH. MIPS Spherical sandwiches two different densities of foam together, with a MIPS sliding layer in between, allowing the outer layer to rotate while the inner layer remains stationary.

In summary, all of MIPS’s efforts are aimed at ensuring that users receive as much protection as possible for their heads during various impacts.

Buying advice?

Typically, helmets with MIPS functionality are about 500 yuan more expensive than regular helmets and weigh a few dozen grams more. Is it worth it? I think it is worth it. Common brands like FOX proframe, Bell Super/Super 2R, TLD D3/A1, etc., all offer MIPS functionality.

The cheapest MIPS helmet? The Decathlon ski helmet, priced at less than 400 yuan…