1. Overview

1. Overview

To optimize energy consumption levels in the cement industry and respond to national low-carbon and environmental protection requirements, efforts are being made to promote energy-saving and carbon-reduction upgrades. This includes the upgrading of grinding equipment and process optimization as part of comprehensive energy efficiency improvement initiatives. The roller press grinding system has become one of the key energy-saving technologies promoted by the state. The bed crushing technology is currently recognized as the most advanced grinding technology. Enhancing the efficiency of roller presses is crucial for unlocking the potential of ball mills. However, the energy-saving effects of roller presses vary among companies, primarily due to poor squeezing effects, low fine powder production, and failure to achieve ideal results. Various issues such as valve malfunctions, inability to control chamber positions, poor quality of material cakes, collapsed chambers, dust emissions, vibrations, and misalignment of rollers affect the operational efficiency of roller presses.

When system operating conditions fluctuate significantly, it increases the difficulty of equipment operation. In the increasingly competitive industry, as cement companies pursue refined operations, the role of the feeding device becomes particularly critical.

2. Development Background of the DAC Arc-Shaped Hyperbolic Feeding Device for Roller Presses

To address the aforementioned issues and further achieve the environmental protection and energy-saving upgrade goals for roller presses, our expert team conducted in-depth research and learning at various plants. Through repeated discussions with on-site technical personnel, we studied advanced feeding technologies from several plants. Combining our years of equipment R&D experience in the grinding industry, we actively explored the research of grinding industrial equipment and developed the sixth-generation DAC arc-shaped hyperbolic feeding device with independent intellectual property rights. This device fundamentally resolves prominent issues such as dust pollution during the feeding process, material flipping on the roller surface, material leakage from the roller sides, high failure rates of feeding devices, and the need for maintenance and disassembly of the feeding device during roller surface hardfacing. It maximizes the squeezing efficiency and operational stability of the roller press while reducing the electrical consumption of the cement grinding system and lowering maintenance costs.

Features of the DAC Arc-Shaped Hyperbolic Feeding Device

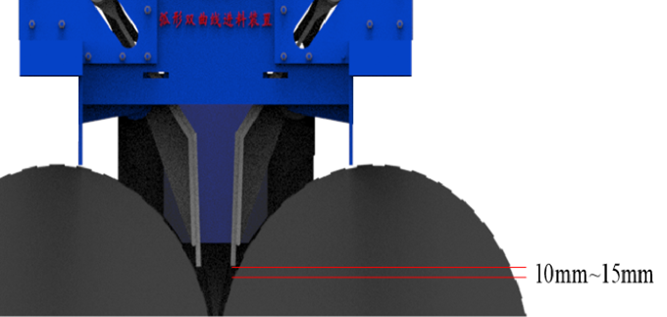

1. The adjustment valve plates move in an equidistant arc shape closely along the roller surface, maintaining a constant distance of 10-15mm during operation, effectively preventing material flipping on the roller surface.

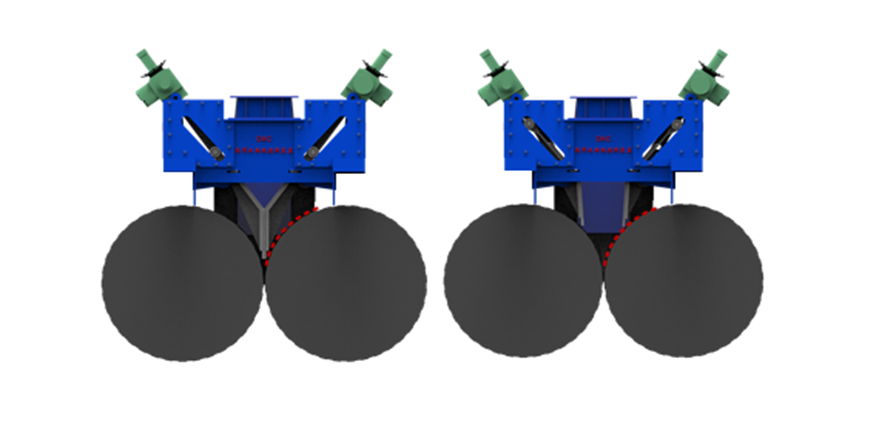

2. The feeding inlet adopts a unique valley cluster-style fully sealed design, promoting the formation of a stable material column and effectively preventing roller misalignment.

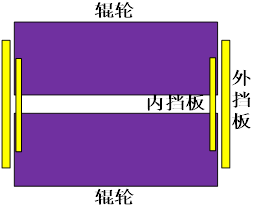

3. The side baffles are designed to be adjustable in segments, effectively reducing material leakage from the roller sides, enhancing material crushing efficiency, and lowering the circulating load.

4. The entire machine features an integrated design that is fully enclosed for safety and environmental protection. Maintenance and hardfacing of the roller surface do not require disassembly of the equipment or any components, improving maintenance efficiency.

5. The device includes a material gas separation structure and a four-sided sealing design, with reserved dust collection interfaces. The discharge area is leak-proof and pressure-stable, preventing dust emissions.

6. It is equipped with an intelligent integrated drive device, featuring simple wiring and an LED display for on-site visual operation. It allows for electric/manual adjustments on-site or via central control, with mechanical and electrical protection devices for upper and lower limit settings, providing dual protection to avoid equipment damage from electrical faults.

Design Features

Real-Time Dynamic Torque Display

When the output shaft experiences a certain torque, the worm not only rotates but also produces axial displacement, driving the cam to create angular displacement, which compresses the cam and raises the support. As the torque on the output shaft increases, the micro-switch controlling the output torque operates, protecting the electric valve and displaying the valve opening in real-time to monitor the working status of the adjustment valve plate.

Curve Fitting/Gap Control

The adjustment valve plate follows the boundary arc of the roller press throughout its full stroke, ensuring that the lower edge of the adjustment valve plate maintains a distance of 10-15mm from the roller surface, stabilizing the material column and pressure, thus stabilizing the bed squeezing. The adjustment valve plate is a global characteristic quantity affected by dynamic loads, so its homogenized design ensures stability during movement.

Efficient Energy-Saving Full-Spectrum Protection

The side baffles are designed to be adjustable in segments, allowing for adjustments based on roller width changes, minimizing the gap between the roller end face and the side baffle, reducing material leakage and improving sealing.

The DAC Arc-Shaped Hyperbolic Feeding Device for Roller Presses: Environmentally Friendly, Energy-Saving, Reducing Consumption, and Increasing Production Efficiency

The DAC Arc-Shaped Hyperbolic Feeding Device for Roller Presses: Environmentally Friendly, Energy-Saving, Reducing Consumption, and Increasing Production Efficiency

Expected Goals After Upgrading to the DAC Arc-Shaped Hyperbolic Feeding Device

1. Improve the working efficiency of the roller press and stabilize operating conditions, thereby increasing hourly output or reducing circulating load to achieve energy-saving and consumption-reducing goals.

2. Flexible control: Central control operators can flexibly adjust the feeding amount of the roller press in real-time according to changes in the process system, ensuring stable operation of the system.

3. High degree of automation: The opening of the adjustment valve plate can be displayed both centrally and on-site, with an integrated intelligent actuator allowing for manual, on-site electric, or remote DCS control in various operational modes.

4. The combination of a discharge pipe and specially designed side baffles achieves double-layer sealing between rollers, resolving issues of material leakage and flipping on the roller press feeding device.

5. Address the issue of material surging in the roller press system, preventing elevator failures caused by surging, improving system operation rates, and reducing unnecessary downtime and workload for personnel.

6. Excellent environmental protection: The entire machine features a four-sided sealed structure with built-in dust collection interfaces, eliminating dust emissions on the roller press platform.

7. The integrated design of the machine and electrical systems simplifies maintenance, reduces costs, minimizes wear parts, and allows for hardfacing of the roller surface without disassembling the feeding device, thus reducing maintenance time and labor intensity for personnel.

3. Application of the DAC Arc-Shaped Hyperbolic Feeding Device

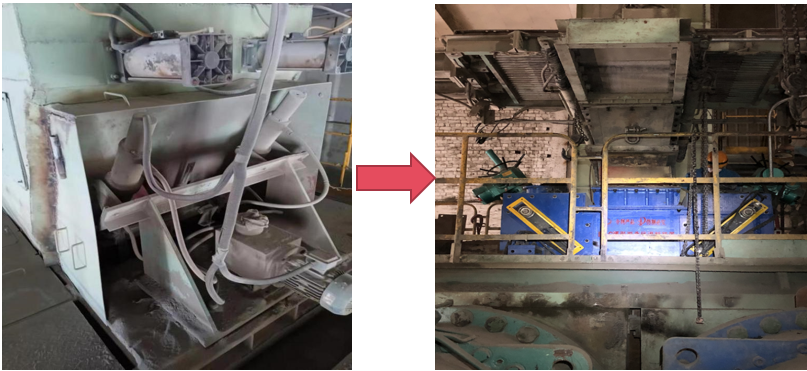

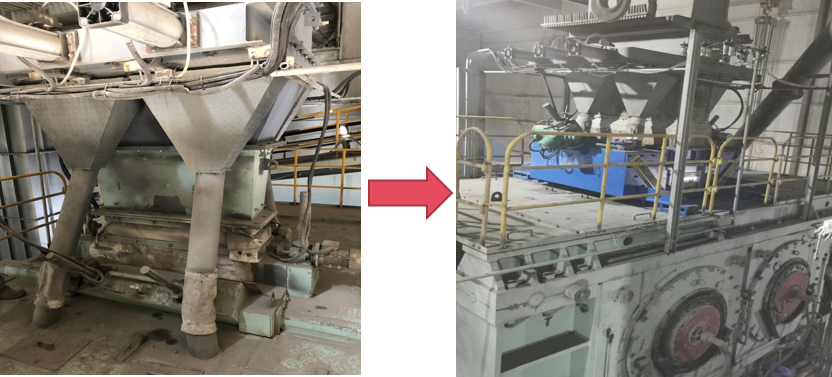

A certain company of Conch Cement upgraded its original G160-140 roller press feeding device to the DAC arc-shaped hyperbolic feeding device. Observations after loading showed a reduction in working pressure/current fluctuations of the roller press, and a decrease in the frequency of roller surface repairs, resulting in smoother operation of the main machine. Under the same roller press indicators, the output of the modified combined system increased by 12.8%, and electrical consumption decreased by over 1 kWh/t. To date, it has been running stably for a year and a half without replacing any spare parts, achieving very satisfactory results.

In June 2024, a certain company in Southwest Cement faced issues with low squeezing efficiency, severe material leakage on both sides of the roller, and significant current fluctuations. After market research, the customer ultimately chose our DAC1814 arc-shaped hyperbolic feeding device. Post-modification, material leakage on both sides of the roller was reduced, current became more stable, output significantly increased, and process electrical consumption decreased by 1.2 kWh/t.

A certain cement company in Anhui replaced its original four-sided adjustable feeding device on the G180-160 roller press with the DAC1816 arc-shaped hyperbolic feeding device in January 2024. Observations showed that under the same roller press indicators, the output of the modified combined system increased from 270t/h to 310t/h, an increase of 14.9%, and electrical consumption decreased by over 1 kWh/t, achieving very satisfactory results.

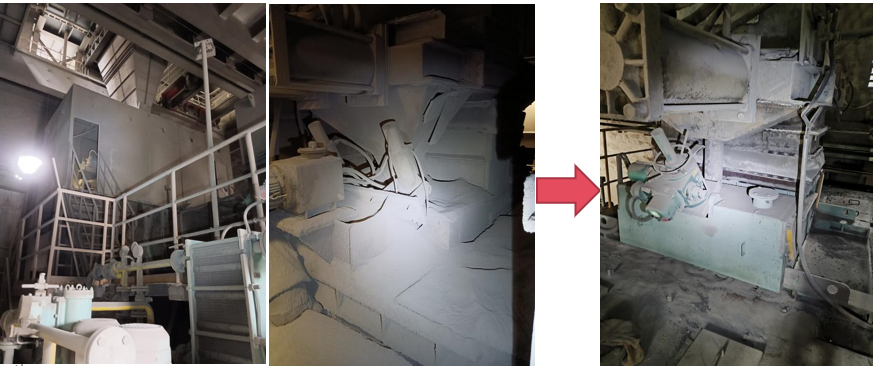

A certain company of Conch Cement faced severe dust emissions, significant material leakage on both sides of the roller, and low squeezing efficiency during the use of the original feeding device on the G180-160 roller press. This severely affected production efficiency, and a dust shield was built on the roller press platform, affecting aesthetics. In early 2024, the company upgraded to our DAC1816 arc-shaped hyperbolic feeding device. After the modification, material leakage on both sides of the roller was reduced, operation became stable, dust emission issues significantly improved, and the dust shield was removed, resulting in a noticeable increase in output and a decrease in process electrical consumption of over 0.5 kWh/t.

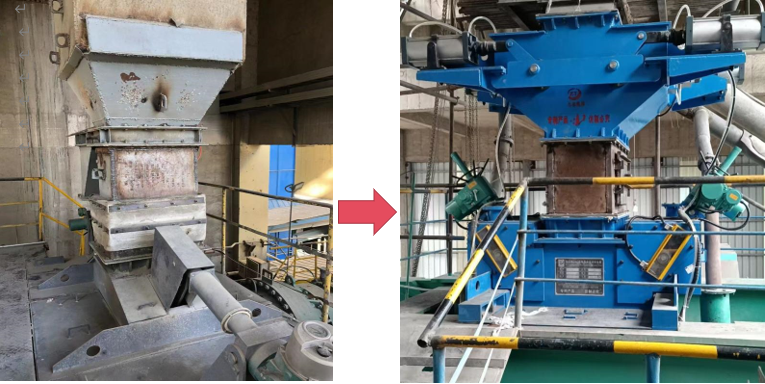

A certain company of Jinglan Cement Group faced prominent issues with the pneumatic gate valve on the raw material roller press G200-180, such as poor sealing and dust leakage, as well as severe material leakage from the original feeding device, leading to low squeezing efficiency, high electrical consumption, and rapid wear of the side baffles requiring frequent replacements. After extensive comparisons, they ultimately chose our DAC2018 arc-shaped hyperbolic feeding device and DVC arc-shaped discharge gate valve. After the modification, the roller press operated smoothly, electrical consumption decreased by about 2 kWh/t, and the working environment improved significantly, achieving good results and receiving positive feedback from users.

A certain company of Jinglan Cement Group faced prominent issues with the pneumatic gate valve on the raw material roller press G200-180, such as poor sealing and dust leakage, as well as severe material leakage from the original feeding device, leading to low squeezing efficiency, high electrical consumption, and rapid wear of the side baffles requiring frequent replacements. After extensive comparisons, they ultimately chose our DAC2018 arc-shaped hyperbolic feeding device and DVC arc-shaped discharge gate valve. After the modification, the roller press operated smoothly, electrical consumption decreased by about 2 kWh/t, and the working environment improved significantly, achieving good results and receiving positive feedback from users. A certain cement company in Yunnan with a roller press specification of G170-100 had been using a pneumatic gate valve for many years, which had poor sealing performance and frequently jammed, leading to significant dust emissions on the roller press platform and low working efficiency, resulting in high electrical consumption in the cement process. This was not conducive to the company’s overall requirements for environmental protection and energy-saving. In 2024, they upgraded to the DAC1710 arc-shaped hyperbolic feeding device and DVC arc-shaped discharge gate valve. After the modification, the roller press operated stably, circulating load significantly decreased, output increased noticeably, and process electrical consumption decreased significantly, leading to high user satisfaction.

A certain cement company in Yunnan with a roller press specification of G170-100 had been using a pneumatic gate valve for many years, which had poor sealing performance and frequently jammed, leading to significant dust emissions on the roller press platform and low working efficiency, resulting in high electrical consumption in the cement process. This was not conducive to the company’s overall requirements for environmental protection and energy-saving. In 2024, they upgraded to the DAC1710 arc-shaped hyperbolic feeding device and DVC arc-shaped discharge gate valve. After the modification, the roller press operated stably, circulating load significantly decreased, output increased noticeably, and process electrical consumption decreased significantly, leading to high user satisfaction. 4. Future Development of Roller Press Feeding Devices – Efficient, Energy-Saving, Clean, and Easy to Control

4. Future Development of Roller Press Feeding Devices – Efficient, Energy-Saving, Clean, and Easy to Control

Intelligent Recognition

1. Precisely identify installation boundary dimensions and personalize the construction of 3D models for intelligent processing and production.2. Intelligent fine control of protective gaps based on dynamic parameters such as material descent speed and weight.Remote Terminals1. Specialized remote terminal control for roller press feeding devices, providing rapid technical solutions.2. Remote control for cleaning residual materials inside the device, enhancing the environmentally friendly human-machine space.Company Introduction

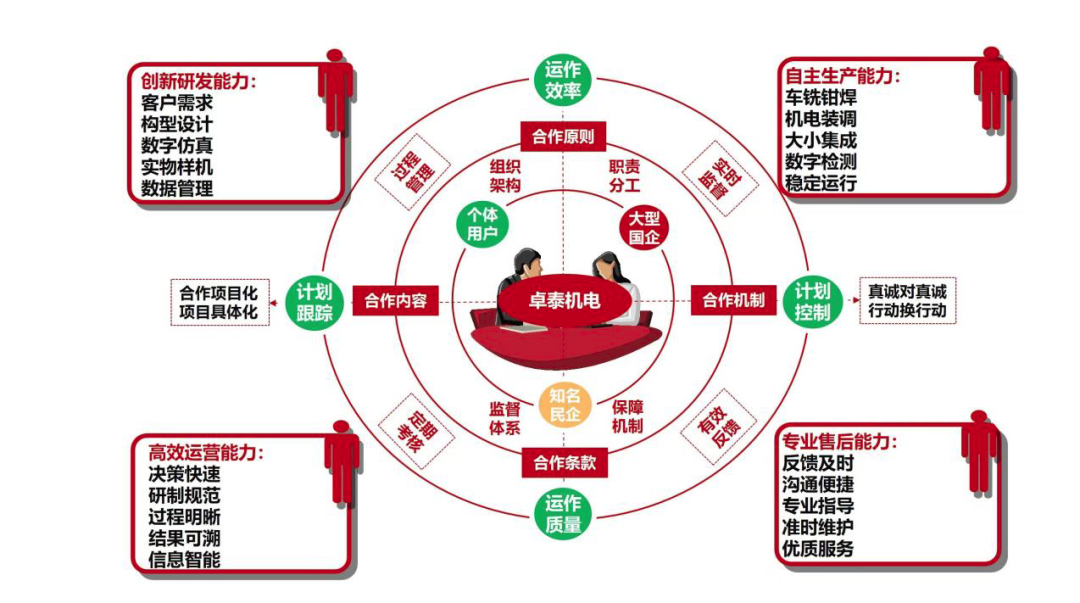

Hefei Zhuotai Electromechanical Equipment Manufacturing Co., Ltd. is a well-known enterprise in the building materials industry, a national high-tech enterprise, a national technology-based small and medium-sized enterprise, a specialized and innovative small and medium-sized enterprise in Anhui Province, and a technical center in Hefei City. The company has established a powder engineering technology research center and specializes in the technical research, development, design, manufacturing, engineering services, and sales of electromechanical equipment and components for cement production lines, as well as material measurement and quantitative feeding equipment. It also has independent import and export rights. The company boasts a team of high-quality professionals, including industry research and design experts, professors, senior engineers, and graduate students with years of equipment design and R&D experience and rich engineering practice and theoretical foundations.

Main products of the company include: powder measurement rotor scales, cement bulk measurement scales, SMF vertical mill lock wind feeders, DAC arc-shaped hyperbolic feeding devices for roller presses, DVC arc-shaped discharge valves, cement equipment accessories (roller press accessories, wire mesh belt elevator accessories, vertical mill accessories, and Feiste coal powder rotor scale accessories), and related technical modifications.

Looking ahead, we will continue to strive for further advancements in all aspects of our work.

Technical Consultation Phone:18119633813 (WeChat same number)15385891025 (WeChat same number)