ECU is a term that is often heard but rarely practiced.

It sounds simple to tune the ECU, with no risks involved, while enhancing horsepower, reducing fuel consumption, and even prolonging engine life?

If it were that easy, those engineers at the manufacturers earning six figures should be fired.

So today, let’s discuss some common issues regarding the ECU.

Image source: internet,if there is any infringement, please contact us

Unless specified otherwise, this article discusses racing modifications and track driving.

Please do not drive illegally modified vehicles on public roads, and do not drive dangerously.

People often say that after flashing a certain program, their car feels different in terms of power, or after using a certain additive, they feel no difference, or after using a certain gasoline, the noise diminishes.

Programs and fuels can indeed have a significant impact on a car’s power, but during discussions among car enthusiasts, these impacts are often theoretical, subjective, and experiential.

What Are the Differences Between Programs from Different Brands?

For the same car, there can indeed be considerable differences in power after writing different brand programs.

It might be that the throttle response in the daily driving range of 2000-3000rpm is quicker (with less time delay), or that the torque from 3000-5000rpm is greater, or that the maximum RPM has increased from 6200rpm to 6700rpm.

When we chat about cars, descriptions of ECU programs often include: “The low-end torque is greater,” or “The high RPM runs smoother,” which are subjective descriptions.

Generally speaking, the principles of programs from different brands are quite similar, but the adjustable parameters may differ, as well as the tuning philosophy and objectives.

So, what data do engineers or shops usually adjust when tuning programs? What feelings do these data adjustments impact during driving? Let’s focus on manual transmission models for the engine.

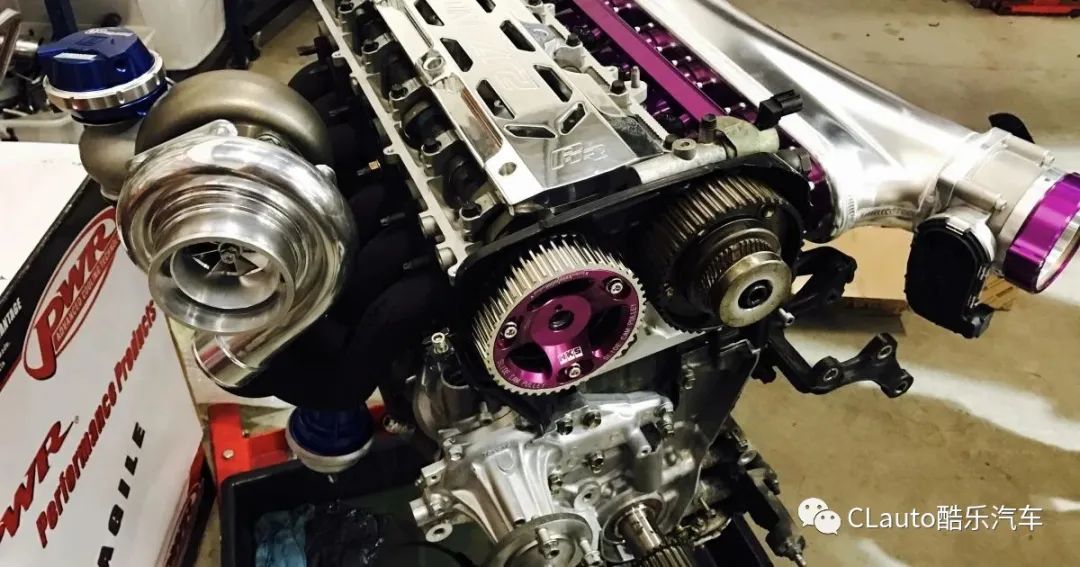

How to Upgrade

First, a diagnostic device will be used to conduct a comprehensive check of the car’s computer system. If there are no issues, a specialized device will read and back up the program from the car’s computer.

Simultaneously, the vehicle identification number, ECU number, part number, and chip will be recorded and photographed. The original program is then sent via the internet to a European programmer, who is responsible for one-on-one tuning.

One-on-one tuning means that the original car is specially tuned based on the customer’s requirements, the test engineer’s opinions, whether the original car hardware has been modified, and the original car’s driving records.

Typically, the tuned program will be sent back within an hour, and then it will be written back into the car’s computer using a specialized device. Finally, a diagnostic device will be used to recheck the car’s computer. If there are no issues, a test drive can commence.

When delivering the car, the program cannot fully utilize its performance yet, as the computer still undergoes an adaptive learning process, which can take a few days or a couple of hundred kilometers to reach optimal performance. The entire process is actually quite simple; for 80% of cars, it can be done directly from the car’s OBD diagnostic port with a laptop and specialized equipment.

Low Boost Mode

Programs from different brands may vary; generally, high, medium, and low boost modes are primarily tuned based on the maximum turbo pressure.

It can be simply understood that the programmer will tune out two or three sets of data based on different maximum boost values, allowing for seamless switching. It requires separate tuning of two or three sets of data, which makes the programming process a bit more complicated.

Some programs’ high and low boost modes are based on a single set of data, adding a “boost limiter” function. In such programs, data needs to be tuned only for the high boost state.

The low boost mode limits the maximum boost value, or it only uses a portion of the high boost data table.

In other words, when the desired boost value is less than the maximum pressure of the low boost, the feeling of low boost is identical to high boost; when the desired boost value exceeds the maximum pressure of the low boost, the boost value will no longer increase, and the torque remains basically constant.

Some models’ factory “sport,” “normal,” and “eco” modes also utilize this method to simply control power. In this case, “eco” may just be forcing you to drive in an economical manner.

The advantage of this type of program lies mainly in the simplicity of tuning different “low boost pressures,” making it suitable for adjustments at any time during daily driving. During the driving process, switching modes without stopping will not cause knocking, stalling, or other inconsistencies.

More Fuel-Efficient Programs

Players looking to tune their programs might not focus on fuel consumption, but it is indeed possible to slightly lower fuel consumption in the program.

Lowering the fuel-to-air mixture concentration in closed-loop conditions usually has one purpose: to reduce fuel consumption under constant low load conditions.

ECU upgrades mainly adjust ignition, fuel injection, air-fuel ratio, boost pressure, valve lift, and timing, thereby enhancing power and torque, with the ultimate goal of reconfiguring the engine’s working curve. Due to the optimized program running faster, more precise ignition and fuel injection, and valve timing adjustments leading to more complete combustion, power is increased without changing vehicle weight, thus reducing fuel consumption.

Or in other words, when driving on a highway at a constant low load for long distances, it can slightly increase range.

To a large extent, the factory’s closed-loop air-fuel ratio of 14.7 in pure gasoline conditions considers emission issues, rather than being designed solely for engine longevity and fuel efficiency.

However, if it is daily commuting in urban areas and emissions are not a concern, adjusting the closed-loop fuel injection to lean remains risky. This is primarily because during non-aggressive acceleration, starting, uphill, and at around 2000rpm, the engine’s load can still be quite high.

Moreover, these situations occur quite frequently.

Check Engine Light

After replacing the catalytic converter, removing the GPF section, adjusting the turbo pressure, and changing the intake piping, the engine check light may illuminate due to numerous operations affecting sensors and actuators.

Some car enthusiasts ignore these lights, allowing them to stay on indefinitely, while others may remove the bulbs for peace of mind. In fact, some brands’ programs can disable certain common error codes, allowing the check engine light to be associated only with one or two specific error codes.

When other error codes appear, these lights will still illuminate normally to indicate that the car has issues.

After modifying the catalytic converter or (and) GPF, some cars will trigger the emission or engine check light. To eliminate this check light, some models’ programs may require disabling the front (Bank 1) or rear (Bank 2) oxygen sensors.

If the front oxygen sensor needs to be disabled, it may be necessary to simultaneously disable the exhaust temperature data. Exhaust temperature is a crucial data point; if it’s lost, we must manage the exhaust temperature ourselves during tuning and driving.

Controlling Coolant Temperature with Electric Fans

When the electric fan operates, it generates noise and some slight vibrations, which can affect the comfort experienced inside the vehicle, especially when idling.

In the factory design, the conditions for the electric fan’s start and stop, as well as its speed, are designed to control coolant temperature, but they also consider some NVH (Noise, Vibration, Harshness) issues.

For car enthusiasts with high power demands, the NVH caused by the electric fan is clearly a minor concern compared to cooling.

Thus, we can adjust the start and stop conditions and speed data of the electric fan in the program, allowing it to run more often and keep the coolant temperature lower.

If the opening and closing of the intake grille can also be adjusted, it can be calibrated in conjunction with the electric fan.

Why Don’t OEMs Design This Way?

ECU manufacturers are all large international companies, such as BOSCH, SIEMENS, etc., whose products are sold worldwide.

Due to differences in fuel quality, temperature, atmospheric pressure, humidity, engine types, and assembly processes in each country, ECU program settings must meet the usage conditions of each country, even in the most severe environments.

Moreover, they must be robust and durable while controlling costs for both production and maintenance; thus, the range set by the original car computer is relatively conservative, leaving some room for upgrades.

Additionally, due to production and maintenance cost control, car manufacturers cannot design a unique engine for every model. From a market perspective, even if the same engine is used, lower-end models need to distinguish themselves from higher-end models, which results in limitations in engine tuning.

For example, the power and torque of the standard version of the A4L are 180hp and 320nm, while the same engine in the sport version is tuned to 211hp and 350nm.

More

-

For performance cars, excess designs like run-flat tires may be meaningless.

-

For a man who owns a family photo of the 90s Nissan GT-R, guess which model he loves the most?

-

How to survive and win in a chaotic battle?

-

Brakes failure? Engineer: Just! Step! Hard!

Today’s Signature