Chen Chuan

Central Party School of the Communist Party of China (National Academy of Governance)

Department of Social and Ecological Civilization Research

Associate Professor

Li Xiaoman

Capital University of Economics and Business

School of Labor Economics

Associate Professor

Decision-Making Alternatives of Artificial Intelligence and Social Buffering

— A Case Study of X Intelligent Power Plant

Source | Sociological Research, 2024, Issue 1

Authors | Chen Chuan, Li Xiaoman

Editor | Xiang Jinglin

In the context of a new technological and industrial revolution, artificial intelligence shows the potential to replace human decision-making. In the digital transformation of the X Intelligent Power Plant, the objective material attributes of artificial intelligence technology constitute a partial replacement of decision-making for engineers and a disruption of existing organizational power structures. Various factors such as the nature of the enterprise, strategic goals, and existing interest patterns lead actors to form social buffering against the impact of artificial intelligence technology through practices such as algorithm rewriting, strategic abandonment, and substitution conversion. The findings of this paper reveal that the impact of artificial intelligence on human society will trigger different social buffering mechanisms, with social factors becoming the buffering layer and filter through which technology influences society.

Marx’s research on the replacement of labor by machines in “Capital” has become a classic example in the field of technology sociology and labor sociology. As Marx pointed out, the revolutionary changes in productivity during the Industrial Revolution led to a series of significant transformations in production relations (Marx, 2018). As the digital society arrives, a new round of technological and industrial revolutions is gradually deepening. With the new generation of information technologies represented by artificial intelligence (AI) being applied, what kind of changes in production relations and even social relations will AI, which has new characteristics compared to traditional machines, bring? What new changes will occur with machines that can “think and decide” replacing humans, compared to the traditional replacement of repetitive manual labor by machines?

Unlike the extensive focus on the labor control effects and inequality effects of artificial intelligence and algorithms in the platform economy and internet technology companies (Cottom, 2020; Kellogg et al., 2020; Rosenblat, 2019; Casilli & Posada, 2019; Jia Wenjuan, Yan Wenqian, 2022; Zhu Fuqiang, 2022; Chen Long, 2020; Wang Linhui et al., 2020; Zhu Qi, Liu Hongying, 2020), we return to the factory field in Marx’s classic research to explore how the application of artificial intelligence technology in new digital and intelligent factories reshapes existing relational and power structures; at the same time, we explore how social factors relate to artificial intelligence technology in specific fields and how they affect the specific application process of artificial intelligence technology. These empirical and theoretical issues form the starting point of this research.

Artificial intelligence refers to the simulation of human intelligence using computers, involving fields such as robotics, language recognition, image recognition, natural language processing, and expert systems (Tencent Research Institute et al., 2017). Compared to traditional computer programs and algorithms, artificial intelligence has undergone tremendous changes in the way and capacity to solve problems. Based on technologies such as big data, Monte Carlo trees, and neural network learning, artificial intelligence can evolve and iterate itself, solving complex problems that only technical experts could previously handle (Mnih et al., 2015).

This paper distinguishes itself from existing sociological studies on algorithms by not equating artificial intelligence with algorithms, but rather viewing it as a whole—an actor with relative subjectivity. Although some scholars point out that the core issue of artificial intelligence lies in algorithms (Qiu Zeqi, 2021; Zhao Lu, 2022), algorithms are the rules by which artificial intelligence operates, possessing a kind of institutional power and the ability to shape and change social realities, but when we consider more of the objective material elements of technology, it becomes clear that what influences social reality is not only algorithms but also data, computing power, sensors, and the carriers of algorithms—processors and other elements. These objective material elements constitute the entirety of artificial intelligence, making it an actor with perception, thinking, and decision-making capabilities. In 2023, the technological direction of “AI agents” in the field of artificial intelligence has attracted much attention, reflecting the trend of technological development and application where AI, as a theoretically significant actor, is gradually enhancing its action capabilities in reality (Han et al., 2023; Kortemeyer, 2023).

(1) Artificial Intelligence Actors: From Repetitive Labor Replacement to Decision-Making Replacement

In the history of machine replacement of labor, non-artificial intelligence machines often replaced relatively simple, repetitive, and procedural labor, with potential replacement targets being relatively lower-level workers (Yu Lingzheng et al., 2021). Even after the rapid development of artificial intelligence technology, some scholars still believe that the work replaced by artificial intelligence is mainly repetitive and procedural work, while jobs requiring creativity and autonomous decision-making are harder to replace with artificial intelligence (Wu Wenfang, Liu Jie, 2021). However, some studies have pointed out that artificial intelligence has a stronger labor replacement capability, which is reflected not only in the replacement of manual labor but also in the replacement of complex cognitive tasks, especially knowledge and experience. Shestakofsky (2015, 2017) noted that past computer automation could only perform some procedural and fixed tasks, while the emergence of artificial intelligence machine learning allows computers to simulate human performance, infer future action patterns based on past data, and find some tacit knowledge through training on a large amount of human-generated data. Thus, the work replaced by artificial intelligence is more complex, transforming from manual labor to intellectual labor, including cognitive, judgment, reasoning, decision-making, and creation tasks traditionally believed to be exclusive to humans. The groups that artificial intelligence may replace in the future may also shift from workers to technical workers, lawyers, judges, engineers, and middle managers (Brayne, 2017; Volokh, 2019; Pasquale, 2019; Burrell & Fourcade, 2021). The overwhelming victory of AlphaGo against the human world champion in Go in 2016 further demonstrated the enormous potential of artificial intelligence in the field of cognitive, judgment, and decision-making replacement (Silver et al., 2016).

During the first Industrial Revolution, the phenomenon of machines massively replacing humans (labor) first emerged. Machines, as non-human actors, theoretically have the potential for agency, but at the technical and experiential level, they still exist as tools. The subsequent technological advancements of each industrial revolution, including computer automation, have replaced increasingly higher levels of human capabilities but have never truly threatened intellectual workers in society—machines remain tools in the hands of technicians to enhance efficiency. Before reaching the critical point of technological evolution, the tool attributes of technology are more evident than its agency attributes, and technology mainly depends on humans in specific practical processes. However, as the quantitative accumulation of automation technology gradually increases, the capabilities of artificial intelligence in practice are becoming stronger, and its role independent of humans is increasingly evident, approaching the level of an independent actor in perceivable terms. The enhancement of artificial intelligence’s agency means that it is moving closer to its original design intention, replacing human intellectual labor at increasingly advanced levels.

Unlike past industrial revolutions where machines primarily impacted frontline manual workers, in the context of the impending Fourth Industrial Revolution, especially with the emergence of new intelligent factories, artificial intelligence possesses the potential technological capability to replace cognition, thinking, judgment, and decision-making for the first time. This implies that the target of technological disruption in the Fourth Industrial Revolution may undergo significant changes. In Marx’s classic factory studies, the initial resistance capacity of the lower working class in the face of machine replacement was relatively weak, and aside from the Luddites’ act of machine destruction, they lacked more effective means of resistance, despite the far-reaching social changes triggered by this disruption. The widespread application of industrial machines at that time aligned with the interests of bourgeois managers. In the decision-making replacement process of artificial intelligence, the technological shock will more directly target the technical management group and even the higher decision-making group, thus this historical process of decision-making replacement may generate more complex social impacts and uncertain social practices.

(2) Different Theoretical Perspectives on the Social Impact of Artificial Intelligence Technology

As a new information action subject (Chen Chuan, 2021), what kind of social changes will the replacement of human decision-making actions by artificial intelligence trigger? From the perspective of technology-society relations, various studies in the traditions of the sociology of scientific knowledge and technology sociology have provided different explanations through three major theoretical schools: technological determinism, social constructivism, and the dialectical relationship between technology and society.

First, technological determinism stems from the Marxist tradition of studying the relationship between technology and society, emphasizing that technology to some extent determines changes in social relations. This theoretical perspective posits that changes in productivity brought about by technology, especially scientific and technological advancements, are the primary driving force of social change, emphasizing the shaping role of technology on society (Compilation Bureau of Central Committee of the Communist Party of China, 2012). Specifically regarding the study of machines and factories, Marx keenly captured the characteristics of machine development during the first Industrial Revolution, pointing out that the technological shock brought by machines impacted workers at the micro level and ultimately led to the rise of large-scale industry and the widespread adoption of the factory system, bringing a series of revolutionary changes to traditional handicrafts and household labor (Marx, 2018). Scholars such as Stuart Russell have pointed out that artificial intelligence can be more rational than humans, greatly enhancing decision-making efficiency and fairness (Russell, 2019). Cognitive psychologists like Daniel Kahneman have noted that humans find it difficult to avoid systematic cognitive biases and errors when making decisions (Kahneman, 2013). In contrast, new machine decision-making, such as that of artificial intelligence, seems to be able to avoid the influence of human factors on decisions, thus its application in production, management, and even social public policy can lead to more equitable social outcomes.

However, more empirical studies indicate the negative social consequences triggered by artificial intelligence. Scholars such as Dan Schiller and Manuel Castells have systematically discussed the concept and history of information capitalism in the context of the development of information technology and communication industries in the United States after World War II, revealing the core power position of capital giants in the digital society (Schiller, 2018; Castells, 2010). Scholars like Jenna Burrell have proposed that large internet capitals and internet elites have shaped a new form of software capitalism (Burrell & Fourcade, 2021). Researchers point out that in the digital society, algorithmic domination has become a means of producing inequality, and algorithmic centrism has gradually emerged, which has become a significant reason for the early negative impacts of artificial intelligence (Burrell & Fourcade, 2021; Engelke, 2020; Chen Long, 2020; Zhuang Jiachi, 2019; Rosenblat, 2019; Kellogg et al., 2020). New digital technologies have also directly brought about a series of impacts and changes in industrial structure, labor space, work methods, and the psychological identity of engineers (MacKenzie et al., 2015; Castells, 2010).

Second, social constructivism argues that the impact of technology on society is not one-dimensional. The viewpoint of technological determinism has prompted challenges from social constructivism, represented by the “technological text” theory (Grint & Woolgar, 1997). To what extent can digital technologies such as artificial intelligence change society? Is it the evolution of technology that determines changes in social structure, or do social structures determine the direction of technological development, replicating existing social operational logic? Scholars such as Keith Grint, representing the sociology of technology, argue that technology is a text that can be written and is constructed by society. Various social factors reshape the development and application of specific technologies in specific spatiotemporal contexts (Grint & Woolgar, 1997). Existing social power structures, patterns of interest distribution, and key interest group actors all play different roles, making the development and application of technology no longer simply rely on the internal evolution logic of technology but instead be shaped and altered by more non-technical factors. In this sense, artificial intelligence technology does not merely develop along the internal logic of computer technology evolution but is influenced by existing social factors, becoming a text written by society.

The intrinsic relationship between the learning-decision-making process of artificial intelligence and big data further enhances the possibility of this theoretical logic. The extensive application of existing artificial intelligence technologies is based on the collection of big data. Big data is, to some extent, a trace of social actions and experiences. Artificial intelligence learns and generalizes specific laws of human society through the collection and processing of big data, simulating human intelligent actions. This process often replicates or even amplifies existing inequalities in society (Barocas & Selbst, 2016; Weinberger, 2019; Engelke, 2020; Eubanks, 2018).

Third, the third theoretical school emphasizes a dialectical relationship between technology and society. Since the 1990s, scholars such as Wanda J. Orlikowski and Qiu Zeqi have attempted to construct comprehensive theoretical frameworks in a series of studies in the field of technology-organization to reconcile the theoretical conflicts between technological determinism and social constructivism (Orlikowski, 1992; Orlikowski & Gash, 1994, 2000; Orlikowski & Barley, 2001; Qiu Zeqi, 2005). Influenced by Giddens’ structuration theory, Orlikowski proposed the structuration theory of technology. She argues that the conflict in previous perspectives on technology-organization relationships stems from the philosophical conflict between subjectivity and objectivity. Technology actually possesses dual attributes: on one hand, it has material characteristics, and on the other hand, it reflects human agency towards technology. Organizational structure is a dynamically generated social process, resulting from the interaction between human actors and the structural characteristics of organizations. In the process of structural generation, technology possesses both objective power and is a product of social construction (Orlikowski, 1992). Examining technology from a practical perspective reveals that technology is a practice-involved technology (technologies-in-practice), which is not simply constructed and shaped by society but changes in the process of use by technology users, in the interaction between humans and technology (Orlikowski & Gash, 2000). Qiu Zeqi’s theory of technology-organization co-construction further clarifies the dialectical relationship between organizations and technology. He argues that the importance of technology to organizational goals, the technological hierarchy, and the structural elasticity of technology are practical characteristics that interact with organizational structure, establishing a relationship of continuous mutual construction in practice (Qiu Zeqi, 2005).

Following the paths of the sociology of scientific knowledge and technology sociology, Ian Hutchby proposed a relatively compromise concept at the macro level of technology-society relations: affordance (Hutchby, 2001). This concept originally stems from Gibson’s cognitive psychology concept. Hutchby argues that the material attributes of technology can change society, but not all material attributes can be applied to change society; the functional affordance of technology needs to be considered. Scholars such as Pete Fussey have pointed out that digital sociology aims to analyze the functional affordance of technology in different social environments, studying how these functional affordances are shaped by social relations, social interactions, and social structures (Fussey & Roth, 2020).

(3) The Social Buffering Mechanism of Technology

The insights from these different theories indicate that when we think about the relationship between technology and society, it is meaningless to fall into the debate of whether society or technology dominates; more importantly, we should examine the practical process in which technology, especially revolutionary technology, encounters society. This is a dynamic, generative, active, and indeterminate process. In such a practical process, once technology is applied and encounters society, it does not experience a smooth process, but rather a non-smooth process filled with structural constraints, actor resistance, and the adaptation of technology itself.

If we return to the classic metaphor of the social organism in sociology, we can say that when the social organism encounters technological shocks such as artificial intelligence, an inevitable spontaneous or non-spontaneous immune mechanism will arise. This may come from the resistance forces of established social structures or from the reflexive resistance and transformation of socially reflexive members. Society, in the face of technological upheaval, is not a passive receiver but serves as an intermediary layer of technological influence, responding to the uncertainties of technological change while maintaining a relatively stable order. This also reminds us of Karl Polanyi’s conclusion when discussing the impact of market institutions on the people: such shocks will trigger movements for self-protection in society (Polanyi, 2001).

We prefer to use the term “social buffering” rather than “social construction” to describe this phenomenon of the relationship between technology and society. The revolutionary evolution of human technology will ultimately bring significant changes to organizational structures and even social structures. Although this overall trend is not deterministic, it is nonetheless dominant and difficult to reverse. If we borrow the relevant concepts of functional affordance to analyze the unfolding of this process, we can see that the unique material attributes of artificial intelligence compared to traditional automated machines constitute potential functional options. These potential functional options are not all applicable. Social factors filter which functions can be activated, and the activated functions are those that have been influenced by society. This means that society influences the possibilities of these artificial intelligence technologies while also being changed by them.

The theoretical framework of this paper differs from the perspective of functional affordance in that Hutchby and others merely propose the concept and perspective of functional affordance without further clarifying it. Inspired by this, in this study, we assume that these objective technological material characteristics represent a series of vectors about A (A1, A2, A3, …, An), which, when activated, need to be filtered through the social buffering layer S, ultimately selectively presenting as SA1, …, SAn in specific practical processes. In this process, not only the characteristics A of the technology side are changed, but the social side S is also quietly reshaped. This theoretical model is illustrated in Figure 1. Before artificial intelligence truly affects society, we cannot predict with certainty how artificial intelligence will change society. As a new action subject, the practical process P of artificial intelligence encountering specific society S determines the future direction of artificial intelligence’s impact on society, and this process is precisely what empirical research in sociology should describe and explore.

We can further consider why there is a discrepancy between the potential options of technology and the actual social consequences of technology during the application process. For example, historically, the invention and application of textile machinery in the UK could trigger the Industrial Revolution and subsequent social changes, while in ancient Chinese society, it did not form a decisive social impact. The concept of functional affordance partially encapsulates this phenomenon. The fundamental reason for this phenomenon is precisely that technology does not exist solely in laboratories or vacuums; the existence of this important social factor leads to a dynamic and complex process when technology traverses the social buffering layer.

As shown in Figure 1, A represents the objective material characteristics possessed by technology, which have the potential affordance to become functional. S represents social factors, which can be viewed as the social buffering layer through which technology acts on humans. SA represents the social technological results presented after technology passes through the social buffering layer, embodying the dialectical unity of objectivity and subjective agency.

Specifically regarding artificial intelligence technology, based on current development trends, these objective material characteristics A include at least two categories. The first category is the material characteristics possessed by general computer technology: artificial intelligence has a computing speed far superior to that of the human brain; artificial intelligence is not influenced by emotions or cognitive biases when making decisions; the decision-making process of artificial intelligence is algorithm-dependent. The second category can be seen as the new features of artificial intelligence compared to traditional computer technology: artificial intelligence has self-decision-making capabilities; the decision-making process is data-dependent; the intermediate links in artificial intelligence’s decision-making are opaque and uncertain (Burrell, 2016; Mitchell, 1997; Schmidhuber, 2015; Russell & Norvig, 2016); artificial intelligence has a perception capability superior to that of humans when combined with sensors; artificial intelligence has self-evolution capabilities, etc.

The specific practical process P at the micro level is what we need to examine in our research. Although practice is full of uncertainties, it is not a completely unknown black box; it is a process in which different actors act in existing practical scenarios under specific resource and power structures.

Based on the above theoretical framework, to understand the practical process of artificial intelligence encountering social factors, we take a case study of an intelligent power plant in China’s power industry to explore how the material attributes and capabilities of artificial intelligence actors have changed the original social relationship structure of the factory in production and management practices, and how existing social relationships, organizations, and power structures influence the deployment and technological evolution direction of artificial intelligence. We do not seek to derive all fields of artificial intelligence applications from a single factory case but rather to glimpse the specific action process of artificial intelligence in technical practice and social factors through the application situation of this factory.

X Power Plant is located in S Province, a traditional energy province in China, and is a coal-fired power plant within a large state-owned capital holding power enterprise. Amid the wave of informatization and intelligent transformation in the electric power industry, X Power Plant was the first in the province to introduce a new generation of digital production and management systems, initially forming an intelligent factory based on the industrial internet. The entire transformation process began in 2020 and includes the construction of multiple components such as industrial internet, internet of things, sensors, digital twins, and artificial intelligence. In May 2022, the transformation project was completed and recognized as being at the international advanced level by the China Electricity Council. The introduction of artificial intelligence is included in the entire digital and intelligent transformation process of the factory, representing a significant technological innovation point and a key differentiator from traditional automation systems. The research team to which the author belongs began synchronous research on the factory transformation process in mid-2020, mainly using participatory observation and interview methods. The subjects of the survey included frontline operators, technical personnel, middle managers, and artificial intelligence engineers involved in the technological transformation of X Power Plant.

(1) Basic Technical Process and Decision-Making Power Structure Before Transformation

Before the digital technology transformation, X Power Plant already had a relatively high degree of automation. Compared to traditional assembly line manufacturing factories, energy production, especially thermal power generation, relies more on large equipment and machines, and the degree of automated operation of machines is also relatively higher. Workers do not directly manufacture products; the production of electricity is completed through large equipment. The core production process of the power plant includes two major parts: operation and maintenance, involving multiple fields such as steam turbines, boilers, electrical equipment, water treatment, thermal engineering, and fuel. The main job types for frontline operations include monitoring machine operations, setting machine parameters, and maintaining and repairing machine equipment.

In terms of organizational structure, around this core electricity production process, X Power Plant has formed five major horizontal organizational structure sections: management, operation, equipment maintenance, environmental safety, and market operations. At the same time, the plant has established five levels of hierarchy from the grassroots frontline operators to the power plant director. We view X Power Plant as a field full of power and social relationships. This field has a relatively fixed power structure surrounding the core task of production. According to the different decision-making powers, we can preliminarily divide the factory into three levels before the introduction of artificial intelligence.

The first level consists of frontline operators, whose main tasks include operating specific equipment according to operation manuals or instructions from the upper-level engineers, closing and opening valves, and conducting inspections and repairs of equipment faults, as well as other physical labor in production processes. Frontline operators are the executors of specific commands, completing work according to instructions or prescribed processes in most cases, and rarely need to make independent decisions unless encountering exceptional situations. Due to the expansion of higher education and the relatively high welfare benefits in the power industry, most frontline operators at X Power Plant are recruited from related majors in universities. These frontline operators possess a high level of relevant professional knowledge and skills and have the potential for upward mobility.

The second level consists of the plant’s middle-level technical managers, who often hold engineering titles and possess a high level of professional technical knowledge and rich frontline work experience. Due to the highly specialized nature of electric power production, professional technical personnel have considerable decision-making power in daily core production operations. Aside from some non-technical management positions, many middle-level technical managers bear management responsibilities for frontline employees in the administrative organization and also need to make judgments, analyses, and decisions on technical issues that arise. Beverly H. Burris, in her research on changes in industrial organizations after World War II, pointed out that the technocracy is an important organizational form (Burris, 1989). The status of experts in this organizational form has become increasingly prominent, and they possess relatively large power within organizations, compressing the original hierarchical structure. At X Power Plant, we can see trends of technological governance and expert governance, with a significant overlap between middle managers and technical experts, as technical elites and engineers promoted from the frontline constitute the middle-level technical management group at X Power Plant. This group plays a crucial role in the plant’s actual operation, possessing considerable decision-making power.

This decision-making power mainly involves technical issues in the production process of the factory, such as judgments on setting equipment parameters, determining the timing for closing valves, and diagnosing and qualifying complex equipment faults, among others. Middle-level technical managers, armed with years of work experience and professional knowledge and skills, often have stronger judgment capabilities than younger frontline staff and have more knowledge reserves and decision-making power than older frontline employees. In a technocratic system, these technical decision-making powers further extend into other areas of daily management, such as the decision-making power of middle-level leaders and engineer groups in equipment departments regarding the selection of repair materials, the decision-making power regarding which processes and construction plans to use for equipment maintenance and updates, and the recommendation rights for professional construction teams, etc. These decision-making powers are built on the trust of the factory’s upper management in the professionalism of the middle-level technical management group.

The third level consists of the plant’s upper management. These managers are responsible for the overall management and final decisions of the entire factory. However, these decisions often do not involve specific technical issues but mostly concern the development strategy of the factory and human resource management. Upper management needs to rely on the middle-level technical management group to carry out the daily management of the factory and also needs to obtain various information about the factory’s frontline operations through the middle-level technical management group.

Before the introduction of artificial intelligence technology for decision-making replacement, X Power Plant was in a relatively stable power structure. The entire operation of the factory heavily relied on the middle-level technical management group. The upward mobility path of the entire hierarchical system was also relatively clear: frontline operators could move up to higher management levels after accumulating experience and learning, making more technical judgments and decisions based on professional knowledge.

(2) The Middle-Level Replacement and Impact of Artificial Intelligence Technology

In 2020, the digital and intelligent transformation project of X Power Plant began. The primary goal of the upper management of the group where X Power Plant is located in introducing this technological revolution was to gain a long-term technological strategic position, i.e., to more accurately achieve a balance between environmental protection and efficiency under the “dual carbon” goals, while improving operational efficiency and reducing pollution emissions, promoting the iterative evolution of traditional energy plants. At the beginning of the project, both the group and the factory’s upper management viewed this project as an important strategic development direction for the factory to enter the era of Industry 4.0. Meanwhile, X Power Plant received ample national funding support, allowing it to introduce cutting-edge digital technologies relatively early among global peer enterprises.

At that time, the entire factory began to introduce a full-process digital production, management, and operation system. Compared to previous automation and information systems, the most significant feature of this system is the elimination of data, control, and decision-making silos based on the industrial internet platform, fully connecting equipment, control, and management processes, particularly incorporating artificial intelligence technology into the construction of this system.

The construction of the new demonstration intelligent power plant adopts a comprehensive logical design based on data + computing power + models + applications from value, business, and technological perspectives, deeply optimizing and reconstructing the entire process of enterprise operations based on a brand-new industrial internet platform, achieving management process automation, process technicalization, and technology visualization, allowing the power plant to transform from a relatively linear, single, and closed operational management model to a collaborative, ecological, and transparent management model closely linked across all elements, value chains, and industrial chains. (Research data: 202109a1)

According to the design by the technology provider, the entire new system includes ten major sections, covering decision-making centers, production monitoring, operational management, equipment management, business management, digital twin factories, digital security, digital office, and more based on the production process and management practices of the power plant. Among them, artificial intelligence plays a significant role in the decision-making center, production monitoring, operational management, equipment management, and business management sections.

The entire project optimized 108 processes in 13 key departments of the factory, newly designed 1250 functional pages, and the total amount of custom-developed code was approximately 20 million lines; completed 15,000 devices and 60,000 pipes in three-dimensional visualization; eliminated 46 data silos, deployed 52 intelligent models, effectively solving key equipment fault predictions, and achieving closed-loop optimization control of major links in the factory; deployed 9 types of image recognition algorithms. (Research data: 202109a1)

In traditional labor replacement processes, machines primarily replaced workers’ physical labor. This is determined by the material characteristics of machines in industrial society. Before the Industry 4.0 revolution, the primary material attributes that machines possessed compared to humans included greater mechanical power, superior physical durability and size, and the ability to produce continuously without fatigue, greatly enhancing the capacity for large-scale industrial production. However, machines could not perceive, judge, and decide intelligently like humans. Therefore, each evolution of machines would replace a large number of frontline workers engaged in repetitive labor. However, after introducing 52 artificial intelligence models at X Power Plant, we found that the potential targets of machine replacement were not merely frontline operators but directly targeted the crucial middle-level technical management group in the factory’s production processes.

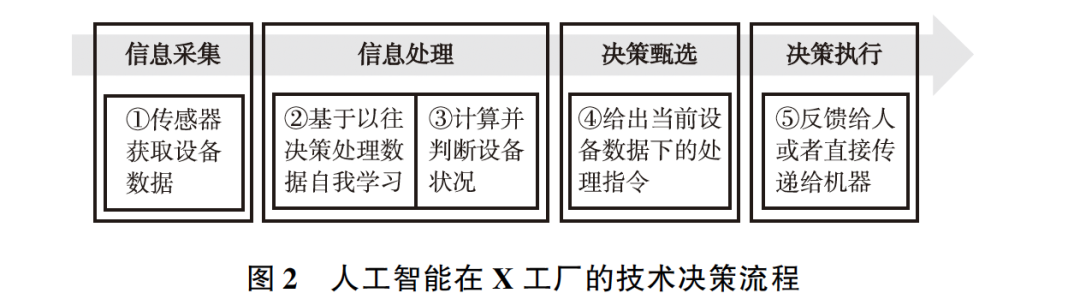

Figure 2 illustrates a typical technical decision-making process of artificial intelligence at X Power Plant. In this process, steps ② and ③ depend on the construction of artificial intelligence algorithm models, while the operation of intelligent models is based on the data perception and previous data acquisition in step ①. The entire decision-making process is the product of the comprehensive operation of sensors, the internet of things, and artificial intelligence technology.

In such a decision-making scenario, the technical judgments and decisions originally required to be made by engineers are replaced by artificial intelligence actors. In traditional scenarios, when inspection workers discover an anomaly in equipment parameters and surface structure, they report this phenomenon to their supervisors. Middle-level technical managers, based on their professional knowledge and experience, would make judgments, hold technical meetings, and propose technical solutions to address the issues. In this process, professional technical managers possess high technical authority, allowing them to fully utilize their expertise. This process not only reinforces the professional identity and sense of achievement of the middle-level technical management group but also consolidates their managerial status in the factory.

It can be said that before the introduction of artificial intelligence models, the middle-level technical management group possessed rich professional knowledge and practical experience, which constituted a moat for the decision-making power of engineers. However, as time progresses and the self-learning evolution speed of artificial intelligence accelerates, the technical decisions made by artificial intelligence can become more rationalized. The technical decision-making moat of the middle-level technical management group at X Power Plant is gradually being crossed with the addition of artificial intelligence actors. As the digital system is gradually deployed and used, engineers at X Power Plant have found that assuming there is no external interference and operations are entirely based on the design provided by the technology company, there will be a noticeable phenomenon of middle-level technical managers being replaced by artificial intelligence in the power plant. The speed of this replacement theoretically depends only on the degree of evolution of artificial intelligence’s decision-making capabilities.

The impact brought by artificial intelligence is multifaceted. In the daily production and operation processes of the factory, the influence attached to technical decision-making capabilities is not limited to production itself but also involves more specific interest issues. As previously analyzed, in a system close to technocratic governance, the authority in technology and organizational management power can, to some extent, be interchanged. Although technical elites may not occupy the top leadership position entirely, they hold significant discourse power over decisions related to technology. If the impact of artificial intelligence is not interfered with, it will at least lead to the following changes.

First, job replacement will bring about changes in organizational structure. The introduction of 52 artificial intelligence models has partially replaced the work of engineers in related processes, rendering some original positions meaningless. These positions include frontline operational roles with certain technical thresholds, but more significantly involve the middle-level engineering group. According to our investigation, after the digital transformation, the number of employees required in department A of X Power Plant decreased from 36 to 4 (Research data: 202109a2).

Second, due to the direct association between technical decision-making and operational and maintenance systems during the entire intelligent system transformation process, the artificial intelligence system directly provided decisions related to operational issues after technical decision-making, further weakening the actual power of middle-level technical managers. For example, before the introduction of artificial intelligence, technical managers’ diagnosis and decision-making regarding equipment maintenance issues were connected to the selection of material suppliers and maintenance providers, while the direct involvement of artificial intelligence often contrasted sharply with the choices made by middle-level technical managers. If artificial intelligence’s decisions are fully adopted, it would mean further stripping technical managers of their traditional powers. If there exists a space for power rent-seeking, this space will also be further compressed.

Finally, the optimization management and direct involvement of artificial intelligence in personnel assessment, organization, and finance will directly disrupt the existing interest patterns. The traditional relationships of mentorship, emotional ties, and loyalty in factories have not been set as parameters for artificial intelligence’s operation. The completely depersonalized approach of artificial intelligence in management is a significant material characteristic of its current operations. The management work of the original technical management group is based on the legitimacy of technical authority, which does not entirely exclude irrational factors; however, on one hand, artificial intelligence weakens the legitimacy of technical authority through the replacement of technical decisions, and on the other hand, it has the capability to directly intervene in the management and control of personnel.

If the introduction of artificial intelligence were merely a one-dimensional process focused solely on maximizing efficiency without considering the existence of social factors, then in this specific practical field of X Power Plant, potential reforms are about to occur, and the entire plant is on the brink of transformation, containing significant uncertainty.

(3) Artificial Intelligence as “Engineers”

In the overall digital transformation process of X Power Plant, the application of artificial intelligence is only part of the digital transformation but presents characteristics of actors different from previous applications of information technology. Before this digital transformation, X Power Plant was already a relatively automated factory, and information systems had been applied in the daily management and operation of the factory. This digital transformation systematically integrated management, operations, and production processes, with artificial intelligence being embedded in the entire production management system of the factory for the first time in history.

Unlike previous information technology upgrades, the material attributes of artificial intelligence make it no longer simply a tool for some middle-level technical personnel, but rather an actor with equal technical judgment and decision-making capabilities. From the observer’s perspective, artificial intelligence possesses a dual attribute of being both a tool and an action subject. This attribute is reflected in a hierarchical structural relationship. From the perspective of upper decision-makers and managers in the factory, artificial intelligence is a tool to achieve their production goals. However, for middle-level technical managers, artificial intelligence is a competitor that can also make technical judgments and engineering decisions.

As shown in Figure 3, for upper decision-makers, artificial intelligence is a tool to achieve higher technical goals. However, once the highest action goals are established, artificial intelligence can possess self-decision-making capabilities in the intermediate links of achieving those goals and form equal competitive relationships with other actors. Of course, not all artificial intelligence models directly replace engineers; those models that are not yet capable of replacing engineers are still used as reference tools for engineers.

What is the reason that in previous computer application upgrades, computers were merely tools for engineers to assist in task completion, while in the reform at X Power Plant, some artificial intelligence has become competitors with equal action status to engineers, possessing decision-making replacement capabilities?

The primary reason is the application of machine learning models such as neural network models in production processes. These machine learning models enable the artificial intelligence at X Power Plant to possess self-decision-making capabilities, which were difficult to achieve in past automated programs. In the early applications of computer programs at X Power Plant, the algorithms were fixed, mechanical programs. After the introduction of artificial intelligence models, computers can make judgments and decisions in complex and uncertain situations, rather than simply mapping existing fixed programs.

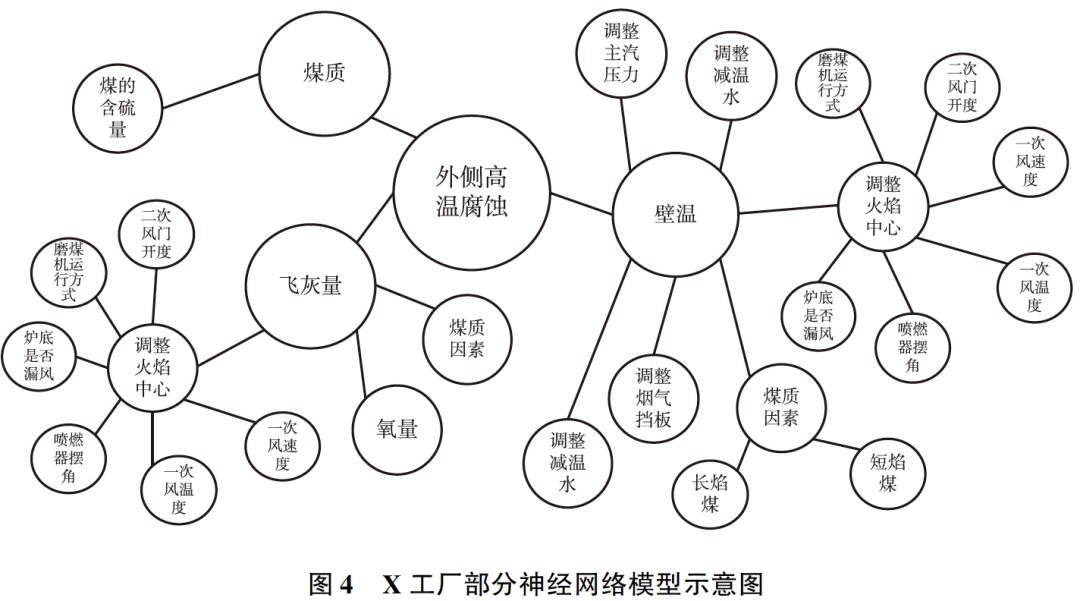

The artificial intelligence applications at X Power Plant are based on chemical-physical models, probabilistic mathematical models, and neural network models. Among them, the fitting ability of neural networks can describe and infer causal relationships between events. Even in situations where the true causal relationships are uncertain, neural network models can continuously approximate the optimal solution through expert experience data learning, statistical regularity calculations, and fuzzy reasoning. Some schematic diagrams of neural network models used at X Power Plant are shown in Figure 4.

The neural network learning models applied at X Power Plant mean that computers have constructed complex functions regarding the causal relationships between various equipment phenomena (indicators) and decisions, continuously approaching the fitting of a series of complex functions, directly establishing the associations between phenomena and technical decisions. Theoretically, this model does not rely entirely on understanding the principles behind engineers’ decisions; it only needs to learn from big data about the relationships between phenomena and decisions to make judgments and decisions in various complex situations (Mnih et al., 2015).

Moreover, compared to engineers at X Power Plant, artificial intelligence has a clear advantage in knowledge evolution. Due to the characteristics of machine learning, artificial intelligence will compare and verify the new data results generated after each technical decision with existing models to achieve a self-optimizing evolution. At the same time, the continuously updated massive expert knowledge database far exceeds the knowledge reserves of an average engineer.

Finally, the full-process digital transformation of X Power Plant, the application of sensors, and the creation of digital twin factory spaces enable artificial intelligence to possess the capability for self-perception and action in digital spaces. In digital spaces, both artificial intelligence and engineers’ decision instructions are transmitted to the next link in the form of information flow, both possessing equal status as information production and action subjects.

The technical decision-making mindset of traditional automation technology at X Power Plant and the technical decision-making after the introduction of artificial intelligence have significant differences. Before the intelligent transformation, technical experts viewed computers as tools, making judgments and decisions based on objective calculation results or indicators, leveraging human knowledge, experience, and intuitive judgment advantages. However, with the emergence of artificial intelligence, most of the experience, tacit knowledge, and inspiration of technical experts, while not fully comprehensible to artificial intelligence, are theoretically largely replaceable.

(4) Conflicts of Actors and the Emergence of Social Buffering Mechanisms

By mid-2021, the hardware deployment of digital systems such as artificial intelligence at X Power Plant was basically completed, and the trial operation phase began. At this time, anticipated resistance emerged. Compared to the smooth application of sensors, the internet of things, and other technologies, the application of artificial intelligence decision-making replacement encountered considerable resistance, with the relevant protesters being the middle-level technical management group of the factory. An artificial intelligence engineer mentioned in an interview with the author the resistance faced by the application of artificial intelligence decision-making replacement.

During our testing, we encountered widespread skepticism from the engineers in the factory, who believed these practices were incorrect, that it was too risky to let machines make judgments. (Interview data: 202112b5)

Workshop director B strongly opposed the use of artificial intelligence in his workshop, arguing that the operation instructions provided by artificial intelligence did not conform to past experiences.

This system’s timing for closing valves is incorrect; it’s too dangerous. If there are environmental issues, we will also face penalties. We will not follow its (artificial intelligence’s) instructions. (Interview data: 202109c1)

Meanwhile, most frontline operators held an open or welcoming attitude towards the introduction of artificial intelligence.

The work has become much simpler, significantly reducing the workload; it’s very easy, and there’s nothing unfamiliar about it. (Interview data: 202109c3)

During this period, a small incident reflected the conflict between the middle-level technical management group and the external artificial intelligence technology designers.

Middle-level leaders responsible for technical management in workshop D had previously used relatively stable construction teams, material suppliers, and construction plans to address technical issues in equipment maintenance. However, the new artificial intelligence model linked the diagnosis, prediction of equipment issues, and material procurement to market-based solutions, arriving at problem-solving approaches that differed from the past. The engineers in workshop D believed that the technical diagnoses and solutions provided by artificial intelligence may not be suitable for special situations, and that each issue should be analyzed specifically, raising concerns about the automated procurement, automatic market bidding, and optimal solution analysis in the artificial intelligence model, deeming it opaque and reflective of the interests of algorithm designers. The opacity of algorithms made it difficult for third-party observers to determine whether this algorithm contained the economic interests of the designers. However, we can at least ascertain that the process of technical diagnosis—technical solution—market procurement in workshop D may contain a space for interests, and the power previously controlled by technical managers has now shifted to the algorithm designers of artificial intelligence, forming a situation of algorithmic centrism.

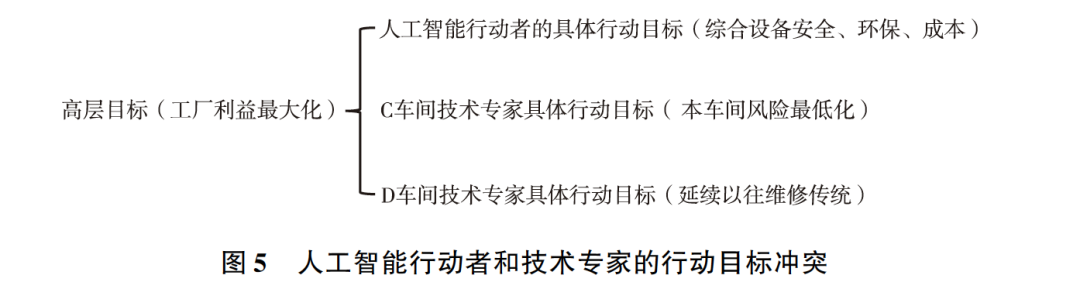

This incident illustrates that in the intermediate process of achieving final goals, as practical action subjects, there may exist conflicts of goals and interests between artificial intelligence actors and human actors. We use Figure 5 to represent the conflicts of action goals between artificial intelligence and engineers in these two events at X Power Plant.

Essentially, artificial intelligence, as a tool for upper decision-makers, reflects the action goals and interests of the technology application subjects. The conflict between artificial intelligence and engineers can be viewed as a game of interests between upper decision-makers and middle engineers. However, from the specific practical process, artificial intelligence has already manifested conflicts of goals with engineers, who nominally also represent the interests of the factory.

The upper management of X Power Plant also faces pressures brought by artificial intelligence technology. On one hand, the middle-level technical management group raises various opinions upwards, which may become an unstable factor in the operation of the factory; on the other hand, the overly intelligent application of artificial intelligence in performance assessments, personnel management, and other areas threatens the legitimacy of upper management’s actions in making personnel arrangements. For instance, the decision to eliminate a large number of technical management positions based on artificial intelligence’s decisions would be unlikely to occur in a state-owned enterprise that pursues stability in economic benefits as well as political and social benefits. Thus, the application of artificial intelligence technology at X Power Plant has introduced new variables, which are essentially new action strategies among various parties within the factory.

1. Algorithm Rewriting

These variables primarily stem from the ongoing and deepening interactions between the artificial intelligence technology suppliers and the technical management group of X Power Plant, i.e., the establishment and maintenance of social relationships between artificial intelligence algorithm designers and middle managers. To better promote intelligent transformation, the technology provider of artificial intelligence engaged in continuous communication and negotiation with the middle-level technical management group. In workshop D, as the traditional process of technical diagnosis—technical solution—market procurement was interrupted by artificial intelligence, relevant personnel expressed the desire to revert to past decision-making methods during discussions with the technology supplier.

The leaders of workshop D hope to maintain past practices, believing that everything operated well before artificial intelligence made decisions for them, and the company did not suffer losses as a result. They think we might manipulate the market procurement results. We believe the algorithm is fair and open, yielding optimal results. However, they believe this process is not transparent. (Interview data: 202112b1)

This information was obtained from interviews with the technology suppliers of artificial intelligence during the research. Due to commercial requirements, most algorithms themselves cannot be fully disclosed, and the “thinking” mechanisms of artificial intelligence also possess opacity (Burrell, 2016). Thus, the algorithms of artificial intelligence represent a non-transparent black box to users of artificial intelligence. Many scholars have pointed out that as artificial intelligence permeates various fields of society, the future digital society will, to some extent, become a “black box society” (Brevini & Pasquale, 2020). From the perspective of third-party observers, if the decision-making process prior to the intervention of artificial intelligence contained opaque human factors that might imply some hidden rules, then the practice of replacing human decisions with algorithms has not made the decision-making process more transparent; rather, it has reignited users’ doubts about the algorithms themselves.

The technological transitions of the artificial intelligence technology provider prove that algorithms inherently contain spaces for social operations. After sufficient negotiation with workshop D, the technology provider of artificial intelligence modified specific parameters and rewrote part of the algorithms, successfully aligning the decisions made by artificial intelligence with the past practices of the workshop. Workshop D believes that the algorithms before modification reflected the interests of the artificial intelligence algorithm designers, while the modified algorithms better align with past practices, reducing the uncertainties brought by new market procurements. As previously mentioned, the design of algorithms has effectively stripped traditional technical managers of their relevant decision-making powers, transferring the power of technical decision-making and market procurement decisions to the algorithms. Both parties balanced the decision-making powers during negotiations, resulting in the rewriting of algorithms. However, the rewriting of algorithms did not fundamentally change or prevent the intervention of artificial intelligence.

2. Strategic Abandonment

Among the ten sections of intelligent transformation at X Power Plant, not all sections were fully utilized after completion of the transformation acceptance. The reason for this is not that the technology provided by the supplier is unusable, but rather that the upper decision-makers at X Power Plant believe that some technologies are not suitable for immediate use.

In the ten sections, the technologies aimed at replacing frontline operators were almost immediately put into use. For example, intelligent cameras and artificial intelligence image recognition technologies directly replaced frontline operators: tasks previously performed by workers, such as inspecting and reporting equipment safety hazards and operational statuses, are now directly completed by machines. The significant characteristic of these technological replacements is that they are directed at machines and involve fewer complex interpersonal relationships.

In contrast, the technologies aimed at replacing middle management groups were only utilized after repeated modifications and negotiations. These technologies often involve relatively complex technical judgments and are associated with certain organizational management and market decision-making functions. At present, due to capability limitations, artificial intelligence is still unable to cover all complex judgments. Therefore, although the middle-level technical management group perceives the potential threat of artificial intelligence and attempts to resist it, their positions cannot be completely replaced in a short time. Thus, after strategically dissolving the direct conflicts of interest brought by artificial intelligence, they have also accepted its application.

Finally, in personnel management, performance assessment, market, and procurement processes, X Power Plant chose to shelve the use of artificial intelligence. The decision-making of artificial intelligence in these areas not only impacts the decision-making power of middle-level technical management groups but may also directly affect the decision-making power of upper management. For upper decision-makers, the results of artificial intelligence’s decisions may merely serve as references; the real decision-making power regarding people and interests still needs to be retained in their hands at this stage. The decision-making results of artificial intelligence in these areas are often overly rationalized and modeled, based solely on efficiency considerations and unable to reflect the complexities of upper management’s decision-making.

Therefore, by mid-2021, despite the fact that the intelligent transformation of X Power Plant had been completed from a technical perspective, artificial intelligence remained in a usable but unused state in some sections. The objective technical characteristics of artificial intelligence theoretically enable it to perform many functions in a modern factory, but not all functional options can penetrate the social buffering layer to ultimately become truly accepted and recognized technology.

3. The Conversion of Replacement

Although the technological options of artificial intelligence are influenced by multiple social factors, we still observe the direct consequences of the impacts brought by artificial intelligence. The organizational structure of the entire factory has changed. In a certain technical department A at X Power Plant, the staffing was reduced from the original 36 to 4. This technical department was completely eliminated after the intelligent transformation, and the personnel who were replaced in this department have become a problem that X Power Plant needs to solve.

Faced with this situation, X Power Plant adopted a conversion strategy for replacement. After the cancellation of department A, X Power Plant established a new department B. The main function of department B is to respond to the demands of informatization and intelligent transformation. Theoretically, its optimal strategy is to recruit personnel with knowledge and skills in artificial intelligence and related areas, but the current main members come from the technical personnel in department A who were replaced by artificial intelligence. X Power Plant believes that these technical personnel can relearn new skills for new positions and effectively integrate new digital technologies with their previous professional knowledge. If the logic of maximizing market benefits were fully followed, X Power Plant should have eliminated these replaced personnel to maximize the reduction of labor costs. However, as a large state-owned energy enterprise in a leading industry, X Power Plant needs to consider many political and social factors beyond economic considerations. The stable operation of the factory, employee sentiment, and social responsibility are all considerations for the upper management of X Power Plant. Therefore, after being the first to introduce artificial intelligence at the provincial and even industry levels, X Power Plant did not experience a large-scale dismissal of middle management personnel and engineers but instead successfully implemented the transformation of organizational structure and job positions.

The reason for this seemingly inefficient action strategy in response to the job changes brought by artificial intelligence decision-making replacement at X Power Plant can be attributed to at least the following social factors. First, the nature of the factory as a state-owned enterprise. Compared to the capitalist factories studied by Marx regarding the replacement of workers by machines, we are studying a production unit with a different ownership structure. Although state-owned enterprises still face economic pressure for market benefits, they will also consider more the stability of their employee workforce and have greater tolerance for the time required for employees’ skill transformation, without implementing simple layoffs after technological decision-making replacement. Second, although external market competition faced by the electric power industry is intensifying, it still retains a strong monopoly. Consequently, the introduction of digital technologies such as artificial intelligence is more of a forward-looking and strategic action rather than purely driven by capital and economic efficiency. In this process, the purpose of artificial intelligence decision-making replacement is not to directly reduce labor cost expenditures but to better obtain long-term technological strategic positions and achieve a more precise balance between environmental protection and efficiency under the national “dual carbon” strategy. Overall, in this specific practical process, the influence of ownership of production materials, the need for technological reform to maintain stability, and long-term planning factors constitute another social buffering effect against the technological decision-making replacement of artificial intelligence, preventing the complete occurrence of the technological impact at X Power Plant according to the logic of technological rationality and economic efficiency.

This replacement conversion plan is not unique to X Power Plant. According to a 2021 research report by the World Economic Forum, HP, during its transformation for the Fourth Industrial Revolution, redistributed the task responsibilities released by technological changes among different roles within the company. Original frontline operators were able to perform complex tasks previously assigned to technical experts, while engineers could accept higher-level skill enhancements and undertake data science work (World Economic Forum, 2021).

Of course, although this strategy of replacement conversion has not directly led to unemployment for the existing middle-level technical management group at the current time point, it will, in the long run, change the future job demands. The elimination of department A has significantly impacted potential job seekers with knowledge of department A, that is, traditional electric power-related knowledge. The newly established department B can currently tolerate the job transitions of traditional professionals, but in the future, it will require direct recruitment of personnel with knowledge in artificial intelligence and related technologies. This also means that although X Power Plant has delayed the technological impact and job replacement of artificial intelligence through the strategy of replacement conversion, it cannot fundamentally reverse the trend of replacement affecting specific groups over a longer period. As the technological spear of artificial intelligence is destined to pierce through certain traditional structures, the buffering layer constituted by various social factors has delayed the consequences of technological impact over time, but structural changes have already occurred.

Ultimately, by mid-2022, X Power Plant successfully completed its intelligent transformation, achieving a situation where humans and artificial intelligence coexist in many positions. Overall, this coexistence of humans and machines has been realized through three micro-strategies influenced by social factors: given the social relationships between artificial intelligence engineers and middle-level technical managers, the technology provider of artificial intelligence altered the original algorithms to ensure the smooth application of artificial intelligence, thereby maintaining the original power structure; the strategy of strategic abandonment indicates the direct filtering effect of social structural factors, meaning that technological possibilities affecting key powers and upper-level interests will not penetrate the social buffering layer in a short time; and the replacement conversion strategy shows that when technology encounters social buffering, job spaces and impact timelines will transform into each other, with the factory exchanging job conversions for time, delaying the direct consequences of artificial intelligence decision-making replacement impacts, but the organizational spatial structure has already changed.

In the case of X Power Plant, the human factors affecting the rewriting, filtering, and reshaping of artificial intelligence technology are closer to a mechanism of expediency and self-protection, but this does not fundamentally reconstruct the influence and impact of artificial intelligence technology. Expediency means that time variables and structural space variables are introduced, allowing the cognitive labor replacement effects brought by technology to be absorbed through changes in organizational structures, delaying the short-term impacts of artificial intelligence’s labor replacement actions. Protection means that when middle-level technical management groups cannot resist artificial intelligence, they require social forces from outside their group to provide protection. At the same time, this phenomenon also confirms the judgment of scholars like Qiu Zeqi regarding the technology-organization co-construction mechanism (Qiu Zeqi, 2005). The significant evolution of the material attributes and capabilities of artificial intelligence technology at X Power Plant directly touches on the core content of production, possessing direct replacement capabilities for some engineers. Those artificial intelligence technologies related to environmental protection, technology, and safety possess strong technical rigidity, directly piercing through parts of the original organizational resource-power distribution structure.

3. Conclusion

Compared to the impacts brought by traditional machines replacing frontline workers, the replacement of middle-level technical management groups by artificial intelligence in decision-making capabilities has become a new phenomenon, which is also a new historical phenomenon following human society’s entry into the Fourth Industrial Revolution and intelligent stage, constituting a shock to the technical management system and traditional power decision-making structures of factories.

From a historical perspective, the digital transformation of X Power Plant may just happen to be at the critical point of the explosion of artificial intelligence technology. Some of the artificial intelligence technologies in the digital transformation of X Power Plant, alongside current technologies like ChatGPT and AI agents, have already shown signs of crossing the moat formed by experience, tacit knowledge, inspiration, and creativity. Just as Julius Caesar’s crossing of the Rubicon River marked significant changes in Western history, we do not dare to assert that artificial intelligence is experiencing a crossing of the Rubicon moment; however, we must carefully and rationally consider its potential transformative possibilities. Once artificial intelligence truly crosses the Rubicon, the social buffering of artificial intelligence technology will not only be an objective immune response but should also become an ethical issue actively initiated by all parties in society.

In this empirical research, the upper decision-makers of X Power Plant and the technology suppliers of artificial intelligence, through micro-level social action strategies, have minimized the direct impacts brought by artificial intelligence technology, allowing the application of artificial intelligence at X Power Plant to be relatively smoothly realized. However, middle-level technical managers find themselves in a state of powerlessness in the face of conflicts of action with artificial intelligence—some middle-level technical experts lack the opportunity to reconstruct technology in the relationship of “use-used” but instead face the risk of being replaced in an equal relationship. This also means that the social buffering against technology must come from higher levels of resource and power structures.

Early deep digital transformations and upgrades in China mostly began with large state-owned enterprises. The factory in this case exhibits differences in ownership structure, economic and social interest orientations, and operational logic compared to private enterprises and foreign enterprises. Theoretically, these different social factors will have varying impacts on the buffering mechanisms of artificial intelligence technology. When X Power Plant faces the negative impacts brought by artificial intelligence, due to considerations of political and social responsibilities, the upper management actors of the factory adopt various strategies to delay the impacts of technology to achieve long-term strategic goals. In contrast, more cost-oriented enterprises may respond to impacts through layoffs, thereby avoiding the social consequences of technological impacts. However, the social impacts of artificial intelligence will not disappear; they will merely shift to the external social level. This necessitates social buffering for the technological impacts at a broader national and societal level.

From another perspective, the coping measures of large state-owned enterprises in the face of technological shocks from artificial intelligence also provide a practical possibility for more universally meaningful social buffering, reflecting the unique social, economic, and cultural influences under which social buffering mechanisms operate in China. The broader political system differences, cultural tradition differences, and social security system differences between Western and Chinese societies may lead to different versions of social buffering processes when facing future technological shocks from artificial intelligence. To a certain extent, the competition direction of artificial intelligence technology applications between countries in the future may also be closely related to the social protection systems of various countries in responding to technological social risks. This requires further research and discussion.