Click the blue text to follow us

When working in industrial control, we often encounter various types of buses. Today, we will learn about one of them, Profibus, which is a widely used fieldbus communication protocol in the industrial automation sector, primarily for real-time data exchange between industrial devices (such as PLCs, sensors, and actuators).

First, let’s look at its classification:

1. Two Main Types of Profibus

1. Profibus DP

Main Purpose: Factory automation (such as production line control).

Performance Characteristics:

High-speed communication (up to 12 Mbps).

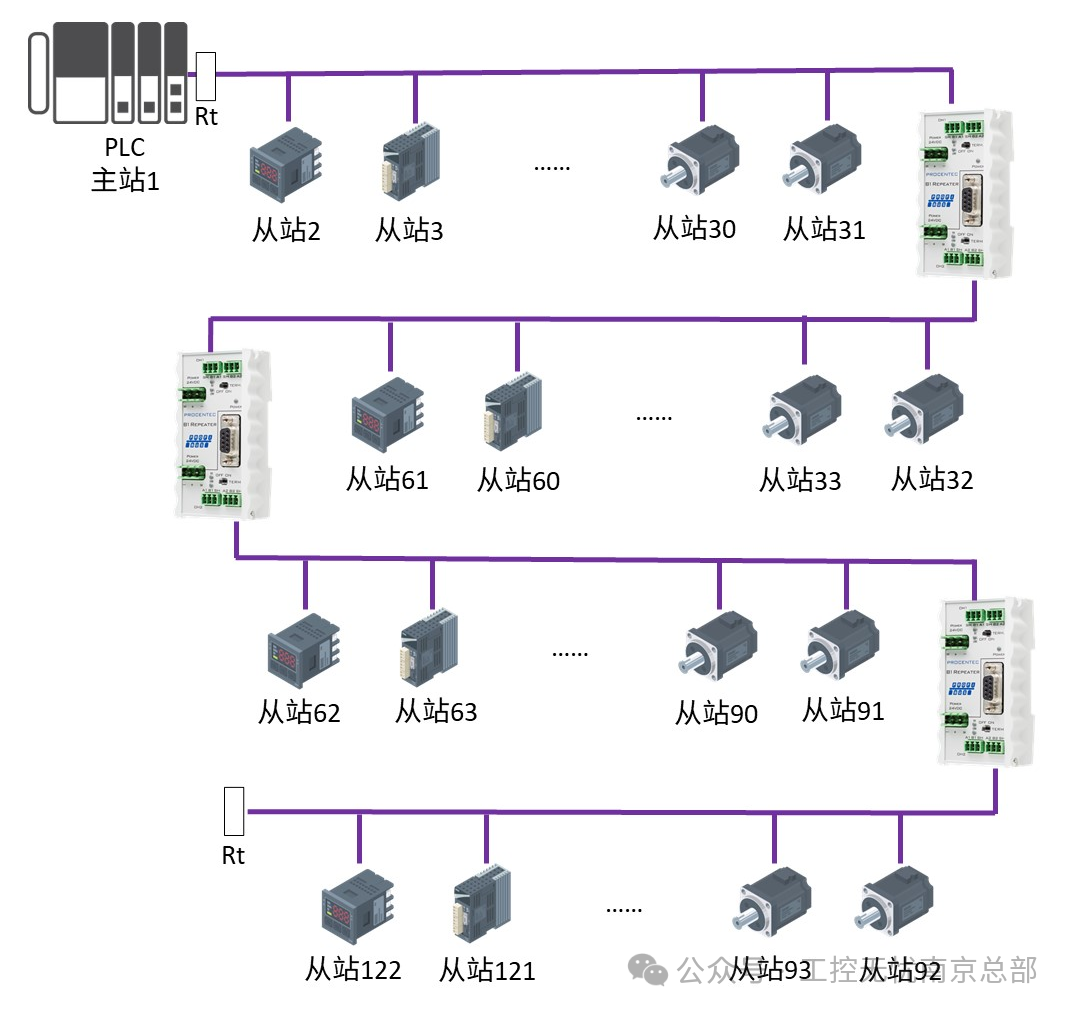

Master-slave architecture (1 master controls multiple slaves).

Supports up to 126 devices, with a maximum cable length of 100 meters (at 12 Mbps).

Typical Applications: Communication between PLCs and frequency converters, I/O modules.

2. Profibus PA

Main Purpose: Process automation (such as in the chemical and petroleum industries).

Performance Characteristics:

Based on IEC 61158 standard, supports intrinsic safety (Ex explosion-proof).

Uses MDP (Manchester Bus Powered) technology, combining communication and power lines.

Fixed communication rate of 31.25 kbps, with a maximum cable length of 1900 meters.

Typical Applications: Connecting pressure transmitters, temperature sensors, and other devices in hazardous environments.

Next, let’s look at its technical features:

2. Technical Features

It is mainly divided into three parts:

1. Physical Layer:

Uses RS485 (DP) or MBP (PA) transmission media.

Utilizes twisted pair cables, requiring termination resistors at both ends of the bus (to prevent signal reflection).

2. Protocol Stack:

Based on the OSI model’s Layer 1 (Physical Layer), Layer 2 (Data Link Layer), and Layer 7 (Application Layer).

The master controls the slaves through a polling mechanism, ensuring real-time performance.

3. Data Format:

Supports periodic data (such as sensor values) and non-periodic data (such as parameter configurations).

Maximum single frame data of 244 bytes (DP) or 32 bytes (PA).

Next, let’s look at the differences between Profibus and Profinet:

3. Differences Between Profibus and Profinet

|

Feature |

Profibus |

Profinet |

|

Technical Basis |

Fieldbus based on RS485 |

Industrial Ethernet protocol based on Ethernet |

|

Real-time Performance |

Millisecond level (DP) |

Microsecond level (IRT mode) |

|

Topology |

Linear or tree structure |

Star, ring, or tree structure |

|

Bandwidth |

Up to 12 Mbps (DP) |

100 Mbps to 1 Gbps |

|

Application Trend |

Traditional devices are still widely used |

Gradually becoming mainstream (especially in IIoT) |

Finally, let’s look at the key points in practical applications:

4. Key Points in Practical Applications

When applying Profibus, we can achieve our functions through the following steps.

1. Network Configuration:

Need to use GSD files (device description files) to configure slave parameters.

The master programming tool (such as STEP 7) needs to import the GSD file to recognize the slaves.

2. Troubleshooting:

Common issues: termination resistors not connected, cable shielding damaged, address conflicts.

Use an oscilloscope to detect waveforms or Profibus diagnostic tools (such as BT200).

3. Alternatives:

When upgrading old systems, a Profibus to Profinet gateway can be used for protocol conversion.

5. Why is Profibus Still Used?

Mature and Stable: Over 30 years of industrial validation, high reliability.

Low Cost: Traditional devices can be integrated without replacement.

Compatibility: Supports devices from multiple manufacturers (Siemens, ABB, Phoenix, etc.).

Profibus is the “classic protocol” of industrial automation. Although it is gradually being replaced by Profinet, it remains irreplaceable in existing devices and specific scenarios (such as explosion-proof environments). Understanding its principles and practical details is crucial for control engineers.

Industrial Control Wuyou Nanjing Headquarters WeChat ID: yixing7713

Industrial Control Wuyou Nanjing Headquarters WeChat ID: yixing7713

If you are interested in this article, scan the code and note: Communication Technology Exchange.

Share

Share Collect

Collect View

View Like

Like