Winding Machine

Winding the positive and negative electrode sheets along with the separator to form the cell.

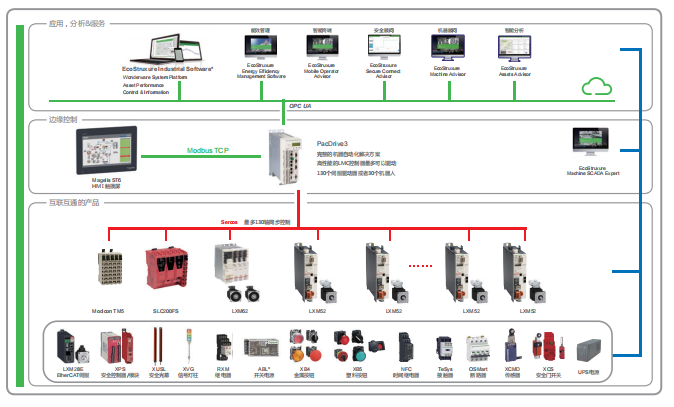

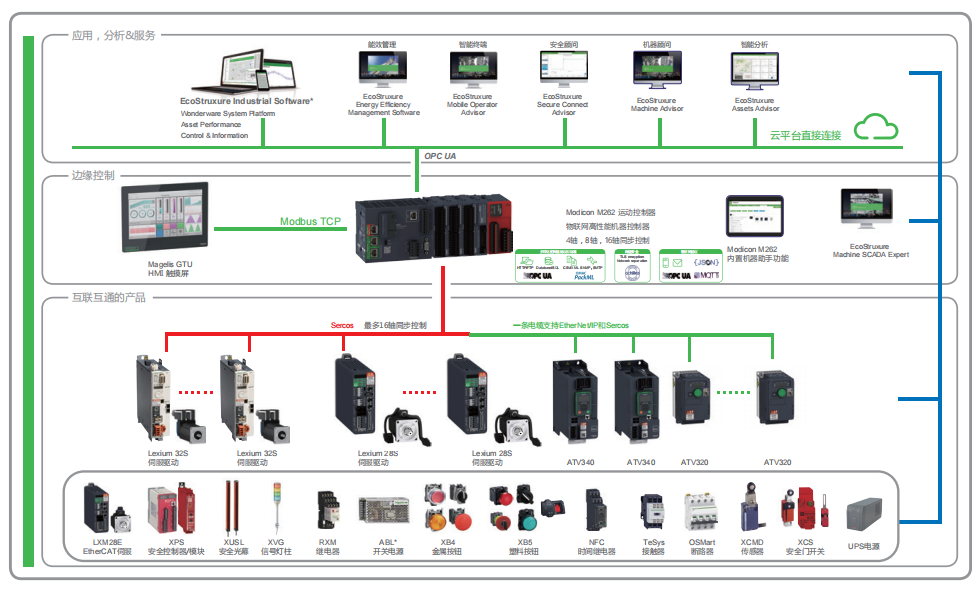

Schneider Solution Architecture Diagram

Key Points

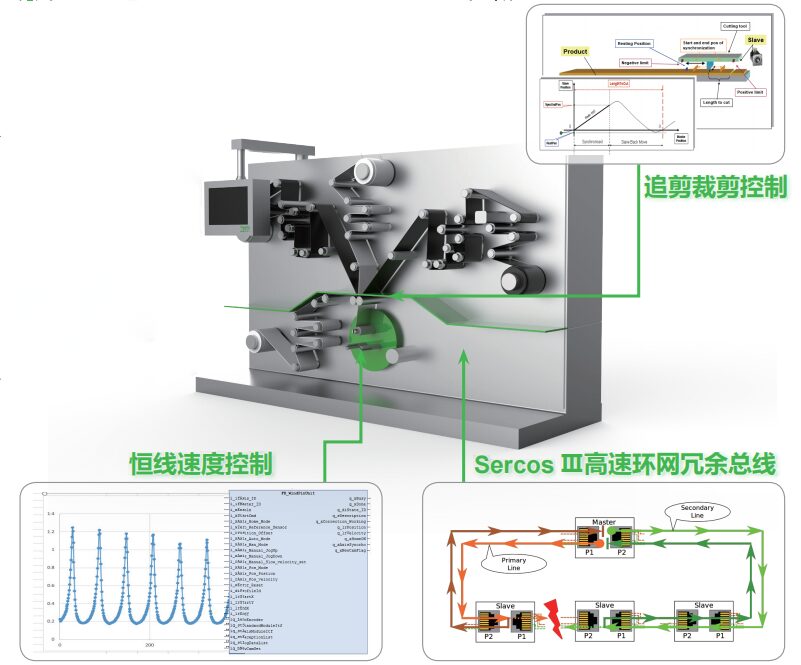

Constant line speed control: Custom variable speed function block to maintain constant winding line speed and stable tension fluctuations.

Tracking cutting control: Utilizing a dedicated tracking cutting control function block to ensure the cutting knife follows during winding.

SercosIII automation high-speed response bus: Supports both linear and ring topologies, with ring network redundancy and hot-swappable devices.

Winding Machine Technical Specifications:

> Irregular line speed 1.2m/s, winding core circumference 0.3m/revolution, alignment ±0.5mm, tension fluctuation ±10%

> Circular line speed 2.5m/s, winding core circumference 0.3m/revolution, alignment ±0.5mm, tension fluctuation ±10%

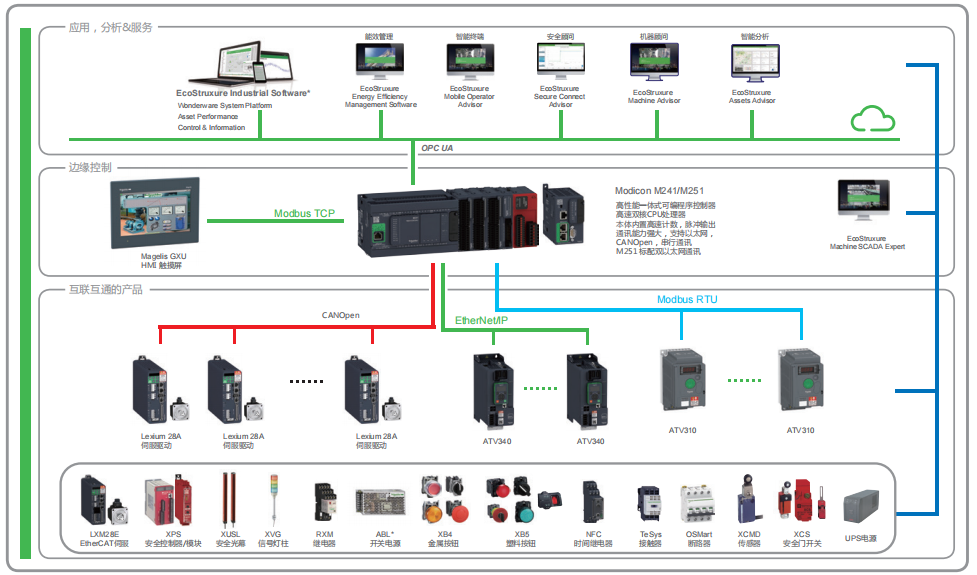

Stacking Machine

Stacking the positive and negative electrode sheets alternately through the separator to form the cell.

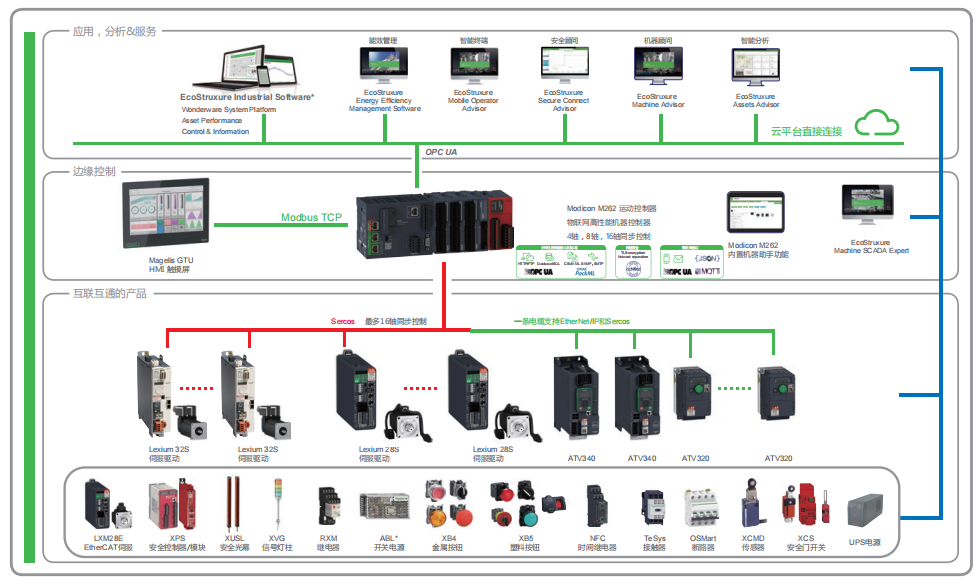

Schneider Solution Architecture Diagram

Key Points

Stability control of separator tension: Confirming the positional relationship between the lateral axis and the buffer roller, electronic cam achieves high-speed stacking with small tension fluctuations, improving stacking speed and rhythm.

Stacking neatness: Algorithm processing of the shading amount of the laser correction sensor to adjust the correction speed, achieving high-precision correction control to ensure neat end faces.

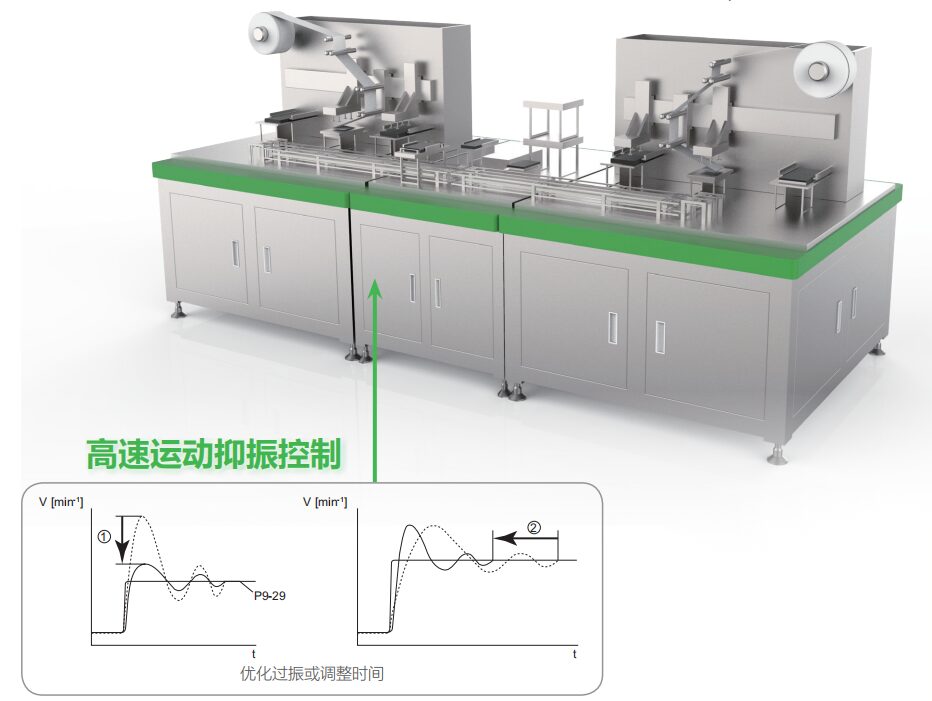

High-speed positioning of the stacking table lateral axis: LXM28 servo vibration suppression function reduces vibrations at the end of high-speed lateral movement, decreasing waiting time and improving stacking quality and efficiency.

(1) Optimized to low overshoot

(2) Optimized to short adjustment time

Vibration suppression is used to compensate for the inherent frequency of the mechanical system. Both optimization criteria can utilize the vibration suppression option.

Dual-station Stacking Machine Technical Specifications:

> Single sheet efficiency: 0.3-0.5s

> Overall alignment accuracy of electrode sheets: ±0.4mm

> Progress of electrode sheets adjacent to the separator: ±0.3mm

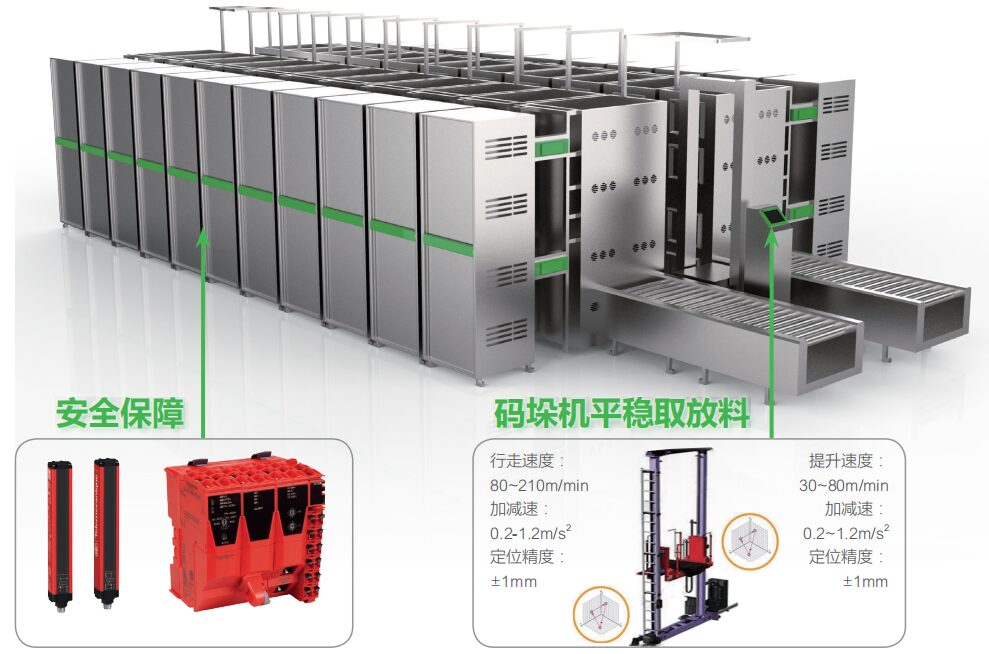

Formation Library

Charging and discharging the lithium battery in a heated and pressurized environment to activate the battery.

Schneider Solution Architecture Diagram

Key Points

Precise pressure control implementation (S-curve positioning):

● Reduce/eliminate positioning overshoot, decreasing acceleration/deceleration time by 20%~40%

● Reduce mechanical vibration, mixed use of frequency conversion servo.

Stable loading and unloading of the palletizer:

● Accuracy ±1mm, better anti-vibration (anti-sway) over 15m, architecture performance exceeding 0.5m/s² acceleration/deceleration.

Safety Assurance:

● Hardware and software safety products to prevent excessive current from damaging the battery pack.

● Over-voltage/under-voltage/breakage/under-current/over-temperature protection functions for people/machines/materials.

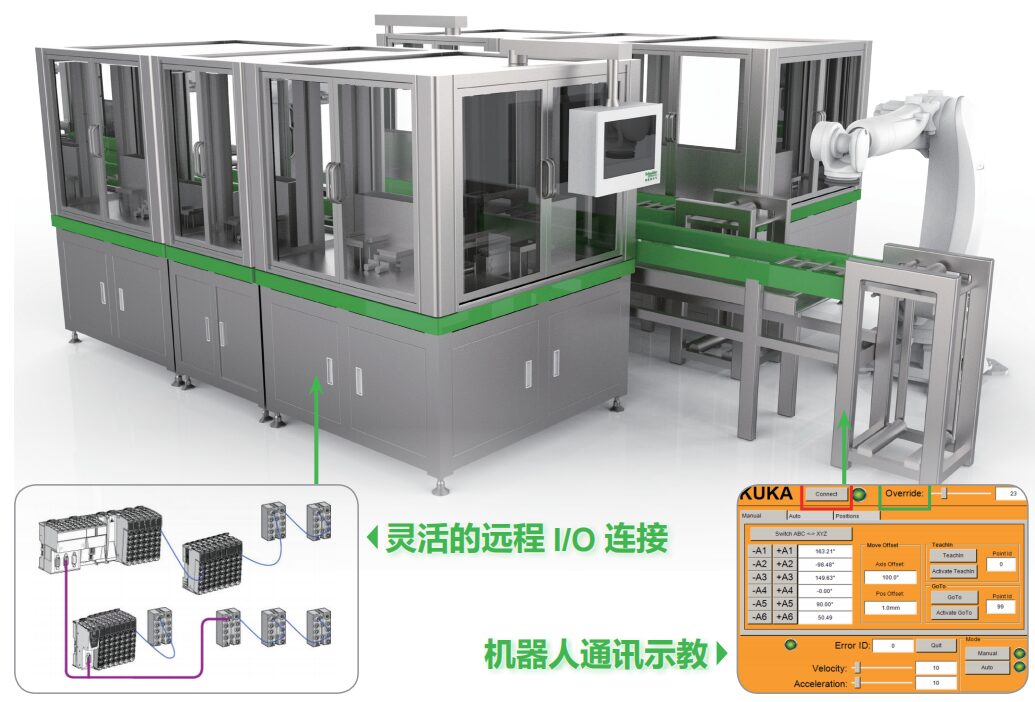

PACK Line

Packaging the batteries.

Schneider Solution Architecture Diagram

Key Points

Rich communication network:

● PLC multi-network support including EtherNet/IP, ModbusTCP, RS485, RS232, CANopen, OPC, etc.

Reduce configuration changes with process variations:

● One SoMachine programming software

● Remote distributed I/O connection method, sectional connections, flexible additions and reductions.

Seamless communication teaching of multiple series robots:

● Multi-network communication media, robot function library.

Source: Schneider Electric