Skip to content

“When it was released, everyone said it was ugly, but it sold out immediately.” – This phrase, previously used to describe the iPhone, is now applied to Apple’s new headset, the Vision Pro. On February 2, after Apple’s official launch of the Vision Pro, it triggered a buying frenzy, with the product “selling out in seconds,” even causing the starting price of $3,499 to be inflated to nearly 90,000 RMB in the grey market.

Can the smart glasses and AR/VR devices that have not gained popularity for so many years really be ignited by Apple? Does the Vision Pro deserve to be called a “revolutionary” virtual reality product? From some trial reports, we see mixed reviews.

Opinions on the experience may vary, but hardware does not lie. Recently, the well-known repair site iFixit once again “first disassembled” the Apple Vision Pro, revealing every circuit board, every screw, and every camera. All the secrets of this ultimate Apple product are exposed for the first time without reservation. We can also take a glimpse into the internal structure and component materials of this expensive Apple headset.

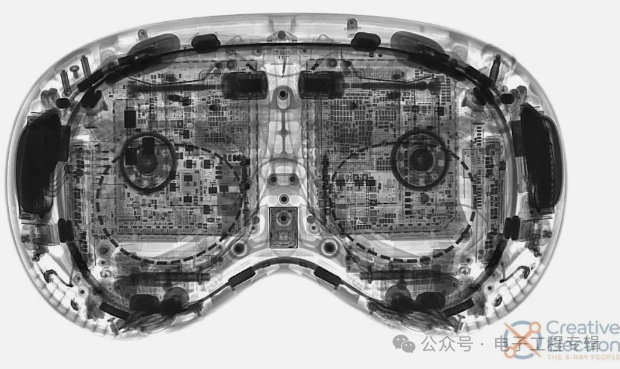

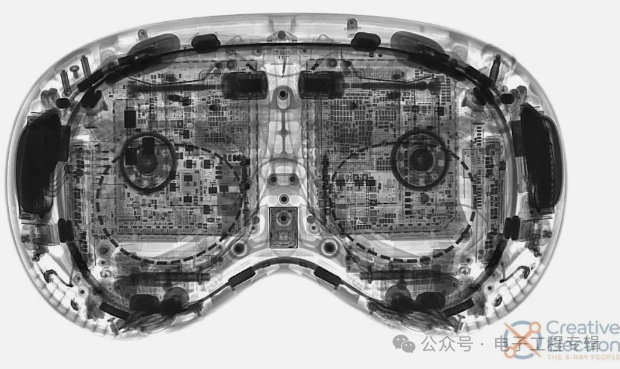

iFixit also found Creative Electron to take an X-ray of the Vision Pro, reportedly costing $3,500 (equivalent to a brand new Vision Pro). In the X-ray image, we can see various cameras, sensors, and a dense array of electronic components on the circuit board.

There is also a 360-degree rotating X-ray demonstration video. It is not difficult to see that this groundbreaking product has a complexity of internal structure that cannot be ignored.

A Machine With Three Interfaces

From the disassembly video, disconnecting the battery line and the Buff Lightning connector of the headband is very simple, requiring only a SIM card ejector tool.

iFixit also “brutally” dismantled the speaker, which is fixed to the sides of the headband and can be removed easily using a SIM card tool. iFixit states that wearable devices are very easy to damage, so having easily replaceable speaker modules is significant.

At the end of the headband, there is a rotating magnetic buckle that connects to the battery connection line, using a non-standard oversized Lightning interface. iFixit calls this “unforgivable”.

In total, there are three types of interfaces on the Vision Pro! The Lightning data cable for the Vision Pro power has 12 pins, and the speaker’s Lightning interface has 10 pins… it’s a bit complex.

The subsequent disassembly process is very routine for Apple hardware: heat gun, pry tool, screws, brackets, and connectors.

(Screenshot from the Vision Pro teardown, source: iFixit, same below)

The first component to be disassembled is the front glass panel, which is a single piece of 3D-formed, laminated, fully curved glass, weighing only 34 grams, glued to an aluminum alloy frame. iFixit spent a lot of time removing it, but a protective plastic film on the glass partially peeled off, seemingly a layer of “tempered film” added by Apple on the outer layer of the Vision Pro.

Based on this, AppleTrack also conducted a durability test, finding that under normal wear conditions, such as walking around the house with headphones and bumping into walls or cabinets, the front glass of the Vision Pro would wear but would not suffer serious damage. If dropped from head height, the front glass of the Vision Pro might completely shatter, and the speaker would likely not escape unscathed. The following image shows the result after AppleTrack dropped it eight times:

If damaged, Apple’s after-sales service will charge $799 just for the glass panel. The Apple website currently shows that the Vision Pro itself has a 90-day warranty, with Apple Care+ priced at $24.99 per month or $499 for two years. Additionally, the accidental damage repair fee for the Vision Pro itself is $299, while the repair fee for the power and data cables is $29.

EyeSight Feature Unveiled

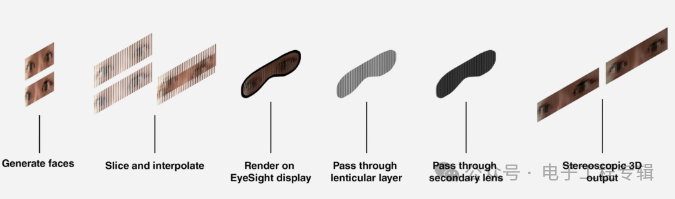

Under the glass panel, there are three layers of screens: an expansion layer, a lens layer, and a flexible OLED display from LG Display. Through these three layers, Apple can achieve the EyeSight feature.

When someone approaches a person wearing the Vision Pro, the device’s screen activates transparency mode, allowing the wearer to see the physical world. At the same time, when the wearer is immersed in a digital environment or using applications, EyeSight provides visual cues about what the user is focusing on to others.

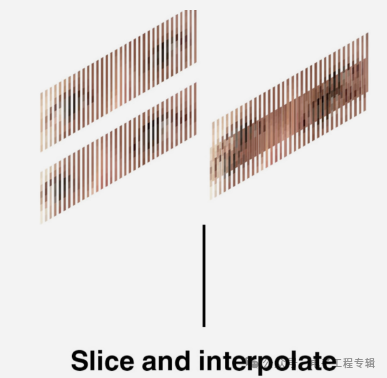

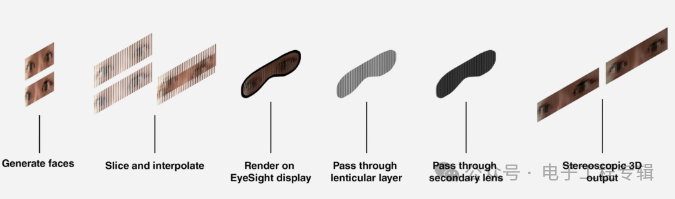

The specific operation is to generate a face using internal cameras and sensors, then VisionOS will “slice and interpolate” the face, rendering it on the EyeSight display. The image passes through a layer of lenses and then through another layer of lenses, ultimately achieving the visual effect of a 3D face image.

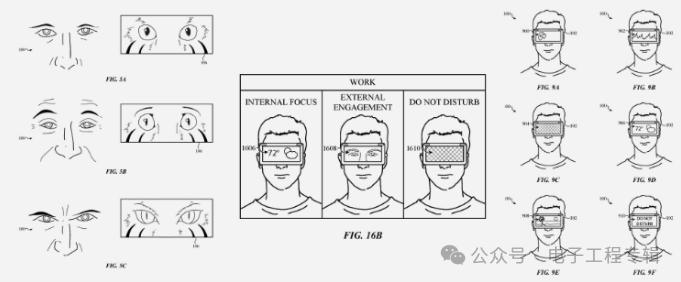

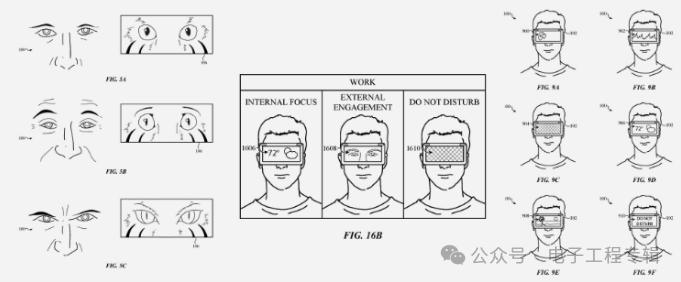

Based on this, Apple also released a 42-page patent report

(https://patentimages.storage.googleapis.com/51/03/12/4b7f034c90465c/US20240012601A1.pdf)

This patent describes three display modes: “Internal Focus,” “External Engagement,” and “Do Not Disturb.”

The patent also shows images that may be displayed on the screen—various cartoon animal eyes, biometric analysis results captured by other sensors, and emotional expressions when users talk to loved ones. The internal cameras can read emotional states and project images based on these emotional states.

EyeSight Imaging & Display Principles

However, ideals are rich, but reality is thin. In fact, based on feedback from the first batch of testers, many people said the EyeSight display is very dim and has a low resolution. “When I wear the headset, you can hardly see my eyes,” a user commented. Regarding this issue, iFixit also analyzed during the teardown: “Apple’s goal is very clear: a 3D animated face with eyes. To achieve this goal, they had to make strategic choices and compromises in design.

The human brain is very sensitive to faces and expressions, which is why the “uncanny valley” phenomenon occurs, and depth perception is part of it. Apple needs to create a believable 3D effect. One reason the 3D effect does not appear truly 3D is the lack of stereoscopic effect. To make something look 3D, we need to see slightly different images with each eye. The Vision Pro solves this problem through double convex lenses.”

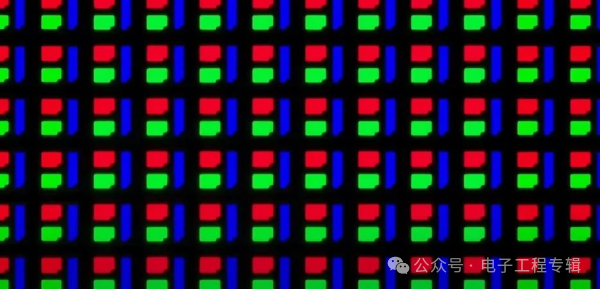

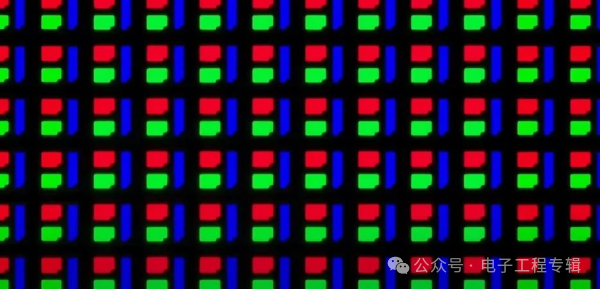

On the surface of the OLED screen, Apple added a layer of lenses.

Vision Pro screen and the lens layer above it

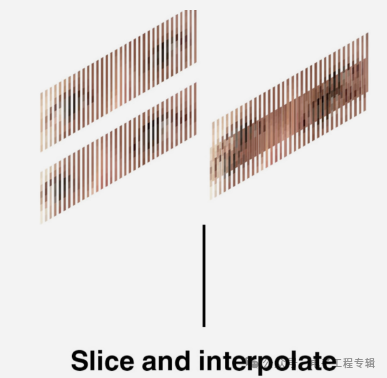

VisionOS slices the facial image into A and B, where A is received by the left eye from one angle, and B is received by the right eye from another angle, so that people outside can see a 3D representation of your face.

iFixit states that this method has certain limitations. The horizontal resolution is greatly reduced, divided among multiple images. For example, if two images are displayed on a 2000-pixel-wide screen, each image only has 1000 horizontal pixels available. Even if we do not know the resolution of the screen or the number of interlaced images, the resolution will inevitably decrease. This is also the main reason why the EyeSight eyes appear blurry.

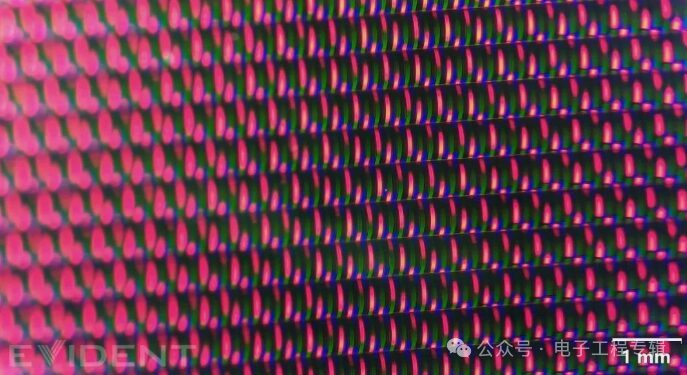

Pixels emit light through a micro-lens structure

In front of the lens layer is another plastic lens extension layer. This layer seems to stretch the projection surface wide enough to fit the width of the Vision Pro. If you remove this lens layer and start the Vision Pro, you will see some very strange phenomena of “squeezing both eyes towards the middle”.

Moreover, the lens may limit the effective field of view. By restricting the effect to the front of the Vision Pro, it can limit the artifacts you may see at extreme angles, somewhat like a privacy filter. The downside is that you have to transmit an already complex, blurry image through another layer of lenses. This makes it even blurrier and darker.

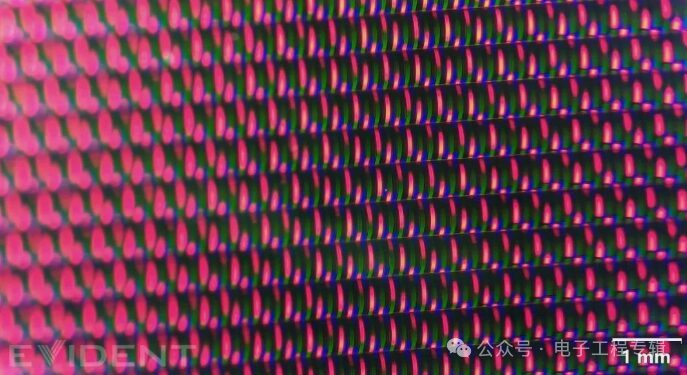

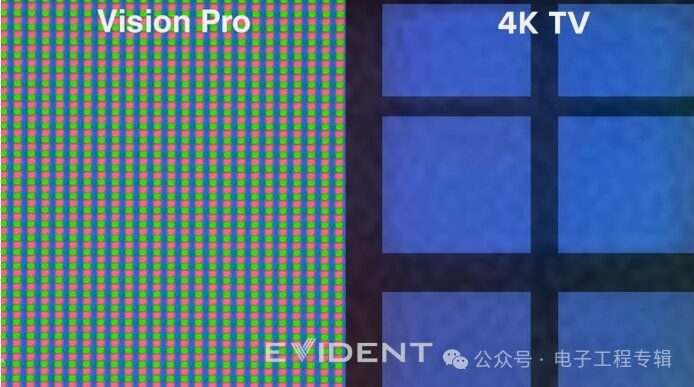

Compressing a 4K TV to the Size of a Stamp with Micro OLED

After disassembling the outer screen, iFixit took apart the optical and display module, including the MicroLED screen, lenses, and related mechanical sliding structures.

The sliding structure of the lenses is compact yet precise.

Data shows that the Vision Pro uses Sony’s Micro OLED screen + Yu Jing Optoelectronics’ 3P Pancake solution. The screen itself is very thin, with most of the module thickness concentrated in the optical module.

The three lenses of the three-piece Pancake optical solution are tightly fitted together, consistent with what Apple demonstrated at the launch. Additionally, the lens module also contains an eye-tracking camera, which is key to the Vision Pro’s eye-tracking interaction.

Yu Jing Optoelectronics is conservative about the sales situation of the Vision Pro in the first half of the year, as the Sony Micro OLED production line will not be upgraded until the second quarter.

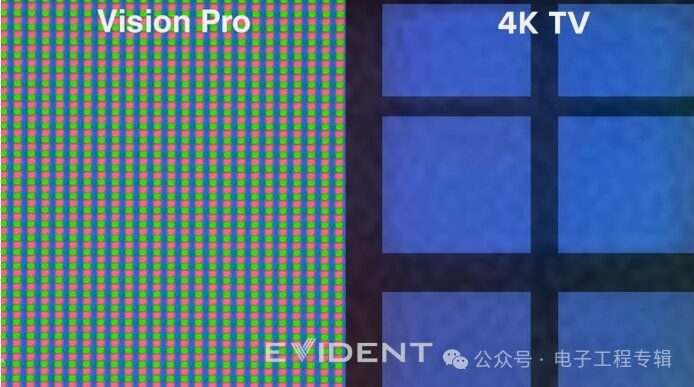

The Micro OLED screen is the most scrutinized component. This screen is said to be the size of a “stamp,” but it contains 11.5 million pixels, exceeding the pixel count of a 4K TV (3840*2160), with two screens totaling 23 million pixels.

PPI of 3386, exceeding competitors like Meta Quest 3 (1218 PPI) and HTC Vive Pro (950 PPI), and significantly higher than the iPhone 15 Pro Max’s 460 PPI.

iFixit used an electron microscope to measure the size of red blood cells on the screen pixels, with the actual luminous part of the screen measuring approximately 27.5 mm in width, 24 mm in height, and an area of about 660 square mm. An area of 1 inch is about 645 square mm, so the actual luminous area of this screen is slightly over 1 inch.

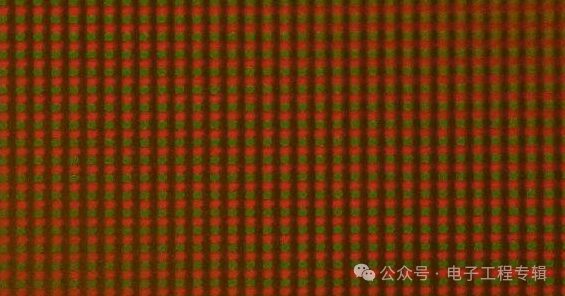

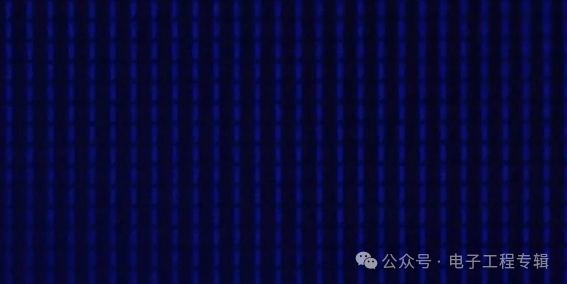

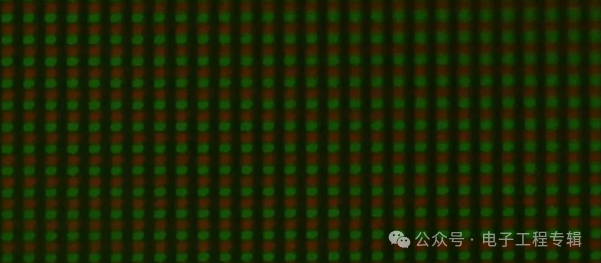

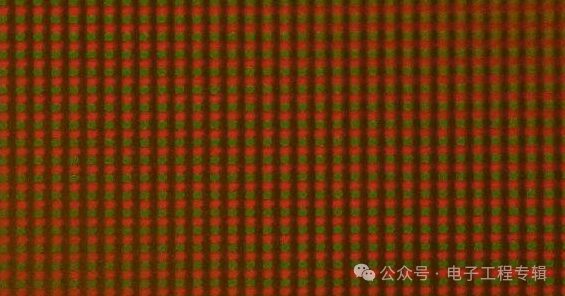

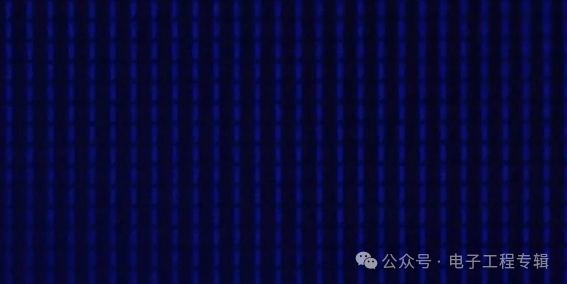

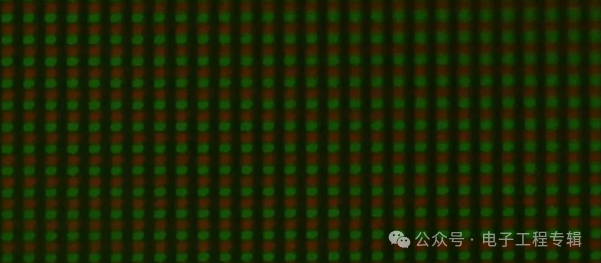

Specifically looking at the structure of each pixel, the red and green sub-pixels are placed vertically on top of each other, while the blue sub-pixel is about twice the length of the red and green sub-pixels, located beside the red and green sub-pixels.

However, according to the microscope images, the blue sub-pixel appears “striped,” while the red and green sub-pixels appear “dot-like,” indicating that the three shapes are not the same.

▲ Red and Green Sub-Pixels

It is worth mentioning that the pixel arrangement captured by iFixit is completely consistent with the pixel arrangement previously shown in Apple’s official video.

▲ Pixel Arrangement Shown in Official Video

After actual measurement, the luminous area of the screen has a total of 3660 horizontal pixels and 3200 vertical pixels, which is equivalent to stuffing 12,078,000 pixels into an area of 0.98 inches.

Why 0.98 inches? In fact, this screen is not a standard rectangle but an irregular octagon with four corners “cut off,” and the four corners are not symmetrically cut off, with each corner cut off to a different area.

The areas cut off from the four corners are 6.95 square mm, 11.52 square mm, 9.9 square mm, and 10.15 square mm, which do not emit light, accounting for 5.3% of the total area of 660 square mm. The remaining luminous pixels total 11,437,866.

Apple’s claimed pixel count of 11.5 million for a single screen is astonishingly consistent with iFixit’s actual measurement, with the discrepancy being more measurement error.

Compact Internal Structure, Must Have a Fan

The two active cooling fans behind the mainboard are quite large. The fans are located between the mainboard and the screen.

Some cameras and sensors are fixed on the same structure.

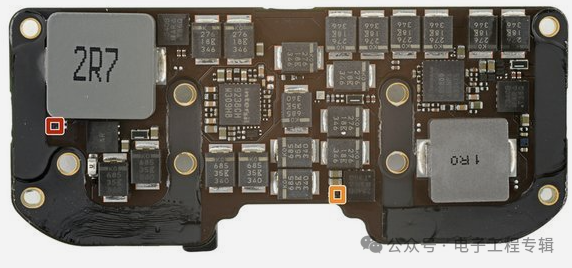

After iFixit cut open the adhesive of the outer screen, the core mainboard of the Vision Pro was exposed.

The Two Main Characters: M2 and R1

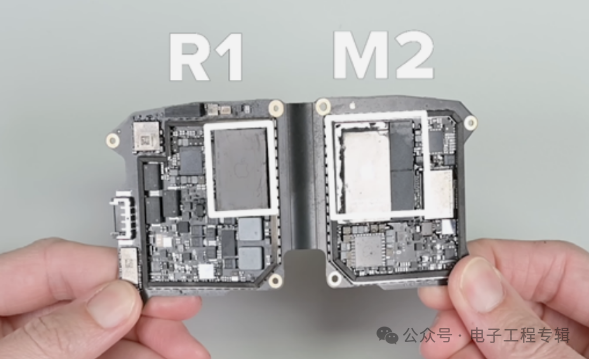

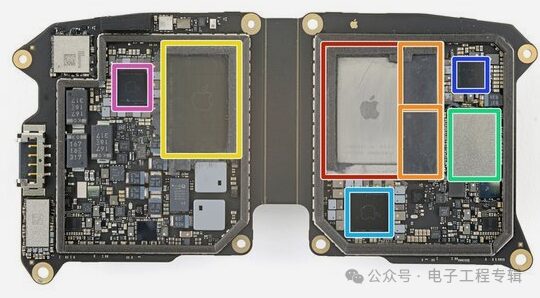

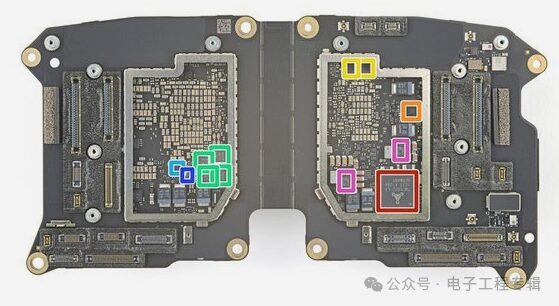

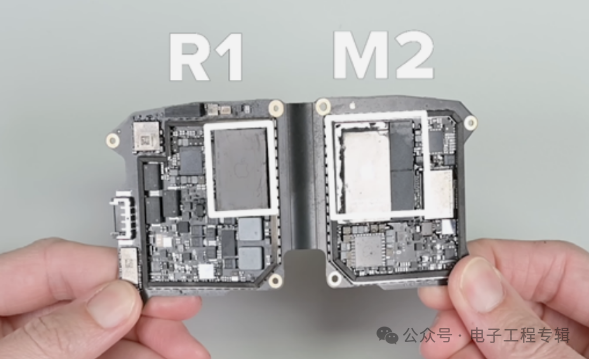

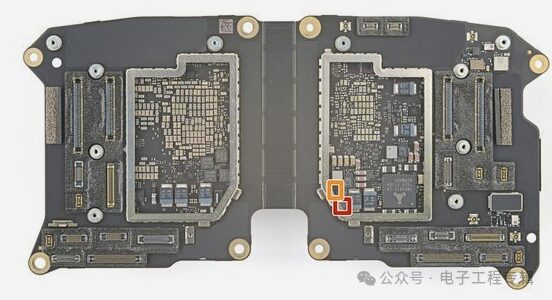

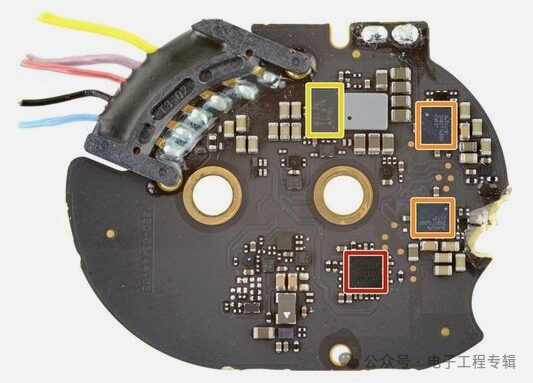

The disassembly video shows that the M2 and R1 chips are located on either side of the mainboard, with both boards using flexible PCB designs, connected in the middle by a flexible PCB.

The R1 chip is specifically responsible for processing inputs from 12 cameras, LiDAR sensors, and TrueDepth cameras, ensuring they operate with minimal latency. In AR applications, you need to project the real-world camera view to the user’s eyes as quickly as possible; otherwise, the actions they perceive may not match what they see, potentially causing nausea.

To keep up with the pace, the R1 uses a real-time operating system. This means tasks are executed at fixed intervals. Most of our computers operate on time-sharing, which may slow down the speed. Just think of the constantly flickering mouse cursor, and you will understand.

In addition to the two Apple chips, there are also some storage chips, communication chips, and wireless connection-related chips.

The battery life of the Vision Pro is also a major concern. The disassembly video shows that the external battery contains “three batteries,” manufactured by Huizhou Desay Battery, a long-time Apple battery supplier.

Close-up of the external battery of the Vision Pro

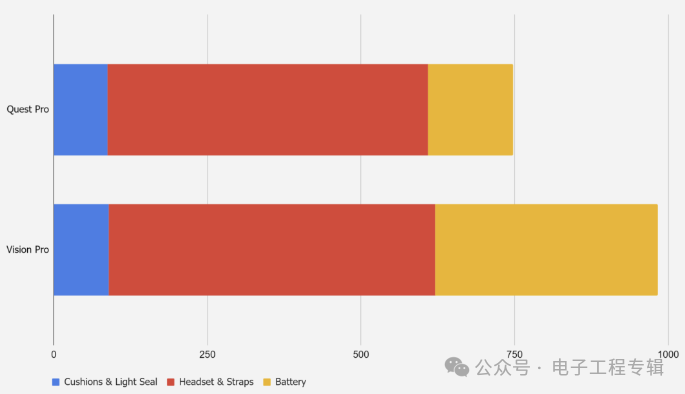

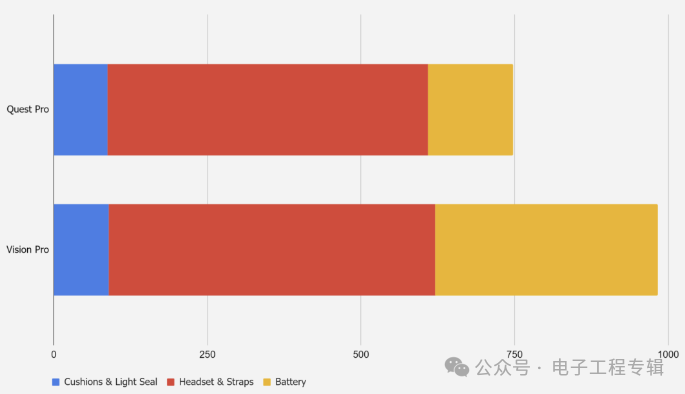

However, iFixit states that the battery pack weighs 353 grams, with each cell having a capacity of 3166mAh, providing a total of 35.9Wh of power. The entire battery weighs 362 grams. The combined weight of the Vision Pro and the battery exceeds 1 kilogram, with all the weight concentrated at the front of the device, increasing discomfort for users during prolonged wear.

Comparison of the Vision Pro’s weight with its main competitor, Quest Pro, shows it is significantly heavier.

As for why Apple uses an external battery, it is due to future EU regulations requiring all electronic products to have replaceable batteries by 2027. Apple is required to allow “sideloading” in Europe, and the external battery design is more about weight, portability, and charging experience considerations.

In the second wave of disassembly, iFixit disclosed the chip models and manufacturers on the mainboard, marking the first exposure of the core 35 chip models and suppliers of the Vision Pro. The analysis report shows a large number of Texas Instruments (TI) chips, along with a NorFlash chip from GigaDevice.

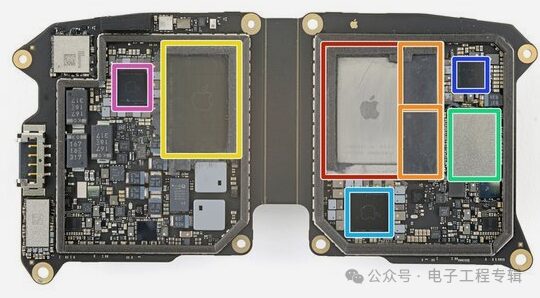

First, let’s look at the front of the mainboard, where we can clearly see a chip with the Apple logo on the right side, which is the Apple M2 processor, while the chip on the left with the Apple logo is the R1 sensor co-processor.

The M2 processor primarily runs visionOS, executing advanced computer vision algorithms, etc. The R1 co-processor mainly processes data signals from 12 cameras, 5 other types of sensors, and 6 microphones, accelerating the processing of sensor data to reduce latency, ensuring real-time content presentation, and reducing the load on the main CPU to lower power consumption. Apple previously stated that the R1 chip can transmit images to the display in 12 milliseconds, achieving almost zero-latency real-time transmission.

Red: Apple APL1109/339S01081E M2 octa-core application processor and graphics processing unit

Orange: Micron MT62F1G64D8WT-031 XT:B 8 GB LPDDR5 SDRAM memory

Yellow: Apple APL1W08/339S01186 R1 sensor co-processor

Green: Kioxia K5A4RC2097 256 GB NAND flash storage

Light Blue: Apple APL109C/343S00627 power management chip

Blue: Apple APL109D/343S00628 power management chip

Purple: Apple APL1004/343S00629 power management chip

Red: Apple 338S00521-B0 power management

Orange: Texas Instruments (TI) LMK1C1104 clock buffer

Yellow: ADI LT8652S 8.5 A / 18 V dual-channel synchronous buck converter

Green: Texas Instruments TPS62125 300 mA buck converter

Light Blue: Texas Instruments TPS61045 adjustable boost converter

Blue: ON Semiconductor FPF2895C current-limiting switch

Purple: Texas Instruments TPS70936 150 mA/3.6 V LDO voltage regulator

Red: USI 339S01015 WiFi/Bluetooth module

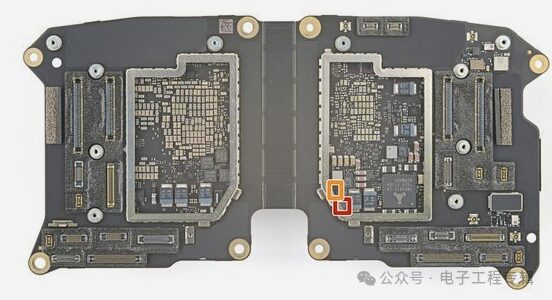

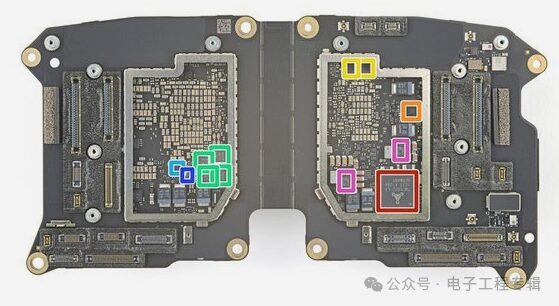

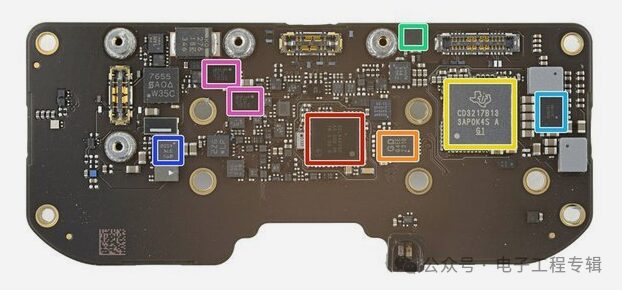

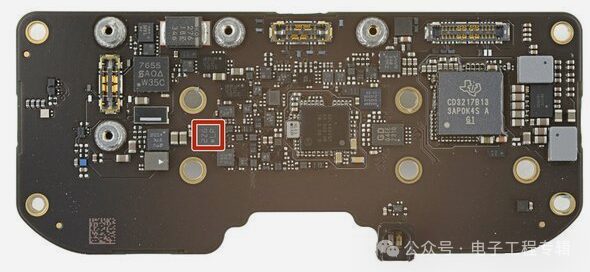

Now let’s look at the back of the mainboard:

Red: ADI TMC5072 dual 2-phase stepper motor driver

Orange: Lattice Semiconductor ICE5LP4K iCE40 Ultra FPGA

Yellow: Possibly Cirrus Logic CS46L11 audio codec

Green: Diodes Incorporated PI2DBS16212A 2:1 multiplexer/demultiplexer

Light Blue: Texas Instruments TMUX1575 four-channel SPDT analog switch

Blue: Texas Instruments TS5A23159 dual SPDT analog switch

Purple: Texas Instruments TPS62135 4 A buck converter

Red: Texas Instruments TLV6703 comparator with integrated reference

Orange: ON Semiconductor FPF2895C current-limiting switch

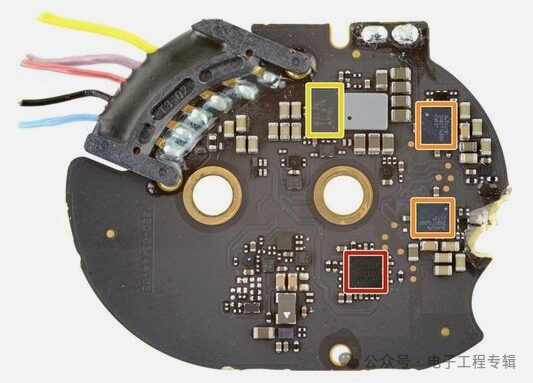

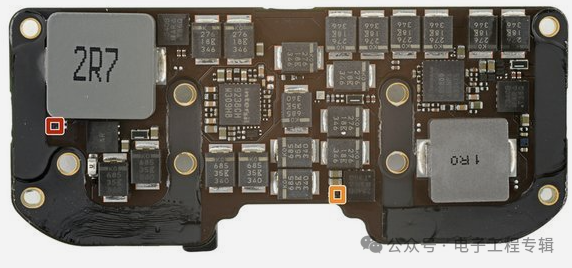

After reviewing the chips on the mainboard of the Vision Pro host, iFixit also analyzed the mainboard inside the external power supply of the Vision Pro.

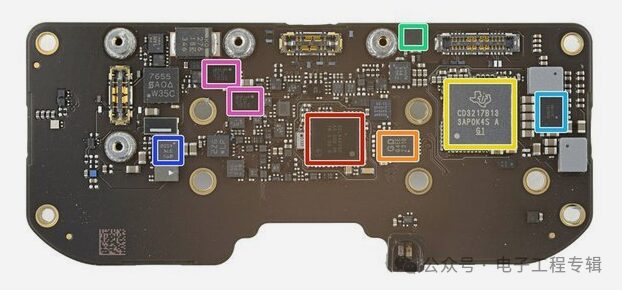

First, let’s look at the front of the charging board:

Red: STMicroelectronics STM32L4A6VG Arm Cortex-M4 microcontroller

Orange: GigaDevice GD25Q80E 1 MB serial NOR flash

Yellow: Texas Instruments CD3217B13 USB Type-C controller

Green: Texas Instruments TPD4S311A USB Type-C port protector

Light Blue: Texas Instruments TPS62180 6 A synchronous buck converter

Blue: Texas Instruments TPS62160 1 A buck converter

Purple: ON Semiconductor FPF2895C current-limiting switch

Red: Renesas ISL9238C buck-boost battery charger

Orange: Renesas RAA489800 bidirectional buck-boost regulator

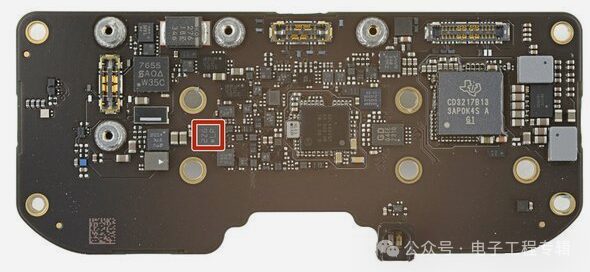

Red: Texas Instruments TMP103A temperature sensor

Orange: Texas Instruments TMP103B temperature sensor

Finally, let’s look at the speaker mainboard of the Vision Pro:

Red: Possibly Cirrus Logic CS46L11 audio codec

Yellow: Texas Instruments SN02776B0A audio amplifier

Green: Texas Instruments TPS62135 4 A buck converter

It is no exaggeration to say that the Apple Vision Pro is the culmination of years of accumulation from products like the iPhone, Apple Watch, AirPods, and iPad. From the teardown, we also discovered many local manufacturers, such as Lens Technology, which developed and produced the front glass panel.

Desay Battery appearing in the Vision Pro supply chain is not surprising, as it is an Apple battery supplier, specializing in developing various batteries, including mercury-free alkaline manganese batteries, lithium batteries, zinc-air batteries, nickel-hydrogen batteries, and more; as well as developing and selling mobile communication products and accessories.

Acoustic components such as speakers are supplied by Goertek. Goertek is also a core supplier in Apple’s supply chain, providing speakers, MEMS, and other precision components (electronic product parts), smart speaker products, and wireless earphone OEM services.

In addition, Luxshare Precision is also involved in the development of Apple’s MR devices, and it revealed last September that the company is preparing for production of the upcoming Apple headset, the Apple Vision Pro.

In terms of chips, besides Apple’s self-developed processor chips in the Vision Pro host and the matching speakers and external power supply, there are also many self-developed power management chips from Apple, as well as a large number of Texas Instruments chips, totaling up to 17. Surprisingly, there is also a domestically produced storage chip from GigaDevice’s NorFlash chip in the Vision Pro.