Abstract: The interoperability of networks is the foundation of the industrial internet. The difficulty of connecting industrial equipment is a fundamental issue faced by the development of industrial networks and a challenge that enterprises must address in their digital transformation. This article analyzes the causes and current status of interoperability issues in industrial equipment, summarizes the achievements made in China to address these issues, and proposes suggestions for future development.

Keywords: Network; Interoperability; Industrial Internet

0 Introduction

The industrial internet is a new type of infrastructure, application model, and industrial ecosystem that deeply integrates the new generation of information and communication technology with the industrial economy. By comprehensively linking people, machines, materials, and systems, it constructs a new manufacturing and service system covering the entire industrial chain and value chain, providing a pathway for the digital, networked, and intelligent development of industries. It is a crucial cornerstone of the Fourth Industrial Revolution. Comprehensive interoperability is a key connotation, essential requirement, and important goal of the industrial internet, effectively stimulating the circulation and application vitality of data elements, thereby driving more agile R&D design, smarter production, more efficient decision-making, and optimized resource allocation, ultimately promoting a leap in productivity. Therefore, interoperable networks are the foundation of the industrial internet. Meanwhile, behind the massive, diverse, and complex industrial equipment systems is fierce competition in global technology, standards, and industries, making equipment interoperability a challenge for the industrial internet to advance to a broader scope, deeper level, and higher standard. This article will focus on analyzing the problems and challenges faced by China’s industrial network interoperability and propose development suggestions.

1 The Difficulty of Interoperability is a Historical Result of the Development of Industrial Network Systems

Humanity has roughly experienced four stages of industrial revolutions, with the evolution of industrial networks corresponding to the last three industrial revolutions. In the 1940s, during the Second Industrial Revolution, automatic control technology began to be widely applied in industrial systems, with communication primarily relying on analog electronic circuit signals, which was the embryonic form of industrial networks. In the second half of the 20th century, the Third Industrial Revolution, represented by computer technology, emerged, with digital communication becoming a new driving force. Fieldbus technology arose in various industries, achieving interconnection among industrial field actuators, sensors, and transmitters, with various industrial bus, industrial Ethernet, and industrial wireless technologies continuously emerging, forming a series of industrial network standards represented by IEC61158 and IEC61784. In the 21st century, the concept of the industrial internet gradually appeared in technological powerhouses such as the United States, Germany, and China, leading to a transformation in the information exchange model between industrial control systems and information systems, with new network technologies such as 5G, TSN, and APL gradually penetrating the industrial field, marking a new phase of comprehensive upgrading of industrial network systems.

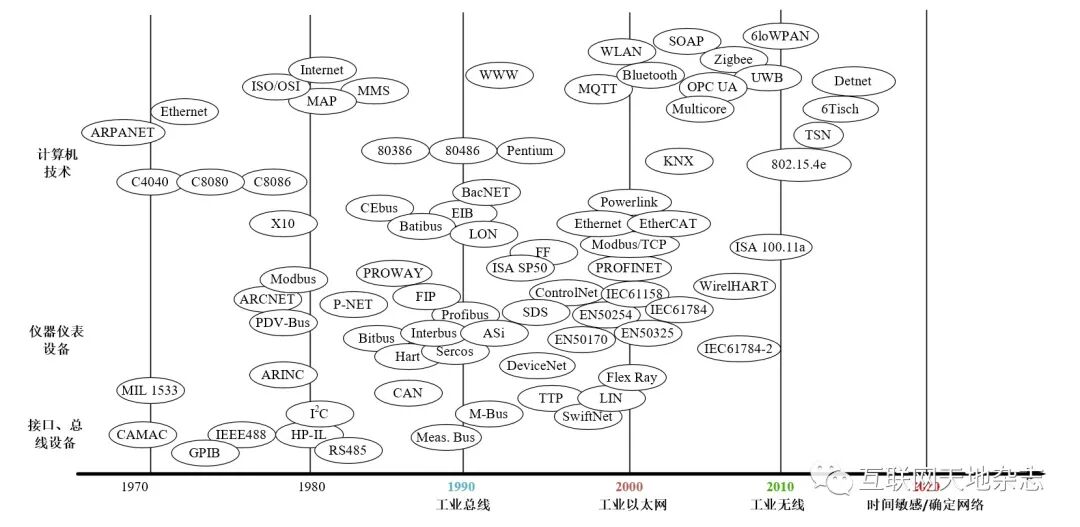

Over the course of more than 200 years of industrial systems, over 80 years of industrial automation, and over 50 years of industrial informatization, industrial manufacturers in various countries and fields have developed a wide variety of closed industrial equipment and systems, making interoperability a common problem faced by global industrial development. The “seven countries and eight systems” of industrial network technology standards is a direct cause of the interoperability issue. For instance, the international standard IEC61158 for industrial buses and industrial Ethernet includes 28 types, and with other industry standards and proprietary technologies used by international giants, there are currently over a hundred commonly used industrial network communication technologies globally, each forming its own system, making effective interoperability difficult (as shown in Figure 1).

Figure 1 Development of Industrial Network Technology

2 The Difficulty of Interoperability is a Common Problem Faced by Global Industrial Network Development

New generation information and communication technologies represented by cloud computing, big data, and artificial intelligence are accelerating their integration with industrial automation technologies, promoting intelligent upgrades in various aspects of industrial enterprises, including design, procurement, production, warehousing, logistics, operations, and sales. New business models such as platform-based design, intelligent manufacturing, networked collaboration, personalized customization, service extension, and digital management have raised higher requirements for data flow, interaction, and collaboration among people, machines, and materials, making network interoperability an urgent issue to be resolved. However, the “two-layer three-level” networks of industrial enterprises are often constructed at different times and by integrating different system devices, leading to difficulties in interoperability between different devices, similar devices from different manufacturers, and even different models from the same manufacturer. A large amount of data generated by devices is either stranded or lost on the production site, making cross-manufacturer and cross-system collaborative interoperability difficult. The most prominent manifestations of the current interoperability issue are the difficulties in network interconnection and data communication.

To facilitate data flow in industrial networks and address interoperability issues, countries are actively promoting the digital transformation and network upgrade of industrial equipment. Since the introduction of High-Speed Ethernet (HSE) technology by the Fieldbus Foundation in 2000, industrial Ethernet technology has become a key focus for upgrading industrial networks. According to statistics from Sweden’s HMS Industrial Networks, by 2018, industrial Ethernet installations in global factory automation surpassed industrial buses for the first time, but the vast existing market has constrained the rapid application of new technologies. In the past decade, with the maturity of new technologies such as 4G/5G, TSN, and OPC UA, countries are accelerating research into these new network technologies to empower equipment interoperability. Organizations such as the Industrial Internet Consortium (IIC) in the United States and the Industrial 4.0 Laboratory Network (LNI4.0) in Germany have established working groups or testbeds for networking, interconnection, and interoperability, studying the application of new technologies. The white paper “Industry 4.0 x Industrial Internet: Practices and Insights” jointly released by China and Germany in 2020 also emphasizes machine connectivity and interoperability as important content and cooperation directions.

3 Prominent Issues of Industrial Network Interoperability in China

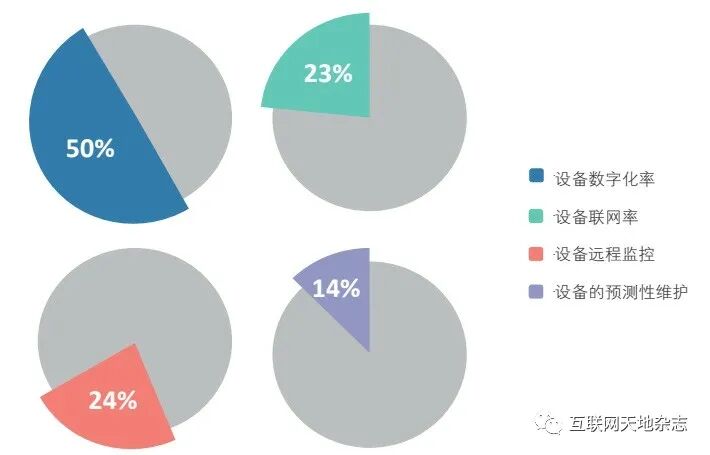

As a major manufacturing country with all industrial categories, China has actively introduced advanced technologies from various countries during its rapid development, which has accelerated its industrialization process but has also led to the presence of almost all network technology standards in Chinese enterprises, making interoperability issues particularly prominent in China’s industrial system. First, the overall networking rate of industrial equipment in Chinese enterprises is relatively low. According to the “Smart Manufacturing Development Index Report 2020,” the networking rate of industrial equipment in China is only 23%, far below the 70% networking rate of the consumer internet during the same period. Second, the autonomy of traditional industrial network technology standards is low. Although China has proposed industrial Ethernet and industrial wireless technology standards, their application deployment is minimal, and industrial network technology still primarily follows international standards, with 71 out of 94 industrial network protocol standards derived from international standards. Third, the digital foundation for networking in small and medium-sized enterprises is weak. A statistical survey conducted by the National Bureau of Statistics in 2019 on 985,000 enterprises showed that less than 20% of enterprises achieved informatization in production and manufacturing management, especially as many small and medium-sized enterprises lack CNC systems or communication interfaces, making it difficult to achieve equipment interoperability (as shown in Figure 2).

Figure 2 Digital and Networked Capabilities of Equipment

Due to the late start of modern industry in China, the weak industrial foundation is the fundamental reason for the interoperability issues in China’s industrial networks. On one hand, traditional industrial networks are closely coupled with industrial automation systems, leading to various industrial network technologies and standards often having their specific regional and industrial markets. For example, CC-link technology is widely used in Japan, while PROFINET and CAN technologies are more prevalent in the automotive industry. China has also proposed technology standards such as Factory Automation Ethernet (EPA) and Wireless Network for Industrial Process Automation (WIA-PA), but due to a lack of support from the industrial chain, they have not been widely commercially deployed, failing to form an industrial scale. On the other hand, due to the overall development level of China’s modern industry still lagging behind developed countries, many factories with historical legacies and low-end manufacturing still have a large number of “deaf” and “dumb” devices, lacking the basic conditions for interoperability, while the high investment and technical barriers of completely redeploying new digital devices deter many enterprises, especially small and medium-sized enterprises.

Industry and market barriers exacerbate the interoperability issues. On one hand, industry-specific technical barriers hinder development. In some industries, specific technologies have emerged based on industry characteristics, such as the SwiftNet bus technology used in the aviation industry, which reinforces the monopoly position of industry leaders and increases interoperability difficulties. On the other hand, strict market barriers exist, with the traditional industrial control automation field and information communication field forming a relatively fixed industrial ecosystem. In the face of new technologies, some niche fields have set special technical standards to create entry barriers, increasing the difficulty of utilizing innovative technologies to solve interoperability issues.

4 Building an Industrial Internet Network System to Solve Interoperability Issues

China has always attached great importance to the development of network technology and industries, considering industrial network interoperability as an important aspect of new industrialization. By continuously implementing the “Industrial Internet Development Action Plan (2018-2020)” and the “Industrial Internet Innovation Development Action Plan (2021-2023),” it has actively promoted the digital transformation of enterprises and built a new industrial network interoperability system, achieving some results.

First, policies have guided the acceleration of digital transformation of equipment. The Ministry of Industry and Information Technology has issued policy documents such as the “Guidelines for the Construction and Promotion of Industrial Internet Networks,” “Special Action Plan for Digital Empowerment of Small and Medium-sized Enterprises,” and “Guidelines for the Construction of 5G Fully Connected Factories” to enhance equipment networking capabilities. Second, a preliminary framework for the network technology standard system has been established. In April 2021, the first international standard for industrial internet, ITUTY.2623 “Technical Requirements and Architecture for Industrial Internet Networks (Based on the Evolution of Packet Data Networks),” was released under the leadership of the China Academy of Information and Communications Technology. In October 2022, the first national standard in the field of industrial internet networks, GB/T42021-2022 “Overall Network Architecture for Industrial Internet,” was published. Third, comprehensive research on key network technologies has been initiated. Over a hundred new industrial network technology standards, including TSN, edge computing, industrial PON, industrial SDN, industrial 5G, and OPC UA, have been developed to standardize equipment interoperability capabilities; dozens of key technology testbeds have been jointly built by supply and demand sides to accelerate the application of new technologies in enterprises. Fourth, the integration and innovative application of industries have been continuously deepened. New network technologies have been applied in multiple industries and enterprises such as steel, automotive, home appliances, petrochemicals, and equipment, showing initial results in quality improvement, cost reduction, efficiency enhancement, greening, and safety. In 2021, the Ministry of Industry and Information Technology released a total of 10 key industries and 20 typical application scenarios for “5G + Industrial Internet.”

Solving interoperability issues will be a long-term process and an urgent problem faced by Chinese enterprises in achieving digital transformation. We are currently entering a rapid development phase of industrial network upgrades, with new wired and wireless technologies represented by Time-Sensitive Networking (TSN) and 5G becoming the direction of industrial wired and wireless evolution. Chinese enterprises still have the opportunity to leapfrog the slow process of traditional industrial network Ethernetization over the past decade and innovate the development of network technology industries. On the other hand, the sudden pandemic in 2019 has significantly impacted China’s economy, forcing enterprises to accelerate digital transformation and advance the process of networking and data clouding for small and medium-sized enterprises, enhancing their core business capabilities, which is particularly important and urgent.

Especially during the current window period for upgrading internal networks, the focus should be on “building an innovative technology system and cultivating an open industrial ecosystem,” vigorously promoting the deep integration and application of innovative technologies with industry. Specific suggestions include: First, increase efforts to tackle key technologies and products, focusing on breaking through the “deaf” and “dumb” issues of industrial equipment, the intelligentization of industrial networks, and the construction of industrial data models. Second, strengthen innovation in networked applications, encouraging enterprises to transform traditional production processes, optimize organizational models, innovate application models, and improve production efficiency based on new network technologies, and encourage state-owned enterprises to be pioneers in the application of innovative technologies. Third, focus on serving the digital transformation of small and medium-sized enterprises, relying on the network construction of various industrial parks to create comprehensive industrial network infrastructure services for small and medium-sized enterprises and explore new models for their network construction. Fourth, accelerate the cultivation of leading innovative enterprises, building a full industrial chain cooperation from product R&D, standard formulation, pilot application to engineering mass production and promotion. Fifth, strengthen standardization construction, developing advanced, unified, and open industrial network technology standards and data standards, while promoting national and industry standards, and enhancing the dissemination and application of key technical standards.

5 Conclusion

China’s industrial internet network system construction started relatively early, fully utilizing the industrial advantages accumulated in the ICT field over the past few decades, accelerating the development of key technologies and industries for equipment interoperability, and achieving certain results. However, the overall scale of China’s industry is large, and its foundation is relatively weak, making it a long way to comprehensively solve the interoperability issues of industrial equipment. Currently, the industrial network is in a window period of upgrading, and Chinese enterprises can seize the opportunity of new technologies such as 5G, TSN, and edge computing to solve the issues of ubiquitous data collection and transmission, building moderately advanced network infrastructure for enterprise interoperability, and achieving leapfrog development.

References:

[1] Industrial Internet Industry Alliance. Industrial Network 3.0 White Paper, June 2023.

[2] International Cooperation Agency, China Academy of Information and Communications Technology, China-Germany Industry 4.0 Project. Industry 4.0 x Industrial Internet: Practices and Insights. [EB/OL]. August 2020. http://www.aii-alliance.org/upload/202009/0907_221723_663.pdf.

[3] China Electronics Standardization Institute. Smart Manufacturing Development Index Report 2020. [EB/OL]. January 20, 2021. https://wap.miit.gov.cn/api-gateway/jpaas-web-server/front/document/file-download?fileUrl=/cms_files/filemanager/1226211233/attach/20211/7433ff18f36f4af68fdcac722b888b4b.pdf&fileName=%E9%99%84%E4%BB%B6%EF%BC%9A%E3%80%8A%E6%99%BA%E8%83%BD%E5%88%B6%E9%80%A0%E5%8F%91%E5%B1%95%E6%8C%87%E6%95%B0%E6%8A%A5%E5%91%8A%E3%80%8B%E6%A6%82%E8%A7%88.pdf.

[4] Industrial Internet Industry Alliance. Industrial Internet Network Connection White Paper (Version 2.0), September 2021.

Originally published in “Internet World” Issue 6, 2023, Author Affiliation: China Academy of Information and Communications Technology, Institute of Technology and Standards, China Academy of Information and Communications Technology, Institute of Industry and Planning Research

Submission Email: [email protected]

Cover Inquiry: 010-57234929-1003, 1053