Source: InnoVision Company

Abstract

The terms Digital Twin, Cyber-Physical Systems, Smart Manufacturing, and Industrial Internet are important concepts frequently used in the practice of the new industrial revolution. Although these four terms are often mentioned separately in various contexts, there are few analytical articles that discuss all four terms simultaneously. This article analyzes the origins, components, connotations, operational logic, and interrelationships of these four terms. They are historically interconnected, sharing many commonalities in essence, yet they also exhibit clear distinctions.

Clearly distinguishing similarities and differences, and grasping the essence of these terms, can help guide enterprises in effectively designing and implementing smart manufacturing and industrial internet strategies. Some content in this article is derived from the new book “Casting the Soul”.

1. IntroductionThe four terms Digital Twin, Cyber-Physical Systems, Smart Manufacturing, and Industrial Internet have become popular buzzwords in recent years. In the domestic industry, Cyber-Physical Systems emerged in 2014, Smart Manufacturing gained traction in 2015, Industrial Internet became prominent in 2017, and Digital Twin rose to prominence in 2019.Are these four terms independent of each other, or are they interrelated? Most people likely believe they are related, but what are the similarities and differences between them? How much commonality exists in their connotations? What is the relationship between their operational logics? It may indeed be difficult to clarify. Based on long-term business practice and theoretical research, combined with the “20-character maxim” from “The Three-Body Intelligent Revolution”—”State Perception, Real-time Analysis, Autonomous Decision-making, Precise Execution, Learning Enhancement“[1], the author attempts to analyze and compare the connotations and essence of the four terms.In terms of research methodology, the author employs an abstract graphical representation: a horizontal line divides the space into two areas, with the upper part representing the cyber space (including digital logic, electromagnetic spectrum, and networks), and the lower part representing the physical space (including machines/devices/business activities/processes, etc.). Four large circles are used to describe the basic connotations, components, and operational logics of each term.

2. Basic Connotation of Digital Twin

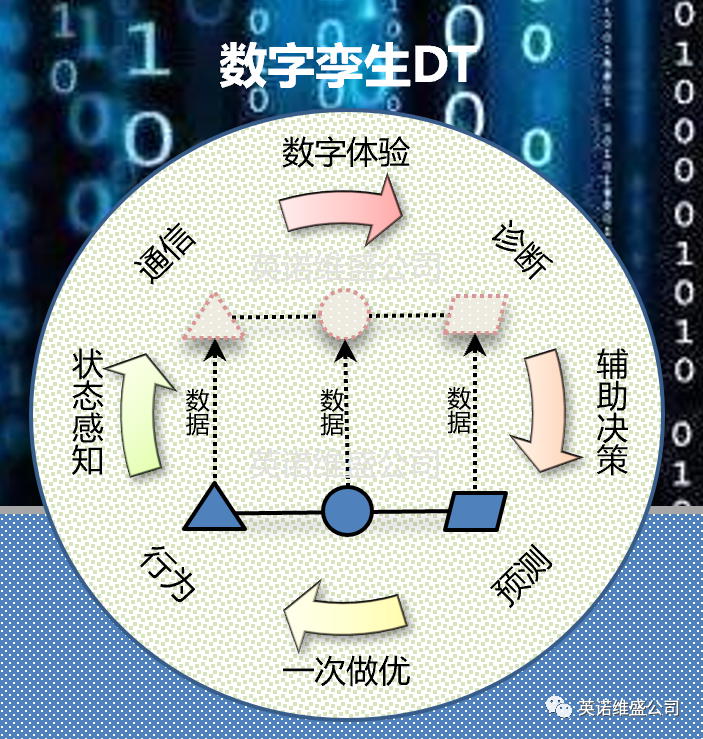

Digital Twin is the result of long-term digitization of elements under the influence of software definition. Here, elements refer to various entities in the physical world, including people, machines, objects, data, graphics, language, and physical information. Therefore, Digital Twin is a digital universal technology formed through long-term development.The author believes that Digital Twin has two meanings: one refers to the precise mapping relationship between the physical entity and its digital counterpart; the other refers to the physical entity and digital counterpart that have a twin relationship, which are referred to as the physical twin and digital twin, respectively. By default, Digital Twin also refers to the digital twin.The term Digital Twin is said to have been proposed by Professor Michael Grieves in 2003 while teaching at the University of Michigan[2]. Currently, there is no industry-recognized standard definition for Digital Twin, and the concept is continuously evolving.After the concept of Digital Twin was proposed, it was quickly applied by the U.S. Department of Defense for the health maintenance and assurance of aerospace vehicles. Companies such as Siemens, Dassault, General Electric, and Parametric Technology in the U.S. have also actively followed suit. Particularly in recent years, with the promotion of concepts like smart manufacturing, Digital Twin has become a universal technology in smart manufacturing, widely applied in industries such as military manufacturing and high-end equipment.Some domestic scholars have also conducted in-depth research on Digital Twin. Professor Tao Fei’s team at Beihang University was among the first to conduct research on Digital Twin, proposing the concept of “Digital Twin Workshop” internationally for the first time and publishing a commentary article titled “Make More Digital Twins” online in the journal Nature. The author has researched and interpreted Digital Twin in works such as “The Three-Body Intelligent Revolution” and “Machine Intelligence: From Digital Workshops to Smart Manufacturing”. Siemens has published a monograph titled “Digital Twin in Practice: Model-Based Digital Enterprises” related to Digital Twin, and consulting firms like Gartner and Deloitte have also conducted in-depth research and technical development assessments on Digital Twin. Deloitte’s 2020 Technology Trends identified Digital Twin as one of the five major trends for the future. These research outcomes have significantly promoted the theoretical research and engineering practice of Digital Twin.The author believes that Digital Twin is a virtual entity created in the digital virtual space through software definition against the backdrop of “digitizing everything that can be digitized”, forming a precise mapping that is extremely similar in shape, state, texture, behavior, and development laws to the real entity in the physical space, allowing the physical twin and digital twin to have diversified mapping relationships with different fidelity (realistic, abstract, etc.). Digital Twin not only continuously occurs throughout the lifecycle of the physical twin but also the digital twin will persist in the cyber space beyond the lifecycle of the physical twin. Fully utilizing Digital Twin can give rise to numerous new technologies and models in smart manufacturing, promoting the application and development of smart manufacturing and industrial internet. The basic connotation and components of Digital Twin are illustrated in Figure 1.

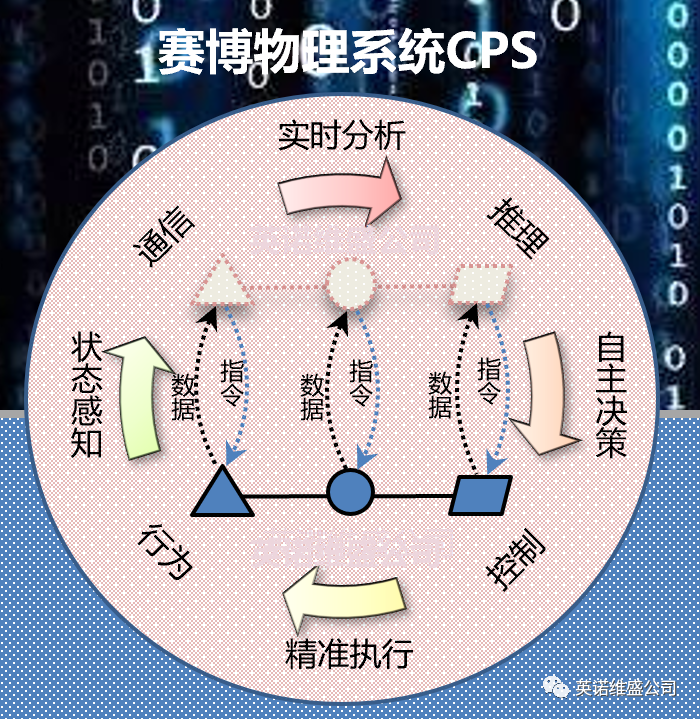

Figure 1: Basic Elements and Mechanism of Digital TwinFigure 1 illustrates three types of content represented by the large circles: the first is the basic elements of Digital Twin, the second is the mapping relationship between the physical entity and the digital counterpart, and the third is the mechanism and operational logic of Digital Twin.The author uses the three adjacent solid geometric shapes “△○□” to represent different types of physical entity elements, and their dashed geometric shapes to represent the digital mapping (digital counterpart or digital twin) relationships of these physical entity elements in the cyber space. The term “data” represents the physical information perceived/collected from the physical entity transformed into bit data, which unidirectionally flows into the digital counterpart. The dashed arrows indicate the direction of data flow between the physical and digital entities. The four clockwise rotating large arrows represent both the conversion process of “physical information – bit data – digital information – digital knowledge – digital decision” and the digital twin mechanism of “State Perception, Digital Experience, Assisted Decision-making, One-time Optimization“.” Models and data are key to evaluating the fidelity of Digital Twin.Models are the core of constructing Digital Twin. Mechanism models can be composed of numerical/digital models, causal models, functional models, system models, detailed design models, simulation analysis models, etc. Data analysis models can also be composed of machine learning models, empirical models, reduced-order models, fault models, etc. The combined application of mechanism models and data analysis models constitutes the source of models for Digital Twin.Data is the foundation for experiencing Digital Twin. The data obtained by the digital counterpart through sensors must accurately and in real-time reflect the operational status of the physical entity device. If there is a certain delay in the network, how long is the delay? If there is interference on-site, can the interference data be excluded? These are all issues that Digital Twin technology needs to research and solve. If these problems cannot be resolved, the experience becomes a performance, and simulation becomes “pseudo-simulation”, turning the digital twin into a manually set digital animation.Having only the two key elements of models and data is still insufficient to fully describe Digital Twin. The digital experience that Digital Twin aims to achieve must be perceptible through the five senses, with the most important perception being visual—i.e., the visualization of models and data, a task that must be accomplished by software. Undoubtedly, software is the carrier of the elements of Digital Twin. Therefore, in the Digital Twin model researched by the author at the China Center for Information Industry Development, the following viewpoint is expressed:Data is the foundation, models are the core, and software is the carrier[10].From the development history of Digital Twin, in terms of models, mechanism models came first, followed by data analysis models based on data collection and big data analysis; in terms of data, model dataization based on IT perspectives came first, followed by data communication and transmission based on CT perspectives. Ultimately, models + data + software evolved into a digital experience technology based on precise data. Digital experience is an extremely important contribution and supplement of Digital Twin to industrial technology, and many new technologies, products, and business models have developed on this basis.For example, at the time of product delivery, both the physical entity of the product and its digital twin will be delivered to the customer, allowing the customer to clearly understand the product’s background, the market demands and functional conditions that constrained its design and manufacturing, and all components’ design, production, testing, and logistics processes are traceable through the digital twin. During the product’s usage and maintenance phase, if complex problems arise that require experimentation or verification, experiments or verifications can be conducted on the digital twin instead of the physical product, allowing for any extreme conditions to be set for any number of virtual developments until satisfactory results are achieved with complete confidence, and only then will verification be conducted on the physical product, thus achieving “verification equals success”[3].The digital twin can be born before the physical entity (constructed by humans) to pre-experience the digital aspects of a product under development, and it can also persist in the cyber space even after the physical entity exits the market or is lost due to natural laws. Therefore, the author also defines the digital twin as the “genetic code” of today’s digital and intelligent society[3]. Typically, digital twins entering the cyber space cannot be completely deleted.Connotation: Connecting the physical world with the cyber world, inheriting in digital form;Essence: Data + Models + Software, optimizing physical products based on digital experience.3. Basic Connotation of Cyber-Physical SystemsCPS was first proposed by Helen Gill of the U.S. National Science Foundation (NSF) in 2006, and it gained global prominence with the promotion and application by Germany in Industry 4.0. Research institutions such as the U.S. National Institute of Standards and Technology (NIST), NSF, Berkeley University, acatech, and Fraunhofer Society have conducted a series of studies and proposed several theoretical frameworks.In recent years, several books related to CPS have been published, such as “The Rise of Machines: The Lost History of Cybernetics” by Professor Thomas Rid of King’s College London, “CPS: The New Generation of Industrial Intelligence” by Professor Jay Lee of the University of Cincinnati, and the “CPS White Paper 2017” compiled by the China Information Physical Systems Development Forum, as well as the co-authored “The Three-Body Intelligent Revolution” by the author, all of which provide different perspectives on CPS.Based on Digital Twin, data is continuously perceived and collected from the physical entity devices represented by “△○□” to their digital twins. If the software in the digital twin provides the most suitable control instructions for the scenario after analysis and reasoning according to pre-set models and rules, the control instructions flow from the digital twin to the controller of the physical entity device, driving the actuators of the device to perform precise actions, achieving better and more accurate control of the physical entity device. This is the essence of CPS. Technically, it completes the intelligent closed loop represented by the four large arrows of “State Perception, Real-time Analysis, Autonomous Decision-making, Precise Execution“[1]. As shown in Figure 2.

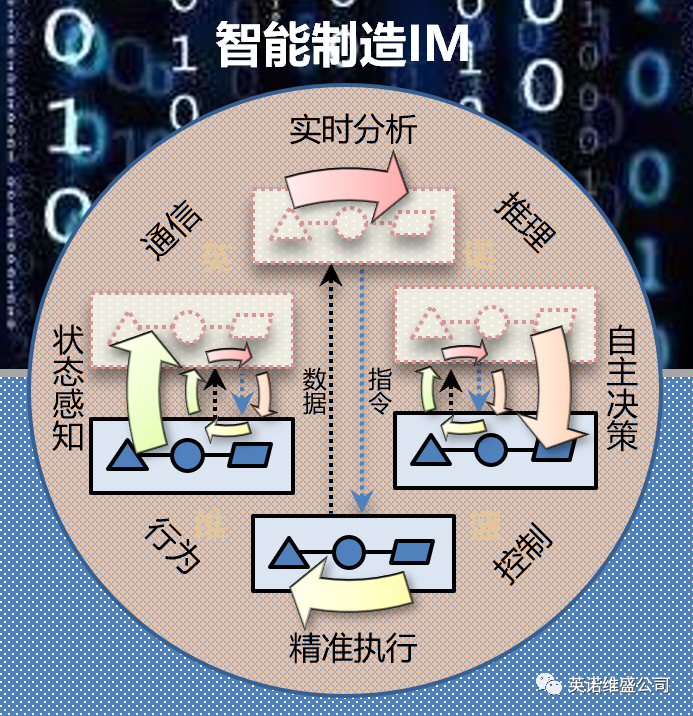

Figure 2: Basic Elements and Mechanism of CPSCPS and Digital Twin have similarities as well as clear differences. The similarity lies in that CPS, like Digital Twin, establishes mapping relationships of varying granularity between the physical and digital realms; the clear difference is that in Digital Twin, data flows unidirectionally from the physical entity to the digital twin, without the behavior of data “controlling physical devices”, while in CPS, control instructions flow from the digital twin to the physical entity device, forming a closed loop with the upstream data. Another clear difference is that after “perception and analysis”, the digital twin achieves autonomous decision-making under software definition, directly controlling the operational outcomes of the physical device.The intelligent closed loop formed by state perception, real-time analysis, autonomous decision-making, and precise execution is a fundamental characteristic of intelligent systems[1], marking an important sign of the Fourth Industrial Revolution, and represents an intelligent manifestation of physical devices integrated with cyber devices. As an enabling technology, CPS plays a key role in smart manufacturing and the industrial internet.CPS is an abstraction and refinement of the basic operating mechanism of smart manufacturing and the industrial internet. In smart manufacturing and the industrial internet, CPS can be found in various forms and scales, appearing at unit level, system level, and system of systems (SoS) levels[4].Connotation: Achieving integrated control of digital and physical; Essence: An intelligent closed loop of “Perception – Analysis – Decision – Execution” for precise control of the physical system’s shape and state.4. Basic Connotation of Smart ManufacturingThe term Smart Manufacturing originated from Japan’s 1990 initiative for the “Intelligent Manufacturing Systems (IMS)” international collaborative research program. In 2015, the State Council of China released “Made in China 2025”, clarifying that smart manufacturing is a primary direction, causing the term to gain popularity again domestically. Today’s smart manufacturing differs in connotation from the “Intelligent Manufacturing Systems” of over 30 years ago.The German Industry 4.0 group proposed achieving intelligent production and service models through “three integrations” in the “Implementation Recommendations for the German Industry 4.0 Strategy Plan”. This involves integrating various IT systems at different levels (e.g., actuators and sensors, control, production management, manufacturing execution, and enterprise planning) to achieve vertical integration and networked manufacturing systems (intra-enterprise links); collaborating with different companies throughout the product lifecycle to meet customer demands, thus integrating the real physical world with the cyber world, achieving end-to-end integration of the industrial chain and the producer-consumer value chain; and integrating various IT systems used in different manufacturing stages and business plans, including the allocation of materials, energy, and information both within a company and between different companies, achieving horizontal integration of the enterprise ecosystem and social collaboration (value network)[6].In 2017, the Chinese Academy of Engineering proposed the “Three Paradigms” of smart manufacturing, stating that digital manufacturing is the first basic paradigm of smart manufacturing, also known as the first generation of smart manufacturing, which serves as the foundation for smart manufacturing; digital networked manufacturing is the second basic paradigm of smart manufacturing, also referred to as “Internet + Manufacturing” or the second generation of smart manufacturing; and the third basic paradigm is digital networked intelligent manufacturing, or the new generation of smart manufacturing. The English terms for the “Three Paradigms” are: Digital Manufacturing, Smart Manufacturing, and Intelligent Manufacturing.The “Three Paradigms” are not only highly forward-looking and systematic but also practical, providing good operational guidance for academic and business research and promotion of smart manufacturing.Smart manufacturing focuses on the manufacturing sector, essentially aligning with Germany’s Industry 4.0, emphasizing that CPS is an enabling technology. The reference architecture model for Industry 4.0 (RAMI4.0) [6] accurately defines and technically elaborates on CPS. The 2013 version of RAMI4.0 primarily discussed CPS, while the 2019 version added discussions on Digital Twin. This indicates that Industry 4.0 inherently includes both CPS and Digital Twin. The same applies to smart manufacturing.The author defines: “Smart manufacturing is a manufacturing paradigm based on CPS technology that constructs a data closed loop of ‘State Perception – Real-time Analysis – Autonomous Decision-making – Precise Execution – Learning Enhancement’, eliminating uncertainties in complex systems through data flow in software, optimizing resource allocation in a given time and target scenario.” The basic elements involved in this definition are:Intelligent Mechanism: State Perception – Real-time Analysis – Autonomous Decision-making – Precise Execution – Learning Enhancement, where the system autonomously operates based on scenarios rather than fixed procedures;Operational Object: Data (the carrier of information and knowledge);Enabling: Algorithms and rules in software (digital knowledge);Essence: Automatic data flow, resulting in ubiquitous information/knowledge;Purpose: Eliminating uncertainties in industrial complex systems;Constraints: Given temporal and spatial scenarios;Value: Optimizing resource allocation in manufacturing.The basic elements and mechanisms of smart manufacturing are illustrated in Figure 3.

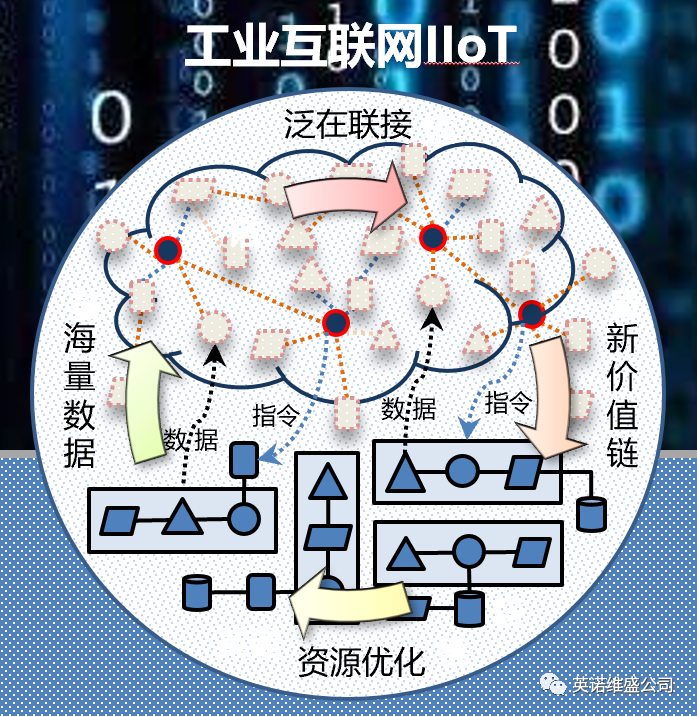

Figure 3: Basic Elements and Mechanism of Smart ManufacturingIn Figure 3, the physical entity devices (solid lines “△○□”) and their digital twins (dashed lines) exist in a precisely mapped manner. However, from the perspective of enterprise assets, physical entity devices may belong to different enterprises/factories/workshops, having different working scenarios, and are relatively closed and fixed in composition, thus expressed in a rectangular box. Data perceived and collected from the physical entity devices flows upward to the digital twin, while control instructions issued by the digital twin flow downward to the physical entity devices (the operational mechanism is referenced in the previous CPS content, where the four clockwise small arrows form a unit-level intelligent closed loop). The four large arrows represent the system-level intelligent closed loop of “State Perception, Real-time Analysis, Autonomous Decision-making, Precise Execution” that continuously operates in a clockwise manner, iterating repeatedly. Through long-term, large-volume deep machine learning, intelligent devices achieve “Learning Enhancement”, and the execution of actions improves over time.In the author’s published work “Machine Intelligence: From Digital Workshops to Smart Manufacturing”, smart manufacturing is briefly described as: smart manufacturing encompasses all activities that transform “human intelligence” into “machine intelligence”[3][5]. From another perspective, human intelligence (human wisdom) is transformed from tacit knowledge into explicit knowledge, which is then written into software, embedded in chips, and integrated into boxes (such as PLCs, DCS, etc.), which are then embedded in physical devices, forming CPS. An increasing amount of “human wisdom” enters physical devices, promoting the explosion of “machine intelligence”, thus leading to intelligent machines and intelligent manufacturing processes. Under software definition and empowerment, a new paradigm of smart manufacturing is formed. Without CPS enabling, there can be no practical implementation of smart manufacturing.Connotation: Optimizing resource allocation in manufacturing;Essence: Achieving intra-enterprise links, value chains, and value networks, constructing a new manufacturing ecosystem.5. Basic Connotation of Industrial InternetTechnically, the Industrial Internet originated from industrial Ethernet and the Internet of Things (IoT) for devices, and the term was proposed by the Shanghai Kelu Software Company in 2007, gaining popularity thanks to the strong advocacy and promotion by General Electric (GE) in the U.S.The “first principle” of the Industrial Internet is to widely connect various machines and industrial systems, thereby achieving the basic logic of “connect – control – optimize – benefit”: data collection is achieved through connection, real-time data transmission, real-time monitoring of devices, and real-time insights into device behavior are achieved through data collection, allowing for precise and detailed optimization of manufacturing resource allocation.The Industrial Internet is slightly more complex than smart manufacturing due to its extensive connections with more industrial elements. The basic connotation of the Industrial Internet is massive data, ubiquitous connections, and optimized allocation of industrial resources, while the industry’s basic expectations are nationwide, large-scale, and cross-industry collaboration (the “three bigs”). Its components and mechanisms are illustrated in Figure 4.

Figure 4: Basic Elements and Mechanism of the Industrial InternetIn Figure 4, similar to smart manufacturing, Digital Twin and CPS coexist. However, the difference lies in that smart manufacturing focuses on the manufacturing sector, using intelligent factories as units, primarily connecting devices and in-process products within the internal boundaries of enterprises (not limited to local); while the Industrial Internet’s connection scope is not limited to enterprise boundaries from the outset, starting with the value chain or even the value network, directly addressing the “three bigs” demands, connecting internal and external elements of enterprises, particularly in terms of industrial products, evolving towards a new value chain network based on the cloud:1. Breaking the limitations of time and space, dismantling the original relatively closed and fixed industrial system pattern, connecting industrial elements such as machines, raw materials, control systems, information systems, products, data, and business activities more widely and flexibly (some physical elements in Figure 4 are no longer within the original box), optimizing the allocation of industrial resources;2. Building an industrial internet platform that supports ubiquitous connections, flexible supply, and efficient allocation of manufacturing resources, establishing a service system based on massive industrial big data collection, aggregation, and analysis, forming a new industrial ecosystem;3. Based on the analysis results of industrial big data, gaining insights into physical activities that have occurred in the physical world but have been unobservable, thus better integrating the real-time information of industrial scenarios, facilitating research and development, production, service, and management decision-making;4. The Industrial Internet continuously promotes the decoupling of hardware/software functions, facilitating the deconstruction of traditional industrial software, and reconstructing it into industrial apps based on microservices and cloud architecture. Therefore, in the cyber space, it is no longer a digital twin that precisely maps to physical devices, but rather a new type of digital twin that is reassembled and reconstructed after disassembling the original digital twin, establishing new connection relationships.Digital twins with new connection relationships and higher degrees of discreteness excel in ubiquitous connections and efficient collaboration, making it easier to optimize the allocation of industrial resources, enabling large-scale control and optimization of “systems of systems (SoS)” and achieving refined operations of large enterprises.In understanding the connotation of the Industrial Internet, the China Center for Information Industry Development and the Industrial Internet Research Institute have also proposed the “three comprehensives” approach: comprehensive elements, comprehensive industrial chain, and comprehensive value chain. Although the terminology and interpretations differ, they all attempt to highlight the new value chain network of the Industrial Internet based on the cloud, and there is a general consensus on the basic connotation of the Industrial Internet across various parties.Connotation: Optimizing the allocation of industrial resources;Essence: A new value chain network based on the cloud, constructing a new industrial ecosystem.

6. Comparative Analysis of the Four Terms

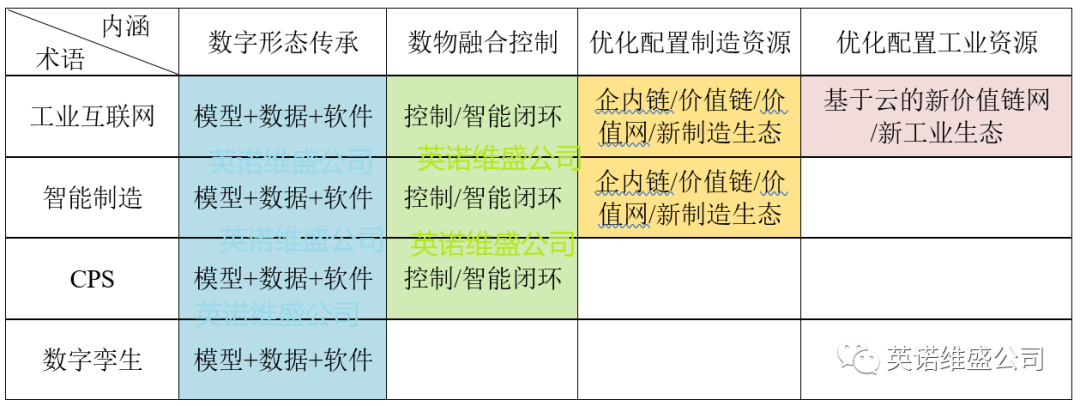

After analyzing the connotations, essence, and main characteristics of the four terms, it is evident that Digital Twin, Cyber-Physical Systems, Smart Manufacturing, and Industrial Internet are historically interconnected, sharing many commonalities in essence, yet they also exhibit clear distinctions.Commonalities: All four terms consist of two basic elements: the physical entities in the physical space and their digital counterparts mapped in the cyber space. They all belong to the activities of the new industrial revolution and can bring new technologies, models, and business formats to enterprises. As a foundational universal technology, research on Digital Twin has received significant attention in the industry in recent years;Differences: In terms of connotation/essence, they are all distinct. Digital Twin primarily involves activities related to mapping, simulating, optimizing, and providing data support for physical entities and business processes in the cyber space, focusing ondigital experience, aiming to maximize the efficiency and quality of operations in the physical world through optimizing the digital twin; when the digital twin integrates with the physical entity and introduces control functions to form an intelligent closed loop, it becomesCPS, enhancing the precise control of the physical entity’s shape and state; multiple multi-level CPS interconnected build intelligent factories, completing the integration and manufacturing control of industrial elements in specific fields based on intra-enterprise links, value chains, and value networks,optimizing resource allocation in manufacturing, forming a new manufacturing ecosystem; the Industrial Internet further disassembles, deconstructs, and reconstructs the intelligent manufacturing system, achieving ubiquitous connections of massive industrial elements, controlling physical devices beyond enterprise boundaries (especially in terms of products),optimizing the allocation of industrial resources on a larger scale, forming a new industrial ecosystem. This is a digital transformation process from within enterprises to outside enterprises, from in-process products to finished products, from value chain networks to new value chain networks, from new manufacturing ecosystems to new industrial ecosystems. Table 1 lists the similarities and differences of the four terms and the digital transformation upgrade process from left to right.

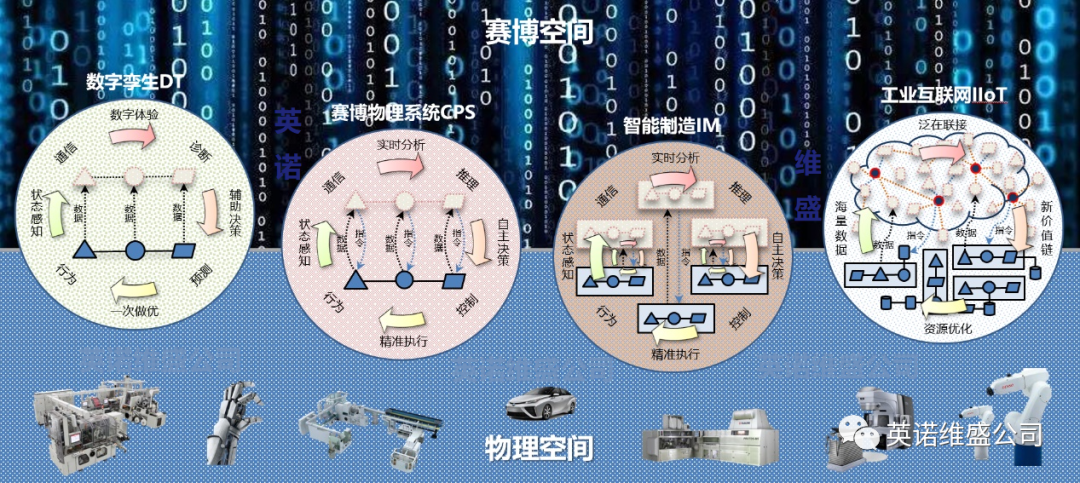

Table 1: Similarities and Differences in Connotation and Progressive Relationships of the Four TermsFrom Table 1, it is evident that Digital Twin, as a digital universal technology, is intertwined with “Models + Data + Software” across the four terms, becoming the “genetic code” of the digital and intelligent society.Figure 5 presents various representations and comparisons of the connotations, components, and mechanisms of the four terms.

Figure 5: Comparison of the Connotations, Elements, and Mechanisms of the Four TermsIn terms of the proportion of cyber and physical spaces, the four terms exhibit subtle differences. Digital Twin originated in the IT field, with a higher proportion of cyber space; CPS emphasizes the deep integration of digital counterparts and physical entities, achieving a relatively balanced equivalence between cyber and physical; Smart Manufacturing, based on intelligent factories, uses CPS to achieve precise control of physical systems, with a slightly higher proportion of physical space; the Industrial Internet, based on a new value chain network in the cloud, connects industrial elements and enhances the collection and processing of industrial data, with a slightly higher proportion of cyber space. This represents an evolutionary process of mutual integration and alternating dominance between the virtual and physical.7. ConclusionDigital Twin, Cyber-Physical Systems, Smart Manufacturing, and Industrial Internet are historically interconnected, sharing many commonalities in essence, yet they also exhibit clear distinctions in connotation, essence, and operational logic. The four terms present an evolutionary process of mutual integration and alternating dominance between the cyber and physical realms in their connotations and components.For these four terms, clearly understanding their similarities and differences, and grasping their essence, can help clarify concepts, restore their origins, and provide clearer guidance for theoretical research and engineering practice, avoiding the artificial blurring of boundaries and functional generalization that could affect the application of these concepts in research and practice. It also helps leverage the strengths of each term, guiding enterprises to effectively implement the specific activities of smart manufacturing and industrial internet in various industry sectors. Due to space limitations, this article only provides a preliminary exposition of the basic connotations and interrelationships of these four terms. As important components of the new industrial revolution, these four terms hold significant practical significance in the research and promotion of smart manufacturing. It is recommended that relevant researchers conduct further studies to more thoroughly and systematically clarify the background, connotations, relationships, technical paths, application scenarios, and typical cases of these four terms. If conditions permit, it is suggested that the government organize relevant experts to compile a white paper on these four terms based on in-depth research, providing useful reference and guidance materials for theoretical researchers and practitioners of smart manufacturing and industrial internet.