When many people hear the word “robot,” words like “cool design,” “powerful functions,” and “high-end” come to mind, thinking of robots as high-tech and flashy like the “Terminator” in science fiction movies. However, this is not the case. In this article, we will explore the basic concepts of robotics and understand how robots accomplish their tasks.

1. Components of a Robot

At the most basic level, the human body consists of five main components:

Body structure

Muscle system, used to move the body structure

Sensory system, used to receive information about the body and the surrounding environment

Energy source, used to provide energy to the muscles and senses

Brain system, used to process sensory information and command muscle movements

Of course, humans also have some intangible characteristics, such as intelligence and morality, but on a purely physical level, this list is quite complete.

The components of a robot are very similar to those of humans. A typical robot has a movable body structure, a motor-like device, a sensory system, a power source, and a computer “brain” that controls all these elements. Essentially, robots are “animals” created by humans, machines that mimic human and animal behavior.

Bionic kangaroo robot

The definition of a robot is broad, ranging from industrial robots that serve factories to home cleaning robots. According to the broadest definition, if something is considered a robot by many people, then it is a robot. Many robot experts (the people who manufacture robots) use a more precise definition. They stipulate that a robot should have a reprogrammable brain (a computer) to move its body.

According to this definition, the difference between robots and other movable machines (like cars) lies in their computer elements. Many new cars have an onboard computer, but it is only used for minor adjustments. Drivers control most parts of the vehicle directly through various mechanical devices. In contrast, robots are physically different from ordinary computers; they are connected to a body, while ordinary computers are not.

Most robots do share some common characteristics.

First, almost all robots have a movable body. Some only have motorized wheels, while others have many movable parts, generally made of metal or plastic. Similar to human skeletal structure, these independent parts are connected by joints.

The wheels and axles of robots are connected by some kind of drive mechanism. Some robots use motors and solenoids as drive mechanisms; others use hydraulic systems; and some use pneumatic systems (driven by compressed gas). Robots can use any of the above types of drive mechanisms.

Second, robots need an energy source to drive these mechanisms. Most robots use batteries or wall power outlets for power. In addition, hydraulic robots require a pump to pressurize the liquid, while pneumatic robots need a gas compressor or a pressure tank.

All drive mechanisms are connected by wires to a circuit board. This circuit directly powers the electric motors and solenoids and manipulates electronic valves to activate the hydraulic system. Valves can control the flow path of pressurized fluids within the machine. For instance, if a robot needs to move a hydraulically driven leg, its controller will open a valve that connects the hydraulic pump to the piston cylinder on the leg. The pressurized fluid will push the piston, making the leg rotate forward. Usually, robots use pistons that can provide bidirectional thrust, allowing parts to move in both directions.

The robot’s computer can control all components connected to the circuit. To make the robot move, the computer will activate all necessary motors and valves. Most robots are reprogrammable. If you want to change the behavior of a robot, you only need to write a new program into its computer.

Not all robots have a sensory system. Very few robots possess vision, hearing, smell, or taste. The most common sense that robots possess is the sense of movement, which is their ability to monitor their own motion. In standard designs, wheels with grooves are mounted at the robot’s joints. One side of the wheel has an LED that emits a beam of light that passes through the groove and hits a light sensor on the opposite side of the wheel. When the robot moves a specific joint, the grooved wheel will rotate. In this process, the groove will block the beam of light.

The optical sensor reads the pattern of the light beam flashing and transmits the data to the computer. The computer can accurately calculate the distance the joint has rotated based on this pattern. The basic system used in a computer mouse is similar to this.

These are the basic components of a robot. Robot experts have countless ways to combine these elements to create infinitely complex robots. Robotic arms are one of the most common designs.

2. How Robots Work

The term “robot” in English comes from the Czech word “robota,” usually translated as “forced laborer.” It is quite fitting to describe most robots. Most robots in the world are used for heavy, repetitive manufacturing tasks. They are responsible for tasks that are very difficult, dangerous, or tedious for humans.

The most common type of manufacturing robot is the robotic arm.

A typical robotic arm consists of seven metal parts, connected by six joints. The computer controls stepper motors connected to each joint to operate the robot (some large robotic arms use hydraulic or pneumatic systems).

Unlike ordinary motors, stepper motors move precisely in increments. This allows the computer to move the robotic arm accurately, enabling it to repeat the same action continuously. Robots use motion sensors to ensure they move precisely as needed.

This six-joint industrial robot is very similar to a human arm, with parts equivalent to the shoulder, elbow, and wrist. Its “shoulder” is usually mounted on a fixed base structure (rather than a moving body). This type of robot has six degrees of freedom, meaning it can rotate in six different directions. In comparison, a human arm has seven degrees of freedom.

A joint of a six-axis industrial robot

The function of a human arm is to move the hand to different positions. Similarly, the function of a robotic arm is to move an end effector. You can install various end effectors on the robotic arm, suitable for specific applications. One common end effector can grasp and move different objects; it is a simplified version of a human hand.

Robotic hands often have built-in pressure sensors to inform the computer of the force exerted when the robot grips a particular object. This prevents the object in the robot’s hand from falling or being crushed. Other end effectors include spray guns, drill bits, and paint sprayers.

Industrial robots are specifically designed to perform the same tasks repeatedly in controlled environments. For example, a robot might be responsible for capping jars of peanut butter on an assembly line. To teach the robot how to perform this task, a programmer will use a handheld controller to guide the robotic arm through the entire sequence of actions. The robot accurately stores the sequence of actions in its memory, and whenever a new jar comes down the assembly line, it will repeat this sequence.

Most industrial robots work on automobile assembly lines, responsible for assembling cars. In performing large volumes of such work, robots are much more efficient than humans, as they are extremely precise. Regardless of how many hours they have worked, they can still drill holes in the same position and screw in bolts with the same force. Manufacturing robots also play a crucial role in the computer industry. Their incredibly precise skills can assemble tiny microchips.

The manufacturing and programming of robotic arms are relatively straightforward since they only operate within a limited area. However, sending robots into the vast outside world complicates matters.

The primary challenge is providing a feasible movement system for the robot. If a robot only needs to move on flat ground, wheels or tracks are often the best choice. If the wheels and tracks are wide enough, they can also be suitable for rough terrain. However, robot designers often prefer to use leg-like structures because they are more adaptable. Creating legged robots also helps researchers understand natural kinematics, which is beneficial practice in biological research.

The legs of robots are typically driven back and forth by hydraulic or pneumatic pistons. Various pistons are connected to different leg components, similar to muscles attached to different bones. Making all these pistons work together correctly is undoubtedly a challenge. In the early stages, the human brain must figure out which muscles need to contract simultaneously to prevent falling while walking upright. Similarly, robot designers must determine the correct combination of piston movements related to walking and program this information into the robot’s computer. Many mobile robots have a built-in balance system (such as a set of gyroscopes) that informs the computer when it needs to correct the robot’s movements.

Boston Dynamics’ latest upgraded Atlas humanoid robot

The bipedal walking motion is inherently unstable, making it extremely challenging to achieve in robot manufacturing. To design a more stable walking robot, designers often look to the animal kingdom, especially insects. Insects have six legs and often exhibit extraordinary balance, adapting easily to various terrains.

Some mobile robots are remotely controlled, allowing humans to instruct them to perform specific tasks at designated times. Remote control devices can communicate with robots using wired connections, radio, or infrared signals. Remote robots are often referred to as puppet robots, which are very useful for exploring dangerous environments or areas inaccessible to humans (such as the deep sea or inside volcanoes). Some robots are only partially remotely controlled. For example, an operator may instruct the robot to reach a specific location but not guide its path, allowing it to find its way independently.

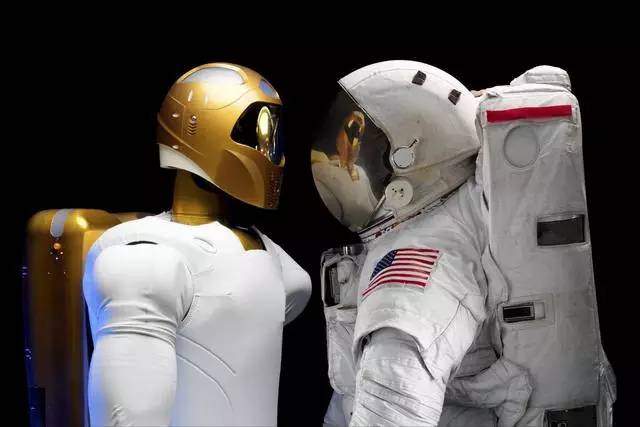

NASA’s remotely controllable space robot R2

Autonomous robots can act independently without relying on any control personnel. The basic principle is to program the robot to respond to external stimuli in a certain way. Extremely simple collision response robots can illustrate this principle well.

This type of robot has a collision sensor to check for obstacles. When you start the robot, it generally moves in a straight line with some deviations. When it encounters an obstacle, the impact force acts on its collision sensor. Each time a collision occurs, the robot’s program instructs it to back up, turn right, and then continue moving forward. In this way, the robot will change its direction whenever it encounters an obstacle.

Advanced robots will apply this principle in more sophisticated ways. Robot experts will develop new programs and sensory systems to create smarter robots with better perception capabilities. Today’s robots can perform excellently in various environments.

Relatively simple mobile robots use infrared or ultrasonic sensors to sense obstacles. These sensors work similarly to the echo-location system used by animals: the robot emits a sound signal (or a beam of infrared light) and detects the reflection of the signal. The robot will calculate the distance to the obstacle based on the time taken for the signal to return.

More advanced robots utilize stereoscopic vision to observe their surroundings. Two cameras can provide depth perception, while image recognition software allows the robot to determine the location of objects and recognize various items. Robots can also use microphones and smell sensors to analyze their environment.

Some autonomous robots can only operate in familiar, limited environments. For example, lawn-mowing robots rely on buried markers to determine the boundaries of the lawn. Office-cleaning robots need a map of the building to navigate between different locations.

More advanced robots can analyze and adapt to unfamiliar environments, even rugged terrains. These robots can associate specific terrain patterns with specific actions. For instance, a rover robot will use its visual sensors to generate a map of the ground ahead. If the map shows a rugged terrain pattern, the robot will know to take an alternate path. This system is very useful for exploratory robots working on other planets.

A set of alternative robot designs adopts a looser structure, introducing randomization factors. When this type of robot gets stuck, it will move its limbs in various directions until its actions yield results. It collaborates closely with force sensors and actuators to complete tasks rather than being guided entirely by a computer program. This is similar to how ants attempt to navigate around obstacles: ants seem to try various methods until they successfully bypass the obstacle.

3. Homemade Robots

In the final sections of this article, let’s take a look at one of the most fascinating areas of the robot world: artificial intelligence and research robots. Over the years, experts in these fields have made significant advancements in robotics, but they are not the only creators of robots. For decades, a small but passionate number of hobbyists have been building robots in garages and basements around the world.

Homemade robots are a rapidly growing subculture with considerable influence on the internet. Amateur robot enthusiasts assemble their creations using various commercial robotic tools, mail-order parts, toys, and even old video recorders.

Like professional robots, homemade robots come in various types. Some weekend hobbyists have created very sophisticated walking machines, while others have designed household robots, and some enthusiasts are keen on building competitive robots. Among competitive robots, the most familiar are remote-controlled robot warriors, like those seen in the show “BattleBots.” These machines are not considered “real robots” because they lack a reprogrammable computer brain. They are just enhanced remote-controlled cars.

More advanced competitive robots are computer-controlled. For example, soccer robots can conduct small soccer matches entirely without human input. A standard robot soccer team consists of several individual robots that communicate with a central computer. This computer “watches” the entire field through a camera and distinguishes between the soccer ball, goals, and players from both teams based on color. The computer continuously processes this information and decides how to direct its team.

Adaptability and Versatility

The personal computer revolution is marked by its exceptional adaptability. Standardized hardware and programming languages allow computer engineers and amateur programmers to create computers for specific purposes. Computer parts are somewhat similar to craft supplies, with countless applications.

So far, most robots are more like kitchen appliances. Robot experts have designed them for specific purposes. However, their adaptability to entirely different applications is not very good.

This situation is changing. A company called EvolutionRobotics is pioneering the field of adaptive robotic software and hardware. The company aims to carve out its niche market with an easy-to-use “robot developer’s toolkit.”

This toolkit features an open-source software platform that provides various commonly used robotic functions. For example, roboticists can easily equip their creations with tracking capabilities, responding to voice commands, and avoiding obstacles. From a technical perspective, these functions are not revolutionary, but what is unusual is that they are integrated into a simple software package.

The toolkit also comes with some common robotic hardware that can be easily combined with the software. The standard toolkit includes infrared sensors, motors, a microphone, and a camera. Robotic experts can use a set of enhanced mounting components to assemble all these parts, including some aluminum body parts and sturdy wheels.

Of course, this toolkit is not meant for creating mediocre works. It costs over $700, which is by no means a cheap toy. However, it represents a significant step toward new robotic science. In the near future, if you want to create a new robot that can clean rooms or care for pets while you’re away, you might only need to write a BASIC program to do so, saving you a lot of money.

4. Artificial Intelligence

Artificial Intelligence (AI) is undoubtedly the most exciting field in robotics and also one of the most controversial: everyone agrees that robots can work on assembly lines, but there is disagreement over whether they can possess intelligence.

Just like the term “robot,” it is also challenging to define “artificial intelligence.” The ultimate artificial intelligence is the reproduction of human thought processes, that is, a man-made machine with human intelligence. Artificial intelligence includes the ability to learn any knowledge, reasoning ability, language ability, and the ability to form one’s own opinions. Currently, robotics experts are far from achieving this level of artificial intelligence, but they have made significant progress in limited areas of AI. Today, machines with artificial intelligence can mimic certain specific elements of intelligence.

Computers have acquired the ability to solve problems in limited domains. The execution process of solving problems with artificial intelligence is complex, but the basic principle is very simple. First, an AI robot or computer collects facts about a situation through sensors (or manual input). The computer compares this information with stored information to determine its meaning. The computer calculates various possible actions based on the collected information and predicts which action will yield the best effect. Of course, the computer can only solve the problems that its programming allows it to solve; it does not possess general analytical capabilities. A chess computer is an example of such machines.

Some modern robots also possess limited learning capabilities. Learning robots can recognize whether a certain action (like moving a leg in a specific way) achieved the desired result (like avoiding an obstacle). The robot stores this information, and when it encounters the same situation next time, it will attempt to perform actions that can successfully respond. Similarly, modern computers can only do this in very limited scenarios. They cannot collect all types of information like humans. Some robots can learn by mimicking human actions. In Japan, robotics experts demonstrated dance moves to a robot, teaching it how to dance.

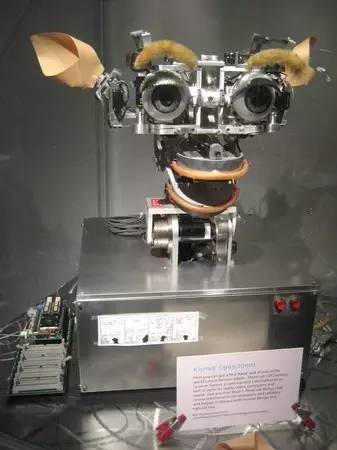

Some robots possess interpersonal communication abilities. Kismet is a robot created by the MIT Artificial Intelligence Lab, capable of recognizing human body language and tone of voice, responding accordingly. The creators of Kismet were interested in the interactions between adults and infants, which can be completed solely through tone and visual information. This low-level interaction can serve as the foundation for humanoid learning systems.

Kismet robot

Kismet and other robots created by the MIT AI Lab employ an unconventional control structure. These robots are not controlled by a single central computer for all actions; their low-level actions are controlled by low-level computers. Project leader Rodney Brooks believes this is a more accurate model of human intelligence. Most human actions are made automatically rather than being determined by higher levels of consciousness.

The true challenge of artificial intelligence lies in understanding how natural intelligence works. Developing artificial intelligence is different from creating an artificial heart; scientists do not have a simple and concrete model to refer to. We know that the brain contains billions of neurons and that our thinking and learning are accomplished by establishing electronic connections between different neurons. However, we do not know how these connections facilitate advanced reasoning capabilities or even the principles of lower-level operations. The neural networks in the brain seem too complex to comprehend.

Therefore, artificial intelligence is largely still theoretical. Scientists propose hypotheses about the principles of human learning and thinking and then use robots to experiment with their ideas.

Just as the physical design of robots is a convenient tool for understanding animal and human anatomy, research on artificial intelligence also helps us understand how natural intelligence works. For some robotics experts, such insights are the ultimate goal of designing robots. Others fantasize about a world where humans coexist with intelligent machines, using various small robots for manual labor, healthcare, and communication. Many robotics experts predict that the evolution of robots will ultimately lead us to become cyborgs, humans fused with machines. There is reason to believe that future humans will implant their thoughts into robust robotic bodies, living for thousands of years!

Regardless, robots will play an important role in our daily lives in the future. In the coming decades, robots will gradually expand beyond the industrial and scientific realms into everyday life, similar to the process of computers gradually entering households in the 1980s.

▶ The editor guesses you may also like these  :

:

How many axes do industrial robots have? This article clarifies it.

The five major pitfalls of factory automation transformation and the top ten essential devices; learn these and you will be a big shot!

In three years, there will be one million industrial robots, requiring 200,000 related professionals. Can vocational education keep up?

Scan the QR code to add the editor as a friend

Secretly tell me what you do, and the editor will “record” it, then add you to our professional technical exchange group to meet more industry elites and big shots!

Secretly tell me what you do, and the editor will “record” it, then add you to our professional technical exchange group to meet more industry elites and big shots!