Today, we bring you the wiring methods for sensors and PLCs, featuring twenty wiring diagrams. Isn’t that a wealth of information? Let’s take a look together!

Overview

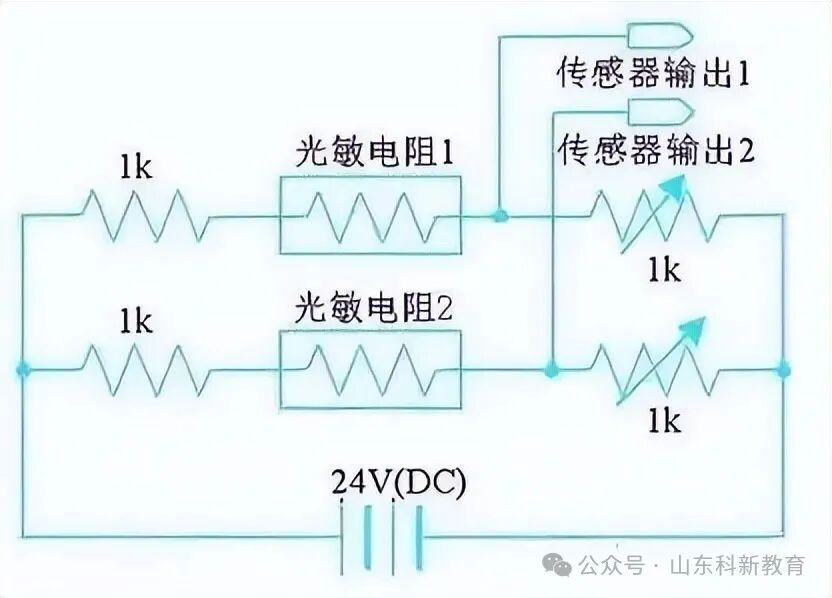

The digital input interface of a PLC is not complex. To enhance anti-interference capability, PLCs use opto-isolators to isolate the input signals from the internal processing circuits. Therefore, the signal at the input end only drives the internal LED of the opto-isolator, which is received by the phototransistor of the opto-isolator, allowing reliable transmission of external input signals.

Currently, PLC digital input ports are generally divided into single-ended common point and double-ended inputs. Due to these differences, users need to understand the wiring methods when selecting external sensors to ensure correct usage, which lays the foundation for subsequent programming work and system stability.

Forms of Input Circuits

1. Classification of Input Types

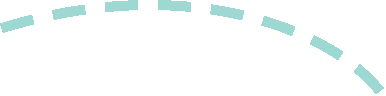

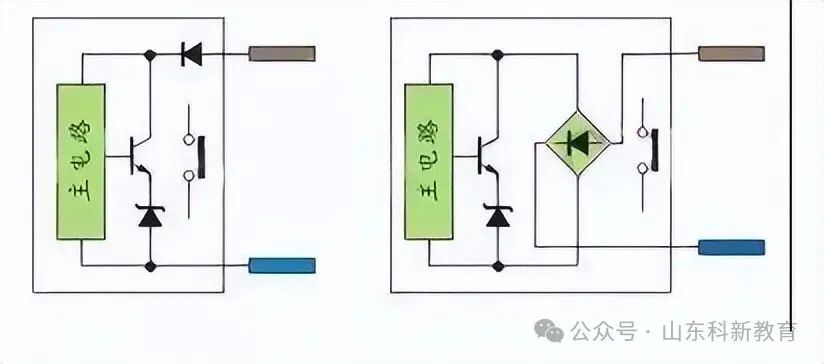

The digital input terminals of the PLC are classified by power supply into DC and AC. By input interface classification, they are divided into single-ended common point and double-ended inputs. Single-ended common point connected to the positive terminal of the power supply is called SINK (sink current), while single-ended common point connected to the negative terminal is called SOURCE (source current).

2. Overview of Terms

SINK type allows current to flow out from the input terminal, so the input terminal can be connected to the negative terminal of the power supply, indicating that the internal opto-isolator is single-ended common point connected to the positive terminal, suitable for NPN type sensors.

SOURCE type allows current to flow into the input terminal, so the input terminal can be connected to the positive terminal of the power supply, indicating that the internal opto-isolator is single-ended common point connected to the negative terminal, suitable for PNP type sensors.

Proximity switches and photoelectric switches with three or four wire outputs are divided into NPN and PNP outputs. For NPN proximity switches and photoelectric switches, when there is no detection signal, the output is high level (with respect to the internal pull-up resistor). When there is a detection signal, the internal NPN transistor conducts, and the output is low level.

For PNP proximity switches and photoelectric switches, when there is no detection signal, the output is low level (with respect to the internal pull-down resistor). When there is a detection signal, the internal PNP transistor conducts, and the output is high level.

The above situations are only applicable when the sensor is in a normally open state.

3. Configuration Types by Power Supply

(1) DC Input Circuit

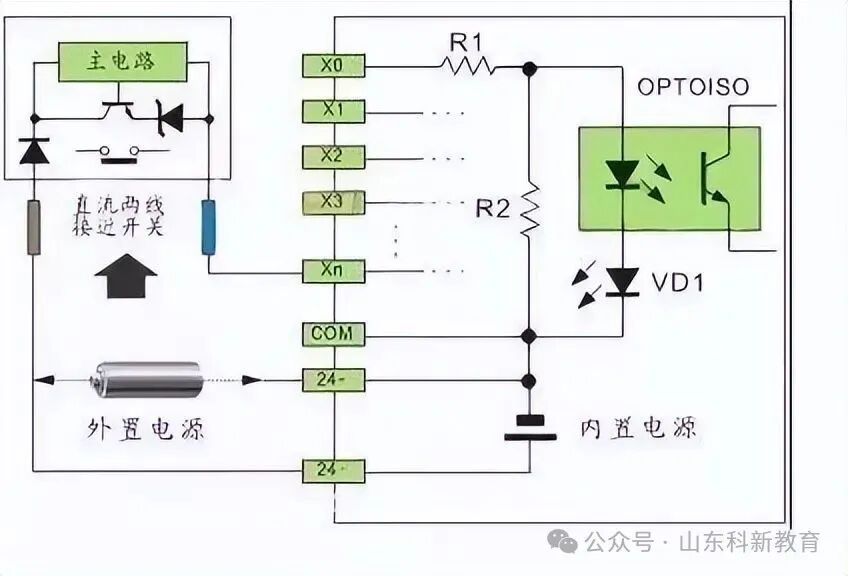

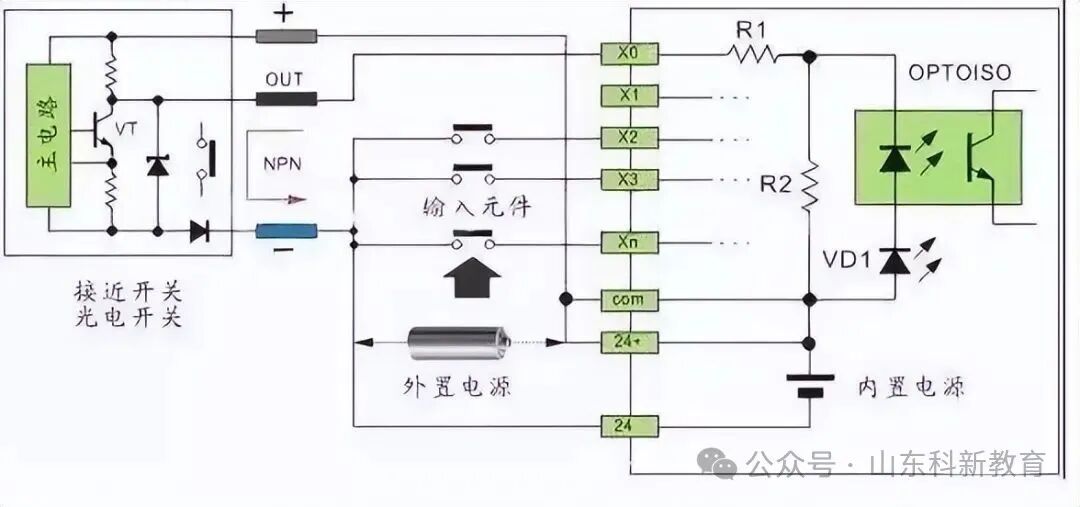

As shown in Figure 1, the DC input circuit requires that the external input signal component be a passive dry contact or a DC active non-contact switch. When the external input component connects to the positive terminal of the power supply, current flows through R1, the internal LED of the opto-isolator, VD1 (interface indicator) to the COM terminal, forming a loop. The internal receiving tube of the opto-isolator receives the signal from the external component, transmitting it to the internal processing; this interface powered by DC is called a DC input circuit.

DC power can be provided by the PLC internally or by an external DC power supply to the external input signal components. R2 in the circuit serves to bypass the current of the opto-isolator’s internal LED, ensuring that the LED is not turned on by the static leakage current of the two-wire proximity switch.

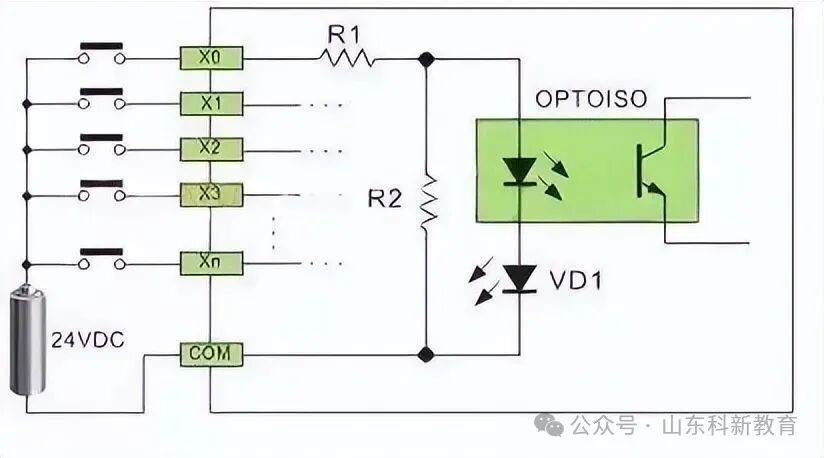

(2) AC Input Circuit

As shown in Figure 2, the AC input circuit requires that the external input signal component be a passive dry contact or an AC active non-contact switch. The distinction from the DC interface is that a step-down circuit and a bridge rectifier circuit are added before the opto-isolator. After the external component connects to the AC power, current flows through R1, C2, and the bridge rectifier, converting it into a step-down DC voltage, with the subsequent circuit principles being consistent with those of DC.

AC PLCs are mainly suitable for relatively harsh environments, where wiring technology does not change much; for example, proximity switches can directly replace original travel switches with AC two-wire.

4. By Port Type

(1) Single-ended Common Point (Comcon) Digital Input Method

To save input terminals, the structure of single-ended common point input connects one end of all input circuits (opto-isolators) inside the PLC to a common internal terminal marked COM, while the other end of each input circuit connects to its corresponding input terminals X0, X1, X2, ….

Common point with N single-ended inputs can create N digital inputs (N+1 terminals), hence we refer to this structure as “single-ended common point” input. When wiring external digital input components, users need to do the same, connecting one end of all input components together, called external common line; the other end connects to the PLC input terminals X0, X1, X2, ….

SINK input method can connect to NPN type sensors, i.e., the X port is connected to the negative terminal.

SRCE input method can connect to PNP type sensors, i.e., the X port is connected to the positive terminal of the entire machine. (External input components can include button switches, travel switches, reed switches, Hall switches, proximity switches, photoelectric switches, light curtain sensors, relay contacts, contactor contacts, and other switch elements.)

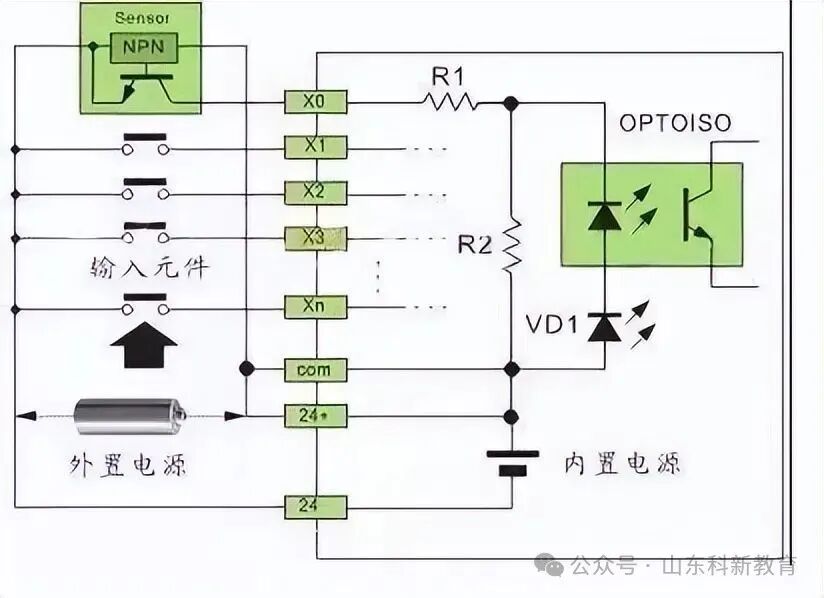

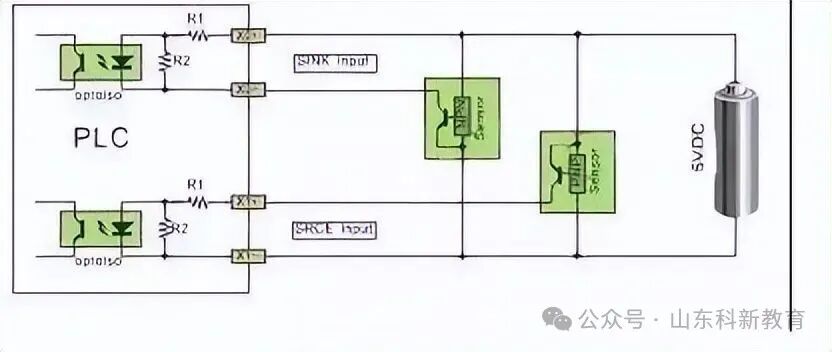

(2) SINK (sink current) Input Method ● Single-ended Common Point SINK Input Wiring (Internal Common Point Terminal COM→24V+, External Common Line→24V-). As shown in Figure 3:

(3) SRCE (source current) Input Method

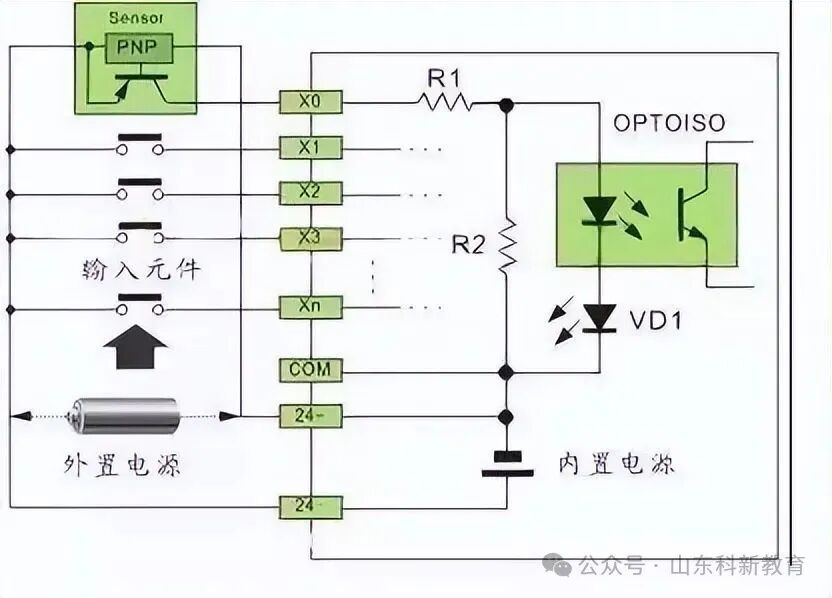

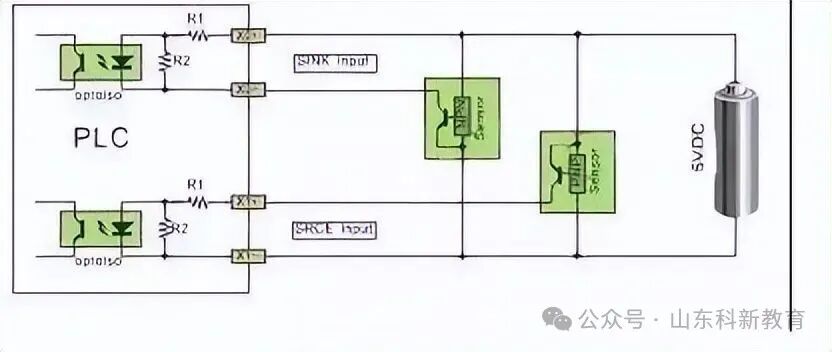

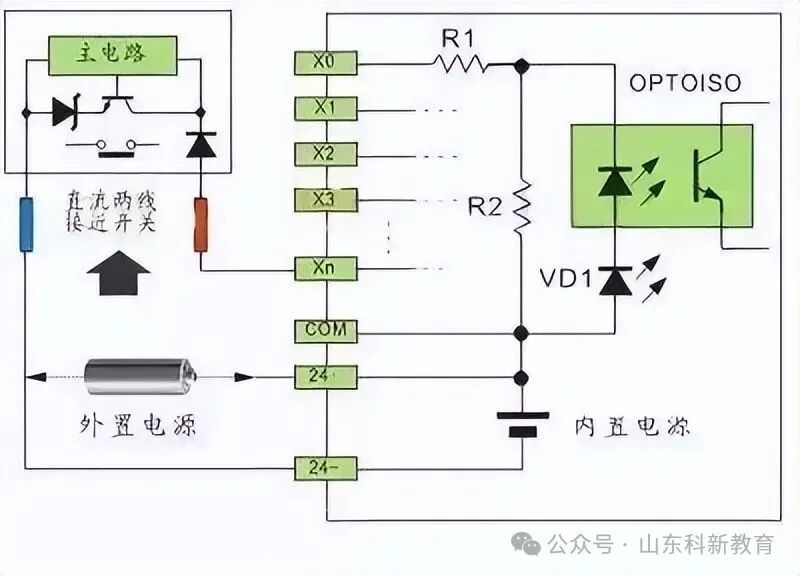

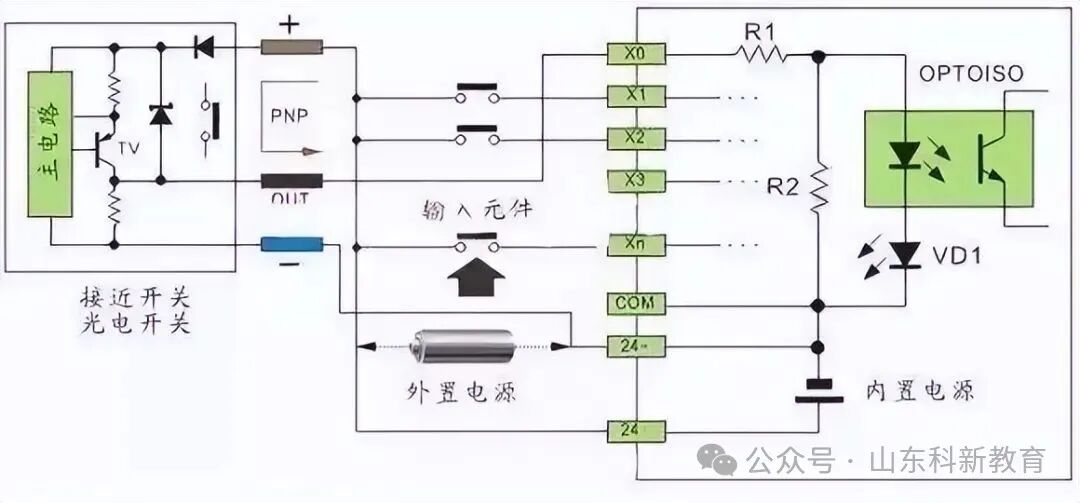

● Single-ended Common Point SRCE Input Wiring (Internal Common Point Terminal COM→24V-, External Common Line→24V+). As shown in Figure 4:

(4) SINK/SRCE Switchable Input Method

The S/S terminal differs from the COM terminal in that COM is fixedly connected to the internal power supply’s positive or negative terminal, while the S/S terminal is non-fixedly connected, depending on the need to connect to either the positive or negative terminal of the internal or external power supply.

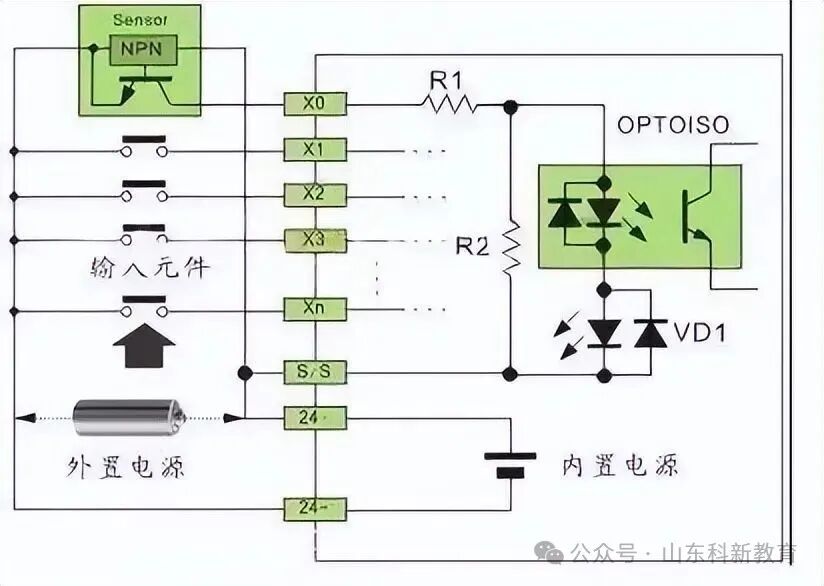

● Single-ended Common Point SINK Input Wiring (Internal Common Point Terminal S/S→24V+, External Common Line→24V-).

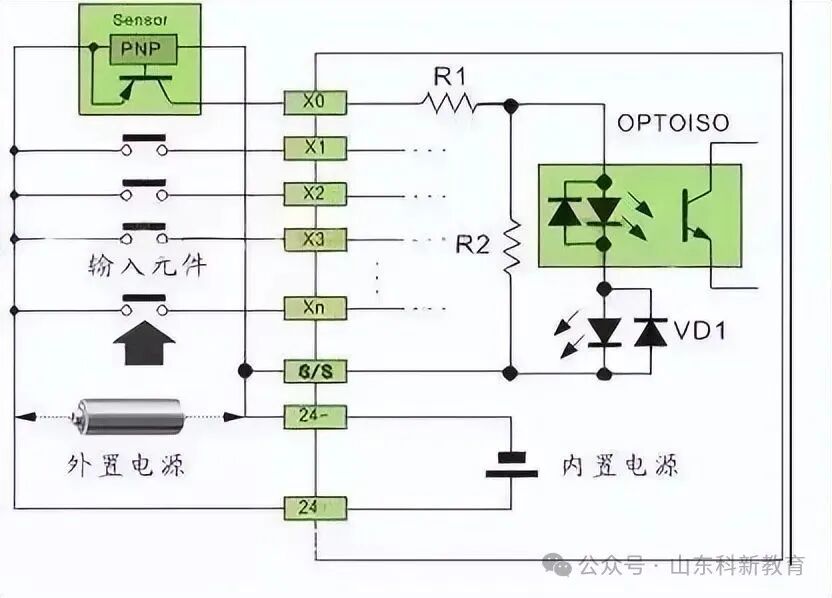

Single-ended Common Point SRCE Input Wiring (Internal Common Point Terminal S/S→24V-, External Common Line→24V+).

(5) When there are many active input components (Hall switches, proximity switches, photoelectric switches, light curtain sensors, etc.) consuming significant power, and the PLC’s built-in power supply cannot meet the demand, an external power supply needs to be configured. Depending on the requirements, a 24VDC switch power supply of a certain power rating can be configured. The external power supply should not be connected in parallel with the internal power supply. According to the characteristics of COM and external common lines, in the SINK (sink current) input method, the external power supply connects to the positive terminal of the internal power supply; in the SRCE (source current) input method, the external power supply connects to the negative terminal of the internal power supply.

(6) A simple way to determine the SINK (sink current) input method is to short the Xn terminal to the negative terminal. If the interface indicator light is on, it indicates SINK input method. The common positive opto-isolator can connect to NPN type sensors. For the SRCE (source current) input method, short the Xn terminal to the positive terminal. If the interface indicator light is on, it indicates SRCE input method. The common negative opto-isolator can connect to PNP type sensors.

(7) For two-wire switch inputs, if they are passive contacts, SINK and SRCE should follow the input component wiring methods shown above. For two-wire proximity switches, it is necessary to determine the polarity of the proximity switch for correct connection.

(8) High-speed Dual-ended Input Circuit

This is mainly used for hardware high-speed counters (HHSC) input, with an interface voltage of 5VDC. In applications requiring high speed and high noise immunity, a dual-line drive method (Line-Drive) is usually adopted. If the working frequency is not high and noise is low, a 5VDC single-ended SINK or SRCE connection can be used, with a current-limiting resistor in series to convert it into a 24VDC single-ended SINK or SRCE connection.

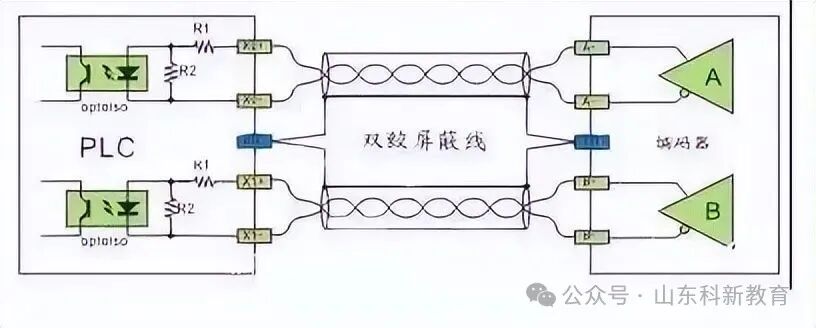

(9) Dual Input End Dual-line Drive Method (Line-Drive).

(10) 5VDC Single-ended SINK or SRCE Connection Method.

(11) 24VDC Single-ended SINK or SRCE Connection Method.

Note: For sensors powered by 24VDC, a current-limiting resistor must be connected in series in the input circuit. R1 should be 10Ω, and R2 should be 2KΩ. If a current-limiting resistor is not connected, it will burn out the interface circuit. The value of the current-limiting resistor should be 2.7KΩ.

External Input Components

1. Passive Dry Contacts (Button Switches, Travel Switches, Reed Switches, Relay Contacts, etc.)

Passive dry contacts are relatively simple and easy to wire. There are no issues with power supply polarity or voltage drop, as shown in the input components in Figures 3-6. This will not be repeated here.

2. Active Two-Wire Sensors (Proximity Switches, Active Reed Switches)

Active two-wire proximity switches are divided into DC and AC. The characteristic of this sensor is that it has two wires. When the output terminal of the sensor is conductive, a holding voltage is required to maintain circuit operation, usually a voltage drop of 3.5-5V, with a static leakage current of less than 1mA, which is a crucial indicator; if it is too high, the opto-isolator at the PLC input terminal will conduct when there is no detection signal.

DC two-wire proximity switches are divided into those with diode polarity protection and bridge rectifier polarity protection. The former requires attention to polarity when connecting to the PLC, while the latter does not. Active reed switches are mainly used for position detection on cylinders and do not require attention to polarity due to the internal bidirectional diode circuit; AC two-wire proximity switches also do not require attention to polarity. As shown in Figure 10:

(1) Single-ended Common Point SINK Input Wiring (Internal Common Point Terminal COM→24V+, External Common Line→24V-). As shown in Figure 11

(2) Single-ended Common Point SRCE Input Wiring (Internal Common Point Terminal COM→24V-, External Common Line→24V+). As shown in Figure 12:

(3) S/S Terminal Wiring Reference Figures 5-6 and Figures 11-12.

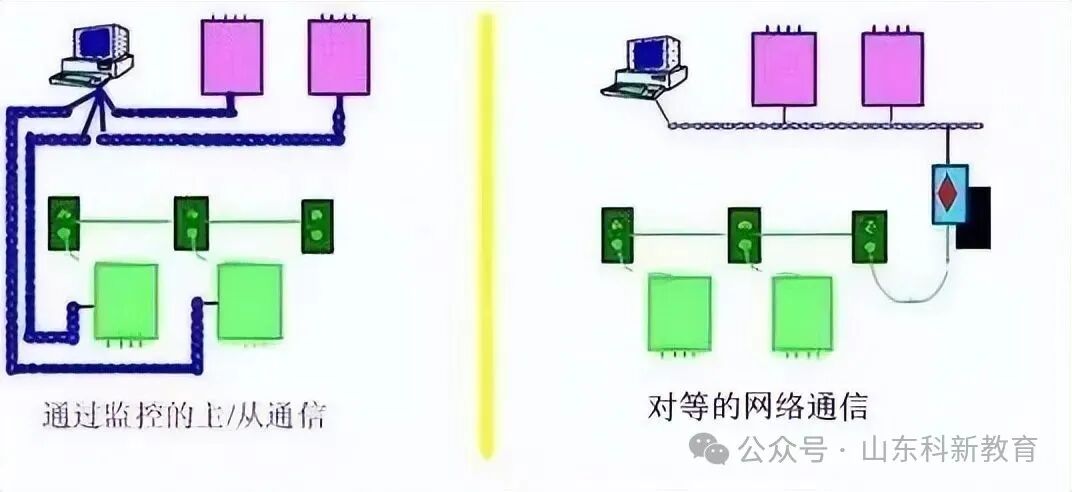

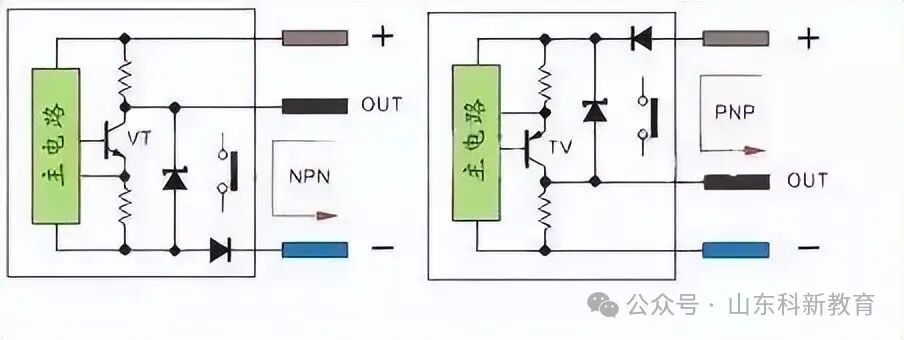

3. Active Three-Wire Sensors (Inductive Proximity Switches, Capacitive Proximity Switches, Hall Proximity Switches, Photoelectric Switches, etc.) DC active three-wire proximity switches and photoelectric switches use transistor outputs, thus sensors are divided into NPN and PNP outputs. Some products are four-wire with dual NPN or dual PNP outputs, which are just opposite states, and there are also NPN and PNP combined four-wire outputs.

For NPN type, when the sensor has a detection signal VT conducting, the current flows from the output terminal OUT to the negative terminal, making the output terminal OUT potential close to the negative terminal, usually referred to as high level flipping to low level.

For PNP type, when the sensor has a detection signal VT conducting, the current flows from the positive terminal to the output terminal OUT, making the output terminal OUT potential close to the positive terminal, usually referred to as low level flipping to high level.

The resistance on the emitter of the transistor in the circuit is a short-circuit protection sampling resistor of 2-3Ω, which does not affect the output current. The resistance on the collector of the transistor is a pull-up and pull-down resistor, providing output potential, facilitating the level interface circuit. Another type of output from the transistor collector is open collector output without pull-up and pull-down resistors.

In simple terms, when the transistor VT conducts, it is equivalent to a contact conducting, as shown in Figure 13:

(1) Single-ended Common Point SINK Input Wiring (Internal Common Point Terminal COM→24V+, External Common Line→24V-). As shown in Figure 14:

(2) Single-ended Common Point SRCE Input Wiring (Internal Common Point Terminal COM→24V-, External Common Line→24V+). As shown in Figure 15:

(3) S/S Terminal Wiring Reference Figures 5-6, Figures 11-12, and Figures 14-15.

The diversity of PLC input interface circuit forms and the output signal forms of external components (sensors) necessitate understanding the PLC input circuit forms and the sensor output signal forms before wiring the PLC input module. This ensures correct wiring of the PLC input module, allowing for smooth operation in practical applications and laying the foundation for subsequent programming work and system stability.

Source: This article is reproduced from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us promptly for deletion. Thank you!

Scan to Follow

WeChat ID|13615417996

Follow the QR code on the left to get free access to

[Siemens Data Collection]