Industrial recirculating aquaculture, as a new and efficient factory-style, intensive farming technology, has significant advantages such as water and land conservation, health and efficiency, controllable environment, and safe product quality. It is an important direction for the transformation and upgrading of the aquaculture industry and a crucial pathway towards a strong fisheries nation.

Industrial recirculating aquaculture started earlier abroad, becoming an important direction for the development of the aquaculture industry in countries like the USA, France, Norway, and Denmark, which have largely achieved mechanization, automation, informatization, and modernization of management. In recent years, with the development of the Internet of Things and smart management technologies, it has gradually developed towards scale and intelligence, establishing mathematical models for operational management centered on the cultured species and expert decision-making systems, initially realizing precise aquaculture and intelligent control.

Although China’s recirculating aquaculture started late, after more than 20 years of development, the technology has significantly improved, achieving a series of core technologies and equipment with independent intellectual property rights. However, compared to foreign countries, there are obvious gaps in intelligence and system stability. After entering the 13th Five-Year Plan, the state has explicitly proposed requirements for green development in aquaculture, combining industry needs and based on international trends in industrial recirculating aquaculture technology. China’s industrial recirculating aquaculture will develop towards intelligent precision, green energy-saving, and efficient cleanliness.

To address the long-term operational stability and reliability issues of China’s recirculating aquaculture systems, as well as the high reliance on human labor for key operational processes such as feeding and harvesting, the technology innovation team of the Aquaculture Machinery and Instrument Research Institute of the Chinese Academy of Fishery Sciences has focused on the precision and intelligent development needs of common key technologies in recirculating aquaculture, targeting the two core processes of water treatment and production control, and has made technological breakthroughs in intelligent water quality control and precise aquaculture management.

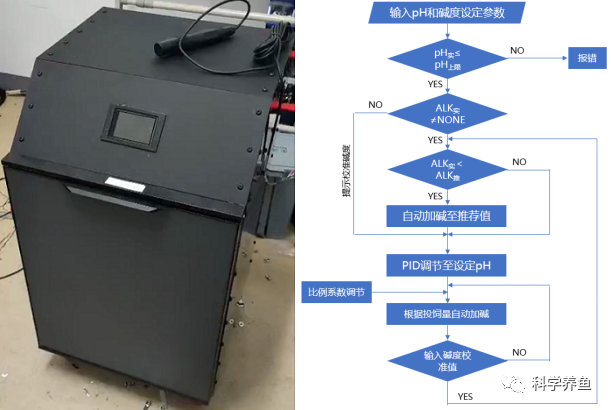

(1) Development of a pH adaptive control system technology based on feeding amount and PID controller, which actively compensates alkalinity to solve the problem of water acidification caused by closed-loop systems, affecting water quality stability and fish growth.

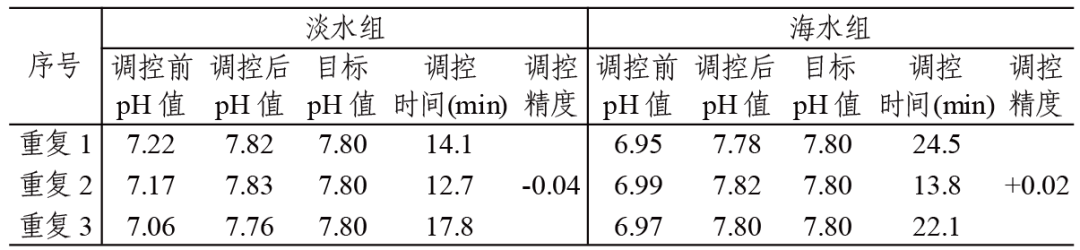

In closed recirculating aquaculture systems, fish respiration and the nitrification reaction in biological filters can lead to the consumption of alkalinity in the water, causing a drop in pH, which in turn affects the health and growth of the cultured species. To address this issue, a pH adaptive control system technology has been developed, based on feeding amount and alkalinity consumption models, which adds alkaline solution to the water at set intervals and quantities while using sensors and fuzzy PID controllers for real-time monitoring and feedback adjustment of pH to achieve precise control. Third-party performance testing results show that the control accuracy error of the equipment under freshwater conditions is -0.04, and under seawater conditions is +0.02 (Table 1). Additionally, a one-month integrated demonstration was conducted in the recirculating aquaculture system of a yellow croaker farming company, and the application results indicate that the pH control accuracy error is within ±0.07.

(2) Overcoming the challenge of precise dissolved oxygen control in recirculating aquaculture systems, developing intelligent control technology and equipment for dissolved oxygen based on the GRU prediction model.

Current dissolved oxygen control in aquaculture ponds mainly relies on manual adjustments of valve sizes to regulate oxygen input. Due to the numerous oxygen-consuming factors in the aquaculture water, manual control cannot ensure timely and accurate adjustments, leading to issues such as oversaturation of dissolved oxygen causing waste or insufficient dissolved oxygen affecting the health of cultured species. To address this, intelligent control technology for dissolved oxygen based on the GRU prediction model has been developed. The main technical principle involves using the GRU machine learning algorithm to construct a fish oxygen consumption rate prediction model, which predicts the oxygen consumption rate of fish groups in real-time based on fish size, water temperature, and dissolved oxygen concentration, further calculating and controlling the amount of oxygen added. When the measured dissolved oxygen deviates from the target value, feedback correction and transfer learning are used to adjust the prediction model. A set of equipment has been developed (Figure 2), mainly consisting of an Arduino UNO motherboard, a CNC constant pressure power supply, a DC solid state relay, an electromagnetic valve, an OLED display, a switch power supply, a rotary encoder module, a proportional valve, and a fluorescence dissolved oxygen sensor. Third-party performance testing results confirm that the equipment’s control accuracy error for dissolved oxygen is within ±0.23mg/L. Additionally, a one-month integrated demonstration was conducted in the recirculating aquaculture system of a yellow croaker farming company, and the application results indicate that the dissolved oxygen control accuracy error is within ±0.54mg/L, saving over 50% of oxygen compared to manual control.

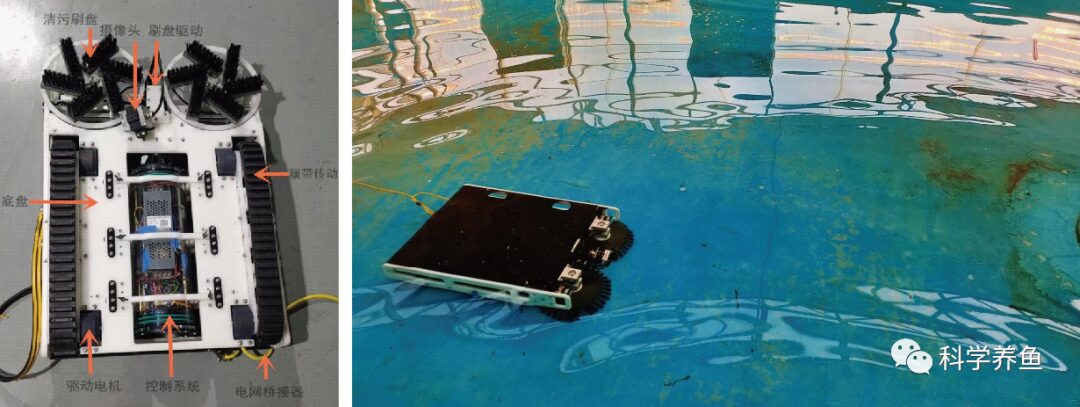

(3) Overcoming the challenge of automatic cleaning of fish pond bottoms, developing an underwater cleaning robot to significantly enhance operational efficiency.

To address the current issue where aquaculture ponds cannot achieve real-time cleaning during operation, automatic cleaning technology has been developed. The main technical principle involves controlling a tracked mobile chassis and its mounted rotary cleaning mechanism via Ethernet communication, allowing the cleaning robot to walk underwater through remote control and to scrub solid particulate matter from the pond bottom, expelling waste through water flow. A set of equipment has been developed (Figure 3), mainly consisting of a tracked drive chassis, a controller, a cleaning brush disc, and its drive components. A one-month integrated demonstration was conducted in the recirculating aquaculture system of a yellow croaker farming company, and the application results indicate that the equipment has good cleaning capabilities, excellent sealing and corrosion resistance, and high stability during underwater operations, effectively reducing the intensity of manual cleaning tasks. The underwater cleaning robot’s cleaning speed is approximately 2 minutes/m2, improving efficiency by about 40% compared to manual cleaning operations.

(4) Overcoming technical challenges affecting mass transfer efficiency of microorganisms and nutrients due to aging biofilms in fluidized beds, developing self-cleaning technology for filter media based on ultrasonic technology, and creating self-cleaning biological fluidized bed equipment.

To address the issues of small specific surface area of filter media and low proportion of functional bacteria, research on filter media enhancement technology has been conducted. The self-cleaning fluidized bed biological filter technology and equipment have been developed, using 0.2mm glass microsphere biological filter media, achieving fluidization of the filter media layer through uniformly rising water flow, ensuring efficient mass transfer between nutrients and biofilms, increasing the specific surface area by more than 10 times compared to porous suspended fillers. Additionally, ultrasonic sensors and automatic siphon devices have been integrated inside the reactor (Figure 4) to achieve automatic cleaning of the filter media. Third-party performance testing results show that the equipment can achieve an ammonia nitrogen removal load of 610.56 g·m-3·d-1, with bed expansion control accuracy within ±4.5%. Furthermore, a three-month integrated demonstration was conducted in the river pufferfish recirculating aquaculture system at the Jiangsu Aquaculture Machinery and Engineering Research Institute, and the application results indicate that the self-cleaning biological fluidized bed can achieve a maximum ammonia nitrogen removal load of 762.5 g·m-3·d-1.

(5) Innovatively developed a spring-type automatic fish gathering equipment to meet live fish pump suction needs, significantly reducing manual labor.

To address the current low mechanization level of live fish gathering operations in China, where manual work can easily stress the fish and capture efficiency is low, a spring-type automatic fish gathering equipment has been developed (Figure 5). The main technical principle involves a single-wheel driven pulley moving along the pond opening, pulling a rope net around the aquaculture pond, utilizing the spring preload to tighten the rope net, achieving the goal of gathering live fish. The entire equipment uses a quick-clamp design, making it easy to assemble and disassemble, and user-friendly. Third-party testing indicates that the pulley moves at a speed of 2.5 cm/s, with a driving power of 25W, achieving a fish gathering rate of 98.2%. Comparative results from production demonstrations show that efficiency has improved by 38% compared to manual methods.

(6) Developed a pipeline-style automatic fish lifting equipment based on the Coanda effect to solve the problems of intermittent operation of existing vacuum pump suction technology, as well as the large size and heaviness of equipment, enhancing mechanization levels in industrial aquaculture.

Current automatic fish suction technologies mainly include vacuum and centrifugal fish pumps, which suffer from issues such as large equipment size and insufficient continuous working capacity, failing to meet the needs of use in narrow spaces of industrial workshops. To address this, an annular jet suction inlet has been innovatively designed, utilizing the fluid wall attachment effect generated by the Coanda effect to achieve the effect of water flow amplification, fulfilling the need for automatic fish suction through high-speed suction water flow. SolidWorks FloXpress software was used to simulate and optimize parameters such as the inlet diameter, contraction angle, nozzle gap width, and inlet flow rate, with results indicating that the water flow amplification effect can reach 1.9 times, and the flow velocity at the suction inlet can reach 3.6 m/s. Third-party performance testing results show that the suction capacity can reach 15.9 kg/min.

This article is copyrighted by the Scientific Fish Farming Magazine

Authors: Zhang Yulei, Zhang Haigeng, Zhang Yufei, Aquaculture Machinery and Instrument Research Institute, Chinese Academy of Fishery Sciences

This issue’s editor:Chen Qian (WeChat ID: xizi-cq, for news tips and reprint authorization, please add WeChat)

★ Click to find the pain points of bullfrog farming and identify the direction for bullfrog farming?

★ Continue to decline! Common fish are stable and rising, while prices of several special water fish have returned to the cost line!

★ Recruitment for part-time business managers + distributors║ Yongrong Biological, established in 2002, specializing in true over-sulfurization!

★ Have you tried aquatic products from countries involved in the Belt and Road Initiative?

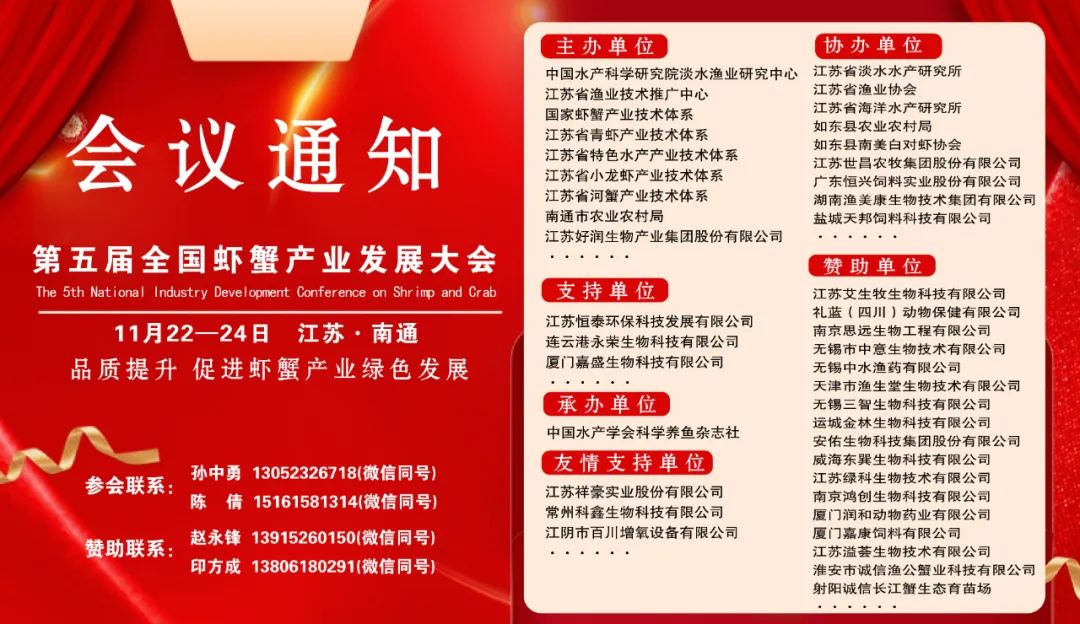

Notice of the Fifth National Shrimp and Crab Industry Development Conference

(Second Round Notice)

1. Breeding and New Variety Selection of Chinese Mitten Crab, Macrobrachium rosenbergii, and Snails

Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences Researcher Xu Pao

2. Tolerance Capacity and Farming Modes of Shrimp Farming Environment

Sun Yat-sen University Professor He Jianguo

3. Current Status of the Crawfish Industry and New Efficient Ecological Farming Models

Jiangsu Provincial Fisheries Technology Promotion Center Researcher Chen Huangen

4. Current Status of the Green Shrimp Farming Industry and Progress in New Variety Selection

Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences Researcher Fu Hongtuo

1. Automation and Intelligent Development of Shrimp Farming

Institute of Oceanology, Chinese Academy of Sciences Researcher Wang Lei

2. Optimization and Technical Upgrade of Small Shed Shrimp Models

South China Sea Fisheries Research Institute, Chinese Academy of Fishery Sciences Researcher Zhang Jiasong

3. New Progress in SPF Seed Breeding of South American White Shrimp

Yellow Sea Fisheries Research Institute, Chinese Academy of Fishery Sciences Researcher Luan Sheng

4. Establishment and Application of Disease Prevention System for Small Shed Shrimp Farming

Jiangsu Marine Fisheries Research Institute Researcher Wan Xihe

5. Discussion on Freshwater Farming Technology of South American White Shrimp

Shanghai Ocean University Professor Dai Xilin

6. Insights from Fourteen Years of Experience in Small Shed Shrimp Farming

New Farmers of Shrimp Farming (Rudong) He Suhua

7. My Views on Industrial Aquaculture Practice

Chairman of Jiangsu Guangya Group Zhu Shiming

1. Seed Production and Seedling Cultivation Technology of River Crabs

Shanghai Ocean University Professor Wang Chenghui

2. Current Status of Crawfish Seed Industry Development and Seedling Breeding Technology

Jiangsu Freshwater Fisheries Research Institute Researcher Xu Zhiqiang

3. How to Achieve High Efficiency in Crab Farming Amid Rising Costs and Falling Prices

Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences Researcher Xu Gangchun

4. Current Status and Trends of Scaled Crawfish Farming in Anhui

Anhui Provincial Fisheries Technology Promotion Station Researcher Jiang Jun

5. Prevention and Treatment of Major Diseases in River Crabs and Crawfish

Jiangsu Freshwater Fisheries Research Institute Researcher Xue Hui

6. Technical Solutions for Replacing Fresh Fish with Compound Feed in the Fattening Process of River Crab Farming

Nanjing Agricultural University Professor Jiang Guangzhen

7. Feeding and Digestive Systems of Crawfish and Green Feed Technology for Large-sized Shrimp

Yancheng Institute of Technology Professor Wang Aimin

1. Introduction of New Varieties of Green Shrimp and Ecological Farming

Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences Researcher Jiang Su Fei

2. New Efficient Seedling Raising Technology for Green Shrimp

Nanjing City Fisheries Research Institute Researcher Zhou Guoqin

3. Key Technologies for Efficient Green Shrimp Farming

Jiangsu Fisheries Technology Promotion Center Researcher Zou Honghai

4. Feed Selection and Feeding Technology for Green Shrimp under New Conditions

Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences Researcher Liu Bo

5. Diagnosis Methods for Green Shrimp Diseases and Exploration of Comprehensive Prevention and Control Technologies

Yangzhou University Professor Zhang Xiaojun

6. Current Status of the Green Shrimp Industry in Tianjin and Major Farming Technology Models

Tianjin Fisheries Research Institute Senior Agronomist Jiang Jufeng

7. Exploration of New Models for Ecological and Efficient Green Shrimp Farming in Ponds

Changzhou Jintan District Fisheries Technology Promotion Center Senior Engineer Xiao Wenwen

November 22-24, 2023; Registration on the 22nd, Conference Reports on the 23rd, Departure on the 24th.

Nantong Grand Hotel (Address: No. 83, Youth Middle Road, Chongchuan District, Nantong City, Jiangsu Province).

Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences

Jiangsu Provincial Fisheries Technology Promotion Center

National Shrimp and Crab Industry Technology System

Jiangsu Provincial Green Shrimp Industry Technology System

Jiangsu Provincial Specialty Aquatic Industry Technology System

Jiangsu Provincial Crawfish Industry Technology System

Jiangsu Provincial River Crab Industry Technology System

Nantong Municipal Agricultural and Rural Affairs Bureau

Jiangsu Haorun Biological Industry Group Co., Ltd.

······

Jiangsu Freshwater Fisheries Research Institute

Jiangsu Fisheries Association

Jiangsu Marine Fisheries Research Institute

Rudong County Agricultural and Rural Affairs Bureau

Rudong County South American White Shrimp Association

Jiangsu Shichang Agricultural and Animal Husbandry Group Co., Ltd.

Guangdong Hengxing Feed Industry Co., Ltd.

Hunan Yumeikang Biotechnology Group Co., Ltd.

Yancheng Tianbang Feed Technology Co., Ltd.

······

Jiangsu Hengtai Environmental Protection Technology Development Co., Ltd.

Lianyungang Yongrong Biological Technology Co., Ltd.

Xiamen Jiasheng Biotechnology Co., Ltd.

······

Jiangsu Aishengmu Biotechnology Co., Ltd.

Li Lan (Sichuan) Animal Health Co., Ltd.

Nanjing Siyuan Bioengineering Co., Ltd.

Wuxi Zhongyi Biotechnology Co., Ltd.

Wuxi Zhongshui Fish Medicine Co., Ltd.

Tianjin Fish Life Bioengineering Co., Ltd.

Wuxi San Zhi Biotechnology Co., Ltd.

Yuncheng Jinlin Biotechnology Co., Ltd.

Anyou Biotechnology Group Co., Ltd.

Weihai Dongxun Biotechnology Co., Ltd.

Jiangsu Lvkai Biotechnology Co., Ltd.

Nanjing Hongchuang Biotechnology Co., Ltd.

Jiangsu Yihui Biotechnology Co., Ltd.

Jiangsu Yulequ Bioengineering Co., Ltd.

Xiamen Jiakang Feed Co., Ltd.

Huai’an Integrity Fish Crab Industry Technology Co., Ltd.

Sheyang Integrity Yangtze Crab Ecological Seedling Farm

······

Jiangsu Xianghao Industrial Co., Ltd.

Changzhou Kexin Biotechnology Co., Ltd.

Jiangyin Baichuan Oxygenation Equipment Co., Ltd.

······

Chinese Society of Fisheries Scientific Fish Farming Magazine

The registration deadline is November 15, 2023. Those who register and remit before November 15 will pay 600 yuan; on-site payment will be 800 yuan.

The conference registration fee includes conference materials, meals, and related activity expenses. Transportation and accommodation are self-catered (Note: Fees are non-refundable if you cannot attend for personal reasons after successful registration and remittance). Please indicate “Shrimp and Crab Conference Registration Fee” when remitting.

Remittance Information

Account Name: Freshwater Fisheries Research Center, Chinese Academy of Fishery Sciences

Bank Name: Jiangsu Bank Wuxi Dafu Branch

Account Number: 810010189300001895

Contact for Participation:

Sun Zhongyong 13052326718 (WeChat same number)

Chen Qian 15161581314 (WeChat same number)

Contact for Sponsorship:

Zhao Yongfeng 13915260150 (WeChat same number)

Yin Fangcheng 13806180291 (WeChat same number)

Important Reminder: Recently, some authors have found fake submission websites for Scientific Fish Farming through search engines. After submission, there has been no follow-up, and some have been scammed for publication fees. The correct submission website for this magazine is: kxyy.fish.cn, and we do not charge any form of review fees. Once accepted, we will pay the remuneration! Please choose the correct website for submission!