Click the above“Mechanical and Electronic Engineering Technology”to follow us

1. Common Types of Sensors

|

Category

|

Subcategory

|

Characteristics

|

Detectable Medium

|

|

Limit Switch

|

Limit Switch

|

Contact type, simple structure, short lifespan

|

Solids that can collide mechanically

|

|

Micro Switch

|

|

Proximity Switch

|

Hall Switch

|

High sensitivity, accurate positioning

|

Magnetic materials

|

|

Reed Switch

|

Lower precision, effective detection distance is short

|

Magnetic materials

|

|

Inductive

|

Long lifespan, anti-interference, effective detection distance is very short

|

Metals or materials with metallic coatings

|

|

Capacitive

|

Long detection distance

|

Bulk or liquid materials

|

|

Electronic Switch

|

Photoelectric

|

Long distance, high sensitivity

|

Solids, liquids, or gases that absorb, reflect, or block light

|

|

Ultrasonic

|

Long detection distance, strong penetration, ineffective at close range

|

Solids or gases that reflect ultrasonic waves

|

In addition to commonly used position sensors, there are:

-

Displacement Sensors (measuring linear or angular displacement)

-

Force Sensors (measuring the magnitude of force and weight of objects)

-

Pressure Sensors (measuring the pressure of gases or liquids)

-

Temperature Sensors (measuring temperature)

2. Applications of Various Types of Sensor Switches

1. Limit Switch

Limit switches are widely used switches. For example, in daily life, the lighting in a refrigerator is controlled by a limit switch, and the automatic door opening and closing of elevators is also controlled by limit switches.

In industrial production, limit switches can work with other devices to form an automated control system. For instance, in machine tool control, limit switches are essential for controlling the movement of workpieces and the automatic feeding stroke, preventing collision accidents. In the control of lifting machinery, limit switches serve to protect terminal limits.

Typical Application:Limit switches are typically used in automatic material handling systems. When the material handling cart reaches the endpoint, the limit switch senses the displacement of the cart and activates the tipping mechanism to unload materials from the cart, then controls the cart to return to the starting point. The limit switch at the starting point will activate the loading circuit after sensing the cart’s return, creating a continuous material handling process, forming an automated material handling production line.

In addition to limit switches, micro switches are a type of contact sensor, mainly used for connecting devices or detecting the status of safety doors on equipment. In mobile phone fixtures, micro switches of this type are also used to sense the presence of materials.

Characteristics: Contact type, simple structure, short lifespan

Detectable Medium: Solids that can collide mechanically

2. Hall Switch (Component)

Hall elements are magnetic sensors based on the Hall effect. They can detect magnetic fields and their changes and can be used in various scenarios related to magnetic fields. Hall elements have many advantages, including sturdy structure, small size, light weight, long lifespan, easy installation, low power consumption, high frequency (up to 1MHz), resistance to vibration, and immunity to contamination or corrosion from dust, oil, moisture, and salt mist.

Typical Application:Hall elements are used in mobile phone fixtures to sense the presence of materials or for fail-safe purposes.

Characteristics: High sensitivity, accurate positioning

Detectable Medium: Magnetic materials

3. Reed Switch

Reed switches, also known as magnetic reed switches or tongue reed switches, are sealed magnetic control mechanical switches that can be used as magnetic proximity switches, liquid level sensors, or reed relays.

Reed switches consist of a pair of elastic reed switches made of magnetic materials, sealed in a glass tube filled with inert gas, with the ends of the reeds overlapping but leaving a small gap. The contact points of the reeds are coated with a layer of precious metal, such as gold or palladium, which gives the switch stable characteristics and a long lifespan.

Typical Application: Reed switches have a simpler structure, smaller size, higher speed, and longer working life compared to general mechanical switches. Compared to electronic switches, they have strong load impact resistance and high reliability. They are well applied in mobile phones, programmable switches, copiers, washing machines, refrigerators, cameras, disinfection cabinets, door magnets, electromagnetic relays, electronic scales, level gauges, remote gas meters, IC card gas meters, water meters, electronic gas meters, and water meters. In electronic circuits, wherever automatic switches are used, reed switches can generally be applied.

Characteristics: Lower sensitivity, effective detection distance is short

Detectable Medium: Magnetic materials

4. Magnetic Switch

Magnetic switches are a specialized term for sensors used with cylinders, mainly applied to detect the position of the cylinder piston. Usually, they are provided by cylinder suppliers based on customer usage.

There are two types of magnetic switches: contact type and non-contact type. The contact type is where the magnetic reed inside the sensing switch is magnetized, causing the contacts to close and generate an electrical signal. When the magnetic ring moves away from the magnetic switch, the reeds lose magnetism, the contacts open, and the electrical signal disappears.

The non-contact type: When the magnetic ring approaches the sensing switch, the transistor conducts, generating an electrical signal; when the magnetic ring moves away from the magnetic switch, the transistor turns off, and the electrical signal disappears.

Characteristics: Lower sensitivity, effective detection distance is short. Detectable Medium: Magnetic ring cylinders

Note: Magnetic switches can only sense the position of the cylinder’s magnetic ring; they cannot control the stopping position and stroke of the cylinder.

5. Proximity Switch

Proximity switches are position switches that operate without direct mechanical contact with moving parts. When an object approaches the sensing surface of the switch within the action distance, the switch can operate without mechanical contact or applying any pressure, thus driving DC devices or providing control signals to computer (PLC) devices. Proximity switches are also designed based on the principle of electromagnetic induction, so they can only detect metallic targets, and the sensing distance varies slightly between different metals. Currently, commonly used proximity switches in automation have detection distances of approximately 1mm, 2mm, 4mm, 8mm, 12mm, etc.

Proximity switches are usually divided into two types based on sensing area: embedded and non-embedded. The embedded type means the sensing head of the proximity switch does not detect metallic targets in its circumferential direction but only detects metallic targets in front of it, which means the sensing head can be installed without exposing the metal mounting bracket. The non-embedded type means the sensing head of the proximity switch detects both the metallic target in front and in its circumferential direction, which means the sensing head must extend out of the metal mounting bracket a certain distance, and there should be no metallic targets within a certain range in the circumferential direction to avoid incorrect judgment. The detection accuracy of proximity switches is higher than that of magnetic switches. Proximity switches are usually used to determine the presence of products or whether tooling fixtures are in place, in scenarios where position accuracy is relatively low.

Based on the sensing medium, proximity switches can be divided into two types: inductive and capacitive. Inductive proximity switches consist of three main parts: an oscillator, a switching circuit, and an amplification output circuit. The oscillator generates an alternating magnetic field. When a metallic target approaches this magnetic field and reaches the sensing distance, eddy currents are generated within the metallic target, causing the oscillation to decay until it stops oscillating. The changes in oscillation and stopping are processed by the subsequent amplification circuit and converted into a switching signal, triggering the control device to achieve non-contact detection. The sensing end of capacitive proximity switches acts as one plate of a capacitor, with the outer casing of the switch acting as the other plate. When an object approaches the capacitive proximity switch, regardless of whether the object is conductive, its dielectric constant will differ from the original medium (air, water, oil, etc.), causing a change in capacitance, which in turn changes the internal circuit parameters of the switch, allowing the detection of the object’s presence and controlling the switch to turn on or off. Capacitive proximity switches can detect any medium, including conductors, semiconductors, insulators, and even liquids and powders.

Inductive Characteristics: Long lifespan, anti-interference, very short detection distance. Detectable Medium: Metals or materials with metallic coatings

Capacitive Characteristics: Longer detection distance

6. Photoelectric Switch

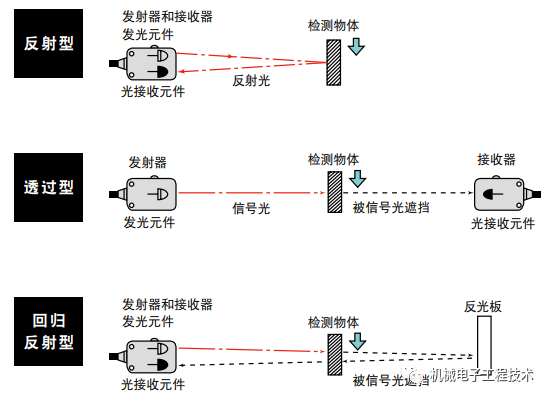

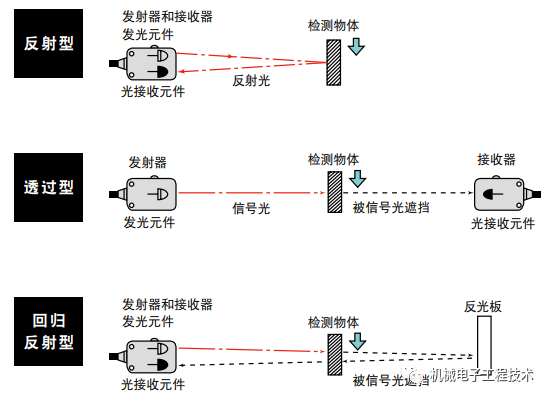

The photoelectric detection method has the advantages of high precision, fast response, and non-contact, and can measure multiple parameters. The structure of the sensor is simple, and it comes in various flexible forms; therefore, photoelectric sensors are widely used in detection and control. The commonly referred to photoelectric switches generally fall into three categories: reflective photoelectric sensors, through-beam photoelectric sensors, and photoelectric sensors using reflective plates. The latter two types detect by blocking light from the target, while the former detects by reflecting light from the target. Thus, the latter two types usually have longer detection distances and higher precision. Due to the high detection accuracy of photoelectric sensors, they are commonly used to detect the precise position of products or workpieces, as well as in feedback devices for stepper and servo systems.

Characteristics: Long distance, high sensitivity

Detectable Medium: Solids, liquids, or gases that absorb, reflect, or block light

7. Ultrasonic Sensors

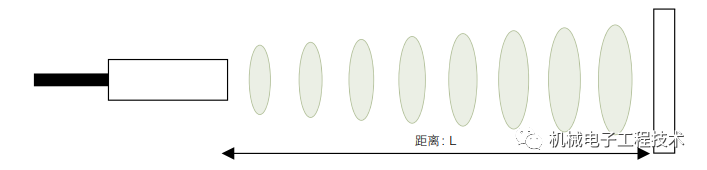

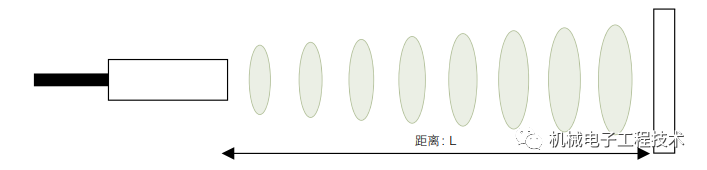

Ultrasonic sensors mainly detect certain parameters or matters by sending and receiving ultrasonic waves. The sending of ultrasonic waves is completed by the transmitter, which primarily generates and radiates ultrasonic waves into the air through the vibration of the transducer. The reception of ultrasonic waves is completed by the receiver, which mainly receives the ultrasonic waves radiated by the transmitter and converts them into electrical energy output. Additionally, the actions of both the transmitter and receiver are controlled by a control unit, which controls the pulse frequency, duty cycle, detection distance, etc. The entire system also requires energy provided by the power supply unit. Thus, under the influence of the power supply and controlled by the control unit, the ultrasonic sensor can complete its required functions by sending and receiving ultrasonic waves.

In industrial applications, the typical uses of ultrasonic waves include non-destructive testing of metals and ultrasonic thickness measurement. Ultrasonic waves have a significant penetration ability for liquids and solids, especially in opaque solids, where they can penetrate to depths of several meters. When ultrasonic waves encounter impurities or interfaces, they produce significant reflections that form echo signals. When they encounter moving objects, they can produce the Doppler effect. Therefore, ultrasonic detection is widely used in industrial, defense, biomedical, and other fields. Ultrasonic distance sensors can be widely used in level (liquid level) monitoring, robot collision avoidance, various ultrasonic proximity switches, and anti-theft alarms, among other related fields. They are reliable, easy to install, waterproof, have a small emission angle, high sensitivity, and can easily connect to industrial display instruments, with the option of providing probes with larger emission angles.

Characteristics: Long detection distance, strong penetration, ineffective at close range. Detectable Medium: Solids or gases that reflect ultrasonic waves

8. Fiber Optic Sensors

Fiber optic sensors are sensors that convert the state of the measured object into measurable light signals. The working principle of fiber optic sensors involves directing a beam of light from a light source through fiber optics to a modulator, where it interacts with the external measured parameters, causing changes in the optical properties of the light, such as intensity, wavelength, frequency, phase, and polarization state, resulting in modulated light signals. These signals are then sent through fiber optics to photoelectric devices and demodulated to obtain the measured parameters. Throughout this process, the light beam is transmitted through the fiber optics, modulated, and then emitted, with the fiber optics serving first to transmit the light beam and secondly to act as a light modulator.

Fiber optic sensors are also detection elements that apply photoelectric signal conversion. Compared to photoelectric switches, they can typically detect smaller targets, have longer detection distances, and higher precision. Therefore, fiber optic sensors are usually applied in more precise detection scenarios and in the positioning feedback devices of stepper and servo systems.

Characteristics: Sensitive, high precision, stable signals over long-distance transmission, and low interference

Detectable Medium: Solids, liquids that absorb, reflect, or block light

Detection Parameters: Measurement of physical quantities such as magnetism, sound, pressure, temperature, acceleration, gyroscope, displacement, liquid level, torque, photoacoustic, current, and strain

9. Grating

Gratings are also sensors that utilize photoelectric signals. Gratings have a large detection area, so they are often referred to as area sensors. The primary application field of gratings is interlocking and safety functions between devices, especially in applications for human protection.

10. Pressure Sensors

Pressure sensors (Pressure Transducers) are devices that can sense pressure signals and convert them into usable electrical signals according to certain rules. Pressure sensors are used to detect the pulling force or pressure applied to or borne by the target object.

11. Thermocouples

Thermocouples are mainly used to detect the surrounding environmental temperature.

Thermocouples are commonly used temperature measuring elements in temperature measuring instruments. They directly measure temperature and convert the temperature signal into a thermoelectric potential signal, which is then converted into the temperature of the measured medium through electrical instruments (secondary instruments). The shapes of various thermocouples can vary significantly based on requirements, but their basic structure is generally similar, usually consisting of thermoelectrodes, insulating protective tubes, and junction boxes, and they are typically used with display instruments, recording instruments, and electronic regulators.

12. Encoders

Rotary encoders are photoelectric devices for rotational measurement that directly convert the measured angular displacement into digital signals (high-speed pulse signals). According to their working principles, encoders can be divided into incremental and absolute types. Incremental encoders convert displacement into periodic electrical signals, which are then transformed into counting pulses, representing the magnitude of displacement by the number of pulses. Absolute encoders have a specific digital code corresponding to each position, so their readings depend only on the starting and ending positions of the measurement, not on the intermediate process.

13. Laser Profile Detectors

Laser profile detectors primarily measure the outline dimensions of target objects accurately.

They scan using motor-driven sensors, collecting horizontal and vertical components to obtain the contour data of the measured surface.

High-precision motors and lead screws ensure the stability and accuracy of horizontal component data; high-precision laser displacement sensors provide high-accuracy vertical components, with data synchronization achieved through hardware between the motor and sensor.

14. Barcode Scanners

Barcode scanners emit light from a light source onto the barcode symbol, and the reflected light is imaged onto a photoelectric converter by an optical system, generating an electrical signal. This signal is amplified by the circuit to produce an analog voltage that is proportional to the reflected light, which is then filtered and shaped to form a square wave signal corresponding to the analog signal, interpreted by a decoder into a digital signal directly acceptable by computers.

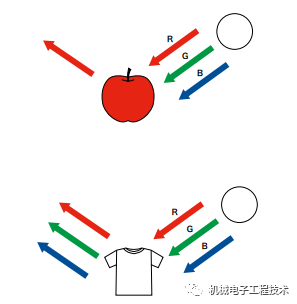

15. Color Mark Sensors

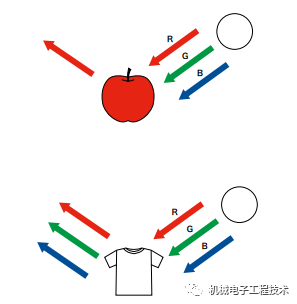

Color mark sensors detect various labels, even those with subtle differences in background colors, with fast processing speeds. They automatically adapt to wavelengths and can detect slight differences in grayscale, regardless of the mixed colors of labels and backgrounds.

Color mark sensors are commonly used to detect specific color marks or spots on objects, achieved by comparing with non-color mark areas rather than directly measuring color. Color mark sensors are essentially reverse devices, with the light source mounted perpendicular to the target object, while the receiver is installed at an acute angle to ensure it only detects scattered light from the target object, avoiding direct reception of reflected light, and allowing the light beam to focus narrowly. Incandescent and monochromatic light sources can be used for color mark detection.

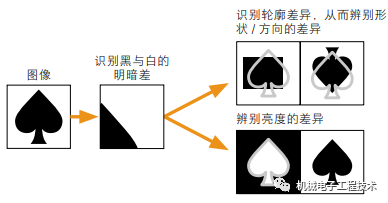

16. Industrial Cameras

Industrial cameras are generally installed on production lines to replace human eyes for measurement and judgment. They capture digital images of targets and convert them into image signals, which are sent to a dedicated image processing system. The image system performs various calculations to extract the features of the target, and based on the results, controls the actions of equipment on-site.

Industrial cameras are often referred to as CCD (Charge-coupled Device) in engineering, and they are mainly used to detect the shape and position of target objects. With the improvement of CCD technology, high-resolution industrial cameras can now be applied in precise measurement fields.