In the wave of intelligent manufacturing and “Industry 4.0”, industrial automation is upgrading from dedicated hardware PLCs to flexible programmable software platforms. As the core control unit of factory automation, PLCs play a fundamental supporting role in achieving the goals of intelligent interconnection and flexible production required by “Industry 4.0”. The performance upgrade of PLCs is directly related to the process of digital transformation in manufacturing.

In response to the limitations of traditional PLC architecture in openness and scalability, Saifang Technology has innovatively launched the RISC-V PLC industrial automation solution based on its self-developed RISC-V application processor — Fang·Jinghong-7110 (JH-7110), empowering industrial control with RISC-V technology, helping enterprises move towards a new stage of efficient and intelligent automation.

This solution centers around the JH-7110 RISC-V application processor, equipped with the OpenPLC open-source framework, compatible with various industrial protocols, suitable for a wide range of automation and control application scenarios, and has the following core advantages:

The JH-7110 application processor has a maximum clock frequency of 1.5GHz, supports multi-task parallel processing, easily handling complex industrial scenarios;

Integrates RT-Linux real-time patches to ensure microsecond-level response, meeting high-precision control requirements;

Supports 8GB large memory configuration, compatible with EtherCAT master station solutions, seamlessly connecting to SCADA systems;

Supports multiple PLC programming languages compliant with IEC61131-3 standards, such as Ladder Diagram (LD), Structured Text (ST), Sequential Function Chart (SFC), Function Block Diagram (FBD), and Instruction List (IL).

The RISC-V PLC industrial automation solution can not only be used as a PLC for industrial and home automation, IoT research but can also construct a complete SCADA (Supervisory Control and Data Acquisition) system with FUXA components. Additionally, paired with Saifang Technology’s EtherCAT master station solution, it can better meet the real-time and reliability requirements of industrial automation.

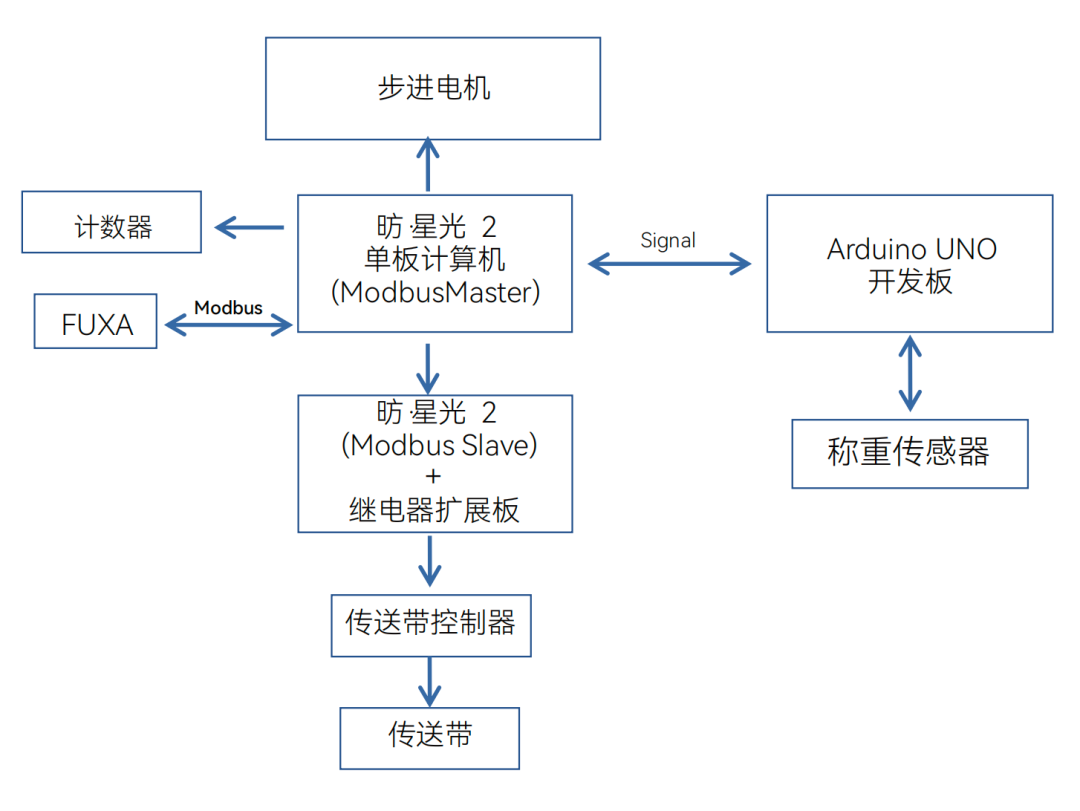

To verify the industrial-grade reliability of the RISC-V PLC, Saifang Technology has set up a complete demo of a packaging box automatic sorting production line, achieving intelligent control throughout the process:

Precise Control

Through Modbus TCP&RTU protocols, it links conveyor belts, weighing sensors, and stepper motors to dynamically adjust sorting paths;

Real-Time Monitoring

The HMI interface visualizes the operating status, improving data collection efficiency;

Efficient Sorting

High sorting accuracy, significantly reducing manual intervention costs.

Packaging Box Automatic Sorting Production Line Diagram

In the packaging box automatic sorting production line, the PLC first controls the conveyor belt via the Modbus protocol to transport the “packaging box” to the weighing sensor. Subsequently, the weighing sensor performs weight detection on the “packaging box” and returns the detection result to the PLC in real time. Upon receiving the detection result, the PLC controls the stepper motor based on preset logic to complete the sorting operation of the “packaging box”. The entire process is efficient, precise, and highly automated.

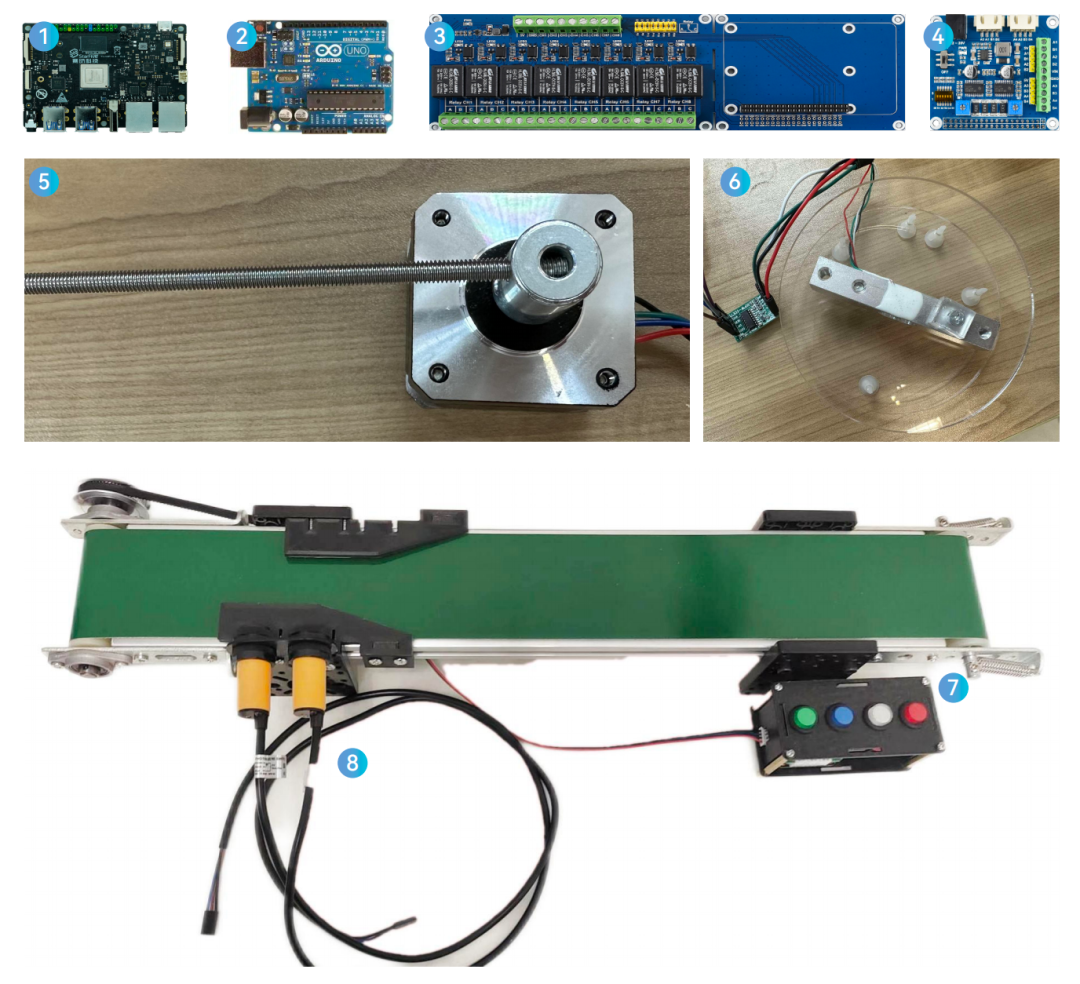

Saifang Technology provides developers with comprehensive development support, including detailed material lists covering core components, interface modules, and peripheral devices, ensuring that developers can quickly build systems.

Material List

Physical Reference

This solution, with its high performance, strong real-time capability, and flexible expansion ability, is suitable for a wide range of automation and control application scenarios. To help developers better apply this innovative solution, Saifang Technology has open-sourced the OpenPLC application guide on Fang·Xingguang 2 in the RVspace community (rvspace.org). You can click the “Read the Original” link at the end to obtain it for free.

More Fang·Jinghong-7110 Eco-Products

Available at “Saifang Mall”