In the context of further cost reduction and efficiency improvement in the industry, the secondary utilization of edge materials in the silicon wafer stage aims to enhance the first-use rate of pulling silicon rods and reduce the recovery and processing of edge materials as well as the amount sent to the furnace, which is currently a hot technology in the industry.

Liancheng CNC closely aligns with customer needs and, based on its optimization understanding of the process, has launched the automation solution for edge processing lines. The Liancheng solution eliminates the precision grinding of large surfaces and, relying on high-precision adhesive technology, avoids frequent adjustments of the mesh at the slicing end, thereby improving overall processing efficiency and effectiveness.

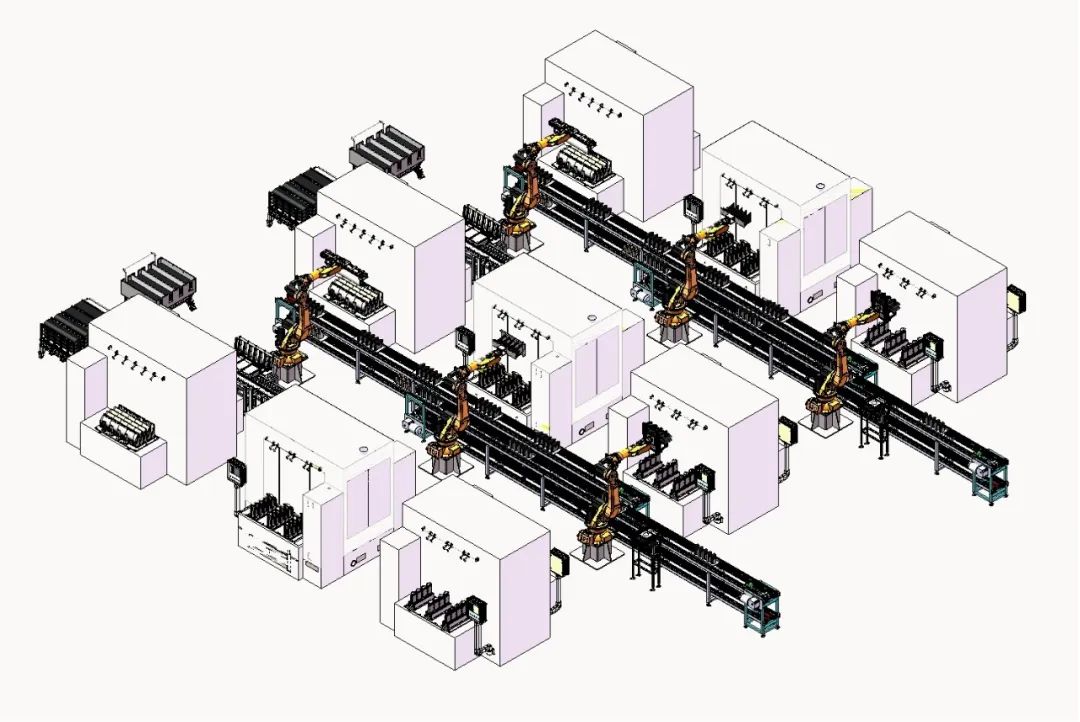

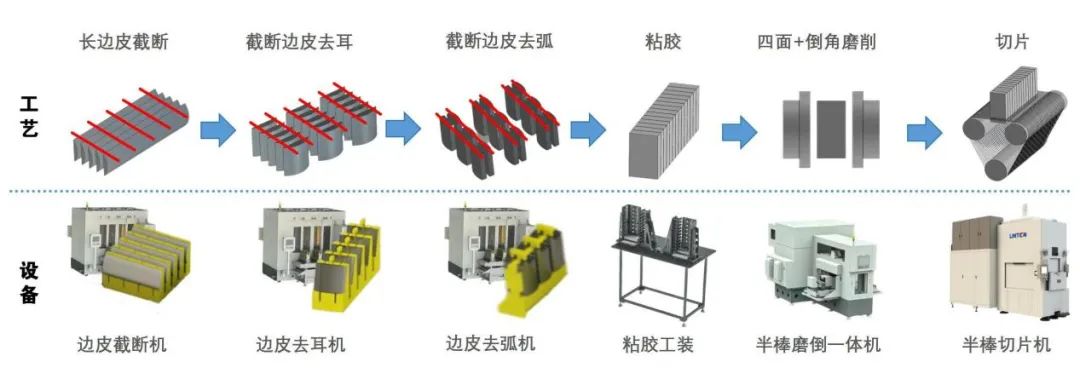

The specific route is shown in the figure below, where the existing production line remains unchanged, and the edge cutting machine, edge trimming machine, and edge arc removal machine are added, along with adhesive fixtures, to achieve a complete edge processing production line.

Edge Processing Technology Route

Product Introduction

Edge Cutting Machine:

|

Product Parameters |

|

|

Processed Edge Length |

250-950mm |

|

Flatness |

±0.2mm |

|

Dimensional Tolerance |

≤0.3mm |

|

Simultaneous Processing Quantity |

5 (pieces) |

|

Wire Diameter |

0.42~0.65mm |

|

Cycle Time |

10min |

|

Main Machine Size |

2900×2800x2500mm |

|

Equipment Weight |

8T |

Edge Trimming Machine:

|

Product Parameters |

|

|

Finished Edge Specifications |

Length 182-230mm / Width 91-115mm |

|

Dimensional Tolerance |

±0.15mm |

|

Perpendicularity |

90°±0.2° |

|

Simultaneous Processing Quantity |

15 (blocks) |

|

Wire Diameter |

0.42~0.65mm |

|

Cycle Time |

10min |

|

Main Machine Size |

2900×2800x2500mm |

|

Equipment Weight |

7.5T |

Edge Arc Removal Machine:

|

Product Parameters |

|

|

Finished Edge Specifications |

Length 182-230mm / Width 91-115mm |

|

Dimensional Tolerance |

±0.15mm |

|

Perpendicularity |

90°±0.2° |

|

Simultaneous Processing Quantity |

18 (blocks) |

|

Wire Diameter |

0.42~0.65mm |

|

Cycle Time |

10min |

|

Main Machine Size |

2900×2800x2500mm |

|

Equipment Weight |

7.5T |

1. Modular Design:

All three main machines adopt a modular design, allowing for switching functions such as cutting, trimming, and arc removal by changing fixtures; all tool heads are equipped with variable pitch functions for automatic specification switching, making operations convenient, stable, and reliable.

2. High Capacity::

The main machine has a simple and compact structure, equipped with dual exchange worktables, ensuring that loading and unloading do not affect the processing process, improving equipment utilization, and increasing single machine capacity.

3. Easy Operation:

Each main machine has a dual operation screen design, combined with dual exchange worktables for easy manual operation; reasonable space allocation allows for convenient threading; the structure is simplified for easy maintenance and servicing.

4. Automation of Edge Processing:

Through the joint automation of the main machines, an automated production line mode can be formed, capable of assembling a single GW processing production line.