Every Week

Science Popularization

3DPrinter Introduction

3D printers, also known as three-dimensional printers, where D means dimensions. This printing technology is a type of additive manufacturing technology, which creates three-dimensional (3D) objects by “printing” layers of adhesive materials. The earliest 3D printing appeared in the 1980s, when it was expensive and the number of products it could print was very limited. In recent years, 3D printer sales have gradually expanded, and prices have started to decrease. 3D printing technology can be used in the production of jewelry and footwear, as well as in industrial design, architectural engineering, civil engineering, automotive, aerospace, dental and clinical hospitals, education, geographic information systems, and more.

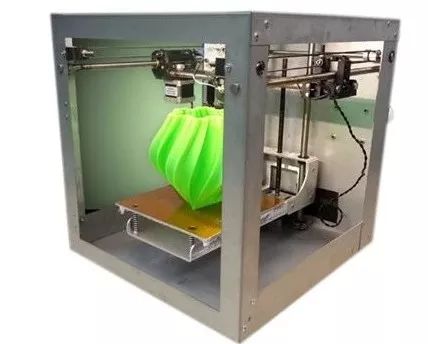

3D printers are machines for rapid prototyping technology. They are based on digital modeling technology, using adhesive materials such as powdered metals or plastics to construct objects layer by layer. Initially, they were mainly used in mold manufacturing and industrial design, often used to create models that can be used immediately.

In fact, 3D printing is not a new technology; this concept originated in the late 19th century in the United States, stemming from a photographic sculpture and terrain modeling technology. By the 1980s, it had taken shape, known as “rapid prototyping,” and was developed and promoted. The China IoT School-Enterprise Alliance refers to 3D printing technology as “the idea of the 19th century, the technology of the 20th century, and the market of the 21st century.” In 1995, researchers at MIT coined the term “three-dimensional printing,” when two graduates modified the inkjet printer concept to extrude solvent onto a powder bed instead of ink onto paper.

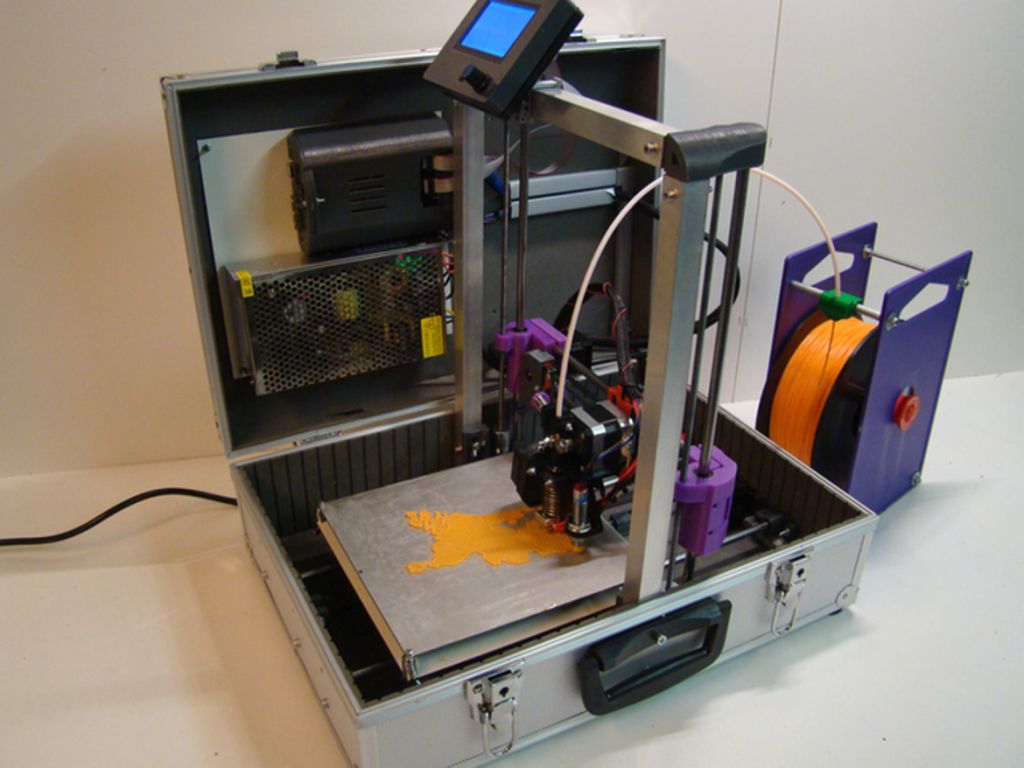

Initially, 3D printers were mostly in the hands of “science enthusiasts” and electronics hobbyists, who primarily used them to print “toys” like jewelry, toys, tools, or kitchen items. Automotive experts also printed car parts and then ordered commercially available parts based on plastic models.

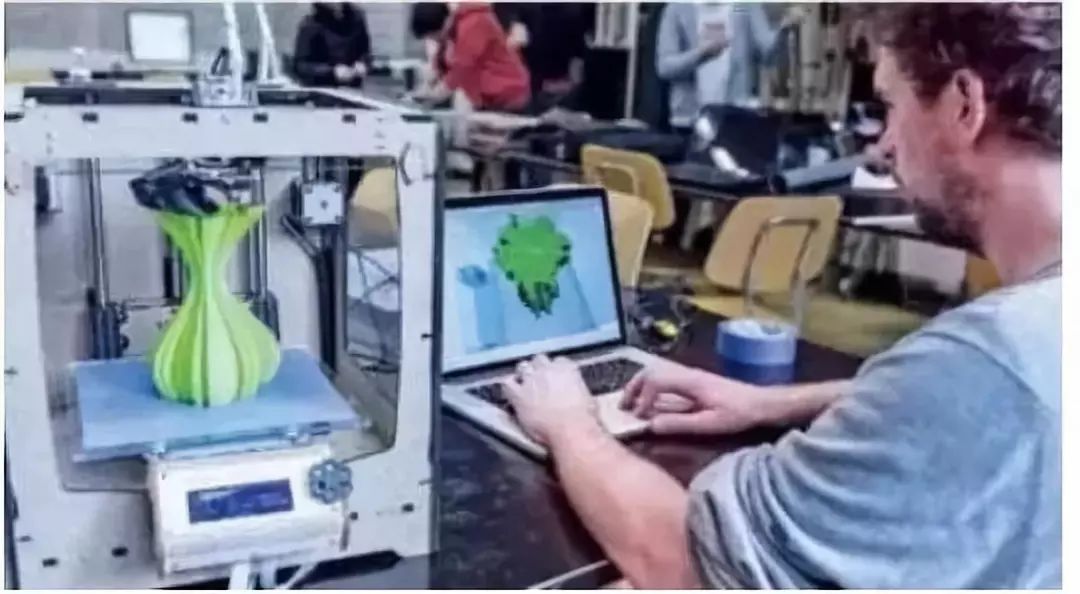

Using a printer is simple. By clicking the “print” button on the computer screen, a digital file is sent to an inkjet printer, which sprays a layer of ink onto the paper to form a two-dimensional image. When using 3D printing, software completes a series of digital slices through computer-aided design technology (CAD) and transmits the information of these slices to the 3D printer, which stacks continuous thin layers until a solid object is formed. Clearly, the biggest difference between a 3D printer and a traditional printer is that the “ink” it uses is actual raw materials.

The principle of 3D printing is: put data and raw materials into the 3D printer, and the machine will layer the product according to the program. 3D printers are fundamentally the same as traditional printers, consisting of control components, mechanical components, print heads, consumables, and media. A 3D printer must first model on a computer, such as animal models, human models, or miniature buildings. Then it is copied to the 3D printer for print settings, and the printer can orderly print them out. 3D printers mainly print by designing a complete three-dimensional model on the computer, and then outputting it.

There are various forms of thin layers stacked by 3D printers. Some 3D printers use “inkjet” methods, spraying a very thin layer of liquid plastic on the casting tray, which is processed under ultraviolet light, after which the casting tray descends a tiny distance to allow the next layer of plastic to stack. Others use “fused deposition modeling” technology, where the entire process uses melted plastic in the nozzle to form thin layers by depositing plastic fibers. Powder particles can also be used as printing media. Powder particles are sprayed onto the casting tray to form a very thin layer, which is then solidified by a sprayed liquid binder; or a technology called “laser sintering” is used to melt powder particles into a specified shape, such as using an electron beam in a vacuum to melt powder particles. 3D printing is completed by layered processing and stacking. The printing process of each layer involves two steps: first, spraying a layer of special glue in the area to be formed, where the glue droplets are very small and not prone to diffusion. Then, a layer of uniform powder is sprayed, which quickly solidifies and bonds upon contact with the glue, while areas without glue remain loose. Thus, by alternating layers of glue and powder, a solid model will be “printed” into shape, and after printing, the loose powder can simply be swept away to “shave” the model, while the remaining powder can be recycled. Of course, when using 3D printing technology, if encountering complex structures like holes and cantilevers, the medium needs to include gel agents or other materials for support or to occupy space. This part of the powder cannot be melted, and in the end, it can be washed away with water or air flow to form pores. Nowadays, various media can be used for printing, from plastics to metals, ceramics to rubber, and more. Some printers can even combine different media, allowing the printed object to be hard on one end and soft on the other.