4575 words | 8 minutes reading

4575 words | 8 minutes reading

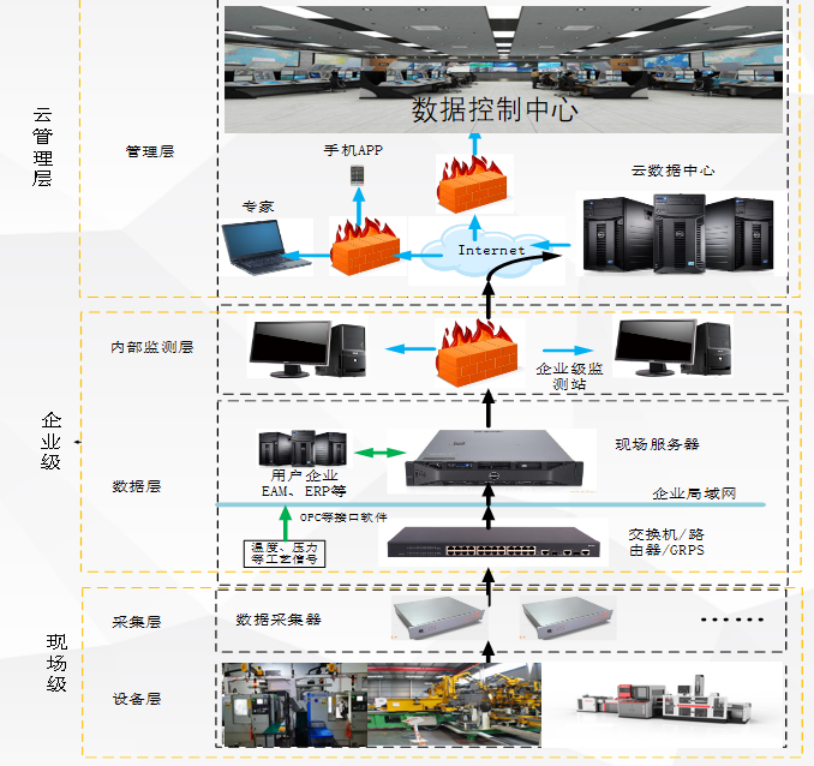

The “Internet + Industrial Cloud Control System” technology facilitates the acceleration of informationization, digitization, and intelligent transformation in machinery manufacturing enterprises, enhancing the innovation capabilities of the machinery itself. It can reduce equipment management costs, improve processing efficiency, and transition all operational data from paper collection to digital storage, avoiding the inconveniences of manual data retrieval, large storage space requirements, and the need for extensive personnel for data entry and analysis. Now, with the help of the Internet + industrial cloud control software, these services can be completed, saving significant costs for enterprises and improving work efficiency by more than double.

1

The Characteristics of Empowering Machinery with the “Internet + Industrial Cloud Control System”

Empowering Machinery with the “Internet + Industrial Cloud Control System”

By equipping machinery with the Internet + industrial cloud control software, it is possible to achieve “fusion efficiency,” digitizing and informationalizing the equipment produced by the company. Through the Internet, data monitoring, collection, program modification, and maintenance can be realized, enabling remote network control and modification of technical and process parameters, thus facilitating the collection and acquisition of big data for the machinery manufacturing industry and promoting an industrial cloud network resource-sharing revolution.

Data analysis combined with experiments or tests to collect product information optimizes process parameters. This will bring an intelligent revolution to the existing machinery manufacturing field. The industrial cloud network control system has the following characteristics:

1. Traditional information collection systems can only be used within the enterprise’s internal network and cannot be accessed externally at any time.

2. Traditional collection systems only record the collected data, and the large volume of data lacks reference, making it inconvenient for enterprise managers to analyze the data.

3. The new collection system is based on the concept of “industrial cloud” as a carrier for information collection and transmission, ensuring greater information security and stability.

4. Utilizing new technologies, the Internet is transformed into a more user-friendly enterprise local area network, reducing the operator’s knowledge requirements of the Internet, with all information operations resembling internal enterprise operations, thus weakening the limitations of operational areas.

5. New technologies facilitate remote maintenance of equipment, allowing real-time understanding of equipment operating status and the ability to change operating programs based on customer requirements, reducing travel costs for equipment companies, minimizing repair response times, and lowering production losses due to equipment failures.

6. Using specialized data collection and analysis software, production information of equipment can be analyzed, allowing for more reasonable arrangements of production processes and cycles. It becomes easier to understand the relationship between product performance and equipment parameters.

7. For specialized products, optimization experiments based on customer parameters can be conducted to further enhance the integrity of the specialized product’s processes, proposing improvement plans after comparing experimental data with actual production.

2

The Three Platforms of the “Internet + Industrial Cloud Control System”

01

Industrial Data Basic Cloud Platform

Realizes the collection and uploading of operational data from equipment distributed nationwide in the machinery industry, including variable monitoring, parameter settings, fault alarms, and updates and upgrades of controller programs.

(1) Provides database storage for historical data.

(2) Provides a monitoring management platform (B/S structure) for management personnel to browse controller data and set parameters for on-site network devices.

(3) Provides trend data and business data reports. Equipment fault alarms, real-time alerts, customizable alarm conditions, supporting pressure alarms and mandatory maintenance alarms (replacement of parts). Status monitoring based on GIS (Geographic Information System) (editing, processing, analysis). Can manage over 2000 devices and can be expanded to monitor more machinery through upgrades.

(4) Provides a remote console for technicians to debug remotely.

(5) Provides database and communication protocol access interfaces. Supports data subscription functions, filters redundant data, reduces garbage traffic, and lowers operating costs. Various network configurations overcome geographical barriers, ensuring smooth communication.

(6) The system can provide intelligent terminals supporting various communication network forms, ensuring that widely distributed devices can communicate remotely using multiple networks.

(7) Variable management based on model types ensures product compatibility and upgradability.

(8) On-site device controller variables can be defined. For different controller types and programming procedures, variable definition methods can be used to meet the requirements for collecting necessary variables.

02

Device Cloud Service Platform

Provides industrial cloud-based mobile data online services for device users. Device users can log into the industrial cloud platform through mobile devices such as smartphones and tablets to directly view equipment operating conditions, maintenance plans, and historical records.

03

Process Cloud Platform

The process cloud platform is a shared platform for setting process parameters for equipment.

(1) Process data collection and analysis based on industrial cloud;(2) Experimental data collection and analysis based on industrial cloud;(3) Process knowledge classification and storage based on industrial cloud;(4) Process knowledge sharing and querying based on industrial cloud;

(5) Laboratory simulation operation based on the industrial cloud platform.

3

The “Internet + Industrial Cloud Control System”

Cloud Terminal Device Access System Development

The cloud terminal device access system uses PLC as the core for device control, with auxiliary monitoring modules for remote data collection terminals. It achieves PLC device networking through various communication methods such as GPRS, 3G, 4G, Wi-Fi, and wired networks, enabling remote programming, debugging, and control of the PLC devices.

Relying on the upper computer software of the remote monitoring terminal to achieve remote programming, online monitoring, online simulation, remote data collection, and remote control of devices.

In this system, to ensure data security and server stability, a dedicated secure channel using VPN over P2P is adopted. This channel not only ensures the isolation of PLC data from ordinary Internet data but also guarantees that PLC data is transmitted directly to the monitoring room without passing through the cloud server, thus reducing the load on the cloud server while further ensuring the security of PLC data.

The cloud terminal device access system is primarily developed for the access of auxiliary monitoring modules for cloud devices, providing a comprehensive network communication and management system. This system offers a VPN communication server based on UDP + P2P architecture, responsible for handling VPN access services for communication gateways. Additionally, the B/S model WEB system provided by the system can flexibly manage and configure communication gateways.

4

The “Internet + Industrial Cloud Control System”

Cloud Device Access Platform

The cloud device access platform includes devices and communication modules deployed in the user’s enterprise and cloud servers and device cloud management centers deployed in the enterprise-level cloud data service center.

01

Enterprise Cloud Data Center

The enterprise cloud data center is an important component of the industrial cloud network control system. The data storage center is the hub for data storage, management, application, sharing, and exchange of internal and external network data within the cloud platform. All business data on the platform is exchanged through internal and external network data centers and processed through application servers.

It provides device data storage functions as a service to all device data, such as external network database cluster system functions, performing create, read, and write operations, providing database services for cloud data service platforms and application hosting platforms.

The database server adopts a dual-machine main and backup database, using two servers that back each other up and execute the same service. When one server in the group fails, the other server can take over the service task, thus automatically ensuring that the system can continuously provide services without manual intervention.

02

Device Cloud Data Collection Platform

The remote control system for devices consists of a cloud device monitoring center, device communication platform, and monitoring devices.

The data interaction center consists of servers, GPRS data transmission modules, etc.

The data communication platform is the GPRS private network of China Mobile.

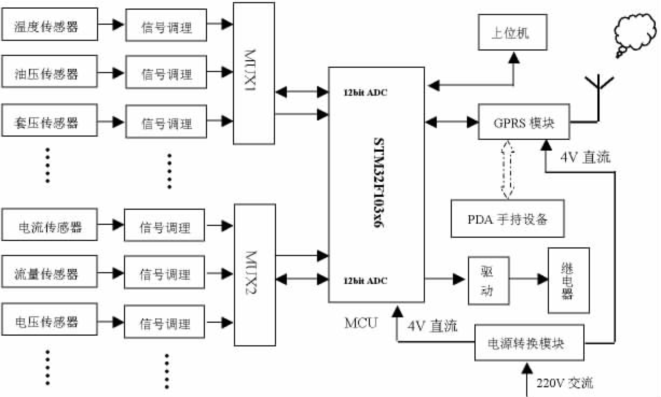

The auxiliary monitoring module for devices includes power modules, collection modules, GPRS transmission modules, converters, speed sensors, current and voltage transformers, temperature sensors, pressure sensors, etc.

The GPRS module uses NI9205.NI wireless data acquisition (Wi-FiDAQ) devices to achieve remote monitoring of electrical, physical, mechanical, and sound signals through IEEE802.11 wireless or Ethernet communication, direct sensor connections, and flexible NILabVIEW software.

The data read and write rate per channel exceeds 50kS/s, with a resolution of up to 24 bits.

Remote monitoring is simplified through NILabVIEW and direct sensor connections.

Protected data is processed with 128-bit AES encryption, meeting the highest commercial security standards.

Seamlessly integrate wireless measurements into existing systems.

The collected data is packaged and processed through a TCP/IP protocol stack embedded in the ROM storage, and then transmitted to the GPRS network via the GPRS module. The STM32F103x6 module contains two serial ports: one connected to the GPRS module and the other connected to the upper computer. The collected data can be observed for accuracy through the upper computer, and on-site personnel can also connect to the GPRS network via handheld PDAs to monitor equipment working parameters in real-time by receiving data sent from the system’s GPRS module.

03

Monitoring Site Communication

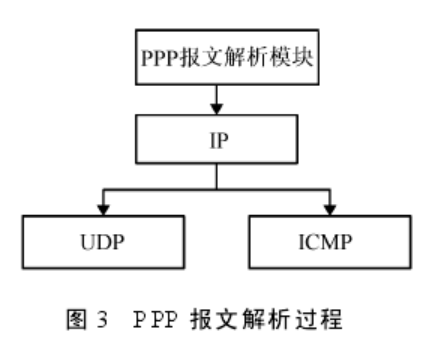

Utilizes TCP/IP protocol to package and unpack GPRS data.

Since GPRS is based on IP protocol, the data packets transmitted between the host and the GPRS server use IP-based packets, so all data messages must be based on IP packets. In China Mobile’s access gateway CM2NET, PPP protocol is generally used for negotiation communication with GPRS terminals.

Communication link requirements:

Unique link detection and automatic repair technology, requiring no manual intervention, providing reliable network connections for the monitoring system.

Connection management technology allows connections or disconnections to be initiated from either side of the network according to user needs, enabling on-demand connections, automatic disconnections, and manual activations, saving network resources and reducing operating costs.

04

Device Data Collection Process

Users set the wireless communication parameters and system data collection parameters related to China Mobile’s GPRS network through the wireless measurement and control host software. The wireless measurement and control host controls peripheral devices for data collection according to the set parameters and transmits the data to the monitoring center via wireless networks such as GPRS, providing comprehensive and real-time monitoring of the equipment working process through web browsing for Internet users.

(1) Data Collection of Equipment Working Process

The measurement and control host is installed in the control cabinet of the equipment, powered by the main circuit power supply of the equipment. This device connects to pressure sensors, temperature sensors, current and voltage sensors, and pressure sensors via wireless or wired methods. The data is packaged and uploaded to the upper computer while also being displayed on the device itself.

(2) Electrical Parameter Collection and Processing

The electrical parameter module is installed in the control cabinet, transmitting electrical signals to the collection terminal via wired methods through current and voltage transformers. The collection terminal uses the GPRS wireless data transmission module to connect to the Internet, packaging the data according to specified formats and uploading it to the backend front-end machine or monitoring center server.

(3) Pressure and Temperature Collection and Processing

The data uploaded by the collection terminal is transmitted online in the form of data packets, with the collected data being packaged twice before uploading: first using the ModbusRTU protocol and then using TCP/IP packaging. The backend computer receiving the data also requires a corresponding unpacking process.

(4) Alarm Information Processing

The server system management program can display the GPRS communication status of each collection terminal network in real-time, providing fault alarm prompts; it can also promptly alert when any collected data appears abnormal.

05

Device Monitoring Software Design

(1) Programming Platform

The design language of the central software adopts the LabVIEW graphical development platform, which supports multi-core processors to achieve parallel operations of multi-threading (data collection, data storage, data analysis), improving operational efficiency. LabVIEW can utilize WinSock to achieve socket communication with the Internet. C++ language is flexible, has significant advantages for low-level operations, and provides substantial support for network programming. The LabVIEW library offers a socket library called CasyncSocket, which makes socket programming stable, reliable, and convenient.

(2) Server Receiving Software Design

The monitoring center data receiving software is written using NILabVIEW programming software. The main function of this software is to receive and send IP data packets of UDP or TCP protocols to achieve IP protocol communication for GPRS terminals.

Since this system will monitor multiple device parameters, a thread should be opened for each device during software design, with each thread listening on different ports and independently receiving and processing data. Data processing includes storing the received parameters in the database while displaying them in real-time on the main interface using curves.

The monitoring center does not require a GPRS module; it can connect to the Internet via broadband, ISDN, or ADSL, using a fixed IP, and can utilize UNIX or Windows servers.

(3) Monitoring Center Web Page Design

Management personnel can conveniently browse system data screens through IE on client computers, gaining real-time insights into the operational information of on-site equipment.

The data display platform supports Internet information publishing, with the screen browser web control seamlessly embedded in the web browser, receiving real-time data sent by the web server, driving the screen configuration files to run and generate dynamic display screens. The access operations are managed by the web server, effectively protecting the management access rights of the enterprise data platform while significantly simplifying the work of client computers and avoiding the severe burden and access congestion caused by repeated client access to the data source.

Management personnel can connect to the Internet remotely using desktop computers, laptops, and other tools. The client displays views in a control manner within a standard web browser interface, allowing for remote (Internet/intranet) visual access to data, with a very simple access process, similar to browsing the web, and with no restrictions on the number or location of remote clients.

The WEB publishing service has Internet publishing capabilities, B/S model client, supporting up to 300 concurrent client logins to the system, storing and retrieving real-time and historical data simultaneously. 200 concurrent clients can retrieve real-time and historical data up to 20,000 data points per second, allowing users to understand various equipment operational information, including individual and system operational statuses.

For internal network users, access can be freely granted based on user permissions through local area networks or virtual private networks (TCP/IP\VPN).

Through the application of the “Internet + Industrial Cloud Control System” in machinery management, empowering machinery has undoubtedly become a major trend in industry development and is also an essential path for upgrading and transforming machinery. For machinery manufacturers in the current era, the first step to riding the wave of this trend is to change their mindset. For machinery manufacturers, understanding the “Internet + Industrial Cloud Control System” a day earlier means becoming a pillar of this industry a day earlier.

Author: Luo Peng, Special Partner at Peking University Zongheng

Click the “Read Original” button below to view all original authors ↓↓↓