Click the card below to follow “OpenCV and AI Deep Learning”

Visual/image heavy content delivered first!

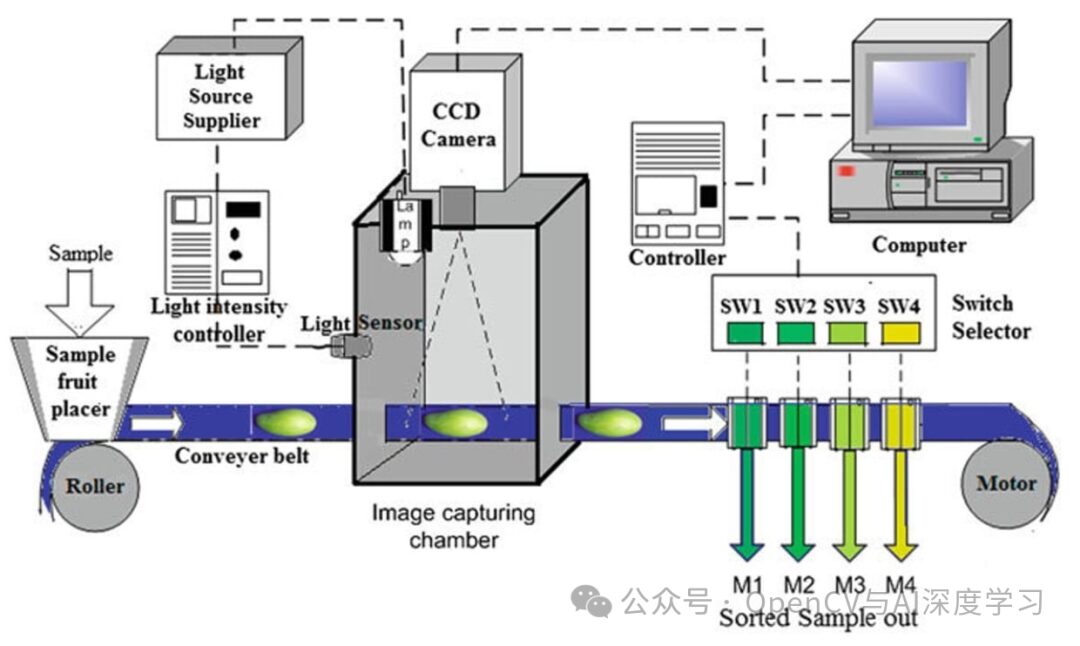

Components of a Computer Vision Sorting System

Using computer vision for automated sorting is a technology-driven process where computer vision systems are used to identify, classify, and sort items or materials based on specific features (such as size, shape, color, texture, barcodes, or other visual characteristics). This approach is commonly used in industries such as manufacturing, logistics, agriculture, and recycling to improve efficiency, reduce labor costs, and minimize errors.

Here are the key components of a computer vision-based automated sorting system:

-

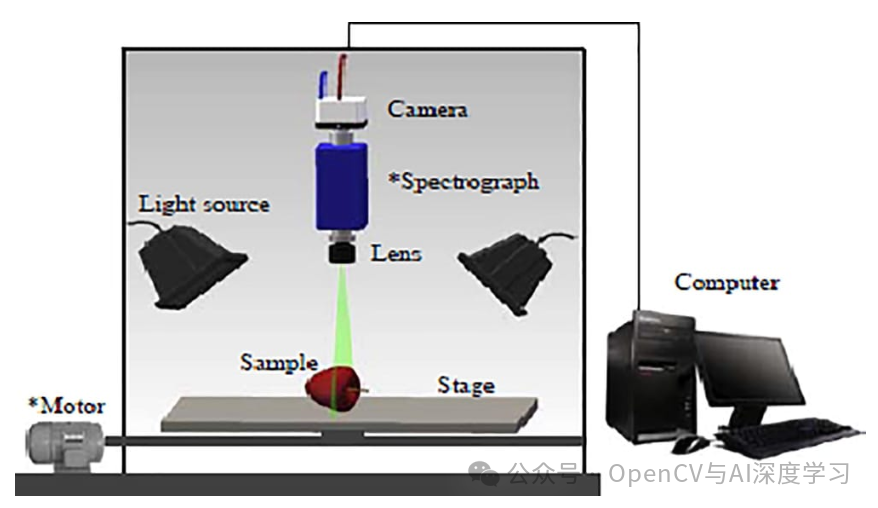

Cameras and Sensors: High-speed cameras capture images or videos of items moving along the conveyor belt. Other sensors, such as depth cameras, infrared cameras, or lasers, can be used to capture detailed object information.

-

Computer Vision Algorithms: These algorithms analyze visual data to identify and classify objects. Techniques such as Convolutional Neural Networks (CNN) or machine learning models are often the foundation of these systems.

-

Sorting Mechanism: Actuators, robotic arms, jets, or diverters physically classify items into appropriate categories based on the analysis.

Case Studies of Computer Vision Sorting Systems

Computer vision-based sorting is applied across multiple industries. Here are some example use cases.

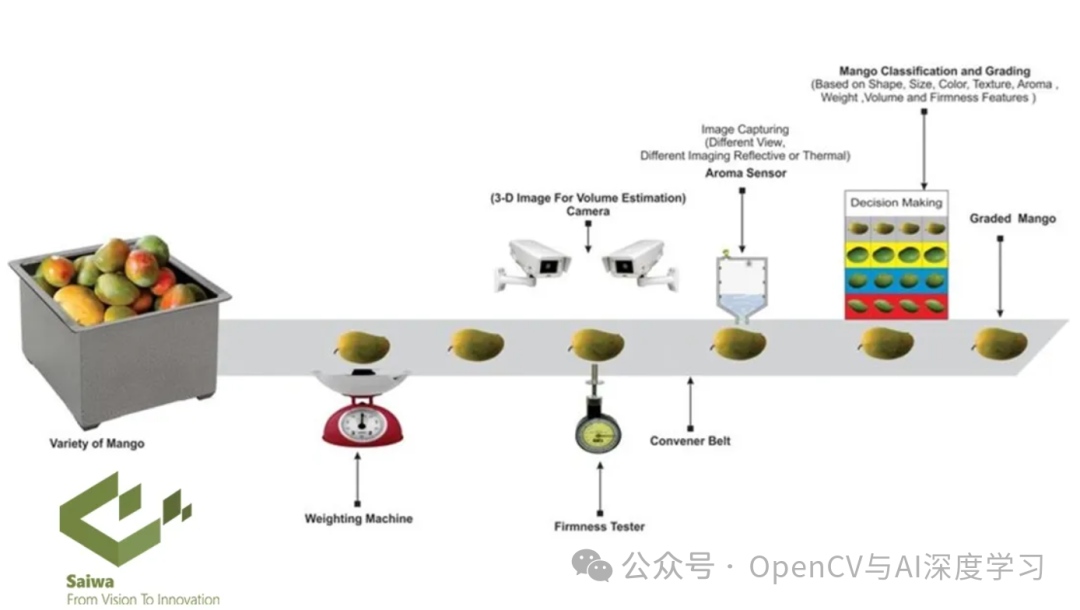

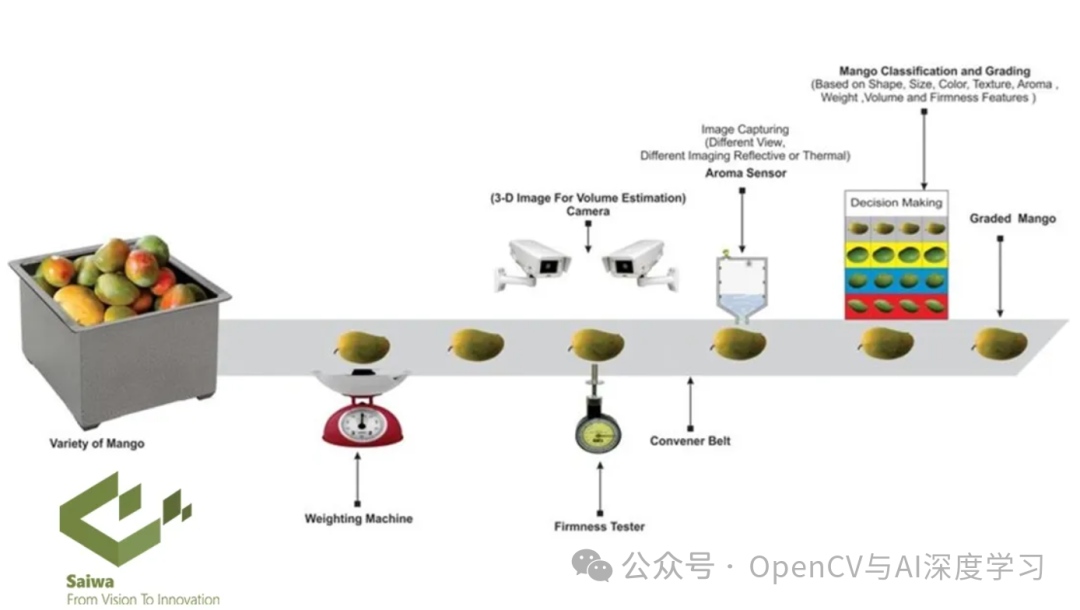

Agriculture: Fruit Grading and Sorting

This computer vision-based system can grade fruits like apples, oranges, and bananas based on size, shape, color, or other physical characteristics. The system uses cameras to capture images of fruits on the conveyor belt, analyzes their quality, and classifies them into grades such as premium, standard, or defective. This system improves efficiency, ensures consistency, and reduces manual labor in grading.

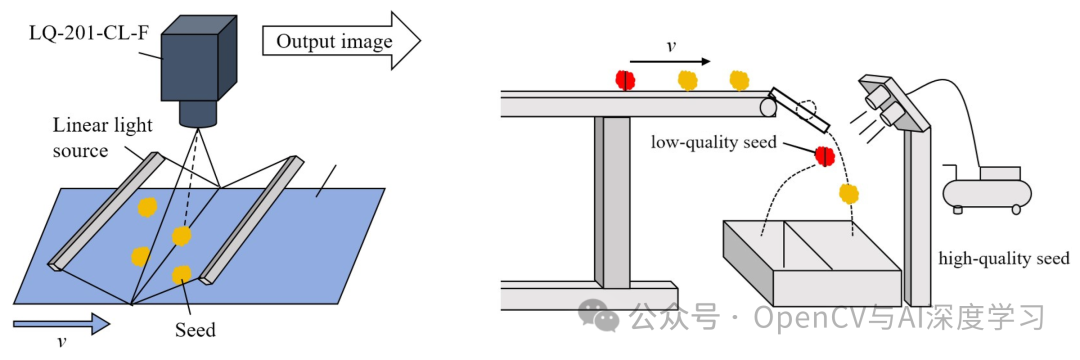

Agriculture: Seed Sorting

This seed sorting system uses high-speed cameras and AI models to batch identify defective seeds or foreign objects. The sorting mechanism separates viable seeds from defective ones based on size, texture, and color. It helps improve the quality of seeds planted and increases crop yield.

Agriculture: Vegetable Defect Sorting

In this vegetable defect sorting system, computer vision models can detect defects in potatoes, tomatoes, carrots, or other vegetables and even fruits, such as cracks, bruises, or spots, and automatically reject defective items from the production line. This ensures that only healthy produce reaches consumers and reduces waste.

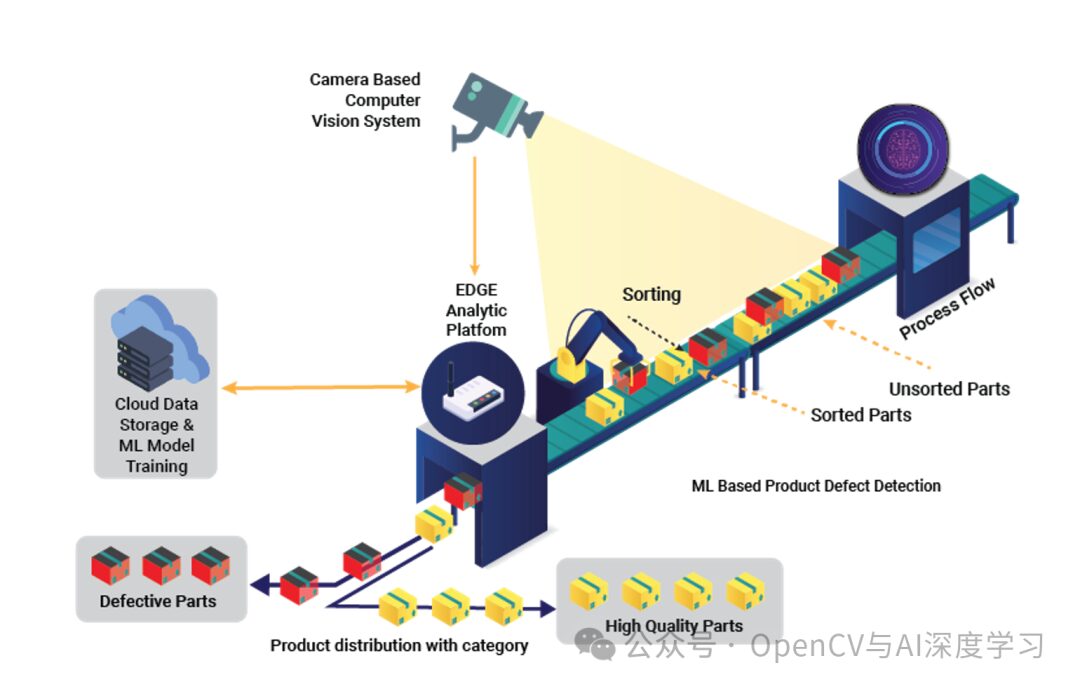

Manufacturing: Defective Product Sorting

This defective product sorting system uses computer vision models to inspect products for defects such as scratches, dents, or missing components on the assembly line. Defective products are marked and automatically removed. It helps improve product quality and reduce customer complaints.

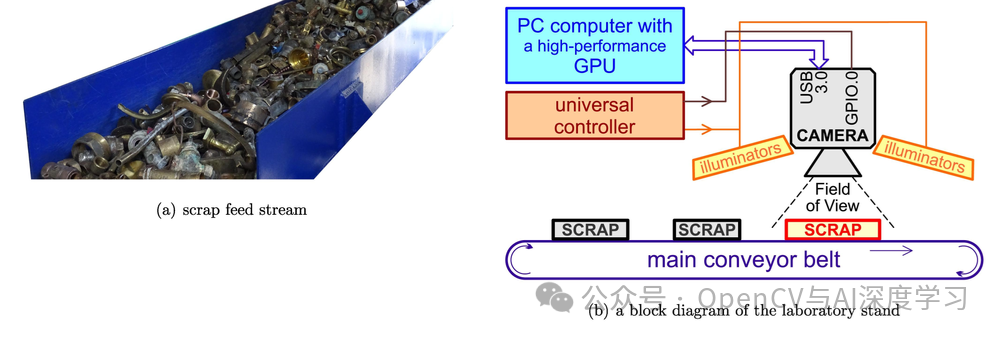

Manufacturing: Metal Scrap Sorting

In recycling facilities, this computer vision-based metal scrap sorting system identifies and sorts different types of metals based on their physical and reflective properties. This helps optimize the recycling process and reduce contamination in recyclable materials.

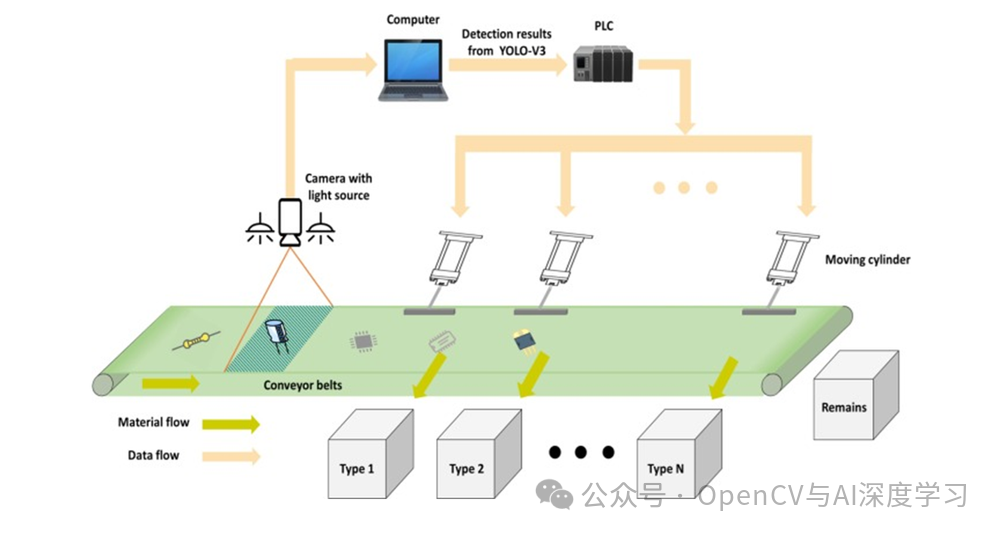

Manufacturing: Electronic Component Classification and Sorting

This electronic component classification and sorting system uses computer vision to identify electronic components such as resistors, capacitors, or chips and sort them based on type, size, and placement requirements. This system improves the efficiency of PCB assembly and reduces errors in component placement.

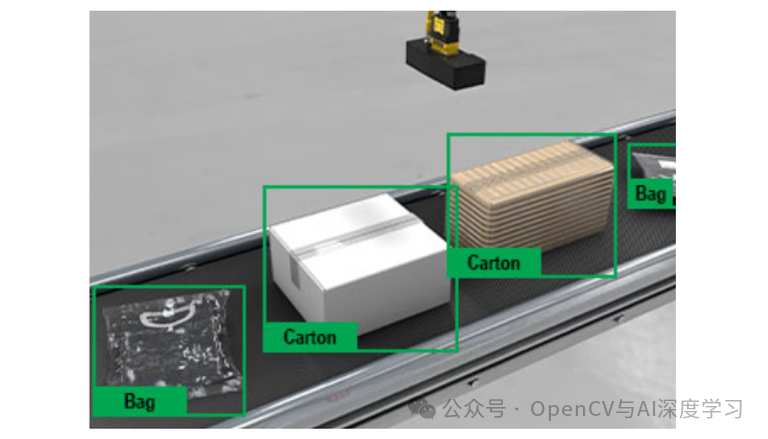

Logistics: Package Sorting in Warehouses

This computer vision-based system enhances package sorting in logistics by automatically detecting and classifying various packages (including boxes, padded envelopes, and plastic bags). By using computer vision to process data, it can change packaging types, prevent route errors, and avoid equipment jams. The system tracks packages on the conveyor belt, and robotic arms move them to the correct boxes. It increases sorting speed and reduces shipping errors.

Supply Chain: Waste and Recycling Sorting

This system uses computer vision to improve the efficiency and accuracy of waste and recycling sorting processes. By using cameras and AI models, the system can identify and classify various materials on the conveyor belt (such as plastics, glass, metals, and paper), ensuring they are directed to the appropriate recycling categories. This automation not only improves sorting accuracy but also significantly reduces the need for manual intervention, thus increasing the recovery rates of recyclable materials and reducing landfill waste. The development of AI-guided robots is aimed at sorting recyclable materials with high precision, thereby improving the overall efficiency of recycling facilities.

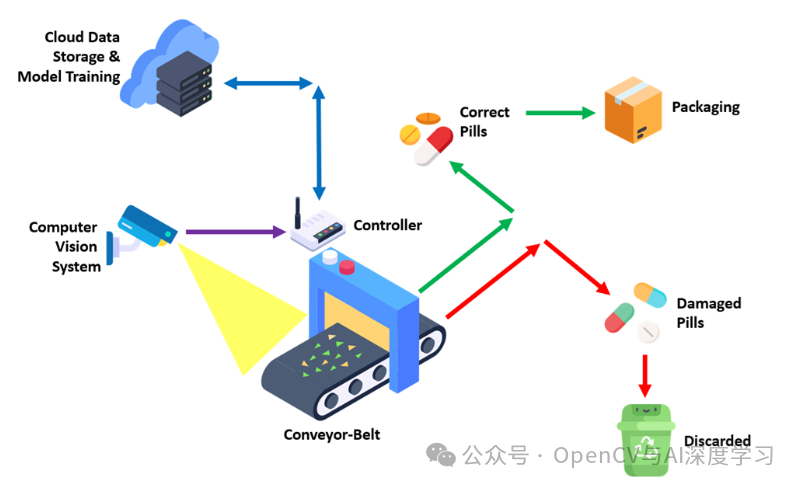

Pharmaceutical: Pill Sorting

The pharmaceutical industry uses computer vision-assisted pill sorting to improve efficiency and accuracy. Automated systems equipped with cameras and computer vision algorithms detect and sort tablets, identifying defects such as chipping, discoloration, or incorrect sizes, ensuring that only quality products pass through the supply chain. For example, pill sorting machines can process many tablets per minute, effectively removing broken tablets and granules. This automation reduces manual labor, minimizes errors, and maintains product integrity throughout the distribution process.

Here, we discussed some use cases of computer vision-based sorting systems. There are countless use cases across various fields. Computer vision significantly enhances sorting processes in various industries through automation and increased accuracy. By integrating computer vision into sorting operations, industries can improve efficiency, accuracy, and productivity.

How to Build an Automated Sorting System

This section explores how Roboflow simplifies the creation of automated sorting systems using computer vision, using apple sorting as an example. As mentioned in earlier sections, the core component of any sorting system is the computer vision model that drives the decision-making process. Here, we will demonstrate how Roboflow helps build such models. The steps outlined below provide a clear path for developing an automated sorting system.

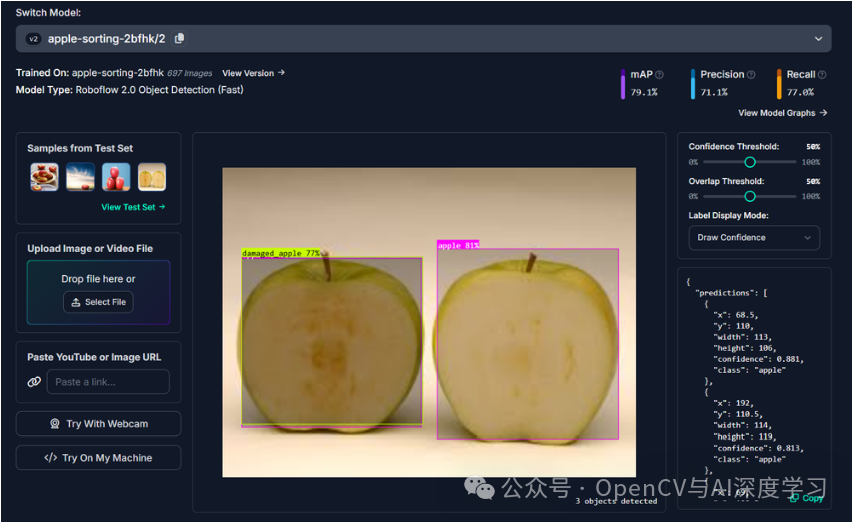

We are developing an Apple Sorting object detection model using computer vision to differentiate good apples from damaged ones. The classes for this project are defined as “apple” and “damaged_apples.” First, create a Roboflow project for object detection to manage the dataset and streamline the model development process.

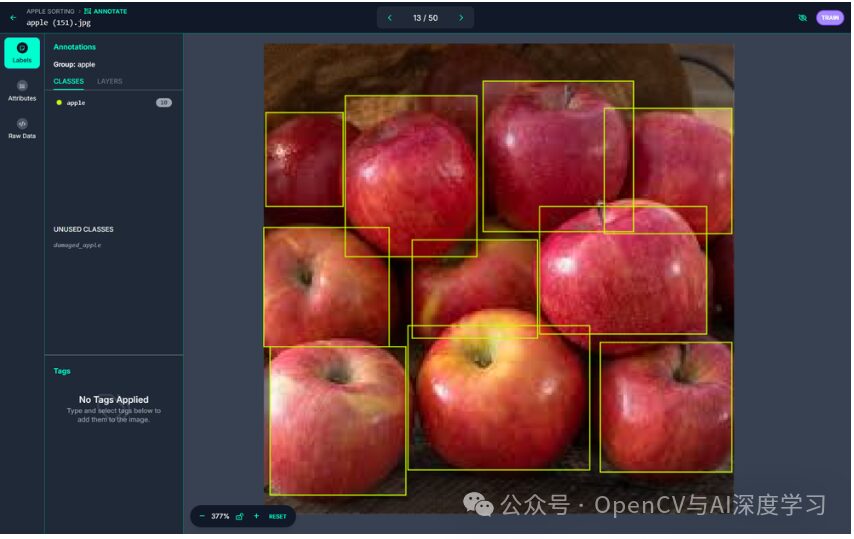

Step #1: Collect and Annotate the Dataset

The first step in building an object detection model is to collect a dataset of various apple images. These images should include various scenarios, such as different lighting conditions, angles, and sizes of apples, to ensure the model’s robustness. The dataset should effectively capture both good and damaged apples to represent these two classes.

After collecting the images, use bounding box tools to perform annotations. Draw rectangles around the apples and label them as “apple” or “damaged_apples.” These labeled bounding boxes serve as ground truth data, allowing the model to learn to accurately identify and classify objects during training.

After annotating the dataset, the next step is to train the object detection model using the Roboflow 2.0 fast object detection pipeline.

The above image shows the results of the object detection model trained using Roboflow 2.0 for apple sorting. The model identifies and classifies apples as “apple” (good) or “damaged_apple,” along with corresponding confidence scores. Performance metrics (mAP: 79.1%, Precision: 71.1%, Recall: 77.0%) indicate the model’s effectiveness in recognizing and classifying apples.

Step #3: Build the Inference Script

In this step, we will learn how to build an inference script using the Roboflow Inference API and the Supervision library. This script processes real-time camera streams to identify qualified and damaged apples and sends the results to the controller for automated sorting. The identified labels are used to transmit commands to control the sorting mechanism via serial port to a connected controller, such as an Arduino development kit. This code supports seamless integration with the sorting mechanism to sort qualified and damaged apples.

api_key = "YOUR_ROBOFLOW_API_KEY"

from inference import InferencePipeline

from inference.core.interfaces.camera.entities import VideoFrame

import cv2

import supervision as sv

import serial

import time

import sys

# Initialize serial communication with Arduino

arduino = serial.Serial('COM4', 9600, timeout=1)

time.sleep(2) # Allow Arduino to reset

def send_command_to_arduino(command: str): """Send a command to Arduino via serial.""" try: arduino.write(command.encode()) # Send command as bytes print(f"Sent to Arduino: {command}") except Exception as e: print(f"Error sending data to Arduino: {e}")

# Initialize annotators

label_annotator = sv.LabelAnnotator()

box_annotator = sv.BoxAnnotator()

# Initialize a variable to store the last sent command

last_command = None

def my_custom_sink(predictions: dict, video_frame: VideoFrame): global last_command # Declare the variable as global to retain its value across calls

# Extract labels from predictions labels = [p["class"] for p in predictions.get("predictions", [])] # Convert predictions to Supervision Detections detections = sv.Detections.from_inference(predictions) # Annotate the frame image = label_annotator.annotate( scene=video_frame.image.copy(), detections=detections, labels=labels ) image = box_annotator.annotate(image, detections=detections) # Display the annotated image cv2.imshow("Predictions", image)

# Determine the appropriate command based on the labels if "apple" in labels: current_command = "G_APPLE" # Command for good apples elif "damaged_apple" in labels: current_command = "D_APPLE" # Command for damaged apples else: current_command = None # No command for other cases

# Send the command only if it has changed if current_command != last_command: if current_command is not None: # Only send if there's a valid command send_command_to_arduino(current_command) last_command = current_command # Update the last command

if cv2.waitKey(1) & 0xFF == ord('q'): return

pipeline = InferencePipeline.init( model_id="apple-sorting-2bfhk/2", video_reference=0, # Use the default webcam on_prediction=my_custom_sink, api_key=api_key,)

pipeline.start()

pipeline.join()

Step #4: Build the Sorting Mechanism

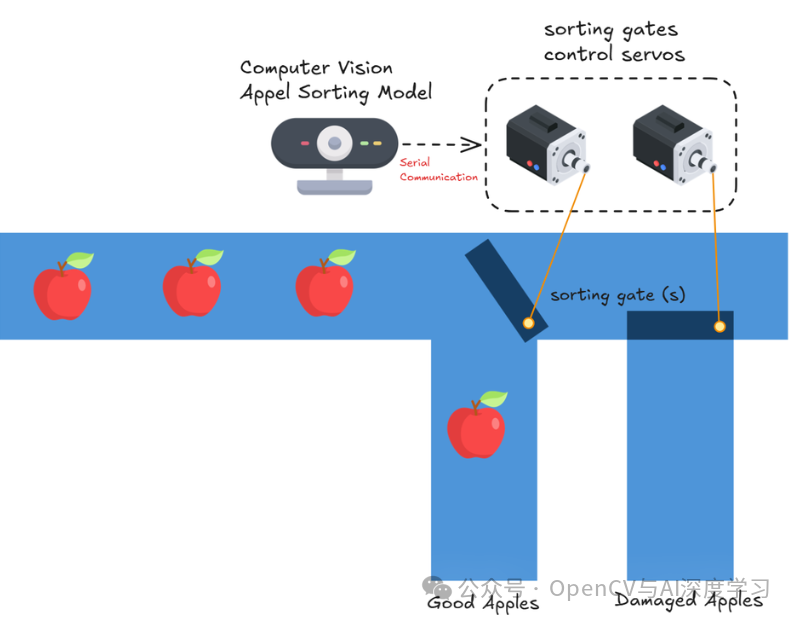

The system shown in the image is an automated apple sorting mechanism where servo systems are used to guide apples to the appropriate boxes based on their classification as “good apples” or “damaged apples.”

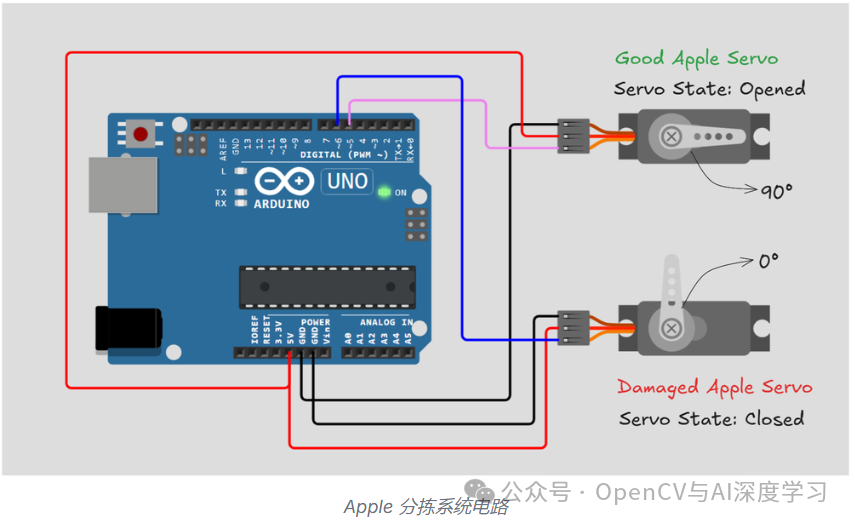

This circuit consists of an Arduino Uno and two servo motors. The servo motors are connected to the PWM pins of the Arduino (pin 5 for Good Apple Servo, pin 6 for Damaged Apple Servo).

Arduino communicates with the computer vision system via USB, receiving commands through the serial port. These commands indicate the servo positions, allowing them to open or close the sorting gates. The circuit ensures that the servo system operates in coordination with the classification results, guiding apples to their respective boxes.

Here is the firmware code for Arduino:

#include <Servo.h>

int servoPin_1=5;

int servoPin_2=6;

Servo good_apple_servo, damaged_apple_servo;

void setup() { // put your setup code here, to run once: Serial.begin(9600); good_apple_servo.attach(servoPin_1); damaged_apple_servo.attach(servoPin_2); good_apple_servo.write(0); damaged_apple_servo.write(0);

}

void loop() { // put your main code here, to run repeatedly:if (Serial.available() > 0) { String command = Serial.readStringUntil('\n'); // Read the command command.trim(); // Remove extra whitespace

// Debug: Print the received command Serial.print("Received command: "); Serial.println(command);

if (command == "G_APPLE") { good_apple_servo.write(90); // Opens sort line for good apple damaged_apple_servo.write(0); // closes sort line for damaged apple

} else if (command == "D_APPLE") { damaged_apple_servo.write(90); // Opens sort line for damaged apple good_apple_servo.write(0); // closes sort line good apple

} }

}

How the System Works

Component Setup

Two servos are connected to the Arduino Uno, with each servo responsible for controlling a sorting path. The Good Apple Servo operates the path for apples classified as “Good,” while the Damaged Apple Servo manages the path for damaged apples.

Classification Process

The computer vision model processes real-time camera streams, classifying apples as “good” or “damaged” using the inference script from Step #3. Based on the classification, specific commands (G_APPLE for good apples or D_APPLE for damaged apples) are sent to the Arduino via the serial port.

Servo Control

Arduino receives the command and adjusts the servo positions accordingly:

-

For a good apple, the Good Apple Servo moves to 90° (open) to allow the apple to pass, while the Damaged Apple Servo remains at 0° (closed).

-

For a damaged apple, the Damaged Apple Servo moves to 90° (open) to guide the apple, while the Good Apple Servo remains at 0° (closed).

Sorting in Action

As the apples pass through the camera stream, the classification triggers the servo movements. The servo system acts as a gate, guiding the apples into separate boxes or chutes, ensuring accurate sorting.

Automation and Feedback

The system continuously processes apples, dynamically adjusting the servo positions based on classification results. This real-time decision-making allows for high-speed, efficient sorting without the need for manual intervention.

Download 1: Common Functions Manual for Pytorch

Reply with “Pytorch Functions Manual” in the backend of the “OpenCV and AI Deep Learning” public account to download the first Pytorch functions manual on the internet, including 14 chapters covering Tensors, basic functions, data processing functions, optimization functions, CUDA programming, multiprocessing, etc.

Download 2: 145 OpenCV Example Application Codes

Reply with “OpenCV145” in the backend of the “OpenCV and AI Deep Learning” public account to download 145 example application codes for OpenCV (implemented in both Python and C++).

Welcome to join the CV learning exchange WeChat group!

If you find it useful, remember to like and share!