As the selection of automotive-grade chips transitions from foreign manufacturers’ monopoly to the gradual introduction of domestic chips, a batch of chip products capable of achieving domestic substitution has emerged. The automotive-grade is an industry with higher stability requirements for chips than consumer and industrial products, so selecting automotive-grade chips requires consideration of more factors, including technical parameters, application scenarios, supply chain stability, cost control, etc. Among these, the most important key points are: automotive-grade certification: automotive-grade chips need to pass the AEC-Q100 certification, which means the chips must meet strict quality and reliability standards. Months of testing involve complex testing and verification processes to ensure product stability and durability under extreme temperatures, humidity, vibration, and electromagnetic interference conditions.

Compatibility and integration issues: Automotive-grade chips need to be compatible with other electronic systems in the vehicle, which involves complex software and hardware integration work. Ensuring all systems can work seamlessly together is a challenge.

Safety and reliability: The safety and reliability of automotive-grade chips are crucial. Any failure or misoperation can lead to serious safety accidents. Therefore, strict testing and verification are required during the development process.

Cost control: While meeting all technical and safety requirements, controlling costs is also a challenge. Cost-effective solutions need to be found to ensure the product’s market competitiveness. Recently, the price game between major automotive brands and suppliers has attracted industry attention.

Supply chain management: Ensuring the stability and reliability of the supply chain, especially in the context of complex international situations, and achieving full domestic production of chips from design to production packaging significantly reduces dependence on overseas suppliers, which is the best alternative solution.

How to choose an MCU manufacturer? According to the following three criteria:

The first criterion is the reusability of chip code, the higher the better. For domestic substitution, as much as possible should be made of previously used code. If it is newly developed, it can also be reused in future expansions.

The second criterion is pin compatibility. If different configurations of MCUs with the same package, or even different series and levels of MCUs, are pin-compatible, then when it is found necessary to upgrade or downgrade the MCU specifications during development, they can be directly replaced without having to redo the board, which is much more convenient.

The third criterion is simpler. If you have contacted the manufacturer or agent about the selection and have not been able to reach them, you can put them at the back of the list. The ones you can contact with good and fast service are the first choice.

After a comparison and selection, Hangshun chips’ automotive-grade MCU stands out:

Automotive-grade requirements: Hangshun chips’ automotive-grade chip has passed the AEC-Q100 certification, which is the testing certification of the International Automotive Electronics Association, meaning the product meets stringent requirements in terms of service life, stability, operating temperature, PPM, etc. In addition, Hangshun chips follow the ISO 26262 full-process standard, which covers the entire product lifecycle and ensures functional safety.

Compatibility and integration issues: When designing the MCU, Hangshun chips not only ensure hardware compatibility with certain international manufacturers’ chips but also achieve more than 95% software compatibility. This design allows customers to quickly replace solutions, saving a lot of time and costs. Additionally, Hangshun chips integrate CRC, AES, HASH, and TRNG hardware computing units to verify the correctness and integrity of data transmission or storage, as well as to achieve encryption and decryption of Flash data.

Safety and reliability: Hangshun chips’ automotive-grade chip uses high-performance ARM Cortex-M3/M0 cores, and the entire chip is developed and produced domestically. The chip has a self-developed floating-point co-processor and a hardware acceleration module for division and square root operations, which has strong data processing capabilities. Hangshun chips have passed the AEC-Q100 automotive certification, while also complying with ISO 9001 and IATF 16949 quality management system certifications, ensuring that the accompanying R&D capabilities and management capabilities are validated.

Quality cost control: Hangshun chips have achieved cost control and efficiency improvement through internal automation and modular strategies. Hangshun chips have developed an automated software platform, which has significantly improved the company’s project efficiency and R&D cycle, reducing project efficiency and time by 30% to 50%. Additionally, Hangshun chips have realized rapid product development through modularization and standardization, ensuring product consistency and reliability.

Supply chain management: Hangshun chips adopt a diversified strategy in supply chain management, rather than relying solely on one wafer factory for production. This diversification strategy not only helps Hangshun chips maintain the stability of the supply chain but also enables them to flexibly respond to market changes, ensuring the company can quickly adjust production and supply strategies in the face of unexpected situations.

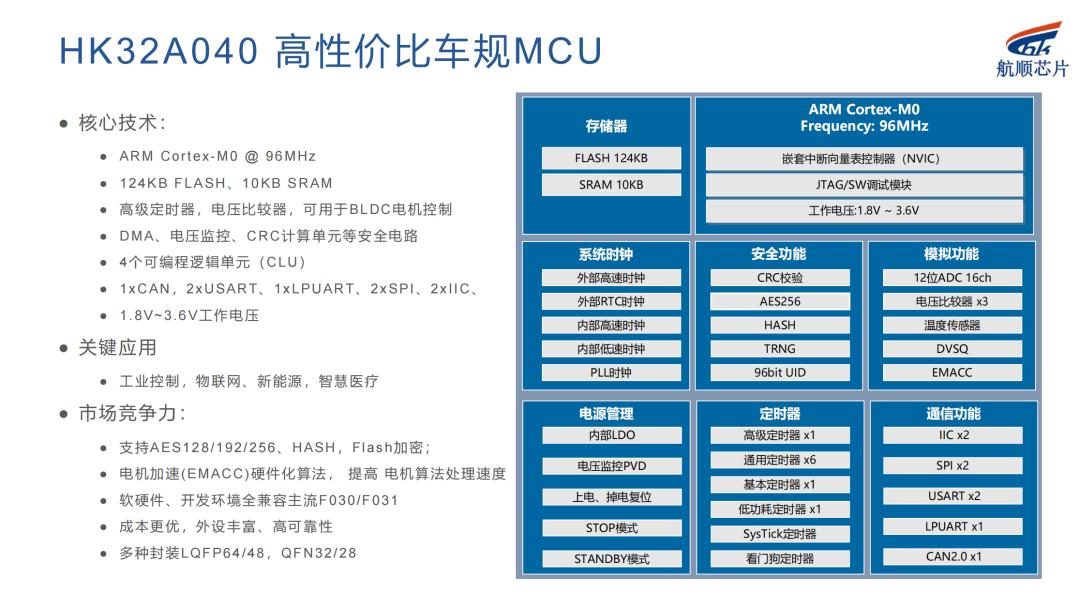

The “chip” choice is born—— HK32A040, the newly launched high-cost performance automotive-grade MCU from Hangshun chips. With a main frequency of 96MHz, built-in CAN controller, and various timers and communication ports, it perfectly meets the needs. There are also development boards and supporting development packages, including drivers and examples, striving to surpass existing market products in all aspects. The functional modules are also compatible with the same modules of other Hangshun products, making expansion development easy. When new products are derived later, existing codes can be reused, achieving twice the result with half the effort.

-

CPU Core

-

ARM® Cortex® -M0 -

Maximum clock frequency: 96 MHz

-

24-bit System Tick Timer -

Supports interrupt vector remapping (via Flash controller register configuration)

-

Operating Voltage Range

-

Single power domain (main power VDD): 1.8 V ~ 3.6 V

-

Backup power (VBAT): 1.8V ~ 3.6V product overview

-

Typical Operating Current

-

Run mode: 6.1mA@96MHz; 1.6mA@8MHz

-

Sleep mode: 4.7mA@96MHz

-

Stop mode:

-

LDO full speed: [email protected]

-

LDO low power: 60μ[email protected]

-

Standby mode: 1.6μ[email protected]

-

Shutdown mode: 0.4μ[email protected]

-

Memory

-

124 Kbyte Flash

-

Supports 0 wait state bus cycle access to Flash when CPU clock frequency is no more than 24 MHz.

-

Flash has data security protection features, allowing separate read and write protection settings.

-

Supports instruction and data encryption for Flash storage to prevent physical attacks on Flash content.

-

10 Kbyte SRAM

-

Data Security

-

CRC check hardware unit

-

Multiple security encryption modules, including AES, HASH, and TRNG

-

Clock

-

External high-speed clock (HSE): supports 4 ~ 32 MHz, typical value is 8 MHz

-

External low-speed clock (LSE): 32.768 kHz

-

Internal high-speed clock (HSI): 8 MHz/14 MHz/56 MHz configurable

-

Internal low-speed clock (LSI): 40 kHz

-

PLL clock: up to 96MHz

-

Chip pin input clock (EXTCLK)

-

Reset

-

External pin reset

-

Power-on reset (POR/PDR)

-

Software reset

-

Watchdog (IWDG and WWDG) reset

-

Low-power management reset

-

Option byte loader reset

-

Programmable Voltage Detector (PVD)

-

8-level detection voltage threshold adjustable

-

Rising and falling edge detection configurable

-

GPIO Ports

-

Supports up to 55 GPIO pins

-

Each GPIO pin can be configured as an external interrupt input

Data communication interfaces

-

2 channels USART: Support for master synchronous SPI and hardware flow control for modems, with ISO7816 interface, LIN, IrDA functionality, and automatic baud rate detection and wake-up from Stop mode. Product overview

-

Up to 2 high-speed SPI: supports 4 to 16 bit programmable data frames, with multiplexed I2S interface.

-

Up to 2 I2C: supports fast mode (1 MHz), SMBus, and PMBus. Supports data reception wake-up in Stop mode.

-

1 LPUART: supports asynchronous serial communication at minimal power consumption, single-wire half-duplex communication, hardware flow control for modems (CTS/RTS), and multi-processor communication.

-

1 CAN: supports CAN protocol (2.0A and 2.0B active mode)

-

Timer and PWM Generator

-

1 16-bit advanced timer (4 PWM outputs, of which 3 have dead-time complementary outputs and brake functions)

-

5 16-bit and 1 32-bit general-purpose timers (TIM2/TIM3/TIM14/TIM15/TIM16/TIM17)

-

1 16-bit basic timer (TIM6)

-

On-chip Analog Circuits

-

1 12-bit SAR ADC (up to 16 channels of analog signal input) maximum conversion frequency: 1MSPS supports automatic continuous conversion, scan conversion function with 3 analog comparators

-

DMA Controller (with 7 channels)

-

Supports triggering from various peripherals such as timers, ADC, SPI, I2C, USART, AES, HASH, etc.

-

Temperature Sensor

-

Analog output connected to A/D converter independent channel

-

CPU Tracking and Debugging

-

SWD Debug Interface

-

ARM® CoreSightTM debug components (ROM-Table, DWT and BPU)

-

Custom DBGMCU debug controller (low-power mode simulation control, debug peripheral clock control, debug and trace interface allocation)

-

Fixed-point Division/Square Root Operation Unit

-

Supports 32-bit fixed-point division, can obtain both quotient and remainder simultaneously

-

Supports 32-bit fixed-point high-precision square root

-

4 Programmable Logic Units (CLU), handling simple logic operations

-

Motor acceleration (EMACC) hardware algorithm to improve motor algorithm processing speed

-

Calendar RTC

-

With alarm function

-

Can wake up from stop or standby state periodically

-

96-bit chip UID identifier

-

Reliability

-

Passes HBM6000V/CDM2000V/MM200V/LU200mA level tests.

-

Operating temperature range(1): -40°C ~ +125°C

Readers who need further information can contact Hangshun chips or the sales and technical support engineers of agents——Phone: 86-0755–88917820, Email: [email protected].