To further promote the innovative development of edge computing, the China Academy of Information and Communications Technology, the Industrial Internet Industry Alliance, and the Key Laboratory of the Integration of Internet and Industry, Ministry of Industry and Information Technology jointly initiated the first edge computing industry promotion project in China, the “Edge Computing Standard Component Plan.” The aim is to form an industrial closed loop of “technology research and development, standard formulation, product testing, application demonstration, and large-scale commercial use,” pushing China’s edge computing into a new stage.

After centralized testing by the China Academy of Information and Communications Technology, the EC13211 high-performance edge general-purpose controller independently developed by Dongfang Electric Group Science and Technology Research Institute Co., Ltd. (hereinafter referred to as “Dongfang Research Institute”) successfully passed this “Edge Computing Standard Component Plan” product test and has been applied in various fields, effectively promoting the intelligent manufacturing and digital transformation upgrade.

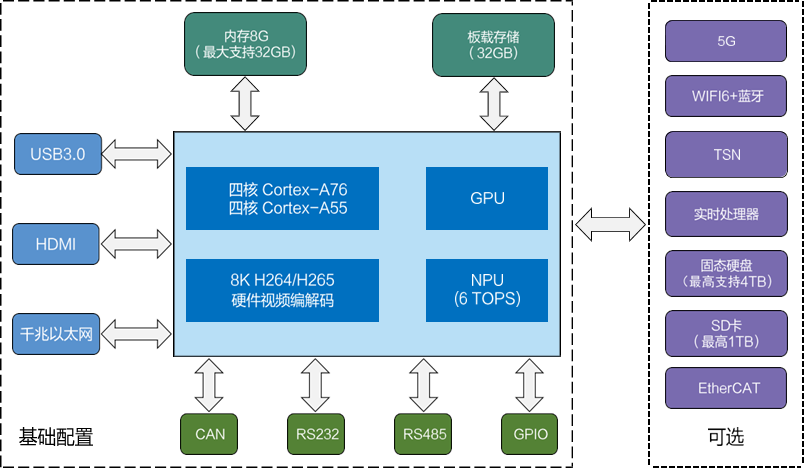

Currently, during the digital transformation process of enterprises, there are numerous scenarios involving data collection, industrial control, machine vision, and AI inference. The centralized processing architecture based on cloud computing not only has high requirements for IT hardware but also cannot meet the on-site demand for high real-time data communication, processing, and control. Edge computing, as a new computing model, collects, processes, and controls data nearby, meeting enterprises’ requirements for high real-time performance and high reliability, while effectively protecting the security of original data. Since data processing is completed on the edge side, only the processed results are transmitted upwards, which can significantly save network bandwidth and reduce IT infrastructure transformation costs for enterprises. With its low cost, high reliability, and flexible scalability, edge computing is more in line with the current stage of digital upgrades for Chinese enterprises. Based on the digital transformation needs of Dongfang Electric Group and combined with the industry trend of edge computing development, Dongfang Research Institute has independently developed the EC13211 high-performance edge general-purpose controller, adopting a multi-core heterogeneous architecture design, with dedicated cores for specific tasks, efficiently integrating functions such as AI inference, 5G, EtherCAT, TSN, video processing, and real-time control, and can tailor hardware as needed to effectively balance product performance, power consumption, and cost. This controller has been applied in batches in multiple production workshops of Dongfang Electric Group, operating efficiently and stably, and is currently gradually promoting its large-scale application in various industries.

EC13211 High-Performance Edge General-Purpose Controller

EC13211 Modular System Architecture

EC13211 High-Performance Edge General-Purpose Controller

EC13211 Modular System Architecture

The EC13211 features domestically produced, high computing power, modularity, rich interfaces, and stability and reliability, making it suitable for various edge computing and control tasks.

🔹Core processor is domestically produced and independently controllable;

🔹Core processor adopts 8nm advanced process technology, offering high computing power with low power consumption;

🔹Multi-core heterogeneous architecture, dedicated cores for specific tasks, balancing video processing, AI inference, real-time control, TSN, and 5G communication;

🔹Hardware can be tailored to provide the best cost-performance ratio;

🔹Rich interfaces to meet various industrial scenario needs;

🔹Fanless passive cooling, stable and reliable.

“Edge Computing Standard Component Plan” Certificate and Testing Report

Case 1: Heavy Lifting Safety Warning System

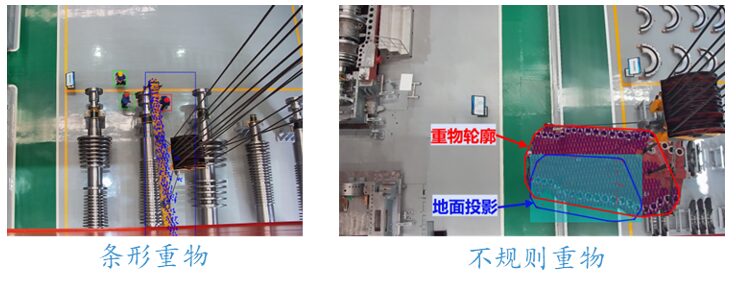

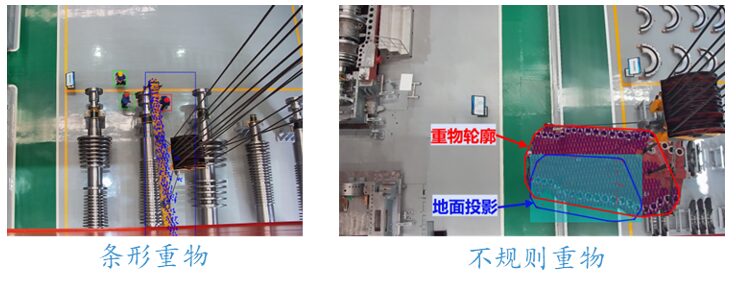

The heavy lifting operation is one of the most common high-risk operation scenarios in the workshop. Based on the EC13211, Dongfang Research Institute developed a heavy lifting safety warning system. The controller is installed on the crane, connecting nearby single-point lasers, 3D laser radars, industrial cameras, and other sensors for real-time data collection, posture perception, and AI visual processing, achieving high detection real-time performance. The system can intelligently identify safety risks such as people standing under the lifted object and people in the forward direction of the lifted object during lifting operations and issue safety warnings, reminding the crane driver to stop operations in time and upload alarm information. This system integrates lifting operation monitoring, risk warning, and violation alarms, significantly reducing safety risks in heavy lifting operations.

Heavy Lifting Safety Warning System Hardware Architecture

Heavy Object Recognition Schematic

Case 2: Intelligent Identification System for Unsafe Behaviors in the Production Workshop

The production workshop has a complex and variable environment, where some common unsafe behaviors of personnel may occur, such as climbing ladders without holding on, not wearing helmets, not properly wearing work uniforms, smoking at the workplace, and using mobile phones during operations. These behaviors can potentially lead to serious safety accidents. Dongfang Research Institute developed an intelligent identification system for unsafe behaviors in the production workshop based on the EC13211, with controllers distributed in multiple locations within the workshop for nearby video collection and AI processing, supporting simultaneous detection of multiple video streams and various intelligent algorithms, efficiently utilizing hardware resources while reducing bandwidth pressure in the workshop to achieve wide-area coverage. This system can real-time discover, display, and upload unsafe behavior alarm information, sending SMS reminders to designated safety personnel for handling, effectively reducing potential safety risks in the workshop.

Intelligent Identification System for Unsafe Behaviors Hardware Architecture

Multi-Stream Video Processing

Dongfang Research Institute is the top-level R&D platform and technology innovation center of Dongfang Electric Group Co., Ltd. It is a national high-tech enterprise, a national innovation and entrepreneurship base for high-level overseas talents, a post-doctoral innovation practice base in Sichuan Province, and an executive director unit of the China Intelligent Manufacturing Industry Innovation Technology Strategic Alliance, as well as a director unit of the Nuclear Power Intelligent Equipment and Robotics Technology Innovation Alliance. Dongfang Research Institute has achieved a series of breakthrough scientific and technological results and numerous engineering application achievements in fields such as smart factories, intelligent manufacturing and services, special environment robots, smart power plants, smart energy, 5G + industrial internet, and integrated protection of energy equipment network security.

Multi-Stream Video Processing

Dongfang Research Institute is the top-level R&D platform and technology innovation center of Dongfang Electric Group Co., Ltd. It is a national high-tech enterprise, a national innovation and entrepreneurship base for high-level overseas talents, a post-doctoral innovation practice base in Sichuan Province, and an executive director unit of the China Intelligent Manufacturing Industry Innovation Technology Strategic Alliance, as well as a director unit of the Nuclear Power Intelligent Equipment and Robotics Technology Innovation Alliance. Dongfang Research Institute has achieved a series of breakthrough scientific and technological results and numerous engineering application achievements in fields such as smart factories, intelligent manufacturing and services, special environment robots, smart power plants, smart energy, 5G + industrial internet, and integrated protection of energy equipment network security.

Contact Person: Huang Yujie

Contact Information: 13086473248 [email protected]

Related News:

Supporting Industrial Equipment Updates | Fifth Batch of “Edge Computing Standard Component Plan” Test Results Released. The first batch of “Edge Computing Standard Component Plan” product testing for 2024 has begun. The China Academy of Information and Communications Technology has launched the 2024 mid-year “Edge Computing Standard Component Plan” product testing solicitation.

Plenary Session丨 The 26th Working Group Plenary of the Industrial Internet Industry Alliance Held in Shanghai

Event丨 Building a New Type of Industrial Network System to Support High-Quality Development of Manufacturing Industry. Event丨 2024 BRICS Exhibition – Industrial Internet Themed Exhibition Successfully Held

5G Factory丨 The First Five-Star 5G Factory Construction Completed. Open Day丨 Global Blueprint for the Development of “5G + Industrial Internet” Launched. International Cooperation Starts a New Journey

Event丨 New Type of Industrial Network Seminar Successfully Held

Solicitation丨 The China Academy of Information and Communications Technology Launches 2024 Mid-Year “Edge Computing Standard Component Plan” Product Testing Solicitation

Plenary Session丨 The 25th Working Group Plenary of the Industrial Internet Industry Alliance Held in Hulunbuir Hailar

Research丨 Alliance Organizes Member Unit Representatives to Conduct 5G Factory Research at Huaneng Yimin Open-Pit Mine

Multi-Stream Video Processing

Multi-Stream Video Processing