Overview of Magnetic Sensors

Magnetic sensors have basic characteristics such as non-contact measurement, high reliability, robustness, and high measurement sensitivity. The magnetic field can penetrate many non-metallic materials, triggering the exchange process without direct contact with the target object. By using magnetic conductors (such as iron), the magnetic field can be conducted over longer distances, allowing signals to be transmitted from areas with higher temperatures. Devices that convert changes in magnetic performance caused by magnetic fields, electric currents, stress, temperature, light, etc., into electrical signals are called magnetic sensors. They are used not only to detect the magnitude and direction of magnetic fields but also in combination with permanent magnets for non-contact detection of various non-magnetic quantities such as position, speed, angle, temperature, and current.

01

Types of Magnetic Sensors

Since magnetic sensors entered practical applications as an independent product, they have been able to detect weak magnetic fields of 10-14T in the human body to strong magnetic fields exceeding 25T, with corresponding types of sensors available for detection.

From an application principle perspective, the types of magnetic sensors mainly include:

02

Applications of Magnetic Sensors

1. Applications in Industry

In the industrial application field, the most popular type of magnetic sensor is the current sensor, including shunt resistors, Hall effect integrated circuits, current sensing transformers, open-loop and closed-loop Hall devices, and fluxgate sensors.

Motors: In brushless motors, magnetic sensors are used for rotor pole position sensing and stator armature current commutation. Many types of magnetic sensors, such as Hall devices, Wiegand devices, and magnetoresistive devices, can be used, but currently, Hall devices are the most widely used.

Additionally, magnetic sensors can provide overload protection and torque detection for motors; AC variable frequency drives are used for motor speed control, achieving excellent energy-saving effects. Due to the increasing advantages of magnetic encoders, they are gradually replacing optical encoders for detecting and controlling motor speed.

Power Electronics Technology: Power electronics technology is the combination of power technology and electronic technology, enabling the mutual conversion of AC and DC currents and allowing free adjustment of current, voltage, and frequency within the desired range.

Using these technologies and products, various special power supplies (such as switch-mode power supplies, arc welding inverter power supplies, etc.) and AC variable frequency drives can be made. The core of these variable frequency devices is high-power semiconductor devices.

Various current sensors based on magnetic sensors are used to monitor, control, and protect these high-power devices. Hall current sensors have a fast response speed and rely on the coupling of the magnetic field and the controlled circuit, not connecting to the main circuit, thus having low power consumption, strong overload capacity, good linearity, and high reliability. They can serve as overcurrent protection drivers for high-power devices and also act as feedback devices, becoming a control link in a self-regulating loop.

Energy Management: The automatic detection system of the power grid requires the collection of a large amount of data, which is processed by computers to monitor the operating conditions of the power grid and adjust load distribution and safety protection. Each control link of the automatic monitoring system can be realized using current sensors and transformers based on magnetic sensors. Hall current sensors have long been used in power grid systems. Electric meters made with Hall devices have transitioned from development to practical application; they can automatically bill and display power factors for timely adjustments to ensure efficient electricity use.

Magnetic Information Recording Devices: In addition to magnetic tapes, disks, etc., magnetic information recording devices also include magnetic cards, magnetic ink recording books, and magnetic records of banknotes, creating a huge demand for magnetic information storage and reading sensors. Currently, inductive magnetic heads, thin-film magnetoresistive heads, and amorphous magnetic heads are widely used. With the increase in recording density, there is a need for higher sensitivity and spatial resolution in magnetic heads. Giant magnetoresistance heads based on multilayer metal films, amorphous alloy heads made from amorphous alloy wires, and giant magnetoresistive heads are in fierce competition.

Traffic Control: Traffic accidents and congestion are significant problems in urban and intercity transportation. Currently, both domestically and internationally, there is an emphasis on developing and constructing vehicle support road systems, intelligent transportation systems, and road traffic information systems. In these new systems, high-sensitivity, high-speed response miniature magnetic sensors are highly useful.

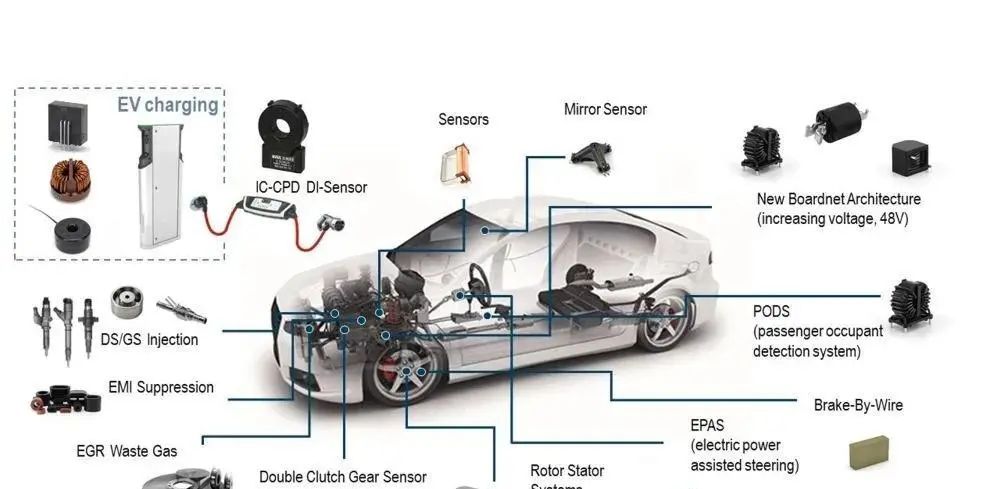

2. Applications in Automobiles

In automobiles, magnetic sensors are primarily used for detecting parameters such as speed, tilt, angle, distance, proximity, and position, as well as in navigation and positioning applications, such as speed measurement, pedal position, gearbox position, motor rotation, power assist torque measurement, crankshaft position, tilt measurement, electronic navigation, anti-lock detection, parking positioning, defect detection in airbags and solar panels, seat position memory, and improving the directional resolution of navigation systems.

In energy-saving and consumption-reduction efforts, the application of magnetic sensors can make motor control or commutation more precise. Additionally, magnetic sensors are present in electronic throttle control systems, battery monitoring, and intelligent fans in automobiles.

3. Applications in the Medical Field

Although the scale of application of magnetic sensors in the medical field is smaller than in the industrial field, they can assist in patient care and monitoring in various situations: ambulances, hospitals, and home care. Whether during surgery, in intensive care units, or in home care, they provide effective means to control movement, airflow, detect blood pressure, and administer medication, thus saving lives or improving quality of life. They are primarily used for motor control in medical devices, such as ventilators, infusion pumps, insulin pumps, and dialysis machines.

4. Applications in Consumer Electronics

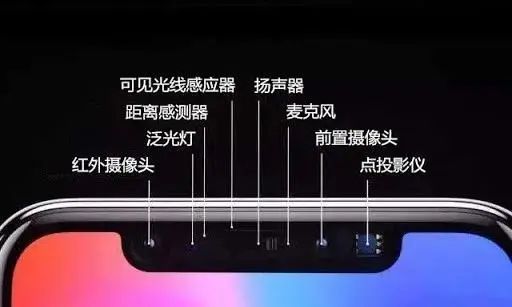

With the global popularity of consumer electronics, the application of magnetic sensors in consumer electronics is also very strong. For example, they are widely used in mobile phones, laptops, electronic toys, electronic compasses, etc.

In multi-axis measurement electronic compasses, magnetic sensors play an important role. Currently, smartphones and tablets equipped with GPS systems use multi-axis measurement electronic compasses as standard, which has allowed magnetic sensors to ride the wave of consumer electronics. The application of magnetic sensors in consumer electronics has also enabled game controllers, laptops, and digital cameras to have geotagging capabilities.

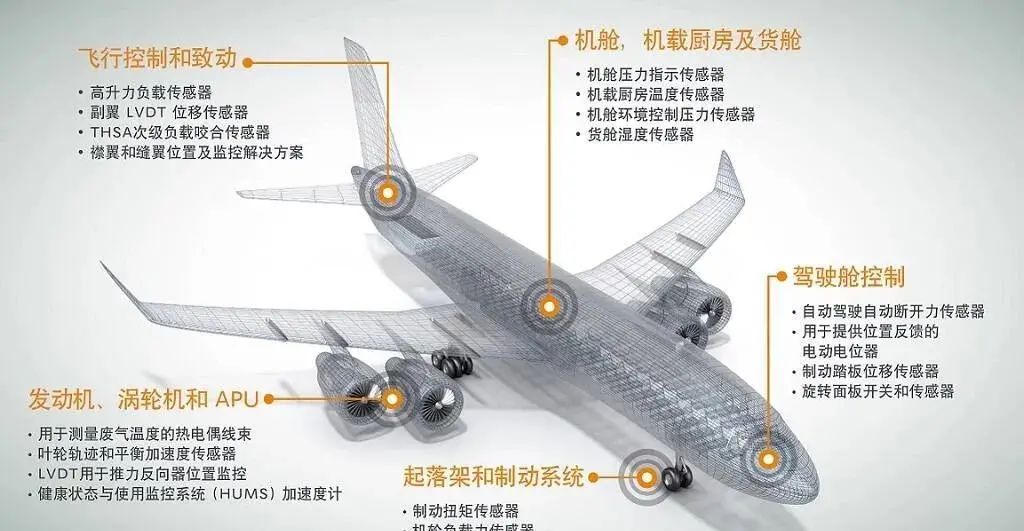

5. Applications in Aerospace, Satellite Communication, and Military Industries

High-sensitivity and low magnetic field sensors can be used in aerospace, satellite communication technologies. As we know, in military industries, with the development of radar-absorbing technology, military objects can be concealed by covering them with radar-absorbing materials; however, they will still generate a magnetic field, which can be detected by magnetic field sensors. Magnetic field sensors can also be applied in satellites to detect objects on the Earth’s surface and the distribution of underground minerals. Electronic compasses play a crucial role in the navigation of weapons/missiles and high-performance navigation devices in marine and aviation.

6. Applications in Environmental Monitoring

The premise of environmental protection is the monitoring of various environmental parameters, which requires the use of a large number of different sensors. Using strong magnetostrictive amorphous magnetic elastic micro magnetic sensors and inductive magnetic sensors, it is possible to simultaneously measure temperature and air pressure in vacuum or sealed spaces without connecting plugs, allowing for remote measurement and long-distance access.

7. Other Industrial Applications

In other industrial applications, magnetic sensors can be used for uninterruptible power supplies for computers and servers, welding systems. In applications with high currents such as large variable frequency motors, open-loop and closed-loop Hall sensors use Hall effect ICs in a small package; they can also increase integration by including a dedicated integrated circuit in the package. Hall ICs are also used in industrial washing machine variable frequency control applications. Besides current sensors, independent Hall effect ICs or magnetoresistive sensor switches also have a significant market, used for motor rectification to reduce ripple and improve performance, or for position measurement, etc.

03

Development Trends of Magnetic Sensors

High Sensitivity: The strength of the detected signal is becoming weaker, which requires a significant increase in the sensitivity of magnetic sensors. Application areas include current sensors, angle sensors, gear sensors, and space environment measurement.

Temperature Stability: More application fields require magnetic sensors to operate in increasingly harsh environments, necessitating good temperature stability, mainly in the automotive electronics industry.

Anti-Interference: Sensors and instruments face various interferences during field operation, such as electrostatic induction, electromagnetic induction, leakage current induction, radio frequency interference, etc., requiring magnetic sensors to have good anti-interference capabilities. Application areas include automotive electronics, water meters, etc.

Multi-functionality, Integration, Intelligence: Multi-functionality can reduce production costs, minimize size, and effectively improve the stability and reliability of sensors. The combination of sensors with microprocessors enables them to not only have detection functions but also information processing, logical judgment, self-diagnosis, and artificial intelligence capabilities, referred to as sensor intelligence. These types of sensors offer multi-functionality, high performance, compact size, suitability for mass production, and ease of use. Achieving multi-functionality, integration, and intelligence requires chip-level integration, module-level integration, and product-level integration. Many magnetic sensors, such as electronic spin resonance current sensors, have already realized integration.

High-Frequency Characteristics: With the expansion of application fields, the operational frequency of magnetic sensors is increasingly required to be high, with primary applications in water meters, automotive electronics, and information recording industries.

Low Power Consumption: Many fields require magnetic sensors to have extremely low power consumption to extend their lifespan. Application areas include implanted magnetic biochips and compasses.

Magnetic sensors are a crucial component in achieving automatic detection and control. Without accurate and reliable measurements of raw data by sensors, signal conversion, information processing, and data display and control would be impossible. Without precise and reliable sensors, there can be no automatic detection and control systems. Thus, it is evident that magnetic sensors play a significant role.