Domestic popular CNC systems are continuously increasing their market share, but foreign brands still dominate the domestic market. In the field of high-end CNC systems, there is indeed a considerable gap between domestic and foreign systems. Although domestic five-axis linkage CNC systems have made certain technological breakthroughs, their functionality is not yet fully developed, and practical application verification is still incomplete. The gap in high-end domestic CNC systems is also reflected in the incompleteness of product series, such as servo motors and servo drives of various specifications from small to large, which are available in foreign markets, while our specifications are limited. In terms of high speed (rapid feed speed above 40m/min), high precision (resolution below 0.1 microns), and multi-channel CNC systems, there is a significant gap between domestic and foreign systems. The metal processing editor has compiled a list of commonly seen CNC system manufacturers in the country, including:

1. Japan FANUC CNC System

FANUC Corporation of Japan is currently the world’s strongest enterprise in research, design, manufacturing, and sales of CNC systems, with a total of 4,549 employees (as of September 2005), including 1,500 researchers and designers.

(1) The highly reliable PowerMate 0 series is used to control small lathes with 2 axes, replacing stepping motors with servo systems; it can be equipped with CRT/MDI that has clear images, easy operation, and Chinese display, or with DPL/MDI that has a high performance/price ratio.

(2) The popular CNC 0-D series is used for lathes, 0-MD for milling machines and small machining centers, 0-GCD for cylindrical grinding machines, 0-GSD for surface grinding machines, and 0-PD for punching machines. (Provided by Metal Processing WeChat)

(3) The fully functional 0-C series 0-TC is used for general lathes and automatic lathes, 0-MC for milling machines, drilling machines, and machining centers, 0-GCC for internal and external cylindrical grinding machines, 0-GSC for surface grinding machines, and 0-TTC for dual-tool 4-axis lathes.

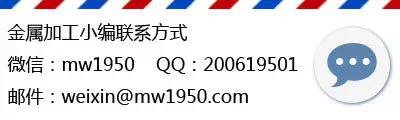

(4) The 0i series overall software function package with high performance/price ratio supports high-speed and high-precision processing and has networking capabilities. 0i-MB/MA is used for machining centers and milling machines with 4-axis 4-linkage; 0i-TB/TA is used for lathes with 4-axis 2-linkage; 0i-mateMA is for milling machines with 3-axis 3-linkage; 0i-mateTA is for lathes with 2-axis 2-linkage.

Figure 1 FANUC CNC System

(5) The ultra-small, ultra-thin CNC 16i/18i/21i series control unit integrates with LCD and features networking capabilities and ultra-high-speed serial data communication. Among them, FSl6i-MB’s interpolation, position detection, and servo control are measured in nanometers. 16i can control up to 8 axes with 6-axis linkage; 18i can control up to 6 axes with 4-axis linkage; 21i can control up to 4 axes with 4-axis linkage.

In addition, there is the CNCl6/18/160/180 series that realizes machine tool personalization.

2. German Siemens CNC System

Siemens is a leading enterprise in the global electronic and electrical engineering field, with its main business concentrated in four major areas: industry, energy, medical, and infrastructure & cities. For 140 years, Siemens has persistently engaged in comprehensive cooperation with China through its innovative technology, excellent solutions, and products, gaining widespread recognition for its continuous innovation, outstanding quality, and reliable reliability. In the fiscal year 2011 (from October 1, 2010, to September 30, 2011), Siemens’ total revenue in China reached 6.39 billion euros (excluding OSRAM and Siemens IT Solutions and Services Group). Today, Siemens has about 30,000 employees in China, with 16 R&D centers, 65 operating companies, and 65 regional offices established.

SIEMENS company’s CNC devices adopt a modular structural design, which is economically feasible, allowing multiple software configurations on a single standard hardware to meet various machine tool needs and become a series of products. With the development of microelectronics technology, more and more large-scale integrated circuits (LSI), surface mount devices (SMC), and advanced processing technology are adopted, making the new system structure more compact, performance stronger, and prices lower. Using the SIMATICS series programmable controllers or integrated programmable controllers, programmed in SYEP programming language, it has rich human-machine dialogue functions and displays in multiple languages. (Provided by Metal Processing WeChat)

SIEMENS company’s CNC devices mainly include SINUMERIK 3/8/810/820/850/880/805/802/840 series.

Figure 2 Siemens CNC 840d

3. Japan Mitsubishi CNC System

Mitsubishi Electric Automation (China) has a total investment of 20 million USD. It mainly produces mechanical devices for power distribution (including low-voltage circuit breakers and electromagnetic switches), electric processing products (including CNC electric discharge forming machines, wire-cut electric discharge machines, laser processing machines), variable frequency speed controllers, servo system machines, CNC devices, and their components, and provides related after-sales services.

Commonly used Mitsubishi CNC systems in the industry include: M700V series; M70V series; M70 series; M60S series; E68 series; E60 series; C6 series; C64 series; C70 series. Among them, the M700V series belongs to high-end products, fully nano-controlled systems, high precision and high-quality processing, supporting 5-axis linkage, capable of processing complex surface shapes of workpieces.

Figure 3 Mitsubishi CNC System

4. German Heidenhain CNC System

Heidenhain develops and produces grating scales, angle encoders, rotary encoders, digital displays, and CNC systems. Heidenhain’s products are widely used in machine tools and automated machines, especially in fields such as semiconductor and electronics manufacturing.

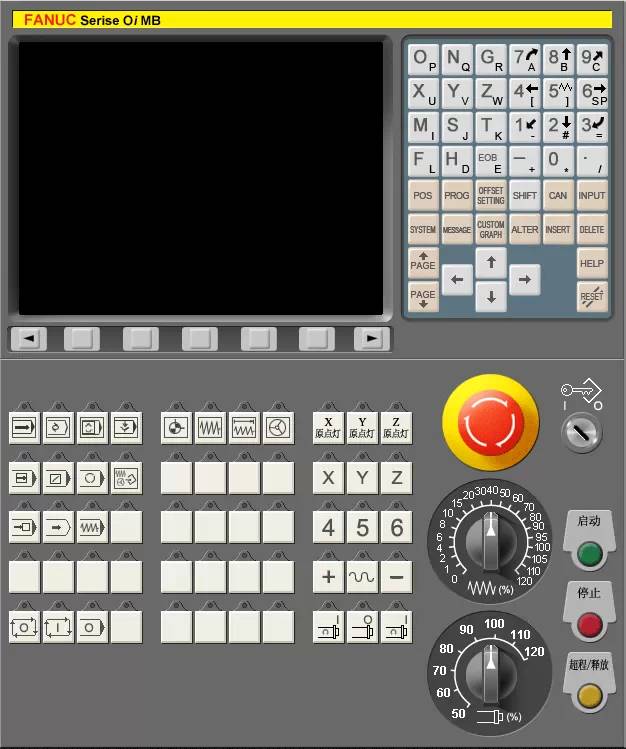

The iTNC 530 control system from Heidenhain is a versatile control system suitable for milling machines, machining centers, or processes that require optimized tool path control, belonging to high-end CNC systems. The data processing time of this system is 8 times faster than that of previous TNC series products, and the equipped “fast Ethernet” communication interface can transmit program data at a speed of 100Mbit/s, which is 10 times faster than before. The new program editor has large program editing capabilities, allowing for quick insertion and editing of information program segments.

Figure 4 Heidenhain iTNC 530 Control System

5. German Bosch Rexroth CNC System

Bosch Rexroth is formed by the merger of the original Bosch Automation Technology Department and the original Rexroth Company in 2001, and is fully owned by the Bosch Group. Bosch Rexroth is a world-renowned drive and control company, leading the world in industrial hydraulics, electronic drive and control, linear drive and assembly technology, pneumatics, hydraulic drive services, and walking machinery hydraulics. The company is registered in Stuttgart, Germany, while its operational headquarters and board office are located in Lohr, Germany. In 2003, the company’s sales reached 4 billion euros, with 25,000 employees.

6. French NUM CNC System

Schneider Automation, a world leader in automation system manufacturing, is one of the largest automation equipment suppliers today, specializing in the development and research of CNC systems. NUM is a well-known international company in France, dedicated to the development and research of CNC systems, and is a subsidiary of Schneider Electric, the second largest CNC system supplier in Europe. Its main products include: NUM1020/1040, NUM1020M, NUM1020T, NUM1040M, NUM1040T, NUM1060, NUM1050, NUM drives and motors.

7. Spanish FAGOR CNC System

FAGOR AUTOMATION is a world-renowned manufacturer of CNC systems (CNC), digital readouts (DRO), and grating measurement systems. FAGOR is part of the Mondragon Group in Spain, established in 1972, focusing on the development of machine tool automation, with products covering CNC systems, servo drives/motors/spindle systems, grating scales, rotary encoders, and high-resolution high-precision angle encoders, digital readouts, and more.

8. Japan MAZAK CNC System

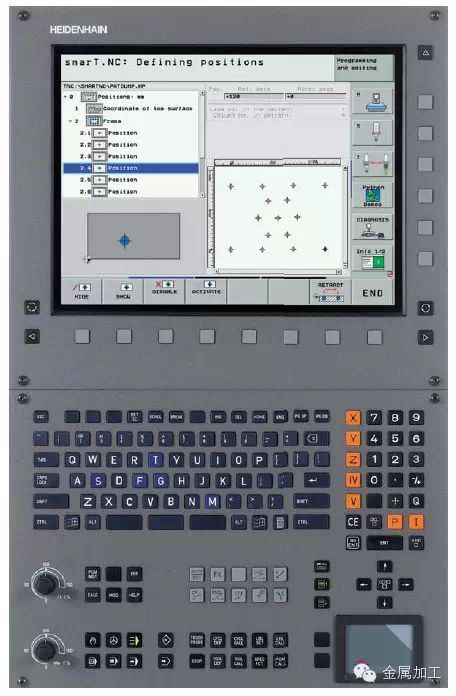

Yamazaki Mazak Corporation was founded in 1919, mainly producing CNC lathes, compound turning and milling machining centers, vertical machining centers, horizontal machining centers, CNC laser systems, FMS flexible production systems, CAD/CAM systems, CNC devices, and production support software.

The Mazatrol Fusion 640 CNC system is the first in the world to use CNC and PC integration technology, realizing networking and intelligent functions of the CNC system. The CNC system can connect directly to the internet to receive 24-hour online maintenance services provided by the Little Giant Machine Tool Company.

undefined

9. Huazhong CNC

Huazhong CNC has CNC devices with independent intellectual property rights forming a series of products at high, medium, and low levels, and has developed a new product of the Huazhong 8 series high-end CNC system that has been matched with several high-end CNC machine tools included in the national major special projects; the performance indicators of its independently developed servo drive and spindle drive devices have reached the international advanced level.

The HNC-848 CNC device is a fully digital bus high-end CNC device aimed at foreign high-end CNC systems, using a dual CPU module structure for upper and lower computers, with a modular, open architecture based on independently developed NCUC industrial field bus technology. It features multi-channel control technology, five-axis processing, high-speed high-precision, turning and milling compound, synchronous control, and other functions of high-end CNC systems, with a 15″ LCD display. It is mainly applied in high-speed, high-precision, multi-axis, multi-channel vertical and horizontal machining centers, turning and milling compounds, and 5-axis gantry machines, etc. (Provided by Metal Processing WeChat)

Figure 6 Huazhong 8 Series Fully Digital Bus High-End CNC System

10. Guangzhou CNC

Guangdong Province has 20 key equipment manufacturing enterprises, and is the undertaking enterprise of the national 863 key project “Industrialization Support Technology for Medium CNC Systems.” Its main business includes the research and production of CNC systems, servo drives, servo motors, chain marketing of CNC machine tools, CNC machine tool engineering, industrial robots, precision CNC injection molding machines, etc.

Guangzhou CNC has CNC systems in multiple fields, including lathe CNC systems, drilling and milling machine CNC systems, machining center CNC systems, and grinding machine CNC systems. Among them, the GSK27 system uses multiple processors to achieve nm-level control; it features a user-friendly human-machine interaction interface, configurable menus designed according to ergonomic principles, making it more in line with the processing habits of operators; it adopts an open software platform, allowing easy connection with third-party software; high-performance hardware supports a maximum of 8 channels and 64-axis control.

Figure 7 Guangzhou CNC GSK27 CNC System

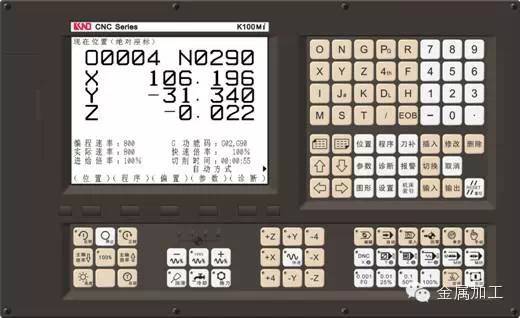

11. KND

Beijing KND CNC Technology Co., Ltd. (KND) was established in 1993 and is a high-tech enterprise engaged in the research, production, sales, and service of CNC systems and industrial automation products. It has dedicated CNC systems for lathes, two-axis machinery, milling machines, machining centers, engraving machines, grinding machines, and specialized CNC systems of various grades.

Among them, K2000M is a new generation high-end CNC milling and machining center system, using newly upgraded hardware and software, achieving an interpolation cycle of 0.25ms, with high-speed response capabilities, and adding various control functions such as 3D solid graphics, multiple ways of tool setting, high-speed high-precision, and breakpoint control, with a maximum control axis number of 3/4/8 axes, and can be configured with KND company’s high-speed servo units and absolute encoders, suitable for various high-performance CNC milling, vertical, horizontal, and gantry machining centers.

Source: Some content is sourced from the internet, and some content is compiled by the metal processing editor. We apologize for any omissions.

Metal Processing WeChat is jointly operated by the “Metal Processing” magazine, founded in 1950 (including cold processing and hot processing bi-monthly), and Metal Processing Online (mw1950.com). It gathers news, technology, products, and market content. Metal Processing provides first-class information and promotion services for the industry through a four-in-one full media service platform of magazines, digital media, events, and services.