1. What is Industrial Equipment Clouding?

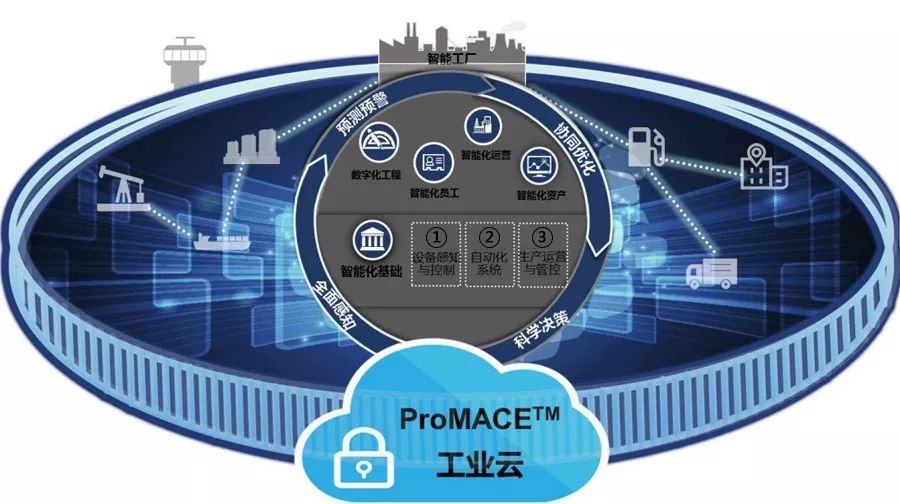

“Industry 4.0” is the fourth industrial revolution led by intelligent manufacturing, which has transformed the manufacturing industry into intelligence by fully utilizing information communication technology and the integration of cyber-physical systems. To realize the concept of “Industry 4.0,” the essential step is to cloud industrial equipment, aiming for intelligent manufacturing to achieve personalized and customized production. Clouding industrial equipment includes not only traditional software elements but also hardware sensors, cloud service platforms, and intelligent controls. It emphasizes not only digitization but also the automation and intelligence of manufacturing and operations, especially in the collection and processing of industrial big data.

2. Why Implement Clouding for Industrial Equipment?

In recent years, with the advent of Industry 4.0 and the Internet of Things era, many equipment manufacturers and end-users of industrial equipment have undergone a major transformation of “Internet + Manufacturing.” Currently, the inability to effectively manage equipment production and operation, along with the challenges of tracking and maintaining sold equipment’s usage and fault status, are two major issues faced by industrial equipment manufacturers and end-users. It is urgent to break the management deadlock and improve enterprise efficiency and competitiveness.

3. How to Achieve Clouding of Industrial Equipment?

Combining the core of clouding industrial equipment—data collection and control—this process can be divided into four levels:

1. Perception Layer: Responsible for connecting devices and obtaining multi-dimensional data. The methods of realization include the following: one type is connecting various PLCs through gateways to achieve data collection and equipment operation status control; another is directly interfacing with various instruments through wired or wireless communication; a third is using gateways to connect a complete hardware control system consisting of controllers and sensors for real-time data collection of status, parameters, faults, etc.

2. Network Layer: Responsible for data transmission and device control. Through GPRS or VPN channels, the collected data is transmitted to cloud communication services, or control commands issued by the platform layer are received to realize interaction with the platform layer.

Industrial Control Box—Achieving Device Connection and Data Transmission

Independently Developed Industrial IoT Gateway by Zhongyi Cloud

· Achieve remote control of industrial equipment

· Achieve remote data collection of industrial equipment

· Achieve remote modification of equipment operating parameters

· Achieve remote localized operation of PLCs

· Achieve comprehensive remote management across fields/devices

3. Platform Layer: Based on cloud computing, it summarizes and processes the collected data. The server processes the data and provides it to the web (PC, tablet, mobile) for display, analysis, diagnosis, and management via web or web service.

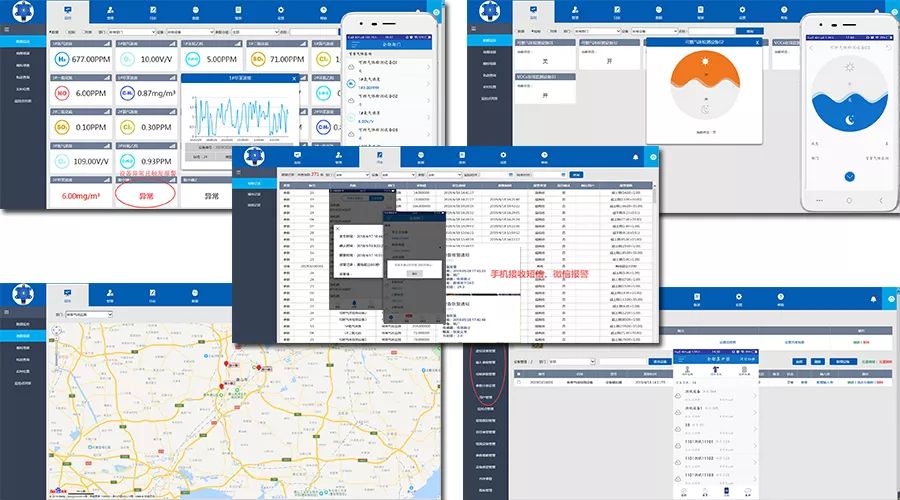

As a cloud service platform provider, Zhongyi Cloud has independently developed a comprehensive IoT management cloud platform (referred to as: Yiyun System) that integrates supervision, control, early warning, and alarm, achieving 24/7 online monitoring through PC and mobile APP, with over 4,000 status inspections daily to ensure the smooth operation of equipment. The platform also provides data analysis tools such as curves, bar charts, pie charts, and reports for better understanding of the overall system operation.

Some Functions of Yiyun System

4. Application Layer, located at the top level, is various applications oriented towards customers. The Zhongyi Cloud IoT comprehensive management cloud platform is a general-purpose platform that does not require programming development on mobile APPs or computer terminals. It has 40 small functional modules across 6 major categories that can be visually assembled to create various IoT application systems that meet user needs.

For detailed solutions, please call for consultation

For more features, please log in to the trial version of the system

For more exciting content, click the blue text below:

Intelligent Greenhouse Monitoring System

Intelligent Monitoring System for Heating and Heat Exchange Station

Soilless Cultivation Remote Monitoring Technical Solution

Successful Case—Soil Smart Management Project

Successful Case—Pasture Smart Management Project

Successful Case—Vanke Archive Smart Management Project

Successful Case—Smart Management Project of a Certain Bank in Shenzhen

Application Case of Indoor Temperature and Humidity Monitoring System for Foxconn Production Line in Chongqing

Application Case of Temperature and Humidity Monitoring System for Beijing Haist Clinical Laboratory