Polycarbonate (PC), a polymer containing carbonate groups in its molecular chain, is currently the fastest-growing general-purpose engineering plastic. In various end-use sectors of PC, the automotive sector accounts for approximately 16% of consumption. PC has been used in the automotive industry for over sixty years, with an average usage of about 11 kg per vehicle (data source: Automotive Materials Technology Working Group). Based on the type of ester groups in PC, there are three main types, among which only aromatic polycarbonate has been industrially produced due to its excellent mechanical properties, represented by bisphenol A type polycarbonate (hereafter, PC refers specifically to bisphenol A type PC).

✦

✦

Production and Application of PC Plastics

Production and Application of PC Plastics

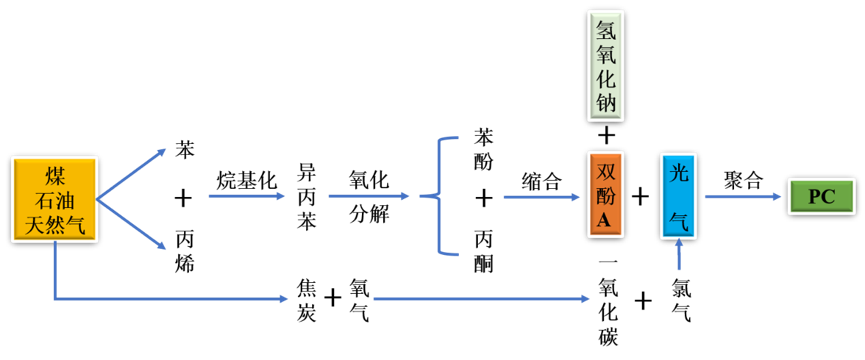

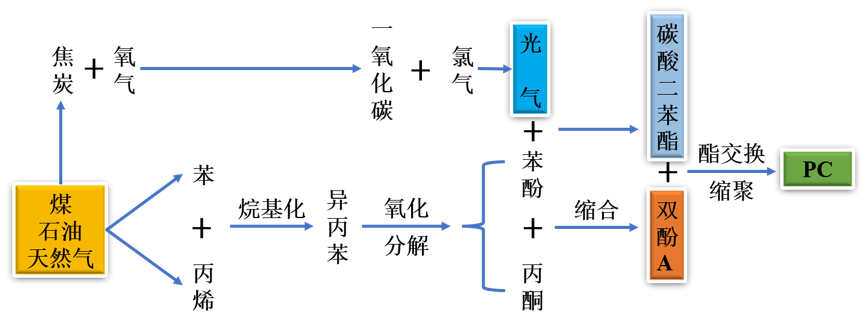

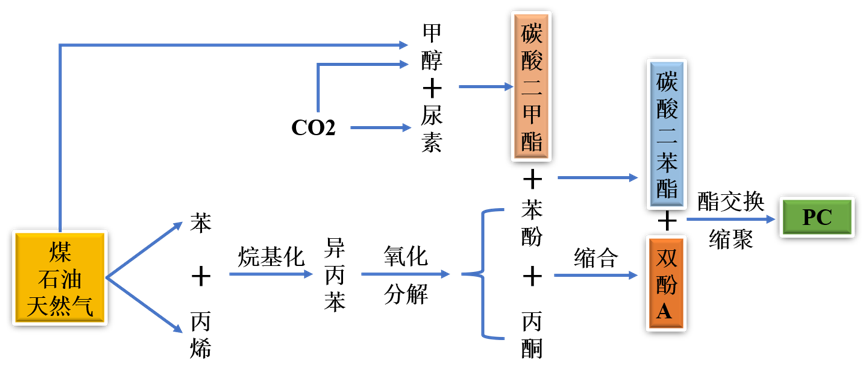

From the perspective of PC production, the upstream raw materials include fossil fuels such as coal, oil, or natural gas. The following diagram illustrates the industrial processes for producing PC. It can be seen that the manufacturing of PC is characterized by a long process chain, multiple synthesis methods, and a large number of intermediates.

Three Production Processes of PC

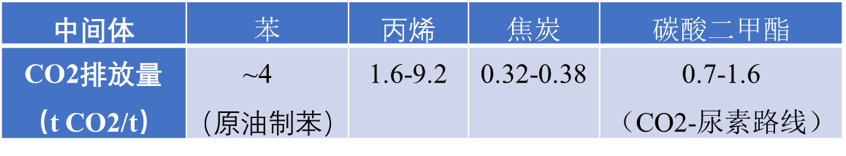

Analyzing the carbon emissions from PC production, the carbon emissions are primarily concentrated in the early production processes of intermediates such as benzene, propylene, and coke. The carbon emission intensity of each intermediate is shown in the table below, with benzene having a relatively high level of carbon emissions (the carbon emission range for propylene varies widely and has been analyzed in the “Plastic Section – Polypropylene”; thus, it will not be elaborated here). The carbon emission intensities of the two phosgene methods for producing PC are similar, while another process using dimethyl carbonate as an intermediate does not use highly toxic phosgene and can utilize CO2 as a raw material. The development of related processes is significant for reducing carbon emissions in PC production.

Carbon Emission Intensity of PC Production Intermediates

Due to its excellent impact resistance, heat distortion resistance, good weather resistance, and high hardness, PC is suitable for manufacturing various automotive components, primarily concentrated in lighting systems, dashboards, heating plates, and defrosters.

With the global upgrade of the automotive industry, the amount of plastic used in vehicles is gradually increasing, and automotive plastics will face more complex environmental conditions, while higher requirements are placed on modified PC for automotive use. Therefore, there is an urgent need for material technology upgrades to meet the development of the automotive industry and the arrival of the low-carbon economy.

Carbon Reduction for PC is Imperative

As the production and consumption of PC continue to expand, it has gradually exhibited characteristics of bulk plastics, and plastics have been included in the carbon tariff commodity list by the European Union as a new industry. According to estimates, China’s PC materials will achieve self-sufficiency by 2025 (mostly low-end PC, while high-performance PC manufacturing technology is still immature domestically), and the export scale will further expand. To prepare for the large-scale export of products, material companies should accurately quantify the carbon footprint of their products and manage compliance under various domestic carbon emission rules and foreign entry rules to accurately declare carbon tariffs and ensure stable product output.

Currently, there are three main carbon reduction measures for PC materials. First, developing bio-based PC, such as replacing traditional petroleum-based monomer bisphenol A with isosorbide derived from biomass. This route has been commercialized abroad but has low production capacity. Second, recycling waste materials, where chemical recycling can better meet the raw material needs for high-end PC. Some companies have achieved the production of PC with 30% recycled waste, which can reduce carbon emissions by about 15%. Third, directly synthesizing PC from CO2, which is an effective strategy to alleviate energy shortages and assist in carbon neutrality. However, the performance of this type of PC is currently poor and cannot meet downstream application needs, requiring further modification. Therefore, domestic PC raw material and modification companies should further strengthen cooperation, accurately extend and supplement the supply chain, continuously promote technological innovation and product iteration, enhance competitive strength, and gradually occupy the high-end market.

It is expected that by 2025, the EU carbon tariff will cover downstream applications of bulk commodities. As the downstream terminal of PC, the export situation for automobiles is becoming increasingly severe. Therefore, automotive companies should focus on the carbon emission data provided by suppliers when procuring PC-related materials, validate the scientificity of their accounting methods, and prepare methods and data reserves in advance to respond to increasingly stringent international trade barriers. The China Automotive Data “Automotive Materials Technology Working Group” has collaborated with the Petrochemical Federation to aim at connecting the upstream and downstream industrial chains and assisting in the low-carbon restructuring of the automotive industry, comprehensively carrying out the preparation of series standards for carbon footprint accounting methods for automotive plastic products, providing solutions to enhance the credibility of domestic automotive materials’ carbon emission data.

References

[1] Wang Yanli. Synthesis Process Routes of Polycarbonate and Its Development Status [J]. Petroleum and Chemical Design, 2020, 37(02): 65-68+7.

[2] Yu Han, Jiang Qingzhe, Song Zhaozheng, Yuan Bo. Carbon Footprint Analysis of CO2-DMC Industrial Chain [J]. Modern Chemical Industry, 2017, 37(03): 9-13.

[3] Duan Lijie, Dang Zhaoliang, Wei Wei. Analysis of Carbon Emission Status and Reduction Pathways of Independent Coking Enterprises [J]. Resource Conservation and Environmental Protection, 2018(11): 37-39.

Based on years of in-depth research in the field of automotive materials, China Automotive Data Co., Ltd. actively responds to the Ministry of Industry and Information Technology’s request to conduct carbon emission analysis of vehicle materials, carbon accounting for material substitution, and research on a series of carbon footprint accounting methods for over ten materials, assisting the sustainable development of the automotive industry towards a green low-carbon future.

For more information, please feel free to contact us!

Wang Luyao

Phone: 15210202057Email: [email protected]

Yun Yang

Phone: 18694274830Email: [email protected]

Song Tao

Phone: 15631686630Email: [email protected]

● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Steel Materials Part 1/2)

● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Steel Materials Part 2/2)

● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials – “Zero Carbon Steel” Technical Path

●Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials – “Scrap Steel Ratio”

● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Aluminum Alloy Materials Part 1/2)

● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Aluminum Alloy Materials Part 2/2)● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Plastic Section)● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (U.S. “Clean Competition Act”)● Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Plastic Section – Polypropylene)

●Carbon Neutrality Research | Overview of Carbon Emissions in Automotive Materials (Plastic Section – Polyamide)

China Automotive Data Co., Ltd.

China Automotive Data Co., Ltd. is based on automotive big data, with automotive domain model algorithms as its pillar, deeply engaged in energy-saving low-carbon, green ecology, market research, and other work. Aiming at the development of “new infrastructure” and “new four modernizations”, it precisely focuses on areas such as cloud computing in the Chinese automotive industry, intelligent networking, intelligent cockpits, and industrial internet (industrial software), through the construction of data infrastructure for the Chinese automotive industry and the establishment of a national-level automotive industry data system, with the mission of “driving industrial transformation with data and leading the future of automobiles with intelligence”, committed to building a “national-level automotive industry data center, national-level decision support institution for the automotive industry chain, and national-level digital support institution for the automotive industry”.

Click the original text for more details!

Click the original text for more details!