The Industrial Internet represents a new strategy, technological layout, and vision for the future, emerging from the powerful technological accumulation of industrialized nations over the past few decades and its integration with the internet. Interpreting these visions and strategies solely from an internet perspective is far from sufficient. In fact, the Industrial Internet is supported by robust technology.

So, where is the Industrial Internet currently? Unfortunately, while the Industrial Internet represents the highest stage of industry, it has only reached the stage of the Industrial Internet of Things (IIoT). This means there is still a long way to go. Sensing is a precursor technology for the IoT, and ensuring the stable operation of the IoT relies on numerous sensing technologies, one of the most critical being sensors.

Sensors are the foundation and core of the Industrial Internet; they are key components of automated intelligent devices. The flourishing development of the Industrial Internet will bring tremendous opportunities to sensor companies.

The Industrial Internet Brings Huge Markets for Sensor Companies

Referring to the stages of Industry 2.0, 3.0, 4.0, and AI 1.0, 2.0, the Industrial Internet can be divided into three stages: Industrial Internet 1.0, which connects IT and OT networks through IP technology-based network connectivity; Industrial Internet 2.0, which collects industrial data to upload and aggregate detailed data related to products, equipment, raw materials, and supply chains, laying the foundation for industrial internet platforms and applications; and Industrial Internet 3.0, which achieves seamless intelligent connection between the physical and digital worlds through AI and edge computing technologies.

Most industrial enterprises in our country are still in the process of moving towards Industrial Internet 1.0, with a few leading enterprises exploring Industrial Internet 2.0, and a few beginning to lay out research on Industrial Internet 3.0. The different stages of Industrial Internet development have varying requirements for sensors, and companies in the sensor and sensing system industry must accurately position themselves. They need to not only see the blue ocean that the development of the Industrial Internet brings to the sensor industry but also to explore effective markets to achieve final output value and profits.

On one hand, the Industrial Internet presents opportunities for sensor companies; on the other hand, it imposes new requirements on sensors, primarily reflected in higher demands for sensitivity, stability, and robustness. Meanwhile, the proliferation of the Industrial Internet means sensors are ubiquitous, leading to increased demands for lightweight, low-power, and low-cost sensors, as well as greater requirements for networking, integration, and intelligence.

Moreover, the applications of sensors in the Industrial Internet span a wider range, resulting in greater demand for the quantity and industrialization of sensors. Currently, the domestic sensor industry still faces challenges such as small company scale and insufficient innovation capabilities, and there is still a significant gap in fully meeting the demands of the Industrial Internet. The recent outbreak of trade frictions between China and the United States, particularly the embargo on core chips, has sounded an alarm for the sensor and application industries. Sensors, like integrated circuit chips, are key components with high technological content; if domestic companies do not increase their efforts in independent innovation, they may face a similar situation in the future.

Wireless Sensor Networks

With the development and integration of sensor, computer, wireless communication, and micro-electromechanical technologies, Wireless Sensor Networks (WSN) have emerged. Wireless sensor network technology uses the same standard as today’s mainstream wireless network technology—802.15.14. It is a new information acquisition and processing technology that will significantly impact human society’s production and lifestyle, following the internet. Wireless sensor networks combine embedded computing technology, sensor technology, distributed information processing technology, and communication technology to collaboratively monitor, perceive, and collect information from different monitoring objects within a distributed network area in real-time.

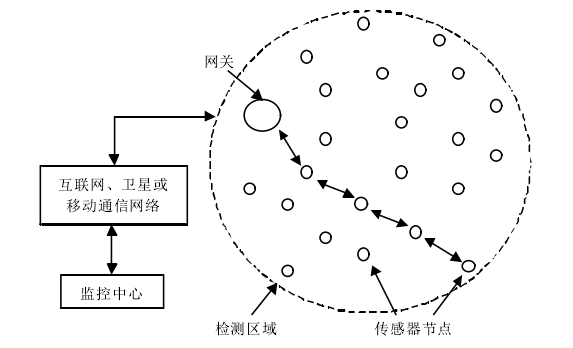

The Wireless Sensor Networks System (WSNS) typically consists of sensor nodes, aggregation nodes, and management nodes.

Communication Architecture of Wireless Sensor Networks

The emergence of wireless sensor networks has attracted widespread attention globally, being hailed as one of the most influential technologies of the 21st century, one of the top 10 technologies that will change the world, and one of the four high-tech industries of the future. Wireless sensor network technology will soon also enter the fields of the Industrial Internet and industrial measurement and control. With the future integration of wireless transmission capabilities into most industrial instruments and automation products, a transition from wired to wireless will be achieved.

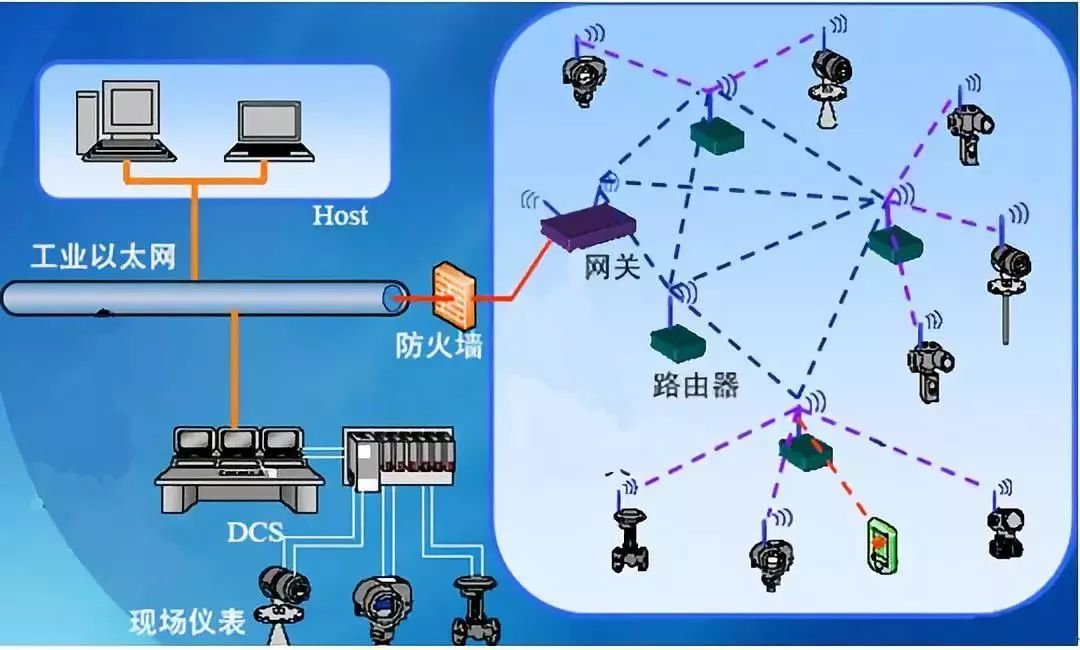

Typical Industrial Wireless Sensor Network

The core components of industrial wireless sensor networks include low-power sensor nodes (which can be powered by batteries, solar cells, or energy generated from wind and mechanical vibrations), network routers (with mesh network routing capabilities), and wireless gateways (which transmit information to the industrial Ethernet and control center or connect through the internet).

Established players in the industrial automation sector, such as GE and Honeywell, have launched various industrial wireless sensor network products and systems, and there are also numerous research institutions and large companies in the domestic market conducting related research.

Applications of Sensor Networks in the Industrial Internet

Today, the Industrial Internet is commonly understood as the automation of industrial environments using sensor networks and machine-to-machine (M2M) communication.

According to a report titled “Sensor Market for the Industrial Internet” published by market analysis company Nano Markets in November 2014, applications of the Industrial Internet include factory automation, building automation, smart grids, and public transportation, predicting that the consumption of sensors in this field will exceed $20 billion annually by 2019. In the future, technicians and maintenance personnel will increasingly use powerful tablets to collect and process information from sensors integrated into industrial machinery.

1. Industrial Environment Monitoring The monitoring scope of industrial environments now covers all aspects of the ecological environment, including routine monitoring of air, water, electromagnetic radiation, and radioactivity; as well as special area monitoring in deserts, mountains, and areas with radiation sources. These environments impose high demands on the flexibility, reliability, and safety of sensor products. Wireless sensor network products can break through traditional monitoring methods, reducing costs while meeting flexibility, reliability, and safety requirements, and significantly simplifying the cumbersome processes of traditional monitoring, facilitating the collection of random research data. As public concern for industrial environments grows, the demand for environmental data collection will gradually expand, leading to increased demand for wireless sensor network products. 2. Smart Grids Currently, global issues related to energy, environment, and climate change are becoming increasingly prominent, prompting countries worldwide to prioritize the development and utilization of clean energy. Smart grids have now become one of the important applications of IoT technology and an inevitable trend in grid development. Smart grids ensure the safety, reliability, and economy of electricity supply through advanced sensing measurement technology, communication technology, advanced control methods, and decision support systems.

To ensure the continuous operation of smart grids, equipment safety assurance has become a critical issue. Given that grid equipment operates under high voltage and high current conditions for extended periods and faces threats from extreme natural environments such as thunderstorms, implementing intelligent monitoring of equipment is particularly important. Wireless sensor network products can remotely monitor grid equipment, understand the operational status of devices, and transmit data to control centers for unified management, while real-time monitoring also enhances maintenance efficiency. As smart grid initiatives progress, the demand for intelligent monitoring of grid equipment has created a vast market for wireless sensor network products.

3. Digital Oilfields The continuous expansion of economic development and social demand is accelerating the rapid increase in the number of oil wells, and the overall scope of oilfield development is also expanding. Consequently, the intelligentization of oilfield production, management, and operations has become a development trend, giving rise to digital oilfields. In the digitalization process of oilfields, wireless sensor network products can achieve real-time monitoring of oil well environments and wellhead equipment, transmitting crucial information such as equipment status and environmental parameters to control centers, issuing alerts, and arranging dispatch when necessary. With the in-depth promotion and extensive demonstration of wireless sensor network products in oilfields, the number of digital oilfields will gradually increase, and the market demand for wireless sensor network products will show rapid growth. 4. Smart Industry China’s manufacturing industry is facing a new round of industrial revolution opportunities, with a pressing need for manufacturing enterprises to utilize IoT technology for transformation and upgrading. Information technology companies are also actively leveraging IoT technology to penetrate the industrial sector rapidly. The introduction of Industry 4.0, centered on intelligentization, aligns with the trend of integrating IoT technology into the industrial field, indicating enormous market development potential in the future. One core aspect of smart manufacturing is the intelligent monitoring of industrial processes. Applying wireless sensor network technology in intelligent monitoring will aid in optimizing industrial production processes and enhancing capabilities in process detection, real-time parameter collection, production equipment monitoring, and material consumption monitoring, thereby continuously improving intelligent monitoring, control, diagnosis, decision-making, and maintenance levels in production processes. With the rapid development of IoT and the further advancement of Industry 4.0, industrial process control centered on intelligentization will develop rapidly, driving market demand for industrial process monitoring system solutions based on wireless sensor network technology. The rapid growth of industrial wireless sensor network products is primarily attributed to the gradual development of the industrial IoT, which was initially government-led. The number of industrial sensing terminals in China has been growing rapidly, with about 700 million industrial sensing terminals in 2014, and it is expected to exceed 2 billion by 2020 with the implementation of China Manufacturing 2025.

Simultaneously, advancements in wireless communication, power consumption, extreme miniaturization (driven in part by MEMS sensors), and embedded computing have facilitated the rise of wireless sensor networks tailored for harsh industrial environments. Industrial wireless sensor network products will continue to grow rapidly until 2019, driven by the transformation of production lines and IT equipment upgrades prompted by the introduction of “China Manufacturing 2025,” and will maintain an upward trend.

In the future, sensors in the Industrial Internet will not only be hardware but also creators of data and services.

2019 Swiss-Italy Smart Manufacturing Delegation

June 28 – July 8, 2019

↓

Registration Channel Now Open

ClickRead the Original Linkat the Bottom

↓ View Details and Register Online ↓