Investment and Financing · A Corner

According to data statistics (source: Guanghui Intelligence), since 2025, major large model companies in China participating in model competition, such as Baidu, ByteDance, Alibaba, DeepSeek, and the “Six Little Tigers,” have released over 45 foundational large models (excluding industry-specific large models), which means a new model is released approximately every 3.3 days.

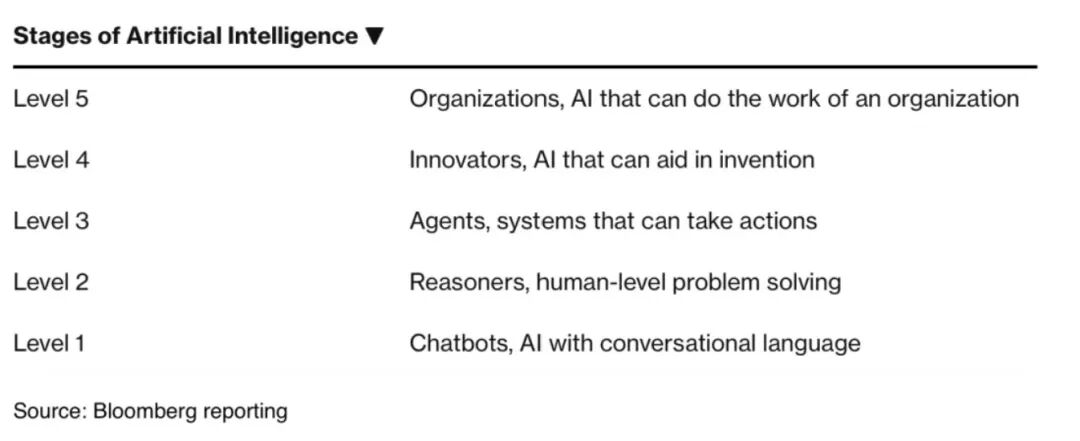

In July 2024, OpenAI defined a five-level system for AGI(see the image below), presenting a clear ladder-like evolution path for artificial intelligence:

0

Level 0 has no autonomous decision-making ability and strictly follows preset rules(such as traditional programs, industrial robots)

1

Level 1 surpasses human performance in a single domain, relying on big data and specific algorithms (such as AlphaGo, medical imaging diagnostic AI)

2

Level 2 integrates multimodal information and can complete cross-domain task combinations (such as household robots coordinating cooking/cleaning/security)

3

Level 3 has a rudimentary form of self-awareness, can set dynamic goals, and reflect on decisions (such as Ava in the sci-fi movie “Ex Machina”)

4

Level 4 approaches human levels, has self-improvement capabilities; cognitive dimensions break biological limits, can conduct interdisciplinary paradigm innovations (such as designing new physical laws). (A 2023 study by Oxford University shows that 85% of AI researchers believe Level 4 will not be achievable before 2100)

5

Level 5 is superintelligence that surpasses human intelligence

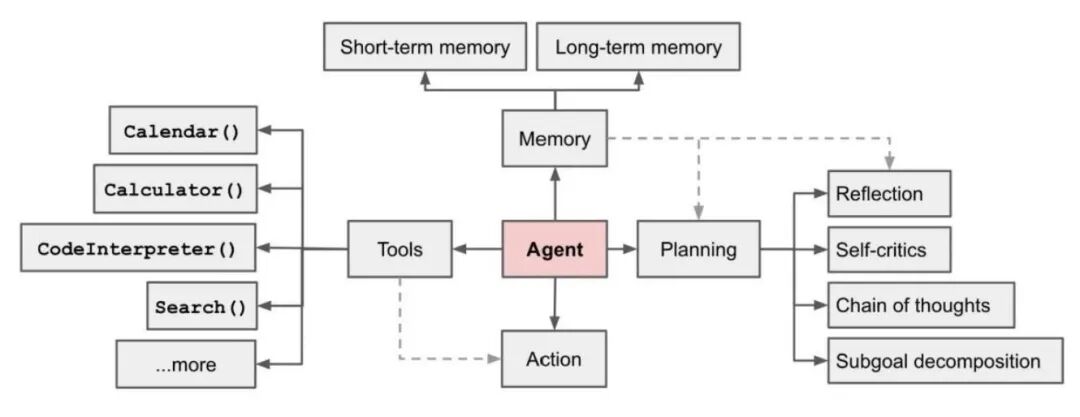

Unlike traditional artificial intelligence,AI Agents possess the ability to achieve given goals through independent thinking and tool invocation. AI agents are roughly positioned at the L3 stage mentioned above. Although there is currently no unified standard in academia, the industry generally agrees that L3 stage AI agents can not only understand the environment and user needs but also autonomously decompose complex tasks and invoke different tools to complete them through planning, memory, and tool usage. For example, an autonomous driving agent can formulate an action plan based on traffic conditions and control the vehicle to execute corresponding operations. They also possess certain multimodal capabilities and slow thinking abilities, enabling them to handle more complex tasks.

Architecture of autonomous intelligent agent systems driven by LLM

AI Agents are driving a paradigm shift in materials science from “trial and error” to “on-demand design,” potentially realizing an industry model of “Materials as a Service” (MaaS), accelerating technological breakthroughs in key areas such as new energy and semiconductors.

First, before the material research and development stage, AI Agents extract material synthesis rules from millions of papers(such as the relationship between solvent selection and yield) to generate verifiable hypotheses. For example, the Cambridge team used an agent to discover the correlation between the stability of perovskite and specific functional groups. They can also transfer rules from biology and chemistry to material design. For instance, agents designed new self-healing polymers by mimicking protein self-assembly.

Secondly, during the material research and development stage, AI Agents can predict new material structures and perform reverse material design.

AI Agents explore unknown material combinations at the atomic/molecular level through reinforcement learning (RL) and generative models (such as GANs, diffusion models). For example, DeepMind’s GNoME project used graph neural networks to predict 2.2 million stable crystal structures, far exceeding human historical accumulation.

Alternatively, they can reverse-generate material structures based on target performance (such as conductivity, strength). The MIT team used agents to generate new electrolyte materials, shortening the research and development cycle of lithium-ion batteries to a few weeks. Agents combined with DFT (Density Functional Theory) calculations quickly assess candidate materials’ electronic structures, thermodynamic stability, etc., replacing some high-cost experiments.

Then, in each stage of small-scale testing, pilot testing, and mass production, there are unique tasks and goals.

In the small-scale testing stage, it mainly involves small-scale laboratory synthesis and preparation. Researchers need to explore suitable process parameters through numerous experiments to determine the optimal conditions for material synthesis. These time-consuming and labor-intensive tasks can be completed by agents in a very short time. Meanwhile, agents establish a composition-structure-performance/structure-activity relationship database by screening different formulations and processes, providing important theoretical support for subsequent material performance optimization and the development of new properties.

In the pilot testing stage, agents can continuously adjust and optimize based on validation results to ensure process stability and reliability.

In the mass production preparation stage, companies need to conduct process engineering design and production line layout, reasonably plan production processes and spaces to achieve efficient and orderly production. Agents identify and resolve potential issues during small-scale production, make final optimizations to process parameters, ensuring smooth formal production and the production of products that meet quality standards. For example, Tesla’s “cobalt-free battery” development involved AI agents screening thousands of nickel-manganese-aluminum (NMA) ratios to optimize electrode material cycle life, supporting the mass production of 4680 batteries.

Reflective Framework of AI Agents

Additionally, testing is a rigid requirement throughout the entire lifecycle of materials, and the core testing needs during the research and development stage and mass production stage have fundamental differences.

Testing during the research process focuses on exploring the mechanisms of materials, aiming to provide rapid feedback to material R&D companies so they can adjust their R&D direction in a timely manner, further optimizing material performance and exploring more efficient processes. AI Agents, combined with automated laboratories (such as Berkeley’s A-Lab), autonomously design synthesis paths, control robots to perform experiments, and analyze results in real-time. For example, A-Lab synthesized 41 new lithium battery materials in 17 days, achieving a success rate of 71%. In material synthesis(such as nanoparticle preparation), agents use Bayesian optimization to adjust parameters such as temperature, pressure, and reaction time in real-time, quickly approaching optimal conditions and reducing trial-and-error costs.

In the mass production stage, testing mainly focuses on “certification testing.” Its core purpose is to meet compliance certification requirements, and the entire testing process is highly procedural and standardized. Through computer vision agents analyzing SEM/TEM images, they identify microstructural anomalies such as grain boundary defects and cracks, predicting material failure risks. Toyota Research Institute utilized this technology to increase the quality inspection efficiency of battery separators by tenfold. For conflicting indicators such as material strength, lightweight, and corrosion resistance, agents use multi-objective optimization algorithms (such as NSGA-II) to find Pareto optimal solutions. For example, Boeing optimized aerospace alloys using agents, reducing weight by 15% while maintaining strength.

The wave of large models is driving the rapid development of AI Agents. If AGI is the ultimate goal of large models, then AI agents are key nodes in the process of achieving this goal. From the perspective of market demand, the trend of enterprise-level agents has already emerged. According to statistics, by 2028, the global agent market is expected to reach $285 billion. By the end of 2024, there will be 500 million agents distributed across various industries.

For enterprises, the true value of AI lies in cost reduction and efficiency enhancement. In the currently most widely used field of intelligent customer service, its value is evident. In the past, the solution rate of intelligent customer service in the industry was around 70%, while after applying large model customer service, the solution rate can be improved to over 90%, saving enterprises thousands of dollars in just a few days.

The field of material research and testing has a high degree of professional complexity, and researchers typically require a PhD in materials. Material testing personnel not only need to master theoretical knowledge in material mechanics, fracture mechanics, metallurgy, etc., but also be familiar with advanced characterization techniques such as scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) to determine the source, propagation path, and specific failure mechanisms of cracks(for example, failure analysis of metallic materials). AI Agents are expected to lower the personnel requirements for material research and testing from PhDs to undergraduates or even technicians. With the assistance of agents, the professional knowledge and experience requirements for personnel can be significantly reduced, allowing more talents to participate in material research and testing work, greatly enriching the talent supply.

AI Agents are accelerating the progress of materials science research in the new materials field. Through data-driven, autonomous decision-making, and interdisciplinary collaboration, they will significantly enhance the efficiency of material discovery, optimization, and production.

AI Agents can make it a saleable and profitable business!

END

Long press the image

Previous Recommendations

● The “Invisible Guardian” of Thermal Management—Thermal Grease

● Structure Determines Performance—Starting from Polyurethane Coatings

● It Wields a Wand in the Sanctuary of Polyurethane

● Mitsubishi Chemical: A Unique Eastern Footnote in the New Materials Industry

No matter where you go

Please click the blue text, we miss you